Key Steps to Improve PCBA Reliability for Long-Term Performance

You need to improve reliability if you want your products to last and keep customers happy. A strong system covers design, materials, manufacturing, testing, and protection. Each step gives you direct value. LTPCBA’s proven expertise ensures you follow the best practices in every phase.

Key Takeaways

Start with a strong design using industry standards and quality materials to build reliable PCBAs that last longer and handle stress well.

Use strict process control and thorough testing during manufacturing to catch defects early and ensure every board meets high-quality standards.

Protect your PCBA with proper cleaning and conformal coating to prevent damage from moisture, dirt, and chemicals, extending product life.

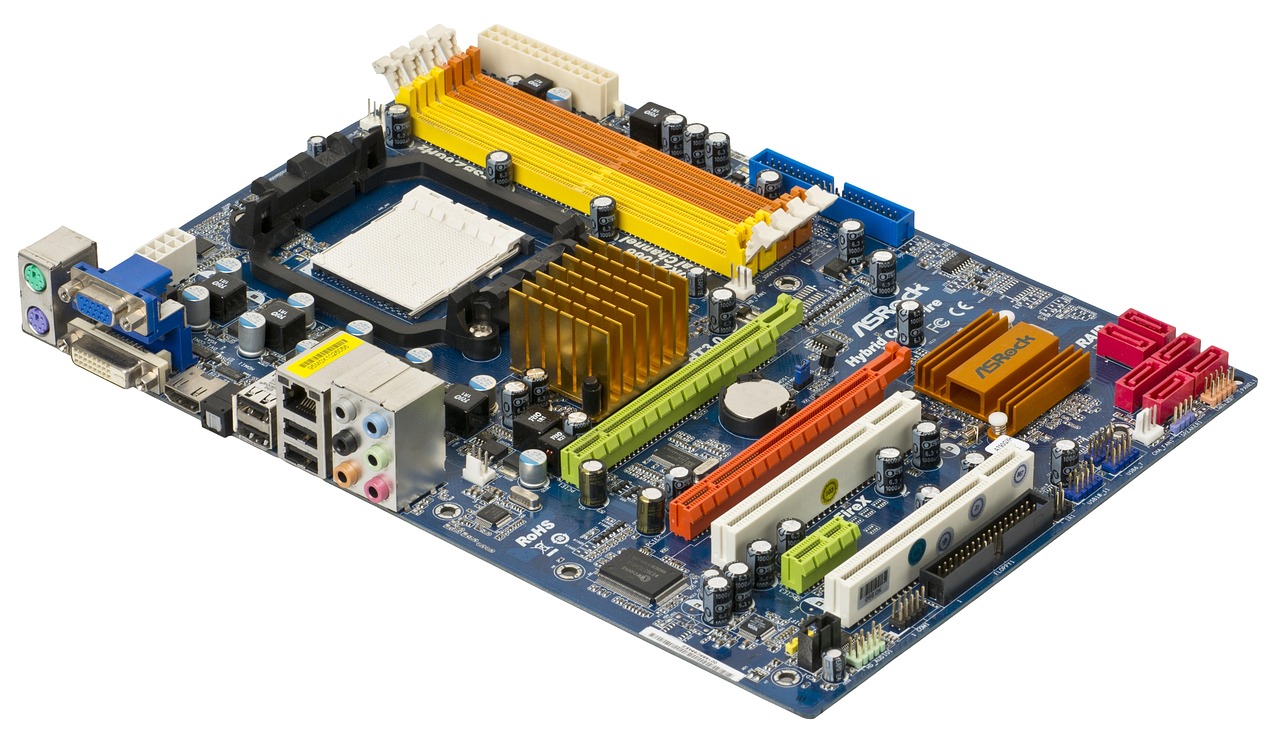

Design & Materials

Design for Reliability

You set the foundation for long-term PCBA performance during the design phase. Start by following industry standards like IPC-2221 and IPC-A-610. These standards guide you in choosing the right materials and layout for your application. LTPCBA always aligns with these standards to ensure every board meets strict reliability requirements.

Tip: Begin dependability assessments early. Use tools like Failure Mode and Effects Analysis (FMEA) to spot and address weak points before production starts.

Many companies have seen success by using flexible and rigid-flex PCBs. For example:

Fitness tracker makers use flexible PCBs to handle daily bending and movement.

Automotive brands choose rigid-flex designs for dashboards, which face constant vibration and temperature changes.

Medical device engineers rely on flexible PCBs in endoscopes for better maneuverability and fewer failures.

You can also:

Use curved traces instead of sharp angles to reduce stress.

Distribute stress evenly across bending areas.

Avoid placing vias or components near high-stress zones.

Reinforce critical areas with metallization layers or meander designs.

Physics of Failure (PoF) methods and accelerated life testing help you predict and prevent failures. These approaches use real-world data from thermal cycling and vibration tests to guide your design choices. When you combine these strategies, you improve reliability and reduce costly failures.

Quality Components

Selecting high-quality components is essential for a reliable PCBA. LTPCBA sources components from trusted suppliers and performs regular audits to ensure quality. You benefit from strong supplier partnerships, which means timely delivery and quick resolution of any issues.

A recent study showed that using quality components and FMEA reduced the defect rate from 0.91% to 0.14%. The lot reject rate dropped from 5500 PPM to 900 PPM. This proves that careful sourcing and strict quality control make a big difference.

Metric | Before Quality Improvement | After Quality Improvement | Improvement |

|---|---|---|---|

Total PCBs Produced | 40,398 | 40,820 | N/A |

Defects Observed | 366 | 58 | Decreased by 308 |

Defect Percentage | 0.91% | 0.14% | Reduced by 0.76% |

Lot Reject Rate (LRR) | 5500 PPM | 900 PPM | Reduced by 4600 PPM |

You should also use traceability systems to track components through the assembly process. This helps you find and fix problems quickly if they arise. Good inventory management prevents shortages and reduces the risk of defects.

Thermal & Signal Integrity

Thermal and signal integrity play a major role in PCBA reliability. You need to design your board to handle heat and maintain clean signals. LTPCBA uses advanced simulation and testing to ensure every board meets these demands.

Use controlled impedance testing to check signal quality.

Apply thermal stress tests, like thermal shock and burn-in, to see how your board performs under extreme conditions.

Follow best practices in trace routing and via placement to avoid signal loss.

Maintain ground plane continuity for stable operation.

Electrical tests such as time domain reflectometry (TDR) help you measure impedance and spot faults. Industry standards like MIL-STD, IEC, and ISO provide frameworks for these tests. By following these steps, you ensure your PCBA can withstand harsh environments and deliver consistent performance.

Note: Adhering to international standards not only improves reliability but also reduces defects and lowers maintenance costs. LTPCBA’s commitment to ISO, IATF, and UL standards ensures your products meet the highest quality benchmarks.

Manufacturing & Testing to Improve Reliability

LTPCBA Process Control

You need strong process control to improve reliability in every PCBA you produce. LTPCBA uses advanced manufacturing systems and automated inspection tools to catch problems early. You benefit from a process that checks quality at every step, not just at the end. Automated Optical Inspection (AOI), X-ray, In-Circuit Testing (ICT), and flying probe tests help find both visible and hidden defects. Teams keep detailed records of all tests, so you can trace and fix any issue quickly.

Here is how LTPCBA’s process control metrics support consistent quality:

Process Control Metric / QA Data | Description / Target Value | Role in Manufacturing Reliability and Consistency |

|---|---|---|

First Pass Yield | Target of 95% | Reduces rework and accelerates delivery |

Pick-and-Place Accuracy | 99.95% | Ensures precise component placement, minimizing defects |

AOI and ICT | Applied at every production step | Enables early detection of defects, preventing downstream failures |

Solder Paste Application | Controlled by stencil thickness | Critical for over 70% of solder joint success |

Reflow Soldering Temperature Control | Precisely maintained | Guarantees consistent and reliable solder joints |

Final Testing | Comprehensive before shipment | Confirms product reliability and performance |

Statistical Process Control | Data-driven quality monitoring | Supports continuous improvement and consistent quality |

Quality Checks (AOI, X-ray, ICT, Flying Probe, Burn-in Tests) | Continuous and multi-stage | Detects visible and hidden defects throughout manufacturing |

Compliance with International Standards (ISO, UL) | Adherence to global quality standards | Builds trust and ensures product safety and reliability |

Pass Rate | Maintains 99.5% | Demonstrates high manufacturing quality and consistency |

Automation and Machine Maintenance | Regular upkeep and automation use | Ensures stable production environment and reduces variability |

Detailed Record-Keeping | Documentation of all tests and processes | Enables traceability and rapid problem resolution |

You can see that every step aims to improve reliability and deliver consistent results. LTPCBA’s commitment to international standards like ISO and UL gives you confidence in the final product.

Cleaning & Contamination

Cleaning is a critical step if you want to improve reliability in your PCBAs. Even small amounts of contamination, such as ionic or flux residues, can cause corrosion, dendrite growth, and leakage currents. These problems lead to failures like electrochemical migration and poor adhesion, especially in high-density designs.

Studies show that cleaning before coating prevents corrosion and leakage current buildup. For example, clean PCBAs show minimal leakage current (0.05 mA) and almost no current surge. In contrast, boards with flux residues can reach up to 10 mA leakage and fail much sooner. You should use cleaning methods like vapor degreasing, aqueous cleaning, or benchtop cleaning to remove these residues. Operator training and controlled cleaning processes further reduce contamination.

Tip: Always clean PCBAs before applying any protective coating. This step helps improve reliability and prevents costly failures in critical applications.

Functional & Environmental Testing

You must verify that every PCBA works as intended and can survive harsh environments. LTPCBA uses a range of functional and environmental tests to improve reliability and ensure your products meet industry standards.

Here are some key environmental tests and their benchmarks:

Environmental Test Type | Description | Relevant Standards and Criteria |

|---|---|---|

Repeated heating and cooling cycles to simulate operational temperature fluctuations. | Temperature range -65°C to +150°C; tests for solder joint cracking, delamination, material degradation. | |

Thermal Shock Test | Rapid temperature changes to assess PCB resistance to sudden thermal stress. | MIL-STD-202, IEC 60068 standards for shock and thermal stress. |

Humidity Test | Exposure to high humidity to evaluate moisture resistance and corrosion potential. | IPC-A-610, MIL-STD-202 humidity test methods. |

Vibration Test | Mechanical vibration to simulate operational and transportation stresses. | MIL-STD-202 vibration profiles. |

Drop Test | Physical drop impact to assess mechanical robustness. | IEC 60068 drop test procedures. |

Functional testing checks signal actuation, waveform quality, and communication protocols. You use tools like oscilloscopes, multimeters, and automated test fixtures to confirm that each board meets its design goals. Burn-in and fatigue tests help you spot early failures and improve reliability before shipment.

Note: Comprehensive test coverage, regular equipment calibration, and test automation all help you improve reliability and reduce costs. Cross-team collaboration between design, testing, and manufacturing teams ensures that every board meets your expectations.

Conformal Coating

Conformal coating protects your PCBA from moisture, dirt, mold, chemicals, and heat. This layer acts as a shield, helping you improve reliability in harsh environments. Parylene coatings, for example, offer superior corrosion protection and dielectric strength. Other coatings, such as epoxy and urethane, provide strong resistance to humidity and chemicals.

Conformal coatings improve insulation and reduce electromagnetic interference.

They allow for tighter component spacing, supporting compact designs.

Proper application ensures consistent thickness and full coverage, which is critical to improve reliability.

You should always clean the board before coating to ensure good adhesion and long-term protection. While coatings do not protect against vibration or shock, they offer excellent defense against environmental threats.

Alert: Choose the right coating type and application method for your product’s needs. This decision will help you improve reliability and extend the life of your PCBA.

You achieve long-term PCBA performance when you follow a holistic approach.

Combine design, material selection, manufacturing, and testing to improve reliability.

Use advanced materials, strong process control, and rigorous testing.

Case studies show this approach reduces failures and extends product life.

Stay proactive and adapt your strategies as technology changes.

FAQ

What is the most important step to improve PCBA reliability?

You must focus on strong process control. This step helps you catch defects early and ensures every board meets strict quality standards.

How does LTPCBA ensure high-quality components?

You get components from trusted suppliers. LTPCBA audits suppliers and uses traceability systems to prevent defects and guarantee reliable performance.

Why should you use conformal coating on PCBAs?

You protect your board from moisture, dust, and chemicals.

Conformal coating extends product life and improves reliability in harsh environments.

See Also

Complete PCBA Solutions From Production Through Final Testing

Cutting-Edge BGA Assembly Methods For Reliable Electronics

Choosing The Right PCBA Supplier To Fit Your Requirements

Comprehensive PCBA Manufacturing Process Guide For All Skill Levels