What is a Hybrid PCB and Its Applications

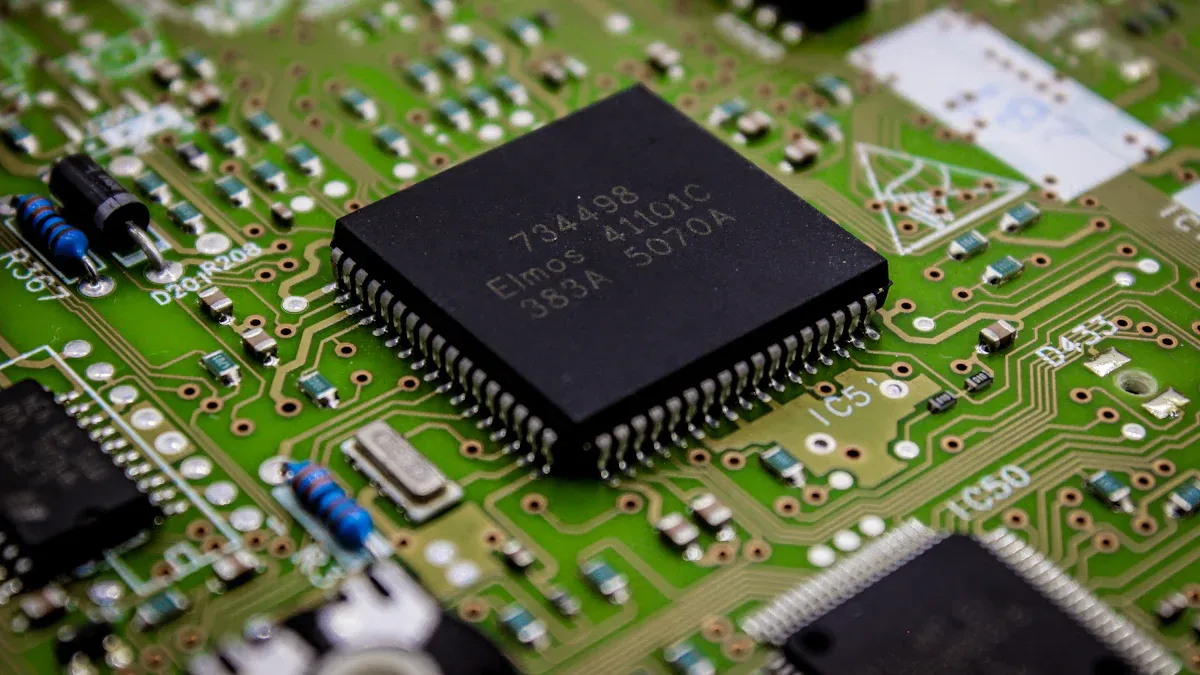

A hybrid PCB uses different materials for better performance. Unlike regular PCBs, these special boards use materials that lose less energy and handle signals better. Many industries now rely on hybrid PCB assembly because it ensures flexibility and excellent functionality.

Hybrid PCBs now make up 25% of the market, highlighting the growing demand for hybrid PCB assembly.

Over half of the demand comes from 5G networks, which require their strong signal quality.

The automotive industry has increased its use by 45%, driven by the rise of electric vehicles and wireless charging technologies.

Focusing on hybrid PCB assembly is essential to meet these expanding needs.

Key Takeaways

Hybrid PCBs use materials like PTFE and FR-4 to work better and save energy.

These boards are important in telecom, aerospace, and car industries, helping with advanced technology needs.

LTPCBA makes custom hybrid PCBs that are reliable and high quality for many uses.

Structure and Materials of Hybrid PCBs

What makes a PCB "hybrid"?

A hybrid PCB is special because it uses different materials together. Regular PCBs usually use one material, like FR-4. Hybrid PCBs mix materials such as PTFE, ceramics, and polyimides. This mix helps the board work well in tough conditions like high heat or strong signals.

For example, FR-4 can give strength, while PTFE helps signals move better. This mix makes the board strong and useful without costing too much. By combining materials, hybrid PCBs are flexible, strong, and work great.

Common materials used in hybrid PCBs

Hybrid PCBs use many materials, each with its own job. Below is a table showing common materials and their uses:

Material Type | Description |

|---|---|

PTFE | Helps signals move fast and lose less energy. |

FR-4 | A strong base material often mixed with others. |

Polyimide | Works well in hot places and is very flexible. |

Ceramics | Handles heat and works well with high-frequency signals. |

Conductors | Metals like Copper, Gold, and Silver make paths for electricity. |

Interconnects | Wires and adhesives connect parts on the board. |

Each material is picked for its special features. For example, PTFE is great for RF systems, while polyimides handle heat well. Ceramics are used when managing heat is very important.

Tip: PTFE materials are popular for RF PCBs because they lose less energy and have flexible dielectric constant (Dk) values.

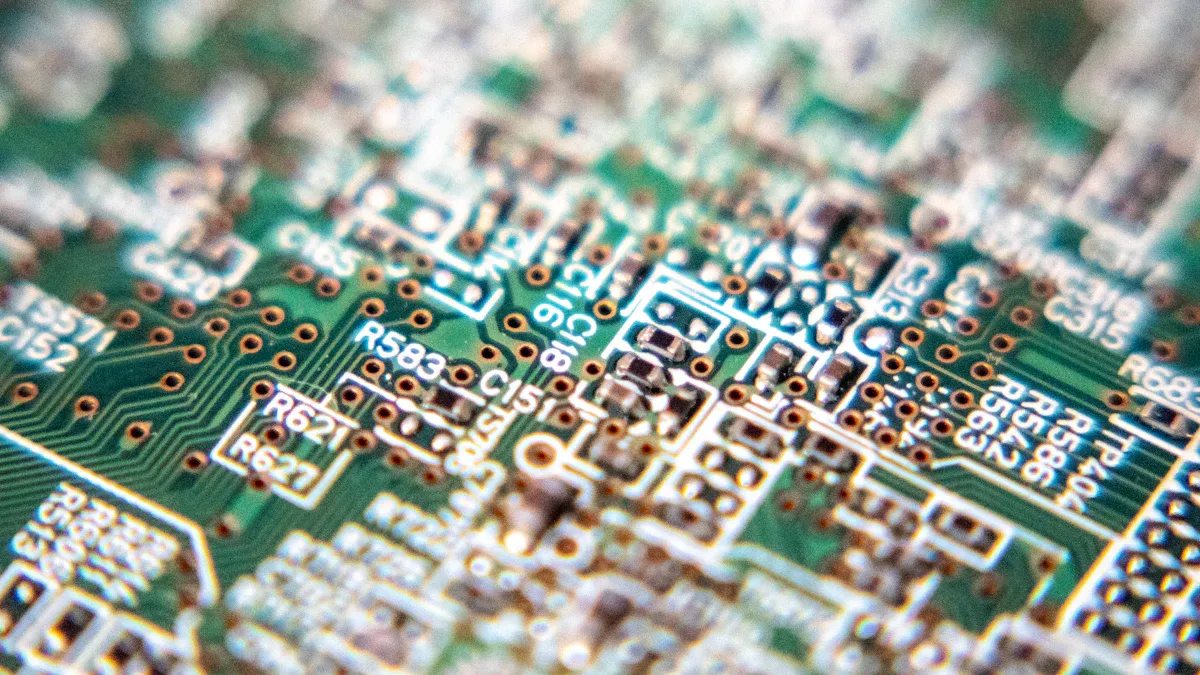

How materials are combined to enhance performance

Materials in hybrid PCBs are placed carefully to improve their strengths. FR-4 might be used for support, while PTFE handles signals. Ceramics can help manage heat in areas with lots of power.

Here’s how mixing materials improves performance:

Benefit | Description |

|---|---|

Signal Transmission | Special materials make signals clearer and faster. |

Thermal Management | Mixing materials helps control heat better. |

Mechanical Strength | Strong materials keep the board durable. |

Cost Efficiency | Using a mix saves money while keeping quality high. |

Reliability | Combining materials makes the board more dependable. |

Size and Weight Reduction | Hybrid PCBs can be smaller and lighter for tight spaces. |

For example, RF PCBs often use PTFE for clear signals, while fillers make it stronger. Layers are added carefully to make the board work well and last long.

By mixing materials, hybrid PCB designs are powerful and affordable. This makes them perfect for industries like telecom, aerospace, and cars.

Benefits of Hybrid PCBs

Better performance and dependability

Hybrid PCBs are made to work well and last long. They mix materials like PTFE, ceramics, and FR-4. These materials help with strong signals, heat control, and less noise. This makes them great for telecom and aerospace uses.

Here’s how hybrid PCBs improve performance and dependability:

Feature | Benefit |

|---|---|

Layers are designed for tasks like heat and signals. | |

Signal protection | Stops interference, lowering noise and signal problems. |

Heat control | Special materials spread heat, making boards last longer. |

Multi-tech integration | Combines features, saving space and simplifying designs. |

These features help hybrid PCBs work well, even in tough conditions.

Flexible designs and uses

Hybrid PCBs are very flexible for different designs. They can be made to fit specific needs. For example, rigid-flex boards mix stiff and bendable parts. This makes them good for small devices or moving systems.

Important design features include:

Aspect | Description |

|---|---|

Rigid-Flex Boards | Mix stiff and bendable layers for many uses. |

Bendable Design | Materials and thickness allow safe bending without damage. |

Trace Layout | Curved lines spread stress, making boards stronger. |

Heat Shock Resistance | Handles quick temperature changes, keeping boards durable. |

These features make hybrid PCBs useful for medical tools and car systems.

Affordable for special uses

Hybrid PCBs balance cost and performance well. They use different materials for specific jobs. For example, FR-4 gives strength, and PTFE improves signals. This mix saves money and reduces waste.

Hybrid PCBs also combine many functions into one board. This means fewer extra parts are needed, saving space and money. Their strength lowers repair costs, making them a smart choice for cars and healthcare industries.

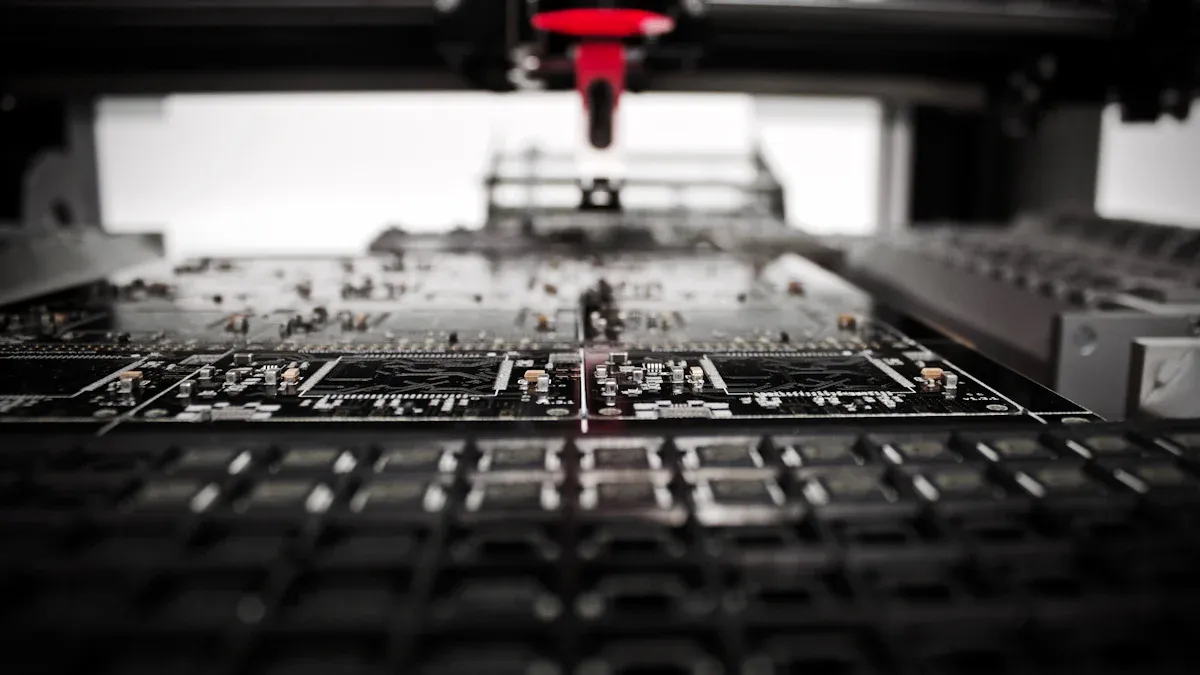

Hybrid PCB Assembly with LTPCBA

LTPCBA’s skill in hybrid PCB assembly

LTPCBA is a top expert in hybrid PCB assembly. They offer smart solutions for many industries. They handle tricky designs, making boards work well and last long. For radar systems, their hybrid PCBs improve signals and manage heat better. In medical devices, they help create small, wearable monitors and implants for patient comfort. In aerospace and defense, their rigid-flex boards fit tight spaces and work reliably. Even in electronics, LTPCBA helps make slim, high-performing gadgets for modern needs.

When you pick LTPCBA, you get a team that knows hybrid PCB challenges. Their skills ensure your boards meet top quality and performance standards.

High-tech tools and quality checks

LTPCBA uses advanced tools to make great hybrid PCBs. They manage heat well, keeping boards cool and working right. They test carefully to catch problems early, ensuring reliable products. Tests check electrical, mechanical, and environmental strength. Accelerated life testing (ALT) shows how long boards will last, giving you trust in their durability.

They follow strict rules like ISO and UL for safety and quality. With LTPCBA, every board meets high standards for dependability and performance.

Custom solutions for many industries

LTPCBA adjusts its services to fit your needs. They help industries like telecom, cars, and healthcare. Their rigid-flex PCBs are perfect for small medical tools and compact electronics. In aerospace and defense, they provide strong connections for tough jobs.

Their focus on customers means you get help at every step. From planning to delivery, LTPCBA works to make your projects successful.

Applications of Hybrid PCBs

Telecommunications and networking equipment

Hybrid PCBs are important in telecom and networking devices. They keep signals strong and reliable for routers, switches, and 5G stations. By using materials like PTFE and ceramics, they reduce signal loss and interference. This makes them perfect for high-frequency tasks.

Description | |

|---|---|

Better Signal Quality | Keeps signals clear by lowering reflections and crosstalk. |

Improved Heat Control | Uses special vias to spread heat, keeping devices stable. |

Higher Durability | Combines stiff and bendable parts to handle tough conditions. |

Saves Space | Allows compact designs by routing in 3D. |

Lower Weight and Cost | Reduces layers and connections, saving money and weight. |

The need for hybrid PCBs in this field is growing fast. They are great for handling fast data and small designs in modern communication tools.

Did you know? Hybrid PCBs are now used in smartphones and robots to solve heat and signal problems.

Aerospace and defense systems

In aerospace and defense, hybrid PCBs are key for critical tasks. They are built to handle heat, vibrations, and radiation. These boards are used in planes, satellites, radars, and missile systems.

Planes use hybrid PCBs for reliable circuits.

Satellites and radars need them for heat control and strong signals.

Missiles and defense systems depend on their strength and accuracy.

The aerospace industry needs military-grade PCBs for important missions. These boards must meet strict rules to ensure success.

Tip: Rigid-flex hybrid PCBs are great for drones because they are light and compact.

Automotive electronics

Modern cars rely on hybrid PCBs for advanced features. These boards power entertainment systems, safety tools, and electric car parts. Their mix of stiff and flexible parts saves space in vehicles.

Characteristic | Traditional Rigid PCBs | Rigid-Flex PCBs |

|---|---|---|

Structure | Fully rigid | Mix of rigid and flexible parts |

Flexibility | No flexibility | Flexible parts allow bending and movement |

Design Needs | Focus on placement | Includes bending and stress considerations |

Uses | General electronics | Cars, planes, robots, wearables |

Benefits | Low cost | Saves space, handles movement, more reliable |

Electric cars have increased the demand for hybrid PCBs. In 2022, electric cars made up most of the growth in the auto industry. These cars need PCBs that manage power and heat well.

Fun Fact: Over 26 million electric cars were on the road in 2022, showing the need for better PCB tech.

Medical devices and healthcare technology

Hybrid PCBs are changing healthcare by making small, reliable devices. They are used in wearable monitors, imaging machines, and implants. Their mix of rigid and flexible parts allows creative designs for patient comfort.

Medical implants use rigid-flex PCBs because they are light and strong.

Wearable devices like fitness trackers depend on hybrid PCBs for flexibility.

Imaging machines like MRIs use them for clear signals and heat control.

Hybrid PCBs are now essential in healthcare. Their reliability makes them perfect for life-saving tools.

Note: As wearable tech grows, the need for hybrid PCBs in healthcare keeps rising.

Hybrid PCBs use materials like PTFE and FR-4 for better results. They are strong, flexible, and save money. These boards are used in telecom, aerospace, and healthcare. LTPCBA is skilled at making hybrid PCBs with advanced tools. They also focus on helping customers with their projects. Learn more about hybrid PCBs and let LTPCBA handle your needs. 🌟

FAQ

What industries use hybrid PCBs the most?

Hybrid PCBs are common in telecom, aerospace, cars, and healthcare. These industries need strong boards that resist heat and keep signals clear. 🚀

How do hybrid PCBs make signals better?

Hybrid PCBs use PTFE and ceramics to stop signal problems. This helps signals move faster, clearer, and more reliably in high-frequency systems. 📡

Can LTPCBA create custom hybrid PCB designs?

Yes! LTPCBA makes custom hybrid PCBs for your needs. They design boards to work well and last long for your projects. 💡

See Also

Understanding PCBA: Key Components And Their Functions

Exploring SMT And DIP Assembly Techniques For PCBA

Essential Guidelines For HDI PCB Surface Mount Assembly