Mixed Technology PCBs: Integrating SMT and DIP Assembly Techniques for Optimal Performance

When you use both SMT and DIP assembly in Mixed Technology PCBs, you get better performance and more options. Many top industries now want high-performance PCBs. The table below shows this market is growing fast:

Metric | Value | Time Period |

|---|---|---|

USD 69.13 Billion | 2023 | |

Projected Market Size | USD 115.31 Billion | 2031 |

CAGR | 7.6% | 2024-2031 |

Companies like LTPCBA give dependable solutions for these needs.

Key Takeaways

Mixing SMT and DIP assembly in PCBs gives many benefits. SMT saves space and makes things fast. DIP makes repairs easy and parts strong.

A careful assembly process is very important. Steps like putting on solder paste and placing parts help a lot. Checking everything well makes mixed technology PCBs work better.

Using good inspection tools helps find problems early. Working with skilled partners like LTPCBA keeps quality high. This makes sure PCBs work well and last a long time.

Mixed Technology PCBs Overview

What They Are

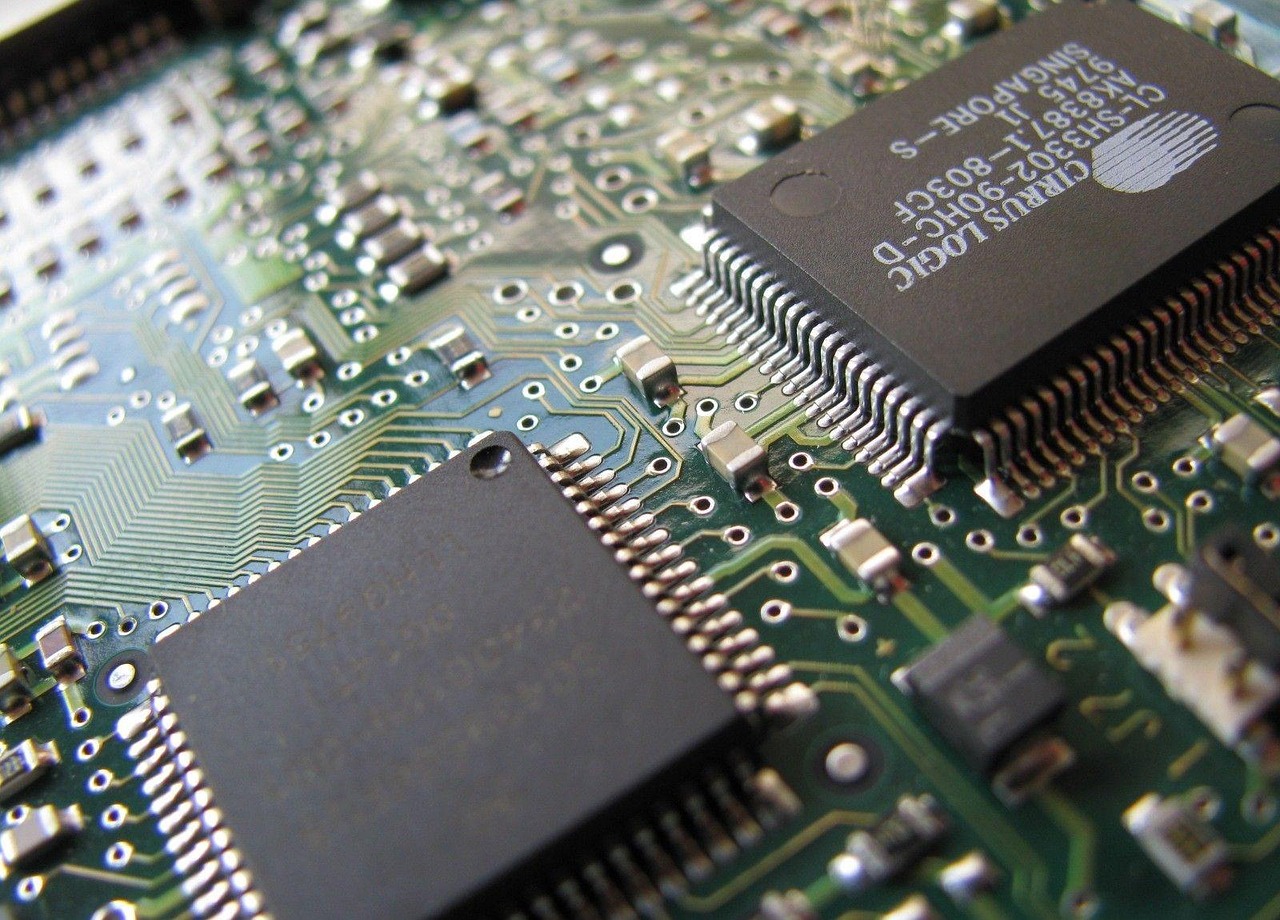

Mixed Technology PCBs are used in many new devices. These boards have both SMT and DIP on one board. This means you can use different parts and ways to put them on. This helps the board work better.

Mixed Technology PCBs need special machines to place parts of many sizes.

Some boards have parts on both sides, so both sides need careful soldering.

Wave soldering is used for some parts, but not all can go through it twice.

Automatic optical inspection looks for parts that are not in the right place or are broken.

Important parts of a PCB are the substrate, copper layers, solder mask, and silkscreen.

These boards are often made from FR-4, which is strong and keeps electricity inside. Some boards for high-frequency use PTFE for better results.

LTPCBA gives you smart solutions for Mixed Technology PCBs. The company uses machines and checks to make sure your boards work well.

Why Integration Matters

When you put SMT and DIP together, you get more benefits. SMT lets you make small and packed circuits. DIP makes it simple to fix and test parts.

Aspect | SMT Strengths | Why Integration Helps | |

|---|---|---|---|

Handling | Easy to repair and prototype | High-speed, automated assembly | Combines ease and efficiency |

Mechanical Strength | Strong and sturdy | Small and lightweight | Balances durability and size |

Application | Good for education, control | Great for phones, fast devices | Fits many uses |

Circuit Density | Takes more space | Saves space | Lets you design flexible layouts |

Mixed Technology PCBs help with many needs in electronics today. This way, you can make boards that are strong and easy to take care of.

SMT and DIP Assembly

SMT Basics

Surface Mount Technology lets you put small parts right on the board. Machines do this job, so it is quick and correct. SMT helps make devices smaller and lighter. You can add more parts to both sides of the board. This way works well for fast circuits and tiny products like phones or medical tools.

SMT terminal blocks can make the board take up less space, sometimes by half.

Using machines makes building faster by about 20-40%.

SMT parts are lighter, which helps in planes and things you carry.

Note: SMT uses special tools like AOI and X-ray to find problems and check quality.

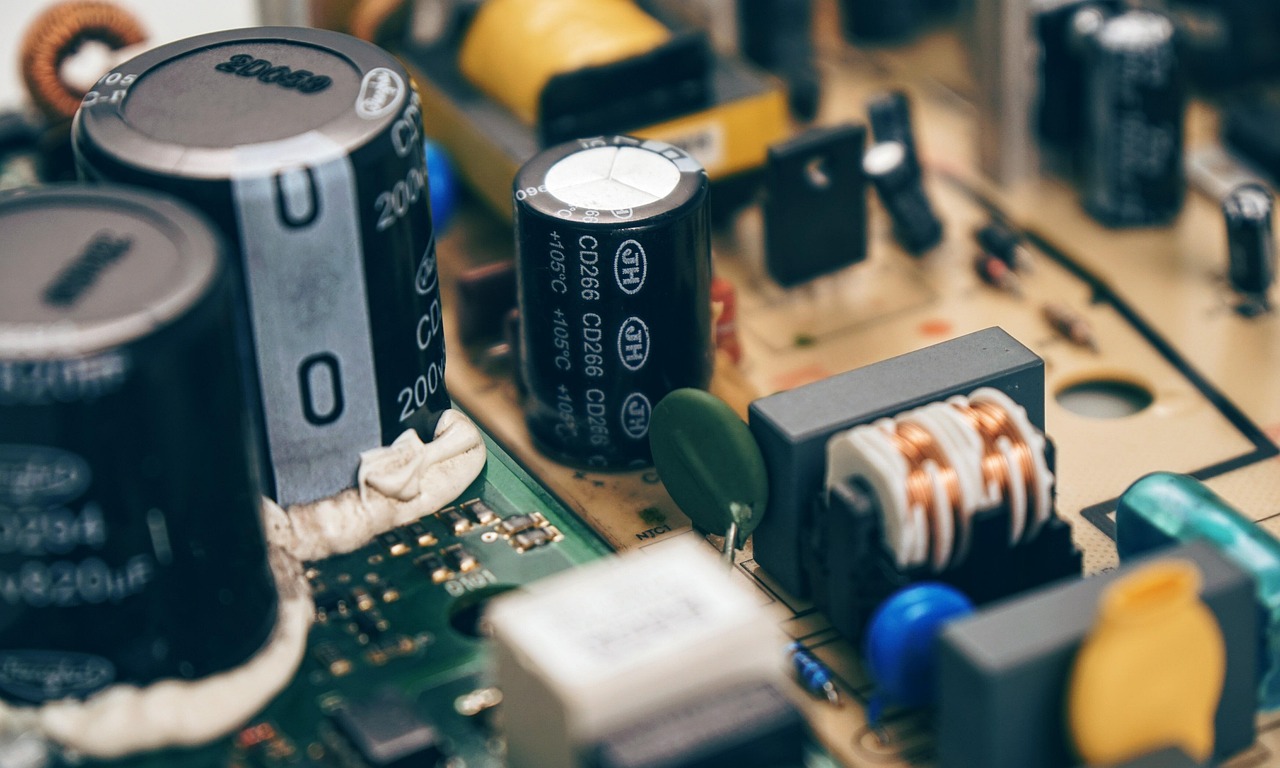

DIP (THT) Basics

Dual In-line Package, also called Through-Hole Technology, uses parts with leads that go through holes in the board. You can solder these parts by hand or with a machine. DIP parts are bigger and simple to hold. They work well in tough places and are easy to fix or swap.

Aspect | SMT (SMD Components) | DIP Components |

|---|---|---|

Automated, high precision | Manual or semi-automated | |

Mechanical Durability | Less robust | More robust |

Repair and Maintenance | Harder to repair | Easier to repair |

Faster | Slower |

Choosing the Right Technique

Pick the assembly method that fits your project best. If you want things fast, small, and good for high speed, use SMT. If you need strong parts or easy fixes, DIP is better. Many engineers use both ways in Mixed Technology PCBs to get more benefits.

Think about signal quality, heat, and power needs.

Check how simple it is to test and fix the board.

Make sure your provider, like LTPCBA, has good machines and checks for both SMT and DIP.

LTPCBA knows a lot about both SMT and DIP assembly. The company uses new tools and careful checks to make sure Mixed Technology PCBs work well for many jobs.

Integration Process and Optimization

Assembly Steps

You must follow a careful process to build Mixed Technology PCBs. Each step helps make sure the board works well and lasts long. Here is a simple list of the main steps:

Apply Solder Paste: A stencil spreads solder paste on the pads for surface mount parts. Machines do this job to cover the pads evenly.

Place Components: Pick-and-place machines put surface mount parts on the board. These machines are very accurate.

Reflow Soldering: The board gets heated so the solder paste melts. This holds the parts in place.

Initial Inspection: People and machines check for misplaced or broken parts. AOI and X-ray tools help find problems.

Insert Through-Hole Components: Bigger or heavier parts are put in by hand or with wave soldering machines.

Final Soldering: Solder holds through-hole parts in place. Wave soldering is often used because it is fast.

Functional Testing: The board is tested to make sure it works in real life.

You can use 3D models and virtual reality to plan each step before building the real board. This helps you spot problems early and avoid mistakes that cost money.

Tip: Using digital tools early lets you fix design problems before making real boards. This saves time and money.

Key Integration Points

When you use both surface mount and through-hole parts, you must pay attention to some important steps. These are called integration points. If you handle them well, your board will be strong and reliable.

Soldering: You need to control heat and timing for both reflow and wave soldering. Too much heat can hurt parts. Too little heat can make weak joints.

Inspection: AOI, X-ray, and in-circuit tests are used at every stage. These tools help you find problems early so you can fix them.

Component Placement: Each part must be in the right spot. Machines help with surface mount parts. Skilled workers are needed for through-hole parts.

Traceability: Track every part and step. This helps you find and fix problems fast if something goes wrong.

Description | |

|---|---|

Real-time Data Collection | Finds changes in the process right away so you can act fast. |

Statistical Process Control | Watches for small changes and helps keep quality high. |

Acceptable Quality Level (AQL) | Sets clear rules for how many defects are allowed. |

Complete Traceability | Tracks every part from start to finish for quick fixes. |

Operator Guidance | Gives clear instructions to workers to keep things running smoothly. |

Smart Manufacturing Systems and Zero Defect Manufacturing use these tools and methods to help you reach high quality. You can lower mistakes and keep your boards working well.

Quality and Reliability

You want your Mixed Technology PCBs to last and work well. Quality checks are very important. You should work with partners who follow strict rules and use both people and machines to check boards.

LTPCBA uses ISO, IATF, and UL certifications to show strong quality control.

The company uses AOI, X-ray, and in-circuit testing to catch problems.

LTPCBA has a pass rate above 99.5% for finished boards, showing high reliability.

Regular audits and training keep workers skilled and processes up to date.

Metric / Certification | Description / Value |

|---|---|

Makes sure quality is managed and always getting better. | |

IPC Standards (IPC-6012C, IPC-A-600G) | Sets rules for how good the boards must be. |

RoHS and UL Compliance | Makes sure boards are safe and follow environmental rules. |

PCBA Manufacturing Pass Rate | Over 99%, showing most boards pass all tests. |

On-Time Delivery | Over 98%, so you get your boards when you need them. |

Customer Satisfaction | Over 95%, meaning most customers are happy with their boards. |

Testing Methods | AOI, X-ray, in-circuit, and functional tests check every board for problems. |

You may face some problems when building Mixed Technology PCBs. Complex layouts, many types of parts, and tight deadlines can make things hard. You can solve these problems by:

Making your board design simple and using standard parts.

Using machines for placing and soldering parts.

Checking quality at every step with AOI and X-ray tools.

Training your team and tracking every part and step.

Working with a trusted partner like LTPCBA, who has the right tools and experience.

Note: Automation and digital tracking help you find problems early, reduce waste, and save money over time.

By following these steps and using smart tools, you can build Mixed Technology PCBs that meet high standards for quality and reliability.

You gain flexibility and strong performance when you combine SMT and DIP in your PCB designs.

Choose the right assembly method for each part.

Check your boards at every step.

Trust LTPCBA for reliable results.

Careful planning and quality checks help you build better PCBs every time.

FAQ

What is the main benefit of using both SMT and DIP on one PCB?

You get more design options. SMT saves space. DIP makes repairs easy. Mixed technology lets you build strong and flexible boards.

How do you check the quality of mixed technology PCBs?

You use AOI, X-ray, and in-circuit tests. These tools help you find problems early. LTPCBA checks every board for high quality.

Can you use mixed technology PCBs for small projects?

Yes! Mixed technology PCBs work for prototypes and small runs. LTPCBA supports both small and large orders.

Tip: Always plan your design before you start assembly. This helps you avoid mistakes and saves time.

See Also

Understanding SMT And DIP Processes In PCBA Production

Top Strategies To Enhance SMT Line Efficiency In PCBA

Comparing Through-Hole And SMT PCB Assembly Performance Benefits

Ways To Improve SMT PCB Assembly For Higher Yield And Efficiency

Through-Hole DIP PCBA: Production, Quality, And Application Insights