How to Perform Effective Incoming Material Inspection for SMC and SMD Components

You can perform a thorough incoming material inspection for SMC and SMD by preparing the necessary documents, visually inspecting parts and using machines, verifying that they meet the correct specifications, testing their functionality, and recording your findings. This inspection of surface-mounted components ensures high-quality SMT. LTPCBA’s advanced inspection tools for electronic parts help reduce errors, increase first-pass yield, and enhance overall SMT quality.

Key Takeaways

Get all needed papers ready before you start checking. This helps you look at the right parts. It also helps you keep good records for quality control.

Use your eyes, AOI machines, X-ray, and ultrasonic tests. These help you find hidden problems early. This makes your SMT assembly better.

Write down every inspection step with digital systems. This helps you track batches easily. It helps you make better choices. It keeps your production steady and fast.

Incoming Material Inspection Steps

Preparation and Documentation

You begin by getting all the right papers ready. You need purchase orders, datasheets, and certificates for each batch. This helps you know what you are checking before you start. You make sure the supplier’s papers match what you need for printed circuit boards and surface mount components. LTPCBA uses a digital system to track every batch from when it arrives until it is put together. This system helps you follow each batch and keep high standards in pcb assembly. Good preparation and keeping records help you control quality and check parts well.

Visual and AOI Checks

After that, you look at the parts and use AOI machines. You check for things like scratches, cracks, or dirt on SMC and SMD parts. AOI uses cameras and special software to find problems like wrong polarity, missing leads, or parts that are not straight. LTPCBA uses smart AOI machines to check every part and solder joint. This makes checking more correct and lowers mistakes from people.

Tip: AOI can find problems that are hard to see with your eyes, so your pcb assembly is better.

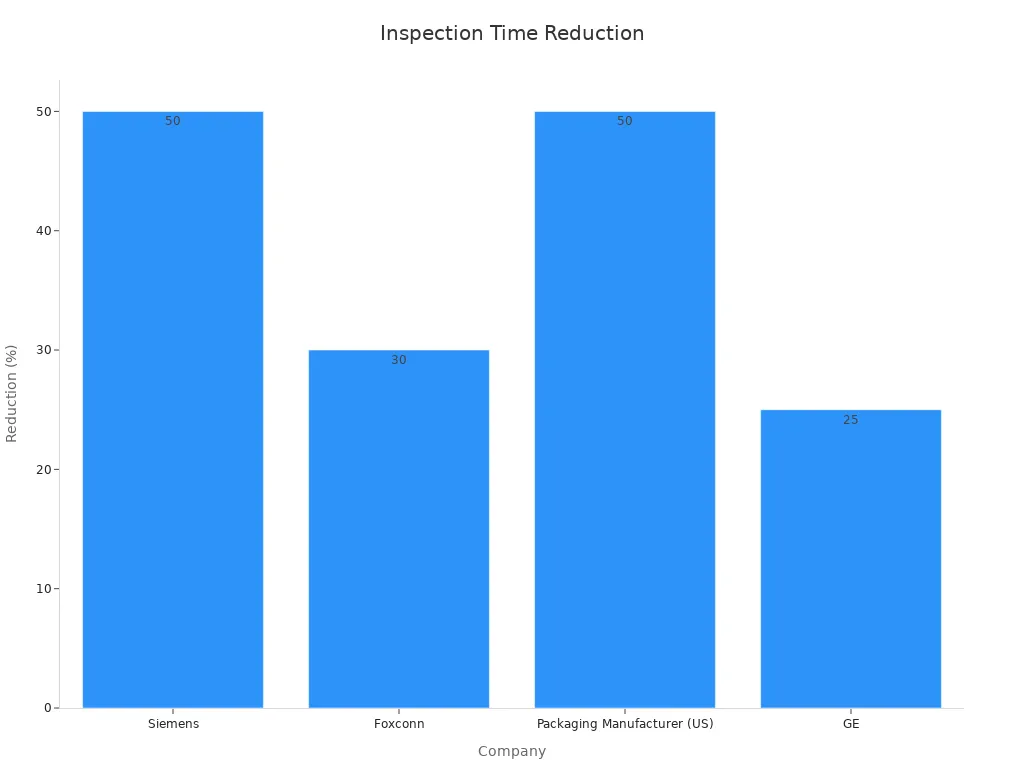

Visual and AOI checks help a lot. Companies like Siemens and Foxconn have found up to 80% more problems and spend less time checking. The table below shows how AOI helps different companies:

Industry / Company | Measurable Improvement Description |

|---|---|

Siemens | 30% more correct checks; 50% less time spent checking |

Foxconn | 80% more problems found; 30% less time spent checking |

Japanese Automotive Parts Manufacturer | 95% of problems found; 30% less money spent on workers |

Packaging Manufacturer (US) | 50% less time checking; 10% less money spent on workers |

Semiconductor Manufacturer (Taiwan) | 10% less waste; 50% more parts checked in same time |

GE | 25% less time checking; 30% less money spent making things |

You can see that using machines to check saves time and money. LTPCBA’s AOI systems help you get good assembly and strong smt production.

X-ray and Ultrasonic Testing

You use X-ray and ultrasonic tests to look inside SMC and SMD parts. X-ray lets you see inside parts and solder joints. It shows problems like empty spaces, bridges, or parts that are not lined up. Ultrasonic testing helps you find cracks or layers that are coming apart inside parts. LTPCBA’s X-ray and ultrasonic machines follow rules like ISO, IATF, and UL. These tests help you find problems early, so your pcb assembly works well and does not fail in smt processes. You trust these tests to check parts before putting them together.

Solderability and Coplanarity

You need to check solderability and coplanarity for good smt assembly. Solderability tests show if leads and pads take solder well, which is needed for strong joints. Coplanarity tests check if all leads are flat on the pcb, so there are no open circuits or weak spots. LTPCBA uses special tools to check solderability and coplanarity for each batch. These tests help make strong solder joints and lower the chance of problems during reflow. You do these checks on solder paste and parts to keep assembly good and reliable.

Note: Good solder joints and flat leads are needed for long-lasting smt production and working tests.

By doing all these steps, you make sure every batch meets tough quality rules. LTPCBA’s focus on quality, smart checking systems, and care for customers set a high standard for incoming material inspection in the pcb assembly world.

Incoming Inspection Reporting

Data Recording and Traceability

You need to keep good records to make sure your incoming goods inspection works well. LTPCBA uses smart systems to write down every step, like visual checks and testing. These systems help you remember what happened at each step. The table below shows how each data metric helps you track and record inspections:

Data Metric / System | Purpose | Contribution to Traceability and Inspection Documentation |

|---|---|---|

Real-time Thermal Management | Watches oven and process settings | Finds problems fast, keeps quality steady, and helps with tracking |

Automated Thermal Profiling | Finds the best heat settings | Lowers mistakes and makes records more correct |

Live Data Output for SPC | Gives real-time data for control | Lets you watch quality and track changes as they happen |

Automated Process Documentation for ISO | Makes records by itself | Helps you follow rules, track steps, and get ready for checks |

Production Documentation Linked to Batches | Saves heat data for each batch | Helps you find problems and check if suppliers did things right |

Automated Optical Inspection (AOI) | Finds defects right away | Writes down results, tracks problems, and helps with quality |

Cp and Cpk Indices | Checks how machines are working | Makes sure soldering is good and helps with tracking |

Root Cause Analysis Tools | Looks for why problems happen | Makes records better and helps fix the process |

You can follow each batch from start to finish in incoming goods inspection, smt, and pcb assembly. This system lets you find where a problem started and show your process is strong.

Decision Making and Next Steps

When you finish checking and testing, you need to choose what to do with each batch. LTPCBA has a clear way to deal with parts that do not meet the rules. Only good parts go on to pcb assembly and smt. Here are the steps you follow:

Find problems during incoming goods inspection and testing.

Write down each problem with proof.

Start actions to fix and stop problems, like finding out why they happened.

Talk with your quality team and suppliers.

You also use numbers like the Non-Conformance Rate (NCR) to see how well your inspection works. A lower NCR means better quality and fewer issues in smt and pcb assembly. You also check suppliers, listen to customers, and inspect at every step to keep things working well.

Tip: Good incoming goods inspection and testing help you find problems early, make your process stronger, and keep your customers happy.

You get good results when you follow each inspection step for SMC and SMD components. Use smart tools, write down what you do, and always care about quality. LTPCBA has a high standard for SMT assembly.

Quick Checklist:

Get all papers ready

Check parts by looking and with AOI

Try X-ray and ultrasonic tests

Test solderability and coplanarity

Write down and check your results

FAQ

What is the main goal of incoming material inspection?

You check parts to make sure they meet your quality standards. This step helps you avoid defects and keep your SMT assembly strong.

How does LTPCBA ensure traceability during inspection?

LTPCBA tracks every batch with digital records. You can follow each part from arrival to assembly, which helps you find and fix problems fast.

Why should you use AOI and X-ray for SMC and SMD inspection?

AOI and X-ray help you find hidden defects. These tools give you better accuracy than manual checks and improve your assembly quality.

See Also

Importance Of SPI Inspection Following SMT Solder Paste Printing

Top SMT Assembly Techniques To Achieve Quality Electronics

X-Ray Inspection Methods Improving PCBA Manufacturing Quality

Challenges Faced During SMT Assembly Conformal Coating Process

Typical SMT Circuit Board Defects And Effective Prevention Tips