Understanding Industrial Serial Screen PCBA in Modern Industries

Industrial serial screen PCBA is very important in industries. It helps devices talk to each other easily and quickly. It moves data in systems with accuracy and trust. These PCBs can handle tough conditions, like temperatures from -40°C to +125°C. They can also survive strong shakes up to 20G. This toughness makes them useful in rough workplaces. New designs make data move 30% faster, helping work get done better. Using special materials like polyimide lowers energy loss by 18%. This improves how well they work in high-frequency tasks.

Key Takeaways

Industrial serial screen PCBA helps devices talk to each other. This makes work faster by up to 30%.

These PCBs are built to handle harsh conditions, perfect for tough jobs.

Special materials like polyimide save energy and work better in fast tasks.

Screens on these PCBs show live data, helping workers decide quickly and wisely.

Working with good PCB makers ensures strong quality and on-time delivery, solving common problems.

What is Industrial Serial Screen PCBA?

Definition and Core Features

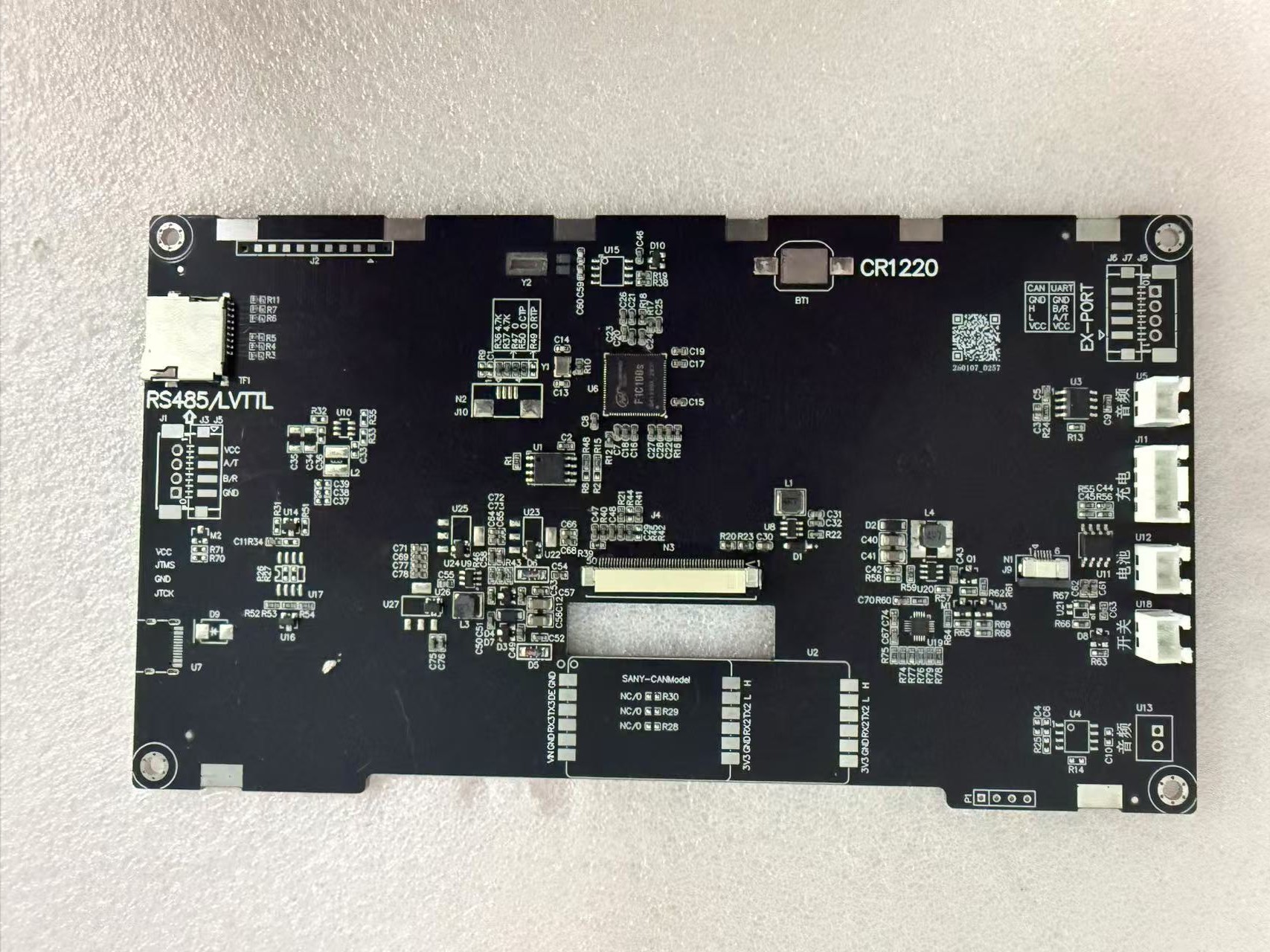

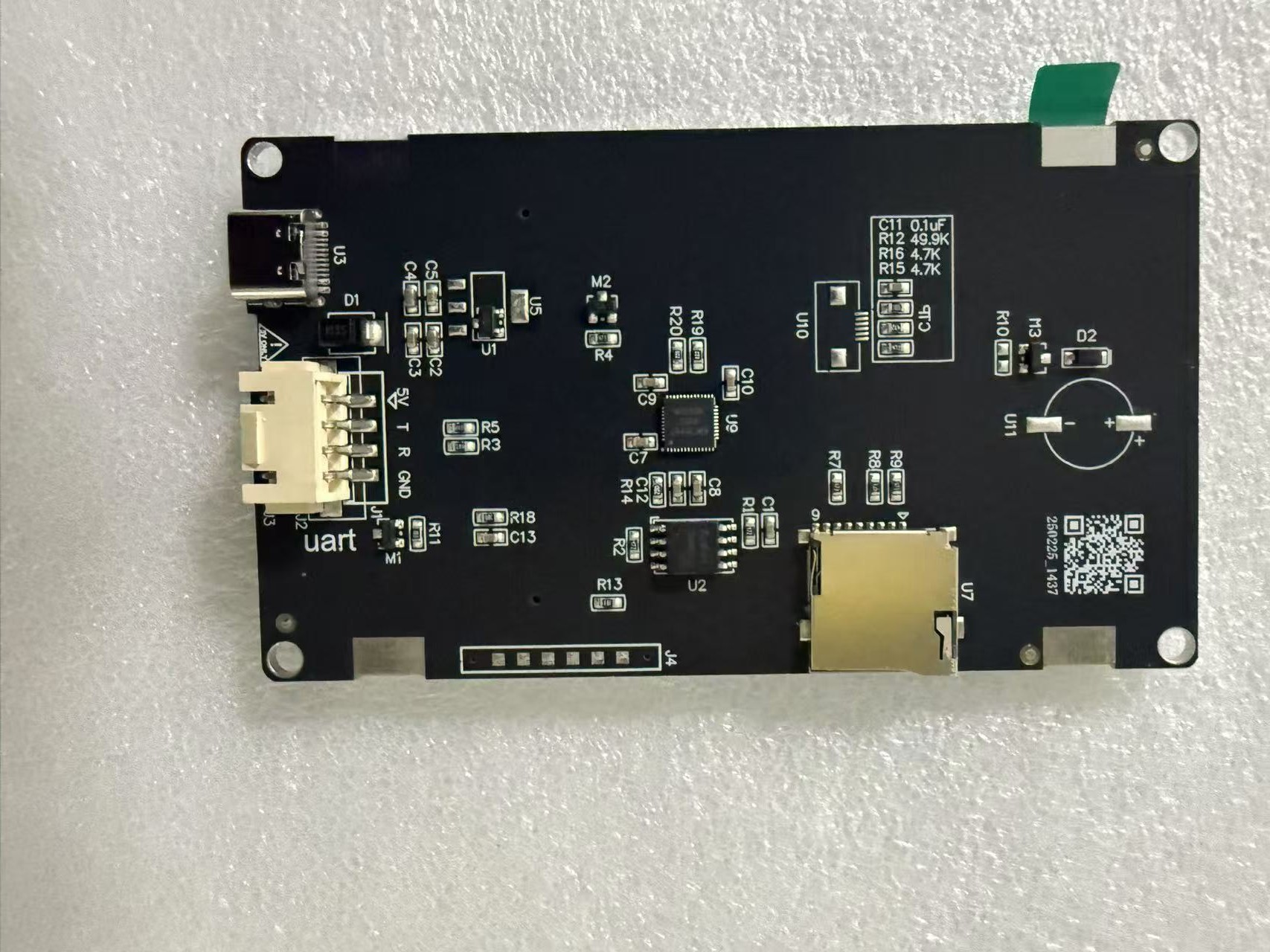

Industrial serial screen PCBA is a special type of printed circuit board assembly made for factories. It helps devices share information using serial communication methods. These boards are tough and work well in extreme heat, cold, or shaking.

Main features include better heat control, strong signals, and durable materials. For instance, aluminum-core boards lower heat by 25%, following IPC-2221A rules. They also meet ANSI C63.4 standards to keep signal noise under 30 dBµV/m, making communication more reliable.

Feature | Specification |

|---|---|

PCB Type | Multilayer Cu (2–3 oz) |

Tg (Glass Transition Temp.) | 170°C |

Solder Mask Thickness | 20% thicker than standard |

Thermal Conductivity (k) | Aluminum-core PCBs: 220 W/m·K |

Operating Temperature Gradient | IPC-2221A: max 15°C/mm |

Signal Integrity Standard | ANSI C63.4: < 30 dBµV/m at 3m |

Differential Pair Impedance | 100Ω ±10% |

Crosstalk Reduction | 40% with guard traces |

Key Components of Industrial Serial Screen PCBA

Industrial serial screen PCBA has important parts that make it work:

Microcontrollers and Processors: These are like the brain, controlling data and tasks.

Serial Communication Interfaces: Examples are RS-232, RS-485, and CAN bus, which help devices talk easily.

Screens or Displays: These show live data, making work faster and clearer.

Thermal Management Layers: Aluminum layers remove heat, keeping the board cool.

Protective Coatings: Special coatings protect the board from water, dirt, and chemicals.

Differences Between Industrial and Standard PCBA

Industrial PCBA is different from regular PCBA in many ways:

Durability: Industrial PCBA handles tough conditions; regular PCBA works in safer places.

Thermal Management: Industrial PCBA uses aluminum cores to cool better.

Signal Integrity: Industrial PCBA follows strict rules like ANSI C63.4 to avoid signal problems.

Material Science: Industrial PCBA uses strong materials for long-lasting performance.

Industrial serial screen PCBA is unique because of its heat control, strong signals, and tough materials. These qualities make it very useful in industries where reliability matters.

How Does Industrial Serial Screen PCBA Work?

Serial Communication in PCBA

Serial communication is how devices share data in PCBA. It sends one bit at a time through one channel. This makes communication steady and reliable in factories. Common protocols like RS-232, RS-485, and CAN bus are used. These protocols keep data safe even in noisy places.

High-frequency signals can weaken due to resistance and material loss. To fix this, PCBA uses special materials like polyimide. These materials lower signal loss and improve quality. Impedance mismatches, which cause signal issues, are reduced. This is done by keeping impedance at 100Ω ±10% as per strict rules.

Role of Screens in Industrial PCBA

Screens are important for showing live data in PCBA. They display key details like temperature, pressure, and flow. This helps workers make fast decisions and work better.

These screens are built to handle tough conditions. They work in temperatures from -40°C to +125°C and survive strong shakes up to 20G. This makes them reliable in hard jobs like car factories or heavy machines.

Integration with Industrial Control PCB Assembly

Industrial serial screen PCBA works well with control PCB assemblies. Together, they create systems that manage tasks with accuracy. For example, aluminum-core PCBs help remove heat, keeping systems cool.

This teamwork improves how parts talk to each other. By following rules like ANSI C63.4 for emissions and IPC-2221A for heat, systems stay strong. This makes them great for industries like cars, energy, and more.

Metric | Value/Standard |

|---|---|

Thermal Conductivity (Al) | k = 220 W/m·K |

Thermal Conductivity (FR-4) | k = 0.3 W/m·K |

IPC-2221A Temperature Grad. | ΔT max = 15°C/mm |

ANSI C63.4 Emission Limit | < 30 dBµV/m at 3m |

Differential Pair Impedance | 100Ω ±10% |

Crosstalk Reduction | 40% |

With strong communication, tough screens, and good integration, industrial serial screen PCBA works well in modern industries.

Applications of Industrial Serial Screen PCBA

Industrial serial screen PCBA is very important in many industries. It helps machines work better and more reliably. Below are some examples of where it is used.

Manufacturing and Automation

Industrial serial screen PCBA is key in factory systems. It helps machines talk to each other smoothly. This makes work faster and reduces delays. For example, in factories, these PCBs share data quickly. Machines can change tasks right away. This leads to faster production and better products.

These PCBs are tough and work in hard conditions. They handle heat, shaking, and electrical noise well. This makes them perfect for factory floors. Using advanced communication methods, they control and monitor machines precisely.

Automotive and Transportation

In cars, industrial serial screen PCBA runs important systems. These include engine controls, entertainment systems, and safety features like ADAS. The PCBs send data between sensors and controls, making cars safer and better.

Transportation also uses this technology. For example, in trains, PCBA helps signals and control centers connect. Its strong design keeps it working even in tough conditions like fast vibrations or temperature changes.

Sector | Impact |

|---|---|

Smaller, smarter devices for better user experiences. | |

Industrial Automation | More reliable and efficient factory processes. |

Medical Devices | Better PCBA tech leads to advanced medical tools. |

Healthcare and Medical Devices

In healthcare, industrial serial screen PCBA powers medical tools. It helps make machines like MRI scanners and ventilators work well. These PCBs send data accurately, which is very important for patients.

The reliability of these PCBs makes them great for life-saving tools. They work well in clean and controlled places. Screens on these PCBs show real-time data. This helps doctors make quick and better decisions for patients.

Industrial serial screen PCBA keeps improving industries by making them faster, safer, and more innovative.

IoT and Smart Devices

Industrial serial screen PCBA is important for IoT and smart devices. These PCBs help devices share data easily and quickly. They are used in smart homes, wearables, and industrial IoT systems. Their design handles high-frequency signals with little loss, making them great for advanced tech.

In IoT setups, these PCBs work well even in tough places. For example, smart factories use them to link sensors, machines, and controls. This connection allows live monitoring and automation, boosting efficiency. Serial communication protocols like RS-485 and CAN bus keep data steady between devices.

Screens on these PCBs make them easier to use. Think of a smart thermostat showing temperature or a fitness tracker showing health stats. These screens give instant updates, making IoT devices more helpful. Also, the strong build of industrial PCBA ensures they last long, even in hard conditions.

With industrial serial screen PCBA, IoT and smart devices become smarter, stronger, and easier to use.

Energy and Utilities

In energy systems, industrial serial screen PCBA plays a key role. These PCBs are used in grid monitors and control panels. They help sensors and controls share data, even in tough conditions. For example, they work well in extreme heat or strong vibrations.

They are also used in renewable energy like solar and wind power. These PCBs connect parts like inverters, sensors, and batteries. This connection helps monitor and improve energy production in real time. Advanced IoT tools, like those from Advantech, make systems even better by analyzing data.

Benefits of industrial serial screen PCBA in energy systems:

Works well in extreme conditions.

Shows live data for smarter decisions.

Improves efficiency with IoT features.

These PCBs are strong and efficient, making them vital for modern energy systems. They not only make systems reliable but also support green energy solutions.

Industrial serial screen PCBA helps energy systems stay strong, smart, and ready for the future.

Benefits and Challenges of Industrial Serial Screen PCBA

Advantages of Industrial PCBA in Modern Industries

Industrial serial screen PCBA has many benefits for industries today. These boards make work faster, improving efficiency by 30%. They help machines work better and more accurately, which is important for factory systems. Smaller designs save space and make devices easier to use.

Another big benefit is saving money. Better processes lower costs while keeping high-quality standards. These boards also help create new technologies like smart factories and IoT systems.

Performance Indicator | Description |

|---|---|

Increased Efficiency | Speeds up work by 30%, making production faster. |

Enhanced Precision | Improves how machines work and assemble parts. |

Miniaturization | Makes smaller devices that save space and work well. |

Cost Reduction | Cuts costs with better manufacturing methods. |

Innovation | Helps create advanced technology for industries. |

These features make industrial serial screen PCBA very useful for modern factories and production systems.

Challenges in Implementing Industrial Serial Screen PCBA

Even with its benefits, using industrial serial screen PCBA can be hard. Sometimes, parts are not available, causing delays in production. Special materials can take a long time to arrive, slowing things down. Keeping quality the same for large projects can also be tricky.

Benefits | Challenges |

|---|---|

Increased Efficiency | Parts may not be available on time. |

Enhanced Precision | Special materials can take longer to get. |

Miniaturization | Hard to keep quality the same for all. |

Cost Reduction | |

Innovation |

To solve these problems, good planning and working with trusted PCB makers are needed. This helps make sure everything works smoothly in factories.

Future Trends in Industrial PCBA

The future of industrial serial screen PCBA looks exciting. Robots and automation will make production faster and cheaper. Better precision will reduce mistakes, making products higher quality. Smaller designs will allow for tiny, efficient devices.

Advancement Type | Description |

|---|---|

Automation and Robotics | Makes production faster and lowers labor costs. |

Enhanced Precision | Reduces mistakes and improves product quality. |

Miniaturization | Creates smaller devices that save space and energy. |

Cost Reduction | Cuts costs with better materials and processes. |

Innovation | Leads to new and better electronic products. |

These changes will also help IoT grow, allowing devices to share live data. As technology improves, factories will become smarter and more efficient.

Industrial serial screen PCBA has changed industries by making communication easier. It boosts efficiency and helps advanced technologies grow. It is used in factories, healthcare, IoT, and energy systems. These boards bring new ideas by being smaller, better, and cheaper. As PCBA improves, it creates powerful devices and exciting progress.

Using expert PCBA solutions can open new doors for industries. Stay ahead in the fast-moving world of technology.

FAQ

How are industrial PCBs different from regular ones?

Industrial PCBs work in tough places with heat and vibrations. They use strong materials to stay reliable. Regular PCBs are for easier tasks and safer conditions.

Why do industrial PCBs need screens?

Screens show live data like temperature or system updates. This helps workers make quick choices and finish tasks faster.

How do PCBs help IoT devices?

PCBs let IoT devices share data smoothly using special protocols. They work well in hard conditions and are great for smart homes or factories.

Can industrial PCBs save energy?

Yes, they use special materials to lower energy loss. This makes them better for tasks needing high power and speed.

Which industries use industrial PCBs the most?

Factories, hospitals, car makers, and energy companies use them a lot. These PCBs make work faster, safer, and more accurate.