Key Cost Factors in Custom PCBA Manufacturing and How to Save

When you explore PCBA manufacturing custom solutions, it’s important to understand the key factors that drive costs and how you can minimize expenses while maintaining top quality. In PCBA manufacturing custom projects, several elements influence your final bill, including materials, board design, components, production volume, lead time, testing, labor, and hidden costs. Labor rates, advanced testing methods such as AOI, and logistics are significant contributors to overall expenses. Additionally, supply chain challenges and specialized finishes can affect your budget. By conducting a thorough cost analysis and planning strategically, you can achieve substantial savings in your PCBA manufacturing custom projects.

Materials

Board design

Components

Production volume

Lead time

Testing

Labor

Hidden costs

Key Takeaways

Choose the right materials and design your board simply to lower costs without losing quality.

Standardize components and plan sourcing early to avoid delays and reduce expenses.

Order in larger volumes to spread setup costs and get better prices per unit.

Plan production schedules ahead to save money, avoid rush fees, and ensure timely delivery.

Work closely with your manufacturer for design reviews, clear communication, and supply chain management to prevent hidden costs and improve quality.

Cost Analysis in PCBA Manufacturing

A detailed cost analysis gives you the power to make smart decisions in your pcba manufacturing custom projects. By breaking down the main factors that influence prices, you can see where your money goes and how to save without lowering quality. Let’s look at how materials, board design, and components shape your custom pcb cost and what you can do to manage expenses.

Materials

Material costs play a major role in pcb manufacturing. The type of material you choose affects both performance and price. Here’s a quick comparison:

Material Type | Typical Use Cases | Material Costs | Performance Impact |

|---|---|---|---|

FR4 | Consumer electronics, appliances | Low | Standard, good for most uses |

Rogers | Aerospace, 5G, defense | High | Superior high-frequency, better thermal management |

Aluminum | LED lighting, power devices | Medium | Good heat dissipation, moderate price |

Hybrid (FR4 + Rogers) | Mixed-signal, RF boards | Moderate | Balances cost and performance |

FR4 is the most common and cost-effective choice for many pcb manufacturing projects. Rogers material costs more but delivers better performance for high-frequency or mission-critical applications. Hybrid boards help you control custom pcb cost by using premium materials only where needed. When you select materials, always match them to your product’s requirements to avoid unnecessary expenses.

Tip: Early collaboration with your manufacturer helps you optimize design and material selection, keeping material costs in check.

Board Design

Board design decisions have a direct impact on custom pcb cost and overall expenses. Simple designs with fewer layers and standard shapes usually cost less to produce. Complex layouts, tight tolerances, and special finishes increase both material costs and manufacturing time.

Standardizing board size and shape reduces waste during pcb manufacturing.

Using common stack-ups and avoiding unnecessary layers lowers custom pcb cost.

Designing for manufacturability (DFM) helps you avoid costly redesigns and delays.

A well-planned board design also makes it easier to estimate costs and manage your budget. LTPCBA uses advanced design software and simulation tools to help you spot potential issues early. This approach supports transparent cost analysis and ensures you get the best value for your investment.

Components

Component choices drive a large portion of your custom pcb cost. Prices vary based on specifications, availability, and manufacturer. Sourcing rare or specialized parts increases component procurement costs and can delay your project. Bulk purchasing lowers per-unit prices but may tie up capital if your project changes.

Standardizing components simplifies sourcing and reduces expenses.

Choosing parts compatible with automated assembly keeps labor costs down.

Planning ahead and verifying suppliers helps you avoid counterfeit parts and supply chain delays.

You should always focus on the critical components that make up most of your BOM cost. Collaborate with experts to optimize your BOM and sourcing strategy. LTPCBA’s transparent approach to pcba manufacturing custom projects includes detailed cost breakdowns and quality assurance at every step. This helps you understand all the factors that influence prices and make informed decisions.

Note: Using dedicated product costing software and maintaining a component database supports ongoing cost management and helps you stay on budget.

A thorough cost analysis lets you categorize costs, focus on the biggest contributors, and plan for different scenarios. By working closely with your manufacturer and using the right tools, you can control custom pcb cost, reduce expenses, and achieve your project goals.

Board Complexity and Expenses

Layer Count

You can control custom pcb cost by reducing the number of layers in your board. Each extra layer in pcb manufacturing adds more material, time, and complexity. The table below shows how layer count affects costs and production:

Aspect | Impact on Manufacturing Costs and Complexity |

|---|---|

Material Usage | More layers mean more materials, raising raw material costs. |

Production Time | Extra layers increase production time with more etching, bonding, and inspection steps. |

Cost Increase | Costs rise by about 30-40% for 4-6 layers, and another 30-35% for 6-8 layers. |

Inspection | Each layer needs inspection, which increases labor and quality control costs. |

Complexity | Multilayer pcba needs precise alignment and advanced assembly, which raises custom pcb cost. |

Equipment | Advanced equipment is needed for layer alignment and testing, increasing expenses. |

If you keep your design to the minimum number of layers needed, you lower both custom pcb cost and production time. This is a key cost reduction strategy in pcb manufacturing.

Board Size

Board size has a direct effect on custom pcb cost and overall expenses. Larger boards use more material and require more complex manufacturing steps. In pcb manufacturing, bigger boards may also waste panel space, which increases costs. You can save money by making your pcba as compact as possible.

Smaller boards use less material, which lowers custom pcb cost.

Efficient panelization lets you fit more boards per panel, reducing waste.

Even small pcba produced in high volume can cost less than large boards in low volume.

Tip: Work with your manufacturer to optimize board size and panel layout for better cost optimisation.

Layout Optimization

Good layout optimization is one of the best ways to control custom pcb cost in pcb manufacturing. You can use several techniques to make your design more efficient:

Group related components together for easier assembly.

Use standard spacing and avoid overly dense layouts.

Plan for heat dissipation by spacing out heat-generating parts.

Keep traces short and avoid sharp angles for better signal quality.

Use panelization and mirroring designs to maximize space and reduce waste.

Design optimization also means following manufacturer standards and avoiding unnecessary cuts or slots. These steps make your pcba easier to build and help with cost optimisation. When you focus on design optimization, you improve manufacturability and reduce errors, which lowers costs.

Note: Early design optimization with your manufacturer leads to fewer changes later and helps you achieve your cost reduction strategies.

Component Choices in PCBA Manufacturing Custom

Standard vs. Custom Parts

Choosing between standard and custom parts shapes your pcba manufacturing custom project’s costs. Standard parts are widely available and often cost less. You can find them from many suppliers, which helps you avoid delays and reduce procurement costs. Custom parts may fit unique needs, but they increase component procurement costs and lead times. When you use standard components, you also make the assembly process smoother and more reliable. LTPCBA recommends standardizing your BOM whenever possible. This approach keeps your pcba project on schedule and within budget.

Placement Density

Component placement density affects both the assembly process and your total costs. High-density layouts complicate pick-and-place operations. You may see more solder bridging and inspection blind spots. These problems can lead to higher labor costs, lower yields, and longer inspection times. Denser packing also requires greater placement precision, which raises assembly costs. You can avoid these issues by following IPC-recommended clearances and working closely with your assembly partner. Early collaboration with LTPCBA ensures your design matches machine capabilities and reduces rework.

High component density increases rework difficulty and labor costs.

Tight spacing can cause defects and slow down inspections.

Proper spacing improves yields and lowers costs.

Sourcing Strategies

Smart sourcing strategies help you control costs and manage risks in pcba manufacturing custom projects. You should start by aligning your engineering and procurement teams early. This step reduces last-minute changes and keeps your project on track. Use BOM management tools to select cost-effective and available parts. Bulk purchasing and vendor promotions can further reduce procurement costs. Always keep backup suppliers and safety stock to handle supply chain disruptions. LTPCBA’s sourcing team uses real-time data and quality checks to ensure reliable component supply for every pcba project.

BOM management software helps you pick the best parts.

Bulk orders and backup suppliers protect your project from shortages.

Tip: Regularly review your sourcing plan and update it based on market trends. This habit keeps your pcba project resilient and cost-effective.

Production Volume and Reduce Expenses

Prototyping vs. Mass Production

You face different processing costs when you move from prototyping to mass production in pcb manufacturing. Prototyping usually involves small batches, which means higher costs per board. You pay for setup and tooling each time, so a handful of boards might cost $50 to $200 each. Mass production spreads these setup costs over thousands of units. Automated machinery and bulk component inventories help you lower the cost per board to less than $1. This shift lets you use cost reduction strategies that make your project more affordable.

Aspect | Prototype PCBs | Mass Production PCBs |

|---|---|---|

Cost per Unit | Higher due to small batch sizes | |

Typical Range | $50–$200 for a few boards | Under $1 per board |

Focus | Flexibility, early validation | Cost efficiency, reliability |

LTPCBA supports you at every stage, offering flexible production capabilities from prototype to mid-volume runs. You can validate your design early and then scale up for mass production without changing suppliers.

Bulk Ordering

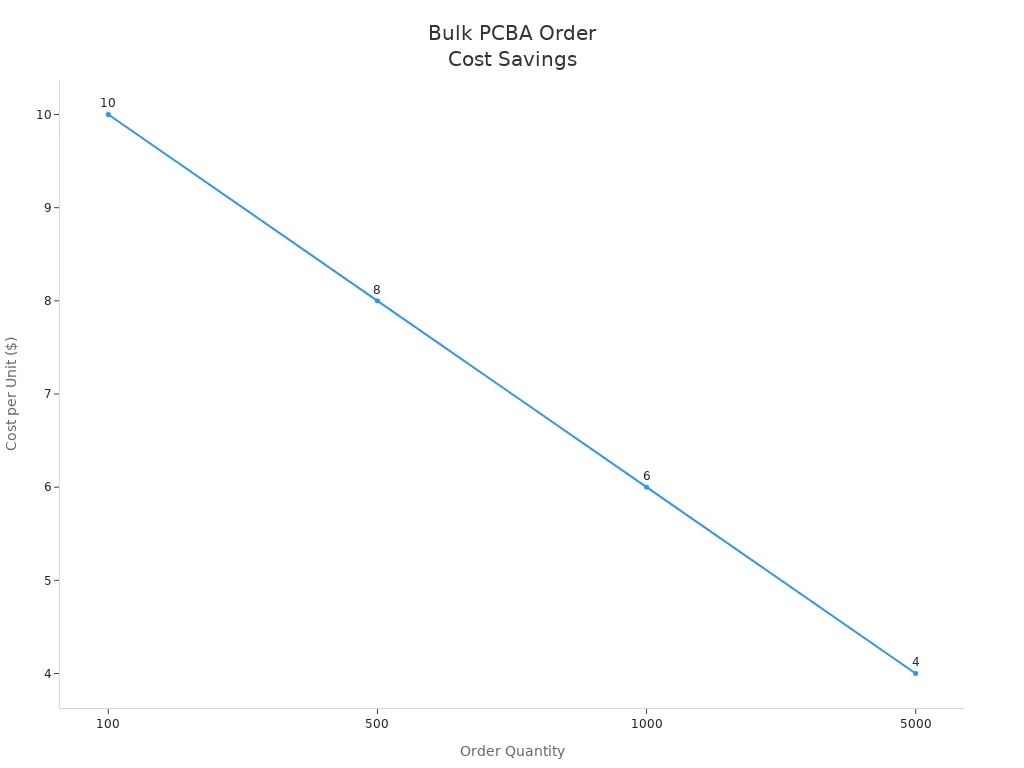

Volume purchasing is one of the most effective cost reduction strategies in pcb manufacturing. When you order pcba assemblies in bulk, you spread fixed processing costs like setup fees and tooling charges across many units. This lowers your cost per unit and helps you manage your budget.

Order Quantity | Cost per Unit |

|---|---|

100 | |

500 | $8 |

1000 | $6 |

5000 | $4 |

When you use volume purchasing, you also benefit from wholesale component prices, reduced non-recurring engineering charges, and improved supply chain stability. Bulk orders make automation possible, which further reduces processing costs and defects.

You optimize production processes and reduce material waste.

You lower shipping costs per unit by consolidating shipments.

You minimize risks of component obsolescence and price hikes.

Scheduling

Smart scheduling helps you reduce expenses and avoid production delays in pcb manufacturing. You can consolidate logistics to cut intermediate shipping steps. Parallel processes, such as simultaneous procurement and production preparation, speed up development cycles. Quick changes within an integrated system minimize wait times. A single point of contact streamlines project management and reduces administrative overhead.

Flexible production lines adapt to demand changes and prevent bottlenecks.

Phased production supports smooth transitions from prototype to mass production.

Integrated testing and early defect detection improve quality and reduce rework.

LTPCBA’s one-stop pcba services include these scheduling practices. You get reliable delivery, efficient production, and lower processing costs.

Tip: Plan your production schedule early and communicate with your manufacturer. You will maximize cost savings and avoid unexpected expenses.

Lead Time and Turnaround

Rush Orders

You might need your pcba project completed quickly. Rush orders can help you meet tight deadlines, but they often come with higher costs. When you request a fast turnaround, manufacturers must prioritize your job. This means they may need to pay overtime, use express shipping, or interrupt other scheduled work. These actions increase expenses. You may also face limited material choices, which can affect both cost and quality. If you plan for rush orders, always check with your manufacturer about possible trade-offs. Quick delivery can save your project, but it usually raises the price per unit.

Tip: Use rush orders only when necessary. Regular scheduling keeps costs lower and gives you more options for materials and processes.

Planning Ahead

Planning your pcba production schedule in advance brings many benefits. You can optimize how resources are used, which reduces idle time and makes the most of production capacity. This step directly lowers your production costs. Well-planned schedules help you get your orders on time, which keeps your customers happy and makes your business more competitive. You also improve overall efficiency, shorten cycle times, and boost productivity. These changes lead to significant cost savings.

Here are some key benefits of planning ahead:

You minimize idle time and maximize production capacity, which reduces costs.

You ensure timely order fulfillment, which improves customer satisfaction and your market position.

You increase production efficiency, reduce cycle times, and save money.

When you work with a manufacturer like LTPCBA, early planning helps you avoid last-minute surprises. You can secure the best materials, lock in lower prices, and keep your pcba project on track.

Testing, Quality, and Expenses

Testing Methods

You need to balance thorough testing with controlling expenses in your pcba project. Several testing methods help you achieve reliable results without overspending. Visual inspection works well as a first step. It catches obvious defects early and keeps assembly and testing costs low. In-Circuit Testing (ICT) offers high fault coverage and precise troubleshooting. ICT requires an initial investment in custom fixtures, but it saves money over time by reducing rework. Flying Probe Testing gives you flexibility for prototypes or small batches. It avoids fixture costs and adapts to changing designs. Automated Optical Inspection (AOI) delivers fast, repeatable checks. AOI reduces manual labor and improves defect detection in the assembly process.

Tip: Combine these testing methods based on your production volume and complexity. You will reduce post-production problems and keep costs under control.

Quality Assurance

Quality assurance in pcb assembly means more than just testing. You must follow international standards like ISO and UL. These standards require investments in quality management systems, training, and advanced inspection equipment such as AOI and X-ray. You need to perform full inspections and maintain strict control systems. These steps increase upfront expenses, but they help you avoid defects and improve product reliability. LTPCBA uses AOI and complies with ISO, IATF, and UL standards. This approach reduces warranty claims and recalls, saving money in the long run.

Full inspections and process audits prevent failures.

Training and supplier evaluation improve quality.

Compliance ensures market access and customer satisfaction.

Streamlining Processes

You can lower assembly and testing costs by streamlining your assembly process. PCB panelization lets you assemble and test multiple boards at once. This method reduces handling time and boosts throughput. Massively parallel in-circuit testing systems allow you to test many boards together, saving time and operator effort. Integrating flash programming and functional testing into one system also cuts down on test stations and floor space. These improvements make your assembly process more efficient and scalable.

Note: When you optimize your assembly process, you reduce operator requirements and test time. You achieve higher quality and lower costs for your pcba project.

Labor, Location, and Overhead

Regional Costs

Your choice of manufacturing location has a big impact on pcba expenses. Shenzhen, China, offers several advantages for pcba production. You benefit from lower labor rates, a skilled workforce, and access to a strong supply chain. These factors help you keep processing costs down. LTPCBA’s Shenzhen facility uses local resources and efficient logistics. You get faster turnaround and reduced shipping expenses. When you select a manufacturer in Shenzhen, you also gain access to advanced technology and automation, which further lowers your overall costs.

Automation

Automation plays a key role in reducing labor and overhead for pcba manufacturing. You see faster production speeds because machines work without breaks or fatigue. Automated material handling cuts down on waste and improves resource use. Consistent machine operation means fewer defects and less rework, which saves you money. Industrial robots and automated systems allow you to produce large volumes with shorter lead times and lower operational expenses. Automation also changes the labor cost structure by reducing the need for manual workers and focusing on skilled technicians. Even though automation requires an upfront investment, you recover these costs through efficiency gains and lower processing costs in bulk production.

Automation increases production speed and consistency.

Automated material handling reduces waste and overhead.

Robots and machines enable mass production with fewer errors.

Automation and outsourcing in electronics manufacturing help you lower labor costs and improve your bottom line.

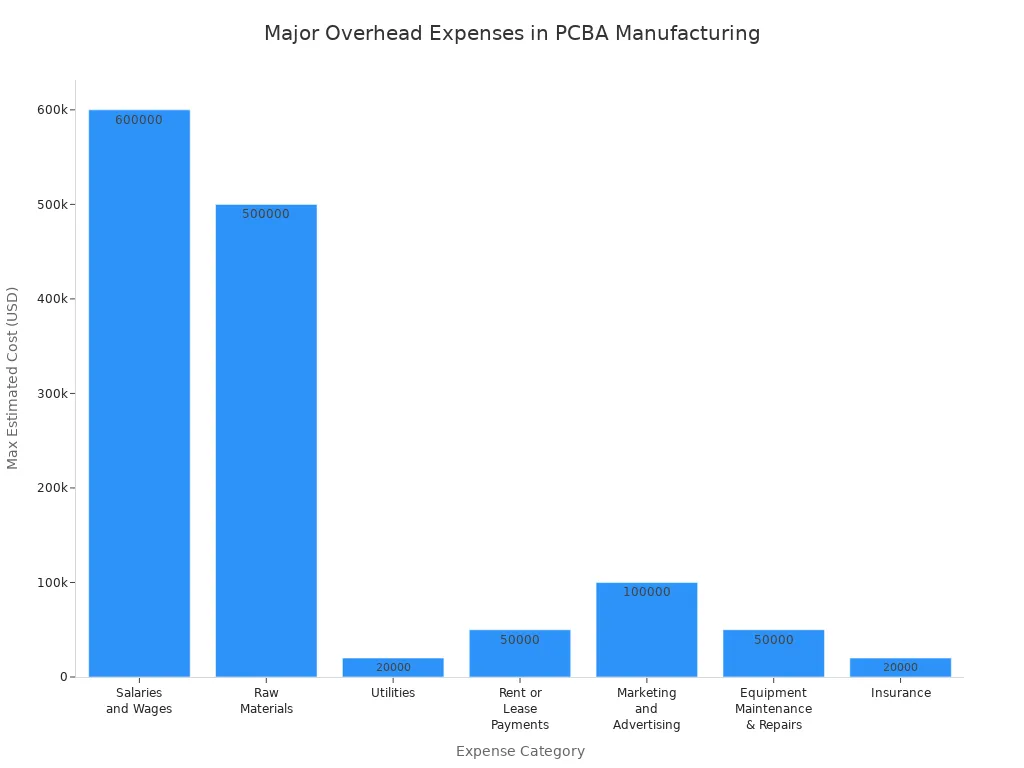

Overhead Management

You need to manage overhead expenses to keep your pcba project profitable. The most significant overhead costs include salaries, raw materials, utilities, rent, marketing, equipment maintenance, and insurance. You can control these costs by optimizing staffing, automating tasks, and negotiating better rates with suppliers. Preventative maintenance and energy-efficient equipment also help you avoid unexpected expenses. LTPCBA uses data-driven strategies and regular audits to keep overhead low and maintain high operational efficiency.

Overhead Expense | Estimated Cost Range | Management Strategies |

|---|---|---|

Salaries and Wages | $200,000 - $600,000 | Optimize staffing, automate tasks, outsource non-core functions. |

Raw Materials | $100,000 - $500,000 | Bulk discounts, local sourcing, inventory optimization, waste reduction. |

Utilities | $5,000 - $20,000 | Energy-efficient equipment, off-peak scheduling, automation. |

Rent or Lease Payments | $10,000 - $50,000 | Balance fixed and variable costs. |

Marketing and Advertising | $20,000 - $100,000 | Focus on digital channels, targeted campaigns, analytics. |

Equipment Maintenance & Repairs | $10,000 - $50,000 | Preventative schedules, service contracts, technician training. |

Insurance | $5,000 - $20,000 | Comprehensive coverage for property and liability. |

Tip: Regularly review your overhead expenses and adjust your management strategies. You will keep your pcba project efficient and cost-effective.

Hidden Costs in PCBA

When you plan a pcba project, you need to look beyond the obvious expenses. Many hidden costs can affect your budget and timeline. These costs often surprise new buyers and can make a big difference in your total spend. Here are the most common hidden costs you should watch for:

Prototyping and testing costs for multiple design iterations.

Tooling and manufacturing setup for custom designs.

Assembly and testing time, which can be expensive for complex boards.

Quality control and certification fees for meeting safety standards.

Shipping costs and logistics for both materials and finished pcba assemblies.

NRE Charges

Non-Recurring Engineering (NRE) charges are one-time fees you pay for development, design, and manufacturing setup. These charges cover tooling like stencils, jigs, and programming files. NRE charges increase your upfront costs, but they do not raise the per-unit price. The size of your board, number of layers, and order quantity all affect NRE costs. If you order more units or combine projects on one panel, you can lower the NRE cost per board. When you reorder the same pcba, you often pay less because the manufacturer can reuse the original tooling. You should always factor NRE charges into your budget, especially for custom or complex designs.

NRE charges include:

Tooling and stencils

Programming and setup

Custom fixtures

Tip: Plan for larger production runs when possible. This spreads NRE charges over more units and helps you control material costs.

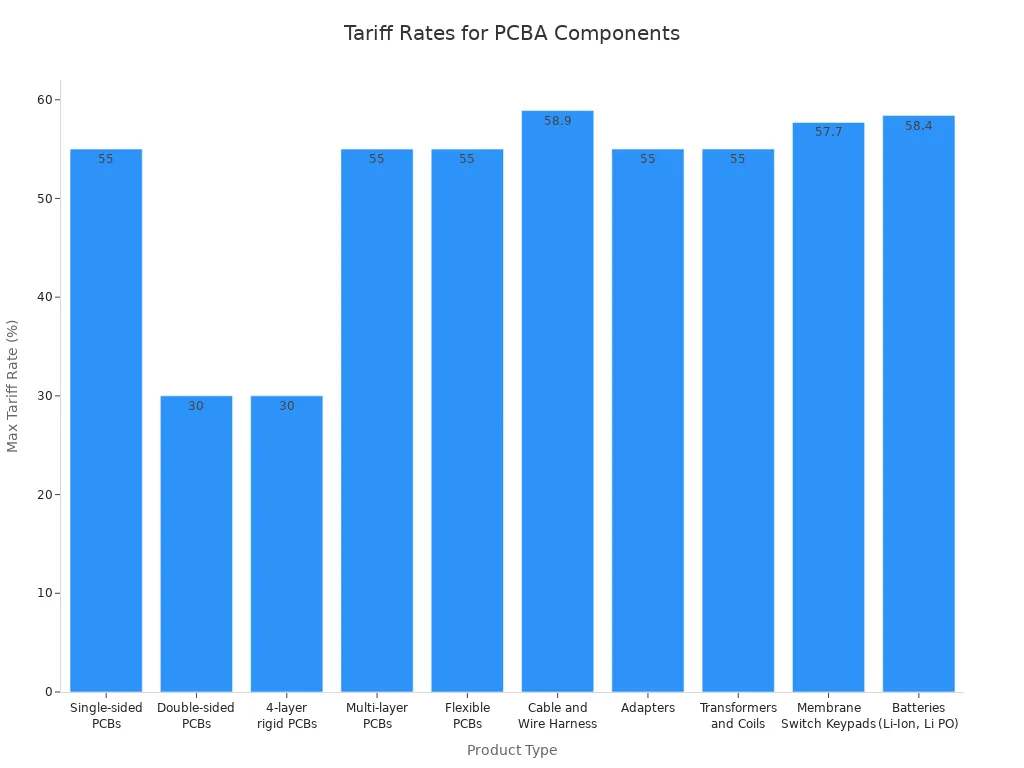

Shipping and Tariffs

Shipping costs and international tariffs can add a large amount to your final pcba price. Tariffs on components and assemblies from China can reach up to 55%. Shipping costs for air freight are high, while ocean freight is slower but cheaper. Supply chain disruptions can also raise shipping costs and delay delivery. You need to include all these expenses in your total landed cost to avoid surprises.

Product Type / Item | Tariff Rate Range (%) |

|---|---|

Single-sided PCBs | Up to 55 |

Double-sided PCBs | Around 30 |

4-layer rigid PCBs | Around 30 |

Multi-layer PCBs (other) | Up to 55 |

Flexible PCBs | Up to 55 |

Cable and Wire Harness | Up to 58.9 |

Adapters | Up to 55 |

Transformers and Coils | Up to 55 |

Membrane Switch Keypads | Up to 57.7 |

Batteries (Lithium-Ion, Li PO) | Up to 58.4 |

You should always check the latest tariff rates and shipping costs before placing your order. These factors that influence prices can change quickly and have a big impact on your budget.

Avoiding Surprises

You can avoid hidden costs by following best practices in pcba manufacturing. Use standard components to keep material costs low and simplify sourcing. Design your boards for easy assembly and choose reliable suppliers. Order in bulk when possible to get better prices, but watch out for minimum order requirements. Do not pick the cheapest supplier if they lack experience or certifications. This can lead to more rework, warranty claims, and even damage to your reputation.

Note: Work with experienced manufacturers for design reviews and sourcing. This helps you optimize costs and avoid unexpected expenses.

If you plan ahead and build strong partnerships, you can reduce hidden costs and keep your pcba project on track.

Best Practices with LTPCBA

DFM and DFA

You can achieve significant savings by focusing on Design for Manufacturability (DFM) and Design for Assembly (DFA) from the start. DFM ensures your design is easy to produce, while DFA makes assembly straightforward. LTPCBA recommends early design optimization to catch issues before production. You should review your layout for manufacturability and check that all components fit standard assembly processes. This cost-saving strategy reduces errors and rework. Use panelization and standard footprints to simplify assembly. You will see better yields and lower costs when you prioritize optimization at every stage.

Tip: Share your design files with LTPCBA’s engineers early. They can suggest improvements for optimization and manufacturability.

Communication

Clear communication leads to better results and fewer surprises. You should provide detailed documentation, including schematics, BOMs, and assembly drawings. LTPCBA offers 24-hour technical support, so you can ask questions and get feedback quickly. Regular updates help you track progress and spot issues early. When you communicate changes or concerns right away, you avoid delays and extra costs. Good communication supports optimization and keeps your project on schedule.

Send complete files and clear instructions.

Respond quickly to questions from your manufacturer.

Schedule regular check-ins to review progress.

Supply Chain Management

Strong supply chain management helps you avoid shortages and delays. LTPCBA uses real-time data to track parts and materials. You should work with their team to select reliable suppliers and plan for lead times. Bulk ordering and early sourcing help you lock in prices and improve optimization. This approach reduces risks and keeps your project moving. Design optimization also plays a role, as simpler designs use fewer unique parts and speed up procurement.

Note: Effective supply chain management and ongoing optimization protect your timeline and budget.

You can lower your PCBA costs by choosing standard components, optimizing board design, and planning production early. Work closely with your manufacturer to catch issues before they become expensive. Use bulk ordering and smart sourcing to save money. LTPCBA offers expert support, fast response, and high-quality results.

Remember: Early planning and strong partnerships help you achieve reliable, cost-effective PCBA manufacturing. Visit LTPCBA to start your next project with confidence.

FAQ

What is the most effective way to reduce PCBA costs?

You can optimize your board design and choose standard components. Early planning with your manufacturer helps you avoid expensive changes. Bulk ordering also lowers your cost per unit.

How does LTPCBA ensure quality while keeping costs low?

LTPCBA uses automated inspection systems and follows international standards. You get reliable products with fewer defects. Efficient processes and local sourcing help control expenses.

Can I order small batches for prototyping with LTPCBA?

Yes, you can order prototypes or small batches. LTPCBA supports flexible production volumes. You validate your design before scaling up to mass production.

What hidden costs should I watch for in PCBA manufacturing?

Watch for NRE charges, shipping fees, and tariffs. You should also consider testing and certification costs. Early communication with your manufacturer helps you avoid surprises.

See Also

Sourcing Electronic Parts Efficiently For PCBA Production

Ways Contract PCBA Manufacturing Improves Business Productivity

Essential Methods To Enhance PCBA Durability Over Time