What is Mixed Technology PCBA and How Does It Work

Experience the advantages of mixed technology PCBA, where both surface mount technology (SMT) and through-hole technology (THT) are integrated onto a single board. Mixed technology PCBA delivers enhanced performance and flexibility, making it an ideal solution for a wide range of applications.

Technology Type | Advantages | Challenges |

|---|---|---|

Mixed Technology PCBA | Merges the strengths of SMT and THT | Increased process risks |

SMT | Speed and efficiency in high-volume production | N/A |

THT | Robustness in specific applications | N/A |

Key Takeaways

Mixed technology PCBA combines surface-mount and through-hole components, offering flexibility in design and enhanced performance for various applications.

This assembly method allows for high-density layouts while ensuring strong mechanical support, making it ideal for demanding industries like automotive and medical.

LTPCBA provides advanced solutions with a focus on quality, efficiency, and fast turnaround times, ensuring reliable circuit boards for both prototypes and high-volume production.

Mixed Technology PCBA Overview

What Is Mixed Technology PCBA?

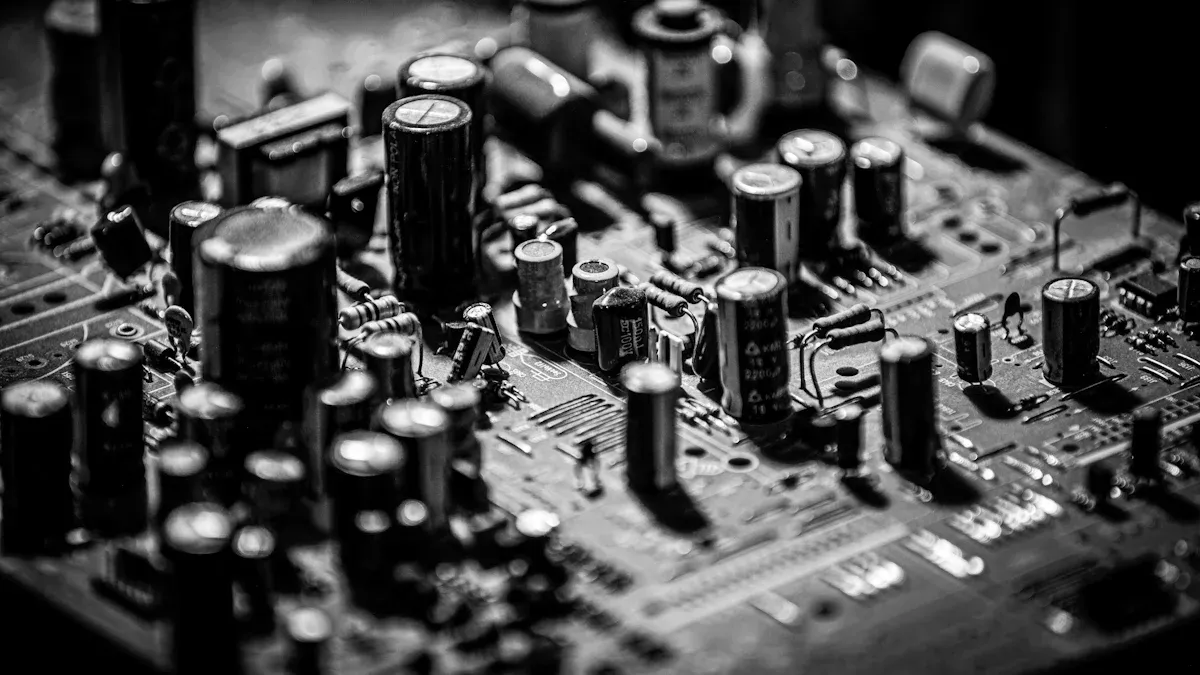

You may wonder what sets mixed technology PCBA apart from other assembly methods. Mixed technology PCBA combines both surface-mount and through-hole components on a single board. This approach allows you to take advantage of the strengths of each technology. Surface-mount components are small and fit tightly onto the board, which helps you create compact and high-density designs. Through-hole components, on the other hand, offer strong mechanical support and handle higher power levels.

Mixed technology PCBs give you the flexibility to design boards that meet complex requirements for performance, durability, and size.

Here’s a quick comparison to help you see the difference:

Characteristic | Mixed Technology PCBA | Traditional PCB Assembly |

|---|---|---|

Technology Used | Combines SMT and THT | Primarily uses either SMT or THT |

Design Flexibility | Greater flexibility due to hybrid approach | Limited flexibility, typically one method |

Component Density | High-density components with SMT | Varies, often less dense |

Mechanical Support | THT provides stronger support for key parts | Relies on one method for support |

Manufacturing Complexity | Needs both reflow and wave soldering | Simpler, one soldering method |

Application Areas | Used in complex devices like automotive, industrial | Common in simpler electronic devices |

LTPCBA specializes in mixed technology PCBA, offering you advanced solutions for both prototype and production runs. You can rely on their expertise to handle the challenges of integrating different component types on your boards.

Key Features of Mixed Technology PCBs

Mixed technology PCBs stand out because they support both SMT and THT components. This combination lets you design boards that are both compact and robust. You can use surface-mount parts for high-density areas and through-hole parts for components that need extra strength or heat resistance.

Some of the main features that make mixed technology PCBs unique include:

Design for Assembly (DFA): You can spot and solve assembly problems before they happen, making the process smoother.

Design for Manufacturing (DFM): You can optimize the fabrication process for both SMT and THT components.

Component Type Consideration: You can select the best components for your application, improving performance.

Placement Methods: You can use different placement methods for SMT and THT, giving you more design options.

Design Rules: You can follow specific rules to avoid obstacles during assembly, which increases reliability.

Feature | Description |

|---|---|

Design for Assembly (DFA) | Identifies potential assembly problems before they occur, ensuring smoother integration of components. |

Design for Manufacturing (DFM) | Focuses on the fabrication process, optimizing it for both SMT and THT components. |

Component Type Consideration | Ensures that the right components are selected for the intended application, enhancing performance. |

Placement Methods | Different methods are employed for SMT and THT, allowing for flexibility in design. |

Design Rules | Predefined rules help avoid obstacles during the assembly phase, making the process more reliable. |

Thermal management also plays a big role in mixed technology PCBs. You can use heat sinks and thermal vias to keep both SMT and THT components at safe temperatures. This helps prevent damage and keeps your boards running smoothly.

Mixed technology PCBs let you combine high power handling with compact, high-density layouts. You can build complex multilayer boards that offer better electrical reliability and improved thermal management. This makes mixed assembly PCBs ideal for demanding applications.

Why Choose Mixed Assembly?

You should consider mixed assembly when you need a board that balances compact design, strength, and performance. Mixed technology PCBs give you the freedom to select the best components for each part of your design. This approach supports both lightweight and high-reliability requirements.

Here are some reasons why manufacturers like you choose mixed assembly PCBs:

Advantage | Description |

|---|---|

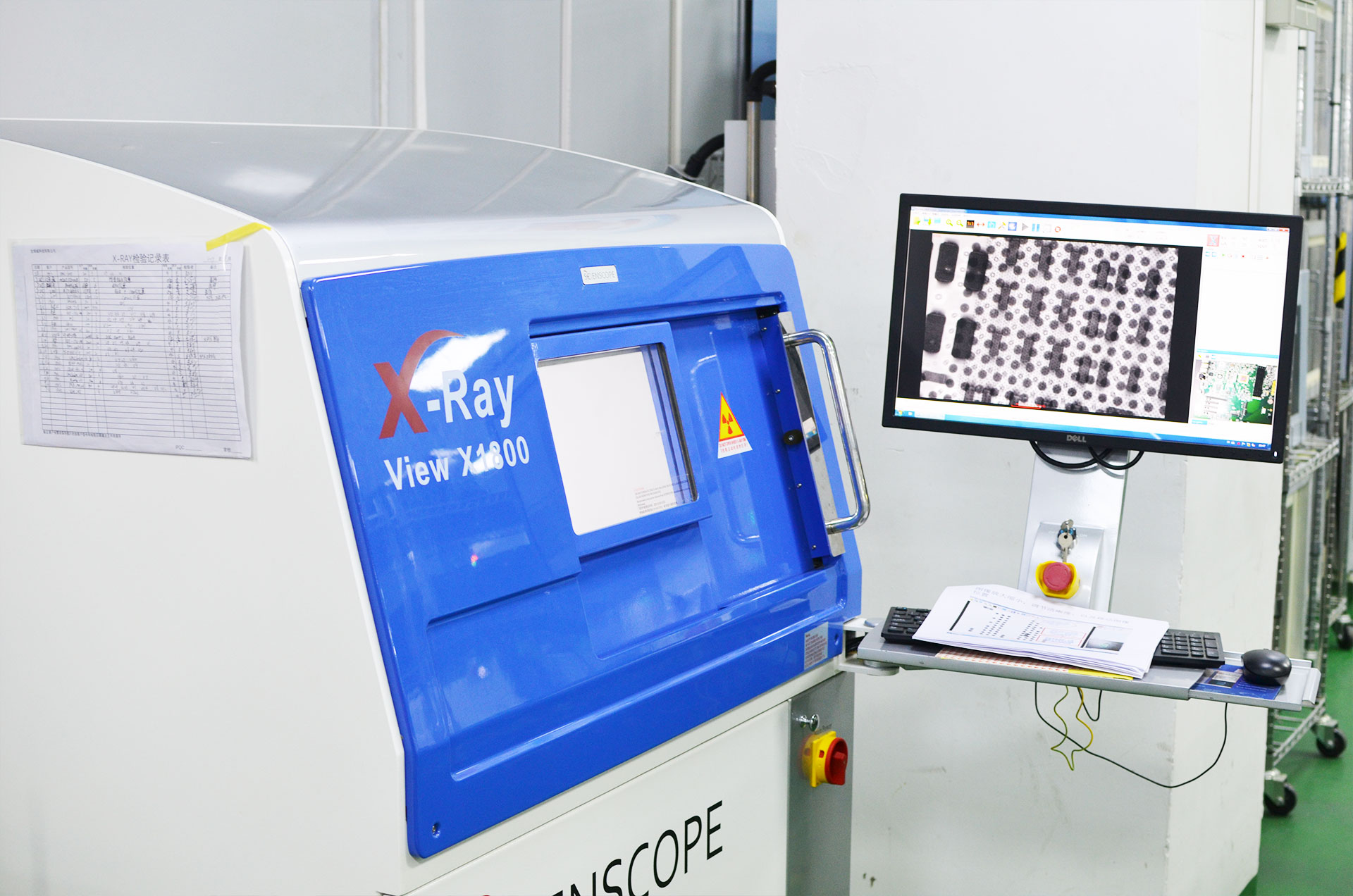

100% inspection | Ensures quality through X-ray technology |

High-reliability | Provides dependable connections |

Lightweight | Reduces overall weight of the assembly |

Increased stress-tolerance | Better performance under stress conditions |

High precision | Ensures accurate placement of components |

You will notice several performance improvements with mixed assembly PCBs:

Performance Improvement | Description |

|---|---|

Enhanced Flexibility | Lets you choose the best components for each section, balancing size and durability. |

Improved Reliability | Through-hole parts offer strong bonds, while SMT parts fit densely packed areas. |

Cost Efficiency | Using both SMT and THT can lower material and assembly costs. |

Performance Optimization | SMT supports high-speed signals, while THT handles higher currents, perfect for complex systems. |

Hybrid assembly, also known as mixed assembly, is especially useful for industries that demand both precision and durability. You can find mixed technology PCBs in automotive, industrial, and consumer electronics. As technology advances, more companies turn to hybrid assembly to meet the needs of IoT, AI, and 5G devices.

LTPCBA delivers mixed assembly PCBs with a focus on quality and efficiency. You can trust their advanced systems and skilled team to provide reliable solutions for your most challenging projects.

Mixed PCB Assembly Process

SMT and THT Integration

You need to understand how mixed technology pcbs combine surface-mount and through hole technology on a single board. This integration lets you use both miniaturized components and strong connectors, which increases design flexibility and reliability. The mixed pcb assembly process involves several key steps that ensure both SMT and through-hole components work together seamlessly.

Description | |

|---|---|

Component Placement | You place both SMT and THT components on the PCB. |

Solder Paste Printing | You apply solder paste for SMT components before reflow soldering. |

Reflow Soldering | You melt solder paste for SMT components to create electrical connections. |

Wave Soldering | You use wave soldering for through-hole components to ensure proper soldering. |

When you combine SMT and THT, you face several challenges. You must manage thermal stress during soldering because SMT components need high temperatures, which can affect THT parts. You also need to design the PCB layout carefully to avoid interference between THT holes and SMT pads. Sequencing the assembly steps is important, as misalignment can damage components. You must use different inspection methods for SMT and THT components to catch defects early.

Thermal stress during soldering can affect component reliability.

Design complexity increases with both SMT and THT on the same board.

Assembly sequencing requires careful planning to prevent misalignment.

Testing and inspection methods must match the component types.

Assembly Workflow at LTPCBA

LTPCBA uses advanced technology to streamline the mixed technology pcb assembly process. You benefit from automated systems and smart inspection tools that improve production efficiency and reduce errors. The workflow at LTPCBA stands out because it integrates all production stages under one roof, which speeds up delivery and ensures consistent quality.

Application | |

|---|---|

Through Hole | You use this for connectors and power components that need strength. |

SMT | You use this for ICs and resistors to achieve miniaturization. |

Selective Soldering | You solve soldering and thermal management challenges. |

Robotic Insertion | AI-driven machines reduce placement errors by 90%. |

Smart Inspection | AOI and X-ray systems detect defects in real time. |

Hybrid Designs | You integrate through hole and SMT processes for compact, durable boards. |

Hitachi Laser Drills | You use these for microvias. |

High-speed Flying Probe Testers | You enhance testing efficiency and accuracy. |

LTPCBA’s workflow differs from standard industry practices. You get advanced automation and hybrid capabilities, which means you can handle both SMT and through-hole components in one process. Communication is streamlined because all production stages happen in one place. This reduces errors and accelerates time-to-market for your mixed assembly pcbs.

Aspect | LTPCBA's Workflow | Standard Industry Practices |

|---|---|---|

Automation | Varies, often less integrated | |

Hybrid Capabilities | Handles both SMT and through-hole | Typically focuses on one technology |

Speed | Enhanced speed due to automation | Standard speeds, often slower |

Efficiency | Streamlined processes reduce errors | More fragmented processes |

Quality Control | Rigorous checks throughout the workflow | Varies, often less comprehensive |

LTPCBA incorporates advanced automation and hybrid assembly capabilities.

You benefit from consolidated production stages, which streamlines communication.

Errors are reduced, and you get faster delivery of reliable circuit boards.

You can expect a quick turnaround time for mixed technology pcbs at LTPCBA. PCB fabrication and parts procurement take 15-20 days. Assembly takes 5-10 days. The total PCB assembly process usually finishes in 20-30 days.

Process | |

|---|---|

PCB Assembly | 20-30 |

PCB Fabrication + Parts Procurement | 15-20 |

Assembly | 5-10 |

Quality Assurance in PCB Assembly

You need high-quality mixed technology pcbs for demanding applications. LTPCBA follows strict quality assurance standards, including ISO 9001, IATF 16949, ISO 13485, GJB 9001, RoHS, REACH, and UL Certification. These standards help you meet industry requirements for automotive, medical, and military products.

IATF 16949 ensures automotive-grade reliability.

ISO 9001 improves operational efficiency and quality management.

ISO 13485 supports medical device compliance.

GJB 9001 applies military-grade quality management.

RoHS restricts hazardous substances for safer electronics.

REACH regulates safe chemical use in products.

UL Certification tests product safety for international markets.

LTPCBA uses several inspection methods to guarantee consistent quality in high-volume mixed technology pcb assembly. Automated Optical Inspection (AOI) detects solder bridges, tombstoning, and misaligned components. X-ray inspection reveals hidden defects in BGAs, QFNs, and microvias. In-circuit testing (ICT) verifies component values and connections. Functional testing validates performance under real-world conditions. Environmental testing ensures durability in harsh environments. Cleaning removes flux residues to prevent corrosion. Conformal coating protects against moisture and dust. Packaging uses anti-static and moisture barrier materials to protect boards during shipping.

Purpose | |

|---|---|

Automated Optical Inspection (AOI) | Detects solder bridges, tombstoning, and misaligned components. |

X-Ray Inspection | Reveals hidden defects in BGAs, QFNs, and microvias. |

In-Circuit Testing (ICT) | Verifies component values and connections, catching shorts or opens. |

Functional Testing | Validates performance under real-world conditions. |

Environmental Testing | Ensures durability in harsh environments through thermal cycling, etc. |

Cleaning | Removes flux residues to prevent corrosion. |

Conformal Coating | Provides a protective layer against moisture and dust. |

Packaging | Protects against damage during shipping with anti-static and moisture barrier packaging. |

AOI systems consistently outperform manual inspection. You can detect surface defects such as stains, missing or wrongly mounted components, soldering flaws, and scratches. AOI can be applied at any stage of the process and run multiple times if needed. This method is cost-effective and helps prevent flaws, which increases production values and ensures reliable circuit boards.

You must also address common failure modes in mixed technology pcb assembly. Solder defects are mitigated by optimizing solder paste printing, using high-quality solder paste and flux, and implementing proper reflow profiling. Regular solder paste inspections and X-ray inspection for hidden solder joints help you catch issues early. Contamination is controlled by maintaining a clean room environment, using protective equipment, and optimizing cleaning processes. Thermal management issues are solved by optimizing reflow profiling, considering thermal zones, and using thermal vias and copper planes. ESD and EOS damage is prevented by implementing comprehensive ESD control programs, using grounded workstations, and providing ESD awareness training.

Mixed technology pcbs require careful processing and inspection to deliver high performance and reliability. LTPCBA’s advanced systems and strict quality standards help you achieve consistent results, whether you need prototypes or high-volume production. You can trust LTPCBA to deliver mixed assembly pcbs that meet your requirements for efficiency, durability, and safety.

Applications and Benefits

Where Mixed Technology PCBs Are Used

You will find mixed technology pcbs in many industries that need both advanced features and strong reliability. These boards support a wide range of products and systems. Here are some of the most common areas where you see mixed assembly pcbs:

Consumer electronics

Automotive

Medical

Defense

Aerospace

Industrial manufacturing

Telecommunications

Smart transportation

Smart agriculture

Mixed technology pcb assembly lets you meet the needs of each industry. You can use hybrid assembly to create reliable circuit boards for everything from medical devices to automotive control units.

Advantages of Mixed Assembly

Mixed technology pcbs offer you several important benefits. You can design boards that fit your exact needs, whether you want high performance or strong durability. The table below shows some of the main advantages you get with mixed assembly:

Benefit | Description |

|---|---|

Increased Reliability | Mixed model pcbs are often more reliable and durable due to diverse electrical properties. |

Fast Turn Around | Allows for a single assembly line, reducing time to market without sacrificing quality. |

Enhanced Stress Tolerance | Distributes stress evenly across the board, improving performance under high-stress conditions. |

You can also achieve SWaP (Size, Weight, and Power) goals in high-reliability systems. Mixed assembly pcbs help you optimize for either precision or speed, depending on your application. The pcb assembly process at LTPCBA supports fast turnaround from design to full-scale production, which boosts your production efficiency.

LTPCBA’s Industry Solutions

When you choose LTPCBA for mixed technology pcba, you get more than just advanced processing. You receive strong customer support and fast service. LTPCBA offers phone, email, and on-site support to keep your operations running. You get replies to your questions within 12 hours. If you need repairs, LTPCBA returns your products within 3 days. You also benefit from a 3-year warranty, with options to extend. Returns are accepted within 7 days, and replacements within 30 days.

You can trust LTPCBA to deliver mixed technology pcbs that meet your needs for hybrid assembly, mixed pcb assembly, and through hole technology. The company’s focus on quality and efficiency ensures your pcba projects succeed, whether you need prototypes or high-volume production. LTPCBA’s pcb assembly process and production efficiency help you get reliable circuit boards every time.

You gain flexibility and reliability with mixed assembly pcba. The process combines SMT and through hole technology for advanced boards. LTPCBA stands out in manufacturing and assembly with a 99.5% pass rate and top certifications. You benefit from fast processing, strong customer service, and efficiency every step of the way.

When choosing a provider, consider these important factors:

Factor | Importance |

|---|---|

Technology Capabilities | Meets design needs |

Quality Assurance | Ensures reliable pcba |

Turnaround Time | Keeps projects on schedule |

FAQ

What is mixed technology assembly in PCB manufacturing?

You use mixed technology assembly to combine surface-mount devices and through-hole components on a single printed circuit board for better performance and flexibility.

How does LTPCBA ensure testing and quality assurance?

You benefit from advanced testing and quality assurance at LTPCBA. Automated inspection and strict standards help you receive reliable printed circuit boards every time.

What are future trends in mixed technology PCBs?

You will see future trends in mixed technology pcbs focus on higher integration, smarter automation, and improved materials for more efficient and powerful electronic products.

See Also

Understanding PCBA: Key Components and Their Functions

Combining SMT and DIP: A Guide to Mixed Technology PCBs

Decoding PCBA: What It Means in Electronics