The significance of nitrogen reflow soldering for automotive SMT products and other PCBA products

Nitrogen reflow soldering makes strong solder joints by stopping oxidation. This method improves how well automotive SMT and PCBA products work. Fields like cars and electronics need accuracy, and this process helps meet those needs with better soldering methods.

Key Takeaways

Nitrogen reflow soldering stops oxidation, making solder joints stronger and cleaner. This makes car electronics more reliable.

Using nitrogen lowers soldering mistakes a lot, reducing errors by up to 75%. This helps create better connections in complex PCBA products.

This process is very important for today’s car electronics, especially in electric cars, as it helps parts handle heat and shaking.

Understanding Nitrogen Reflow Soldering

What is nitrogen reflow soldering?

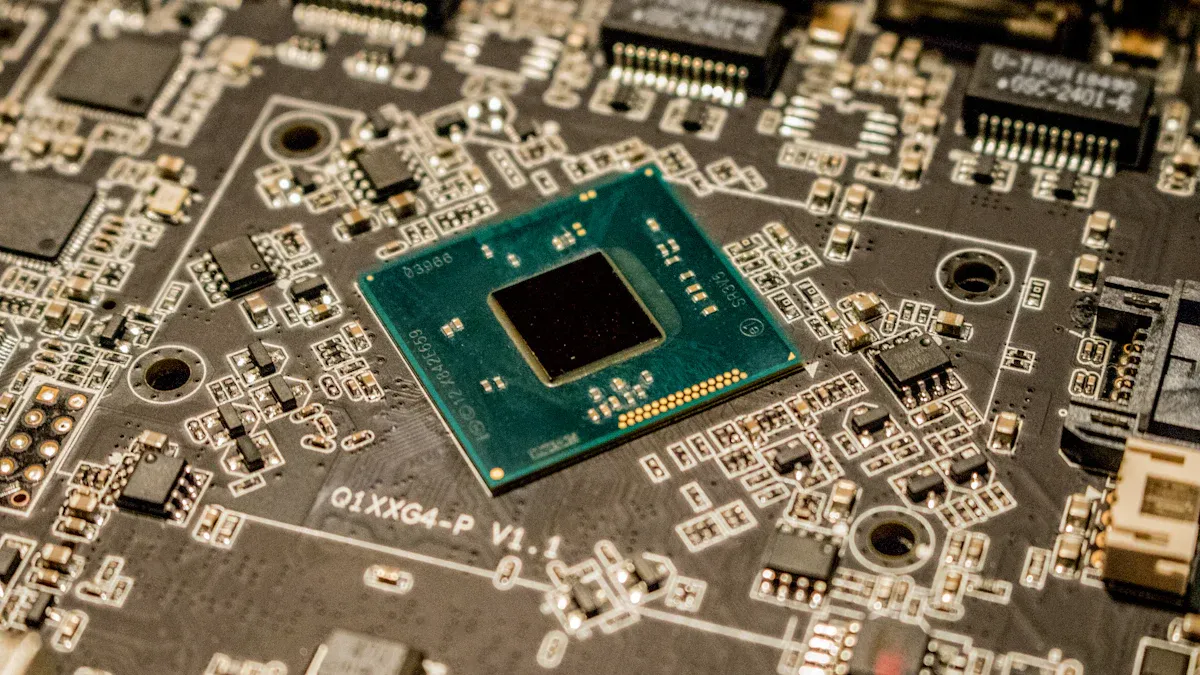

Nitrogen reflow soldering is a special way to join parts on a circuit board. It uses pure nitrogen gas in an oven to stop rusting during soldering. This keeps the metals clean and free from dirt.

The process has several steps:

Heat the solder paste to start the flux.

Melt the tin powder as it gets hotter.

Keep the high temperature for 40 to 70 seconds to make strong metal bonds.

Let it cool so the solder hardens and makes strong links.

Using nitrogen stops oxygen from mixing with the solder paste. This is important to avoid mistakes. It also helps the solder spread better and make strong joints.

How does nitrogen reflow soldering improve soldering quality?

Nitrogen reflow soldering makes soldering better by keeping oxygen out. Less oxygen means fewer mistakes like solder balls and bridges. Without oxygen, the solder paste stays good.

Research shows nitrogen can cut down fixing by 40% on the solder area. A full nitrogen system can lower fixing by 75% compared to air systems. Nitrogen also helps solder stick better, making joints stronger and nicer.

This method also helps different fluxes work well, giving steady results. By lowering mistakes and making strong joints, nitrogen reflow soldering meets high standards in car and electronics industries.

Benefits for Automotive SMT Products

Better reliability for car electronics

Car electronics need to work well for safety and performance. Nitrogen reflow soldering helps meet these needs. It makes strong and steady solder joints, which improve how long parts last in cars. For example, systems like ADAS need good soldering to work in tough conditions. These systems need accuracy and strength, which nitrogen reflow soldering provides by stopping rust and making better joints.

More cars now depend on electronics, showing why this is important. From 2020 to 2025, car electronics are expected to grow by 10% each year. This growth means better soldering methods are needed for complex car electronics. Nitrogen reflow soldering helps these parts handle tough car conditions, making it a key process in the industry.

Fewer soldering problems

Soldering mistakes can hurt how car electronics work and stay safe. Nitrogen reflow soldering lowers these mistakes by keeping oxygen away during soldering. This stops problems like bridges, gaps, and rust, making cleaner and stronger connections.

Studies show this method works well. Using nitrogen reflow soldering has cut defect rates by up to 30%. One factory saw its defect rate drop from 19% to 0.7% after using better soldering tools. This is very helpful for cars, where even small mistakes can cause big problems. By lowering defects, nitrogen reflow soldering ensures car electronics meet high standards.

Stronger performance in tough conditions

Car electronics often face heat and shaking in tough places. Nitrogen reflow soldering makes solder joints stronger to handle these stresses. It creates solid connections that survive heat changes and physical stress in cars.

Electric vehicles (EVs) make this even more important. EVs need electronics for power, batteries, and motors. Nitrogen reflow soldering keeps these parts working in hard conditions. As EVs become more popular, the need for this soldering method will grow.

Fact/Statistic | Explanation |

|---|---|

More EVs mean higher demand for strong electronic parts in cars. | |

ADAS Importance | ADAS needs great solder joints for safety and good performance. |

Role of Nitrogen Reflow Ovens | These ovens help make strong parts for tough car conditions. |

By making solder joints stronger, reducing mistakes, and improving reliability, nitrogen reflow soldering solves big challenges for car electronics. This process ensures parts meet the high demands of modern cars, making it essential for car electronics production.

Advantages for Other PCBA Products

Stronger and longer-lasting solder joints

Making strong solder joints is very important for PCBA products. Nitrogen reflow soldering uses nitrogen gas to stop rusting. This keeps the solder paste clean and working well. It helps the solder spread better and make strong connections.

Nitrogen also helps the flux work longer, improving the bond between parts and the board. Over time, this makes solder joints stronger and last longer. A study showed defects dropped from 82 per million to 37 per million after using nitrogen reflow soldering. This proves it makes PCBA products more reliable and higher in quality.

Less rust during soldering

Rust can weaken solder joints and hurt PCBA performance. Nitrogen reflow soldering fixes this by using a nitrogen-filled space. This stops rust and keeps the solder paste clean.

Nitrogen helps the solder stick better to the board.

It makes the flux work well during the whole process.

By stopping rust, it improves the quality of solder joints.

These benefits make nitrogen reflow soldering great for reducing mistakes and making better PCBA products.

Better performance for many uses

PCBA products are used in many areas, like gadgets and machines. Nitrogen reflow soldering helps by controlling heat during the process. This even heating and cooling protect the solder joints.

The process also removes leftover flux, making cleaner boards. By stopping rust and making strong joints, nitrogen reflow soldering helps create high-quality PCBA products. Whether for small tests or big production, this method ensures good and lasting results.

Nitrogen Reflow Soldering vs. Air Reflow Soldering

Differences in solder joint quality and reliability

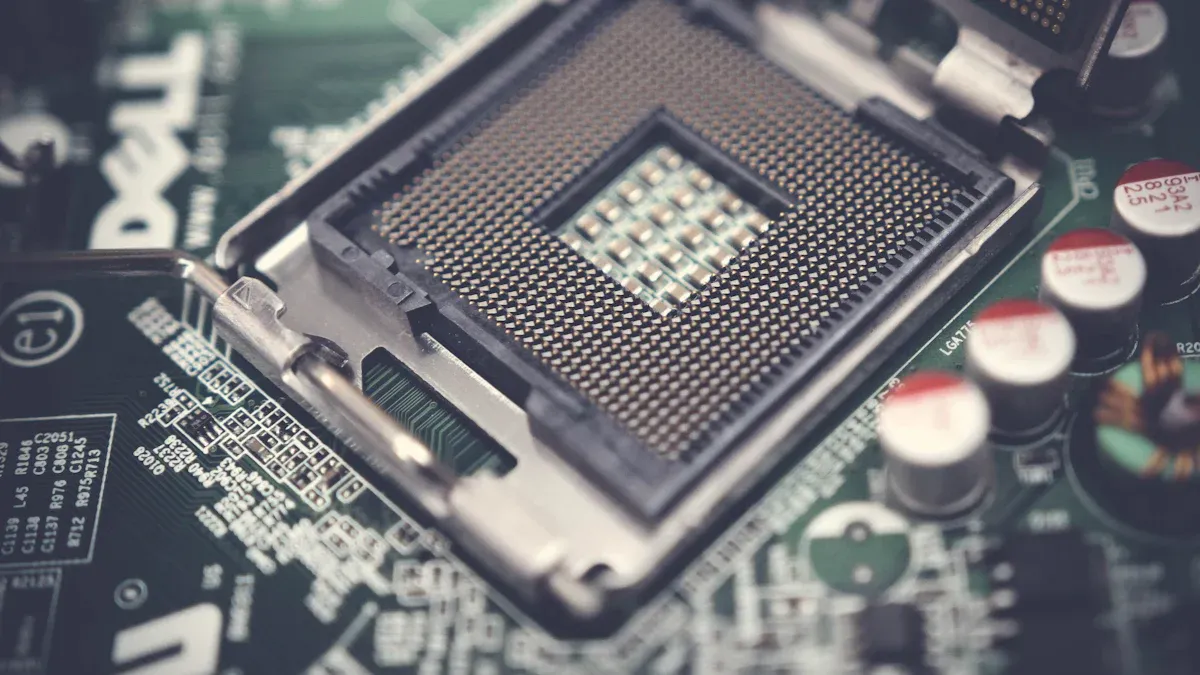

Nitrogen reflow soldering makes cleaner and stronger solder joints. It uses nitrogen gas to stop oxidation, which weakens connections. Air reflow soldering lets oxygen mix with solder paste. This can cause problems like cracks and voids. Nitrogen reflow soldering is better for tough jobs like car electronics.

Impact on defect rates and oxidation

Nitrogen reflow soldering lowers defects and stops oxidation. Studies show big improvements:

Defects dropped from 82 to 37 per million in two years.

One project had 183 failures with air but only 3 with nitrogen.

Another project saw air cause 302 failures, while nitrogen reduced it to 100.

Nitrogen also cuts flux residue by 66%, reducing test failures. These changes make nitrogen reflow soldering great for high-quality PCBA products.

Why LTPCBA prioritizes nitrogen reflow soldering

LTPCBA uses nitrogen reflow soldering for better quality and reliability. This method helps make strong solder joints and reduces oxidation. It ensures fewer defects and better performance. Whether for cars or other PCBA uses, LTPCBA delivers top results with this advanced process.

Industry Applications and Trends

Role in automotive electronics manufacturing

Car electronics are getting more advanced and need better production methods. Nitrogen reflow soldering helps make strong and reliable connections. Systems like infotainment and ADAS need solder joints that can handle heat and shaking. This process stops rust and makes parts last longer.

Electric and hybrid cars rely on electronics for power and control. Nitrogen reflow soldering improves these systems by stopping oxidation. It also makes solder joints stronger and helps them last. As cars become more complex, this method is key for making better electronics.

Applications in consumer and industrial electronics

Nitrogen reflow soldering is also used for gadgets and machines. Smaller devices need precise soldering for tiny parts. This process ensures clean and strong connections for modern electronics.

Evidence Type | Details |

|---|---|

Regulatory Compliance | Rules like RoHS push lead-free soldering in Europe and Asia. |

Market Value | Electronics manufacturing was worth $477 billion in 2021. |

Expected Growth | The market will grow more by 2027, needing better methods. |

Technological Advancements | New tools like temperature control improve soldering accuracy. |

Cost Reduction Initiatives | Fewer defects and faster production save money over time. |

Sustainability Trends | Companies use greener methods to meet eco-friendly goals. |

These changes show why nitrogen reflow soldering is important for making high-quality electronics.

LTPCBA’s commitment to advanced nitrogen reflow soldering

LTPCBA uses top nitrogen reflow soldering methods to meet high standards. This process makes strong solder joints and lowers mistakes. Whether for cars or gadgets, LTPCBA delivers great results. By using new technology and following trends, LTPCBA stays a trusted choice for PCB assembly.

Nitrogen reflow soldering is key for making dependable automotive SMT and PCBA products. It lowers errors, improves solder strength, and meets modern industry needs. As PCBs become more complex, this method becomes even more important.

By stopping oxidation, it ensures great soldering, vital for top-quality car electronics.

Evidence Type | Description |

|---|---|

Market Growth | Car and telecom industries increase demand for nitrogen reflow ovens. |

Complexity of PCBs | More complex PCBs need advanced nitrogen reflow soldering ovens. |

Quality Assurance | Nitrogen reflow soldering stops oxidation, improving soldering quality. |

With skill in this method, LTPCBA delivers excellent results, making it a reliable choice for PCB assembly.

FAQ

Why is nitrogen reflow soldering better than air reflow soldering?

Nitrogen reflow soldering stops oxidation, making solder joints cleaner. It lowers defects and boosts reliability, perfect for cars and advanced PCBA products.

Can nitrogen reflow soldering handle tricky PCBA designs?

Yes, it works great for complex designs. It spreads heat evenly, makes strong joints, and reduces mistakes, even for small and detailed PCBA layouts.

Why does LTPCBA choose nitrogen reflow soldering?

LTPCBA uses this method for top-quality results. It reduces errors, strengthens solder joints, and ensures reliable performance for cars and other PCBA uses.

Tip: Check out LTPCBA’s website to explore their nitrogen reflow soldering tools and services.

See Also

Understanding The Effects Of Reflow Soldering Temperature Zones

The Influence Of Solder Paste Quality On SMT Soldering

Importance Of SPI Inspection Post SMT Solder Paste Printing