How to Implement Effective PCBA Quality Control in Manufacturing

You achieve effective pcba quality control through a systematic approach that combines process standardization, targeted inspections, and advanced testing. This strategy enhances pcba quality control by reducing defect rates and boosting product reliability, predicting and preventing errors before they disrupt production. Leading manufacturers like LTPCBA set the standard for pcba quality control by embracing innovation and strict quality standards in every pcba project. When you follow best practices in pcba quality control, you help create a process that supports zero-defect goals and delivers consistent, high-quality results.

Key Takeaways

Set clear quality standards and follow strict procedures to reduce defects and improve product reliability.

Control key manufacturing stages like solder paste printing, component placement, and welding to prevent errors early.

Use advanced inspection methods such as Automated Optical Inspection, X-ray, and functional testing to catch defects quickly.

Invest in ongoing staff training to ensure everyone understands quality processes and can spot issues promptly.

Analyze inspection data and customer feedback to find root causes of problems and continuously improve your PCBA process.

PCBA Quality Control Basics

Quality Standards and Procedures

You set the foundation for effective pcba quality control by establishing clear standards and procedures. LTPCBA follows international certifications such as ISO, IATF, and UL. These standards guide every step in the manufacturing process and ensure that each pcba meets strict quality requirements. When you use these standards, you reduce the risk of defects and improve product reliability. Consistent documentation and process guidelines help your team maintain high quality control across all projects.

Control Points and Process Setup

You need to identify and manage critical control points throughout the manufacturing process. Each stage presents unique challenges that can affect final product quality. The table below outlines key control points and best practices used in leading Shenzhen factories:

Process Stage | Challenges | Key Control Points | Shenzhen Factory Best Practices |

|---|---|---|---|

Solder Paste Printing | Variations in stencil precision, paste viscosity, squeegee pressure, PCB flatness affecting solder volume and defects | Stencil design, paste storage/temperature/mixing, printing parameters, real-time SPI monitoring | Use of laser-cut high-precision stencils, 100% automated SPI inspection, MES for real-time monitoring |

Component Placement | Miniaturization, high density, odd shapes, placement accuracy, misalignment, reversed polarity | High-precision placement machines, feeders, vision systems, program optimization | Investment in ultra-high-speed placers with 3D vision, experienced engineers optimizing placement programs |

Reflow Soldering | Temperature profile control critical to avoid cold joints, tombstoning, thermal damage, warpage | Precise temperature profiling, oven uniformity, nitrogen atmosphere | Rigorous profile validation, nitrogen-inerted ovens, profile data logging linked to MES |

Wave stability, temperature, contact time affecting joint quality, solder bridges, balls | Wave height/stability, solder pot temperature, conveyor speed/angle, flux application | Parameter optimization, selective soldering to reduce thermal shock, enhanced post-wave AOI | |

Cleaning | Removal of flux and ionic residues critical to prevent corrosion and migration | Cleaning agent selection, process optimization, contamination testing | Adoption of eco-friendly aqueous or no-clean processes, ionic contamination testers for high-reliability boards |

Inspection & Testing | Detecting solder, component, assembly defects efficiently and thoroughly | Multi-level inspection: AOI, X-Ray, ICT, FCT | Robust testing regimes integrating AOI, X-Ray, ICT, FCT, strong test program development |

Overarching Controls | ESD damage, material management, documentation, continuous improvement | Strict ESD control, component traceability, digital MES documentation, data-driven process optimization | Shenzhen factories excel in ESD systems, supply chain robustness, MES-enabled documentation, and lean manufacturing |

By focusing on these control points, you can prevent errors before they impact the final product. LTPCBA uses advanced process setup and real-time monitoring to maintain high standards in pcba quality control.

Staff Training and Compliance

You must invest in staff training to ensure everyone understands quality control procedures. Well-trained employees can spot issues early and follow best practices at each manufacturing stage. LTPCBA provides ongoing training and clear compliance guidelines. This approach helps your team stay updated on the latest inspection methods and process improvements. Quick response and strong customer support from LTPCBA further reinforce a culture of quality and reliability.

Key PCBA Manufacturing Stages

Solder Paste Printing

You start pcba production by focusing on solder paste printing, which sets the foundation for quality. You must control stencil design, paste viscosity, and printing parameters to achieve consistent solder deposits. LTPCBA uses automated solder paste inspection (SPI) systems to monitor every print in real time. You maintain cleanliness by storing paste at the correct temperature and mixing it thoroughly before use. You verify materials before printing to prevent defects and ensure stable pcba production. These steps help you avoid solder bridging, insufficient deposits, and other common issues in manufacturing.

Welding and Assembly

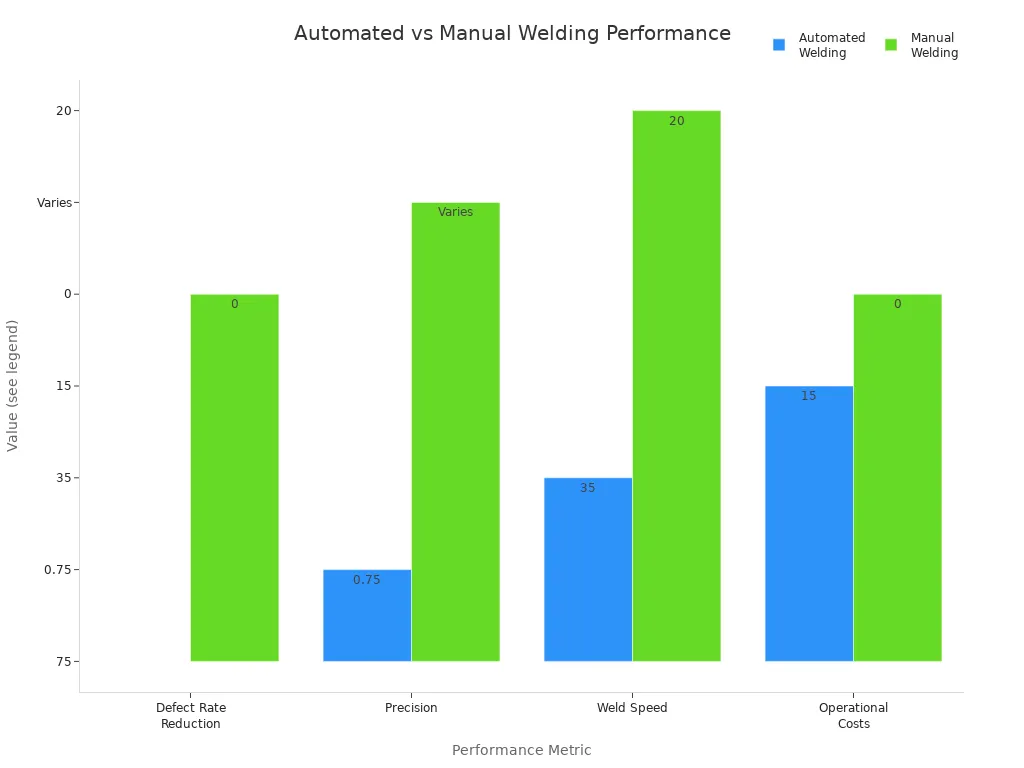

You move to welding and assembly, where control over process parameters is essential for quality outcomes. LTPCBA leverages automated welding systems that outperform manual welding in defect reduction and consistency. The table below compares automated and manual welding in manufacturing:

Performance Metric | Automated (Robotic) Welding | Manual Welding |

|---|---|---|

Defect Rate Reduction | Up to 75% reduction in defect rates; around 15% reduction on average | Higher defect rates due to human error and fatigue |

Precision | High precision (up to 0.75 mm) | Variable precision depending on skill |

Weld Speed | ~35 welds per minute | ~18-20 welds per minute |

Quality Consistency | High repeatability, real-time sensor feedback | Quality varies with operator skill and fatigue |

Quality Control | Automated defect detection in real time | Manual inspection dependent on operator |

Operational Costs | 10-15% reduction in waste and rework | Higher costs due to rework and waste |

Safety | Reduced human exposure to hazards | Higher risk of exposure to heat and fumes |

You benefit from advanced sensors and adaptive control, which maintain optimal weld quality and reduce variability in pcba production. Automated inspection systems detect surface imperfections and dimensional errors, enabling immediate corrections. You ensure a clean environment and verify materials before welding to support high-quality outcomes.

Component Placement

You reach the component placement stage, which is critical for pcba reliability. LTPCBA uses high-speed placement machines with 3D vision systems to achieve precise alignment and minimize errors. You control feeder setup and placement programs to optimize accuracy. You verify materials and components before assembly, which impacts solder joint integrity and overall pcba quality.

Strict supplier qualification and material verification ensure stable and consistent pcba production.

Proper material selection influences solder joint strength and failure rates.

Advanced testing during assembly helps you detect and eliminate defects early.

Verifying materials before placement prevents defects and improves reliability.

You maintain cleanliness throughout the process, which supports stable manufacturing and reduces contamination risks. By controlling key processes at each stage, you enhance pcba quality and deliver reliable products.

Inspection and Testing for Quality

You strengthen pcba quality control by implementing a robust inspection and testing strategy at every stage of manufacturing. You rely on advanced equipment and skilled technicians to identify defects early and ensure consistent quality. LTPCBA sets the standard in the industry by combining automated systems with manual expertise, giving you confidence in every product that leaves the factory.

Automated Optical Inspection (AOI)

You use Automated Optical Inspection (AOI) to check for defects after component placement and soldering. AOI systems scan each board with high-resolution cameras and compare the images to reference standards. You detect issues such as missing components, misalignment, solder bridges, and polarity errors. AOI provides rapid feedback, allowing you to correct problems before they affect the entire batch. LTPCBA integrates AOI into its manufacturing lines, ensuring every board meets strict quality requirements.

Tip: AOI reduces human error and speeds up the inspection process. You can inspect thousands of solder joints in seconds, improving throughput and reliability.

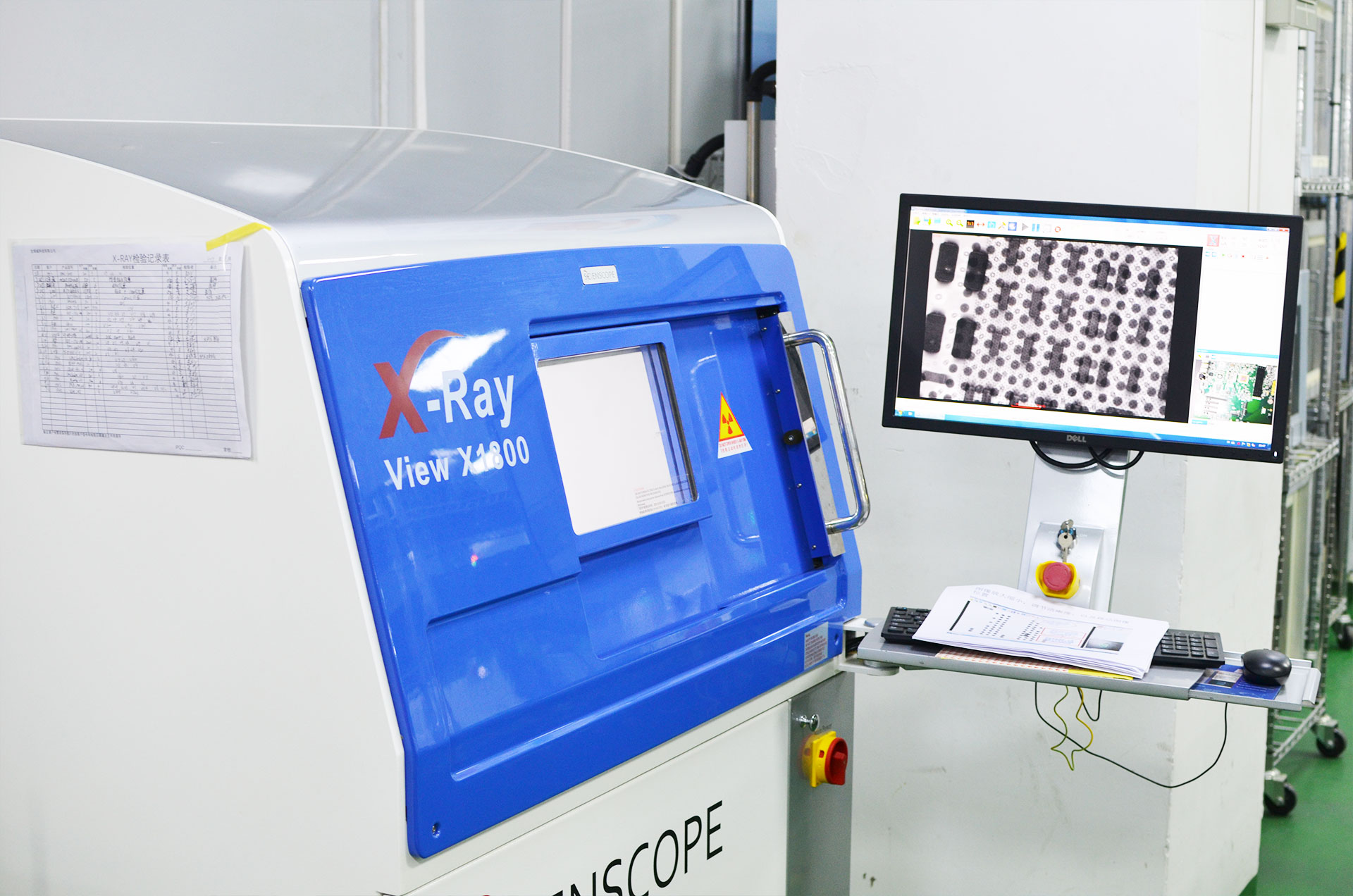

X-ray and Functional Testing

You apply X-ray inspection to uncover hidden defects that visual inspection cannot detect. X-ray systems reveal solder joint integrity beneath components like BGAs and QFNs. You identify voids, cold joints, and bridging that could cause failures in the field. LTPCBA uses advanced X-ray equipment to guarantee the highest standards in manufacturing.

Functional testing checks whether the assembled board performs as intended. You simulate real-world operating conditions and verify that each circuit responds correctly. You also use in-circuit testing (ICT) to measure electrical parameters and confirm proper connections. Burn-in testing exposes boards to elevated temperatures and voltages, helping you catch early-life failures. These methods ensure that only reliable products reach your customers.

Testing Method | Purpose | What You Detect | LTPCBA Practice |

|---|---|---|---|

X-ray Inspection | Reveal hidden solder defects | Voids, cold joints, bridging | Advanced X-ray for BGA/QFN |

Functional Testing | Verify board operation | Performance issues | Simulated real-world conditions |

In-Circuit Testing | Measure electrical parameters | Shorts, opens, wrong values | Automated ICT stations |

Burn-in Testing | Stress boards to catch early failures | Latent defects | Controlled burn-in environments |

Manual Visual Inspection

You complement automated systems with manual visual inspection. Skilled technicians examine boards for cosmetic flaws, solder quality, and component orientation. You catch subtle issues that machines might miss, such as discoloration or minor scratches. Visual inspection remains essential for prototypes and complex assemblies where automated systems may not cover every detail.

You document findings from every inspection and testing step. You use this data to improve manufacturing processes and prevent recurring issues. LTPCBA analyzes inspection results to drive continuous improvement, maintaining a 99.5% pass rate and high customer satisfaction.

Note: You should combine automated and manual inspection for the most effective quality inspection strategy. Data from inspections helps you refine processes and achieve zero-defect goals.

You build a reliable manufacturing process by integrating AOI, X-ray, functional testing, and visual inspection. You ensure that every board meets your quality standards and delivers dependable performance in the field.

Continuous Improvement with LTPCBA

Data Analysis and Feedback

You drive ongoing improvement in pcba production by analyzing data from every inspection and test. Statistical Process Control (SPC) helps you monitor manufacturing trends and spot variations that may signal defects. You use real-time data to adjust processes and maintain high standards. Root Cause Analysis tools, such as Fishbone Diagrams and the 5 Whys Technique, allow you to pinpoint the underlying causes of defects. This approach ensures that you address problems at their source, not just the symptoms.

SPC tracks defect rates and process stability.

Fishbone Diagrams visualize possible causes of issues.

The 5 Whys Technique guides you to the root of each problem.

Customer feedback plays a vital role in your quality management system. You collect input on product quality and satisfaction, then use this information to identify non-conformities. Feedback triggers root cause analysis and corrective actions, helping you reduce defects and improve consistency. By listening to your customers, you strengthen your process and deliver better results.

Root Cause and Corrective Actions

You respond to quality challenges by investigating every defect and implementing targeted corrective actions. When inspection reveals a deviation, you launch a structured analysis to find the root cause. You document each step and verify that your solution prevents recurrence. LTPCBA integrates customer feedback into its corrective action process, ensuring that you address real-world concerns. This cycle of detection, analysis, and correction keeps your pcba production reliable and efficient.

You build trust with your customers by acting quickly and transparently. Every corrective action improves your process and supports long-term quality goals.

Ongoing Training and Optimization

You maintain high standards by investing in ongoing training for your team. Regular workshops and skill updates keep everyone informed about the latest inspection methods and process improvements. You optimize production by reviewing performance data and refining workflows. LTPCBA’s commitment to continuous learning and process optimization supports a 99.5% pass rate and customer satisfaction scores above 80%. These results match or exceed industry benchmarks, reflecting strong order fulfillment and low scrap rates.

Consistent training and process optimization help you achieve stable pcba production and deliver reliable products to your customers.

You achieve the highest PCBA quality by following a systematic, multi-stage approach. Combining process controls, thorough inspections, and continuous improvement ensures reliable results. LTPCBA stands out as a trusted partner, offering expertise and advanced technology. To improve your process, review the table below for actionable steps based on industry best practices:

Step | Action |

|---|---|

Design | Assess thermal risks, use proper materials, and protect sensitive components |

Assembly | Optimize soldering, control stencil printing, and inspect before and after assembly |

Testing | Use AOI, X-ray, and functional tests for defect detection |

Start implementing these steps to strengthen your PCBA quality control today.

FAQ

What quality standards does LTPCBA follow?

You benefit from LTPCBA’s strict adherence to ISO, IATF, and UL certifications. These standards ensure your PCBA projects meet global quality and safety requirements.

How does LTPCBA detect defects during assembly?

You rely on advanced inspection tools like AOI, X-ray, and functional testing. Skilled technicians also perform manual checks. This multi-layered approach helps you catch defects early and maintain high product quality.

Why is staff training important for PCBA quality?

You need well-trained staff to spot issues quickly and follow best practices. Ongoing training at LTPCBA keeps your team updated on the latest inspection methods and process improvements.

How can you improve PCBA quality control in your process?

Start by setting clear standards, using automated inspections, and analyzing feedback.

Regularly review your process and invest in staff training.

These steps help you reduce defects and deliver reliable products.

See Also

The Role Of X-Ray Scanning In PCBA Quality Assurance

Comprehensive PCBA Solutions From Production Through Final Testing

Ensuring High-Quality Output With Modern Turnkey PCBA Facilities

Essential Methods To Boost PCBA Durability And Performance

The Importance Of AOI In Maintaining PCBA Manufacturing Standards