Industrial Equipment PCBA Success Stories That Inspire

You see the impact of a reliable industrial equipment pcba company in your daily work. PCBA drives innovation in medical devices, industrial controls, and automotive solutions. When you trust an industrial equipment pcba company like LTPCBA, you unlock unmatched quality and performance. Every pcb we deliver supports your goals. Choose a pcb partner that inspires progress.

Key Takeaways

Choose LTPCBA for unmatched quality and performance in industrial equipment PCBA. Their advanced technology ensures your projects succeed.

Experience the benefits of aluminum PCBs, including superior thermal conductivity and lower operating temperatures, which enhance reliability and efficiency.

Trust LTPCBA's commitment to quality assurance. Their rigorous testing processes and high pass rates guarantee reliable and durable PCB assemblies.

LTPCBA Industrial Equipment PCBA Applications

Real-World Applications

You want your industrial equipment to deliver outstanding performance and reliability. LTPCBA helps you achieve these goals with advanced pcb assembly and manufacturing services. You see the growing role of aluminum pcbs in solving thermal challenges. These aluminum pcb application examples show how you can overcome heat issues in high-power applications.

Unmatched thermal conductivity sets aluminum pcbs apart. You benefit from a thermal conductivity of around 200W/m·K, which is much higher than standard FR4 boards. This means your equipment can dissipate heat efficiently.

You experience dramatically lower operating temperatures. Testing proves that junction temperatures drop by 20°C to 30°C compared to FR4, boosting reliability and durability.

Higher power handling capacity lets you use high-brightness LEDs that exceed 10W per LED, all while staying within safe thermal limits.

Minimized thermal resistance maximizes cooling performance, so your equipment runs smoothly.

Low weight and durability make aluminum pcbs ideal for industrial environments that demand strength and resistance to vibrations.

You see these aluminum pcb benefits in real-world applications every day. LTPCBA’s expertise in aluminum pcb application examples gives you the confidence to tackle heat management challenges. You rely on these thermal management solutions to keep your equipment running at peak efficiency.

High Tg pcb technology is another game-changer for industrial applications. You face constant heat, vibrations, and chemical exposure in your work. High Tg pcbs offer superior thermal stability, moisture resistance, and chemical resilience. You trust high Tg pcb to endure high temperatures and mechanical stress, ensuring continuous operation and reliability. An industrial equipment manufacturer in Japan improved reliability and durability by switching to high Tg pcbs for motor drives. The new pcbs increased power density, improved efficiency, and reduced equipment size and weight.

You also benefit from flexible pcbs in your industrial equipment design. Flexible pcbs reduce the size and weight of electronic assemblies, allowing you to create compact and efficient systems. You improve reliability by minimizing interconnections, which are common points of failure. Flexible pcbs withstand harsh conditions, including vibrations and temperature extremes, ensuring durability and performance. You achieve controlled impedance designs, which minimize signal loss and maintain high-speed performance. Flexible pcbs absorb mechanical stress and maintain signal speeds up to 10 Gbps, making them perfect for high-frequency applications. You simplify your designs and reduce labor costs by up to 20%, streamlining your production process.

LTPCBA’s advanced technology and automated systems set you up for success. You benefit from a 99.5% pass rate in product delivery, which means you receive reliable and high-quality pcb assemblies every time.

LTPCBA’s strengths include:

Advanced technology for pcb assembly

Automated systems for efficiency and accuracy

ISO, IATF, and UL certifications for quality assurance

High pass rate for reliability and durability

You see how LTPCBA’s real-world applications solve your toughest challenges. You trust LTPCBA to deliver pcb solutions that meet your needs for performance, reliability, and efficiency.

Quality Assurance and Innovation

You want your industrial equipment to perform flawlessly. LTPCBA’s commitment to quality assurance and innovation ensures you get the best results. You rely on strict process control metrics to guarantee reliability and durability.

Process Control Metric | Description | Role in Manufacturing Reliability |

|---|---|---|

First Pass Yield | Target of 95% | Reduces rework and accelerates delivery |

Pick-and-Place Accuracy | 99.95% | Ensures precise component placement, minimizing defects |

AOI and ICT | Applied at every production step | Enables early detection of defects, preventing downstream failures |

Final Testing | Comprehensive before shipment | Confirms product reliability and performance |

You benefit from automated optical inspection (AOI), X-ray inspection, in-circuit testing (ICT), functional testing, and environmental testing such as thermal cycling and vibration tests. These quality assurance processes ensure your pcb assemblies meet the highest standards for reliability and durability.

LTPCBA’s commitment to international standards like ISO, IATF, and UL gives you peace of mind. You know your products meet strict quality benchmarks, which enhances reliability and reduces defects.

Innovation drives LTPCBA’s success. You see the impact of advanced manufacturing, quality standards, and design for manufacturability in every pcb application. LTPCBA’s customer support stands out, offering 24-hour technical support and quick response times. You receive quotes within 2-3 working days, helping you plan and manage your projects efficiently.

Aspect | Impact on Customer Satisfaction |

|---|---|

Advanced Manufacturing | Ensures high product quality and fewer defects |

Quality Standards | Improves reliability and product life |

Design for Manufacturability | Reduces defects and enhances reliability |

Customer Support | Provides 24-hour support and quick response times |

Satisfaction Scores | Often exceed 80%, indicating strong service commitment |

You experience the benefits of LTPCBA’s innovation and quality assurance in every project. You achieve cost-effectiveness, reliability, and outstanding performance in your industrial equipment applications. LTPCBA’s quick response and customer support help you overcome challenges and reach your goals.

You see how LTPCBA’s strengths in technology, automation, and quality assurance drive efficiency and reliability. You trust LTPCBA to deliver pcb solutions that inspire progress and set new standards in industrial equipment applications.

Customer Success Stories

Manufacturing Automation

You want your manufacturing line to run smoothly and deliver top-quality products. Many companies face tough challenges when building reliable automation systems. You may struggle with component shortages, design errors, or soldering defects. These problems can slow down your projects and hurt your results.

Here is a table showing the most common challenges and how you can solve them:

Challenge | Description | Solution |

|---|---|---|

Component Availability | Shortages in chips and capacitors | Work with trusted suppliers and diversify sources |

Design Errors | Poor pcb design causing delays and defects | Collaborate with manufacturing teams and use simulation tools |

Soldering Defects | Cold solder joints and bridges affecting reliability | Use automated soldering and quality materials |

Thermal Management | Heat causing performance issues | Use thermal simulation and smart component placement |

Miniaturization | High component density leading to defects | Use advanced design tools and precision equipment |

Testing and Quality Control | Inadequate testing missing defects | Use in-circuit testing and automated test equipment |

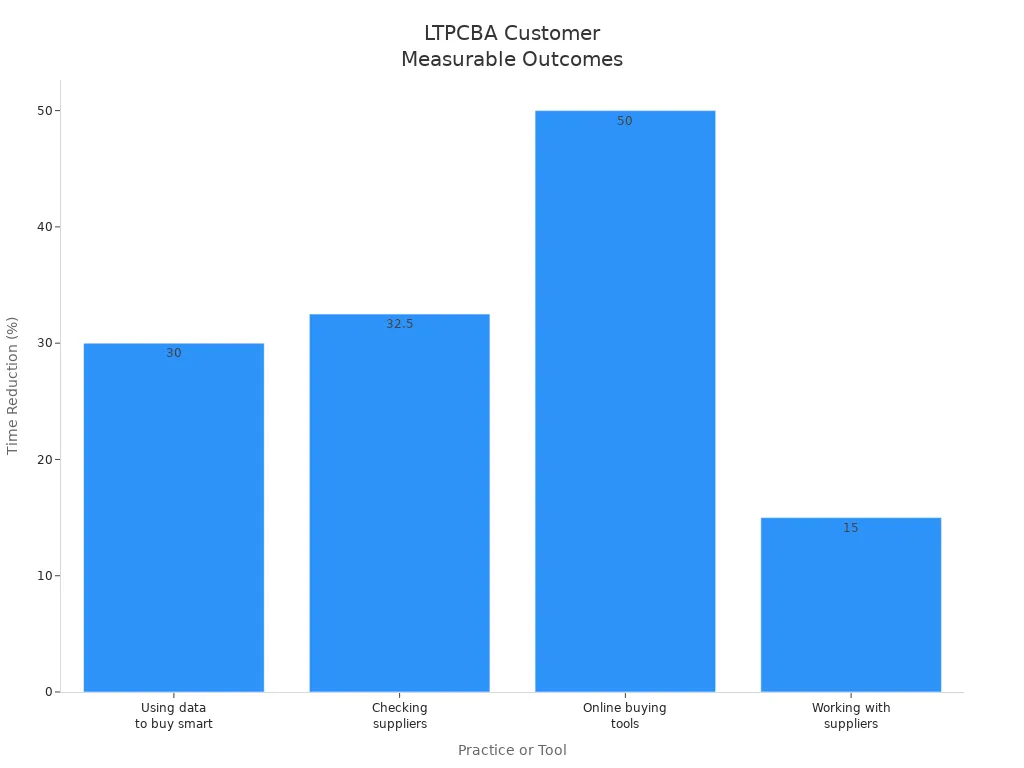

You can see how LTPCBA helps you overcome these obstacles in your successful pcb projects. One study shows that by using smart online buying tools, you can cut buying time by 50%. Another company saved 15% on parts and reduced wait times by up to 40% by checking suppliers and working closely with them. This means you can focus on more important work and finish your projects faster.

You want your automation systems to be reliable. LTPCBA uses advanced AOI systems and X-ray testing to catch placement errors and hidden defects early. AOI uses high-precision cameras and lighting to inspect every pcb. This process finds faults before they become bigger problems. You benefit from high-quality images and fast data processing, which keeps your manufacturing line efficient.

You also gain from LTPCBA’s expertise in handling and storage. They control temperature, humidity, and stress to protect flexible layers. They choose the best materials, like polyimide and rolled-annealed copper, for durability and flexibility. LTPCBA fine-tunes thermal profiles and runs thermal cycling tests to reduce heat stress and solder joint failures. These steps help you achieve high reliability in your automation applications.

You can learn from these pcb design success stories. One manufacturer improved reliability by switching to rigid-flex pcb assemblies. They saw fewer defects and faster assembly times. Another study showed that using AOI and in-circuit testing led to a 99.5% pass rate, which is higher than most industry benchmarks.

Tip: When you use advanced inspection and testing, you boost your project’s reliability and reduce costly rework.

Automotive and Energy Solutions

You know that automotive and energy projects demand the highest standards. Your pcb assemblies must survive harsh environments, extreme temperatures, and constant vibrations. You also need compact designs and strong protection against electromagnetic interference.

LTPCBA helps you meet these challenges. Here are some key issues you may face in automotive pcb applications:

Harsh operating environments with heat, humidity, and vibration

Miniaturization of components, which increases complexity

High reliability standards for safety and performance

Electromagnetic interference from multiple systems

Complex supply chains and cost constraints

You can trust LTPCBA to deliver solutions that work. They use design reviews to make sure your pcb meets reliability standards before production. Material tracking ensures every part meets strict quality rules. Rigorous testing, including AOI, X-ray, and in-circuit tests, catches defects early. Environmental stress testing simulates real-world conditions, so your pcb can handle anything.

Here is a table showing how LTPCBA’s process improves your projects:

Aspect | Description |

|---|---|

Design Reviews | Checks design for reliability before production |

Material Tracking | Ensures all materials meet quality standards |

Rigorous Testing | Validates reliability with multiple tests |

DFM Reviews | Optimizes assembly for fewer defects |

Automated Inspection | Uses AOI/X-ray to catch defects early |

Electrical Testing | Confirms function with in-circuit tests |

Environmental Stress Testing | Simulates real-world conditions like heat and vibration |

Adherence to Standards | Meets IPC-A-610, ISO, UL, and RoHS for quality and safety |

You can see the benefits in real customer success stories. One automotive company improved reliability and reduced defects by 30% after switching to LTPCBA’s solutions. Another energy sector project achieved a 99.5% pass rate and met all international standards. These pcb design success stories show how you can reach your goals with the right partner.

LTPCBA’s commitment to quality stands out. You get 24/7 customer support, fast response times, and a team that cares about your success. Their pass rate of 99.5% beats most industry benchmarks. You can trust them to deliver reliable pcb assemblies for your most demanding projects.

Here is a quick comparison:

Metric | Industry Benchmark | |

|---|---|---|

Pass Rate | 99.5% | Varies (typically lower) |

Certifications | ISO, IATF, UL | Varies (not all companies have) |

Customer Support | 24/7 | Varies (often limited) |

You can draw inspiration from these pcb design success stories. Every project shows that with the right approach, you can overcome challenges and achieve outstanding results. Your next successful pcb project could be the next story that inspires others.

You see how LTPCBA’s pcb expertise and quality assurance drive success in industrial equipment applications.

Capability | Impact |

|---|---|

AOI | |

X-ray | Ensures component integrity |

Functional Testing | Prevents faulty boards |

Choose a partner with strong engineering support and responsive service.

Let LTPCBA inspire your next project.

FAQ

What makes LTPCBA a trusted partner for industrial equipment PCBA?

You get reliable results every time. LTPCBA uses advanced technology, strict quality checks, and fast support. You see your projects succeed with their expertise.

Tip: Choose a partner who values your success and delivers on promises.

How does LTPCBA ensure PCBA reliability in high-temperature applications?

You benefit from special materials and smart designs. LTPCBA tests every board for heat resistance. Your equipment performs well, even in tough conditions.

Feature | Benefit |

|---|---|

Heat-resistant | Lasts longer |

Smart design | Handles tough tasks |

Can LTPCBA help you with urgent PCBA projects?

You receive quick quotes and 24-hour support. LTPCBA responds fast, so you meet your deadlines and keep your business moving forward.

See Also

Exploring The Role Of Serial Screen PCBA In Industry

Ensuring Quality Production Through Advanced Turnkey PCBA Solutions

Choosing The Best Turnkey PCBA Manufacturer For Your Project

Improving PCB Manufacturing Efficiency With EMS Companies

Boosting Business Efficiency Through PCBA Contract Manufacturing