How to Choose the Right Turnkey PCB Assembly Partner in the USA

Selecting the right turnkey PCB assembly services USA partner is essential for your success. It’s important to evaluate their quality standards, robust process control, industry certifications, and responsive support. A reliable provider of turnkey PCB assembly services USA can enhance your product, reduce costs, and ensure timely delivery. Key factors to consider in a turnkey PCB assembly services USA partner include:

Advanced turnkey PCB assembly services USA

Demonstrated quality across all services

Consistent and clear communication

Streamlined and efficient turnkey processes

Key Takeaways

Pick a turnkey PCB assembly partner with good quality standards and key certifications. This helps make sure your products are safe and work well. - Find a partner who uses modern testing and checks their process often. This helps find problems early and gives you great results. - Choose a company that talks clearly, gives quick help, and delivers on time. This keeps your project going well and on track.

Turnkey PCB Assembly Services USA

What Is Turnkey PCB Assembly

If you need turnkey pcb assembly services usa, you want help with every step. Turnkey pcb assembly means the company does all the work for you. You send your design files to them. They get the parts, make the pcb, put it together, test it, and send it to you. This way, you only talk to one company. It also helps stop mistakes from happening.

Most pcb assembly makers in the USA have two main types of turnkey pcb assembly services usa:

Full turnkey pcb assembly: The company gets all the parts, puts the pcb together, tests it, and ships it.

Partial turnkey pcb assembly: You give some parts, and the company does the rest.

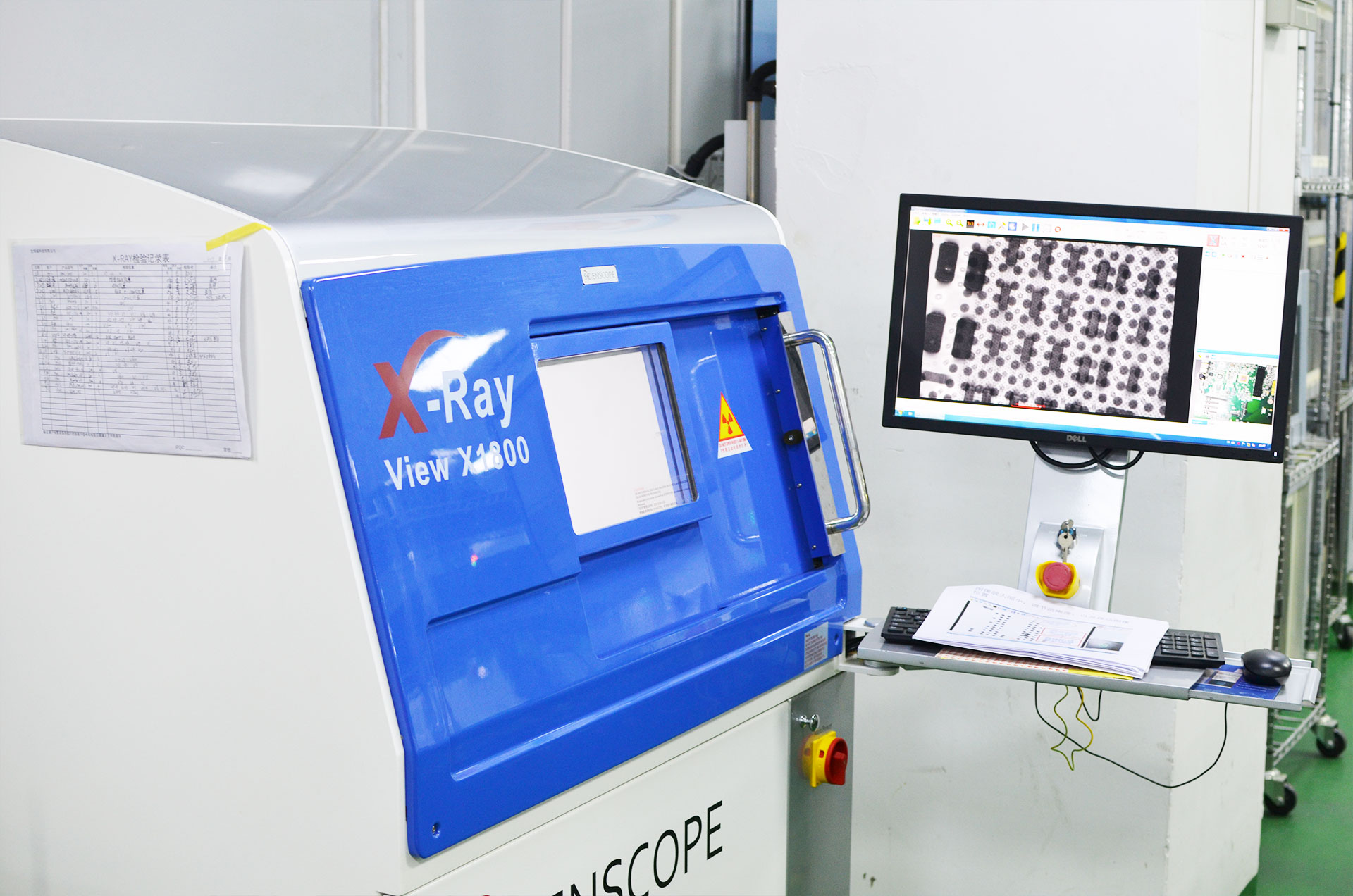

You can pick from different ways to put the pcb together, like Surface Mount Technology (SMT), Through-Hole, or both. Many pcb assembly services can also do custom pcb assembly for special projects. Testing like Automated Optical Inspection (AOI) and X-ray inspection help make sure the pcb is good.

Why Choose Turnkey Services

Turnkey pcb assembly services usa help you save time and money. You do not have to work with many companies. The pcb assembly company does everything, so you can work on your design and business. Turnkey pcb assembly vs consignment pcb assembly shows turnkey is faster, costs less, and has better quality checks.

Here are some main benefits of turnkey services:

Lower costs because of buying in bulk and less shipping

Good quality with early error checks

Easy project management with just one contact

Flexible services for small or big jobs

Turnkey pcb assembly services usa make the whole pcba process simple and dependable. You get fast, high-quality results for your custom pcb assembly needs.

Key Criteria for a PCB Assembly Partner

Quality and Certifications

You want a pcb assembly partner who cares about quality. High standards and certifications mean they care about good products. When you pick a turnkey pcb assembly company, check if they have the right certifications for your industry. These certifications show the partner uses strict quality checks and follows world rules.

Here is a table that lists important certifications and what they mean:

Certification | Description | Relevance to PCB Assembly in USA |

|---|---|---|

IPC (IPC-A-610D) | Sets rules for pcb assembly and quality. | Makes sure assembly is good for OEMs and EMS. |

ISO 9001 | International rule for quality management. | Shows they can meet rules and laws. |

ISO 13485 | Quality system for making medical devices. | Needed for medical pcb assemblies. |

IATF 16949 | Rule for quality in car parts. | Needed for car pcb assembly. |

UL Listing | Safety check for fire and electric risks. | Important for safety and trust. |

RoHS Compliance | Stops bad chemicals in electronics. | Makes sure making is safe for the planet. |

ITAR | U.S. rule for defense technology. | Needed for defense pcb assemblies. |

MIL-STD | U.S. military rule for performance and trust. | Used for military and tough electronics. |

A strong pcb assembly partner like LTPCBA has ISO, IATF, and UL certifications. LTPCBA also has a 99.5% pass rate, which shows they are very good and reliable. These things set a high goal for any turnkey pcb assembly company you look at.

Process Controls and Testing

You want a partner who uses good process controls and testing. These steps help find problems early and keep quality high. The best turnkey pcb assembly companies use both machines and people to check every board.

Key quality control steps include:

Automated Optical Inspection (AOI) to find problems early.

In-Circuit Testing (ICT) to check each part.

Solder Paste Inspection (SPI) to stop soldering mistakes.

Functional Testing to make sure the board works.

Automated X-Ray Inspection (AXI) to find hidden problems.

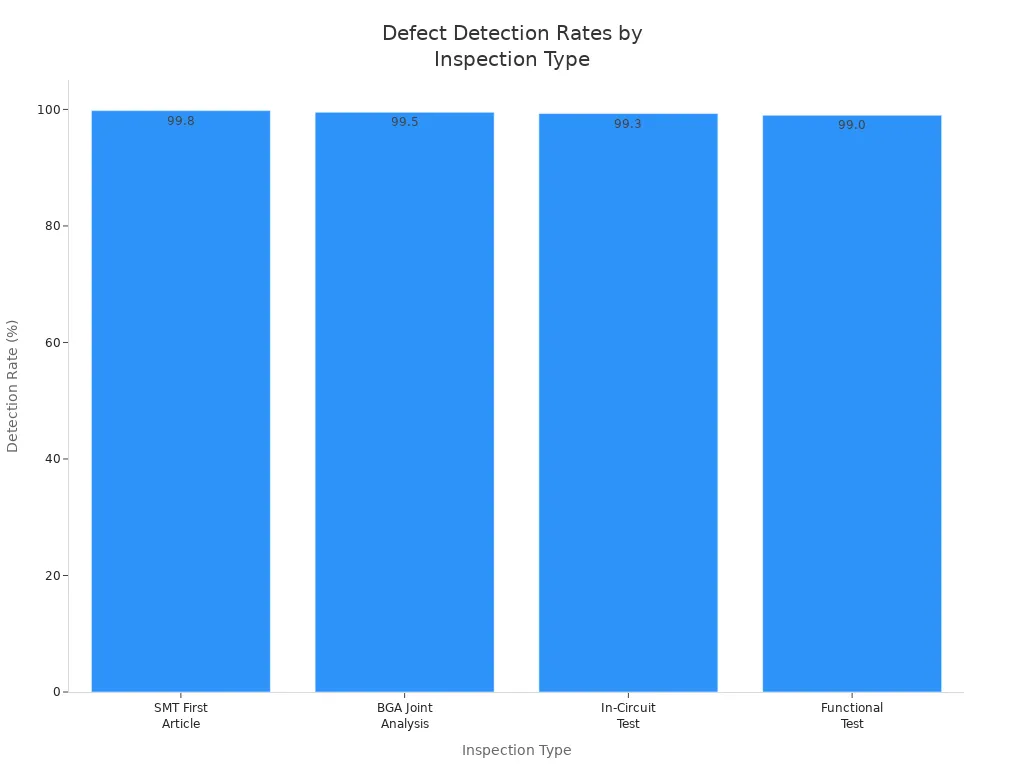

Here is a chart that shows how new testing helps find more problems:

Automated assembly systems help stop problems before they start. They use real-time checks and digital records to catch mistakes early. This way, there are fewer problems and better turnkey pcb assembly results.

Technical Expertise

You need a pcb assembly partner with strong technical skills. This means they know every step, from design to final tests. A good partner can handle big or small jobs and uses the best equipment. You get help from their knowledge for easy or hard projects.

Look for these signs of technical skill:

Help from start to finish, from prototype to big orders.

Fast SMT assembly and careful part placement.

Through-hole technology for strong connections.

Advanced tests, like functional and in-circuit checks.

Custom packaging and special coatings.

Use of good materials and strict checks.

Expert help for design and fixing problems.

Can work with tricky parts like BGA, QFN, and tiny pieces.

Follows industry rules and has certifications.

LTPCBA uses machines and new tech to give steady, high-quality results. Their skills make sure your turnkey pcb assembly project meets all needs, even if it is hard.

Customer Support

Good customer support helps your project go well. You want a partner who answers fast and keeps you updated. Good support means you get answers quickly, updates often, and help with problems.

LTPCBA is great at this with 24-hour tech support and fast quotes in 2-3 days. They help in emergencies and have a 99.5% pass rate. These things show they care about customers.

Key parts of good support include:

24/7 help for questions and emergencies.

Engineering help for design and making questions.

When your pcb assembly partner gives great support, you can focus on your work. They handle the details. This trust leads to better project results.

Turnaround and Delivery

Fast and steady delivery is very important for you. You need a turnkey pcb assembly partner who can meet tight deadlines and keep quality high. Normal turnaround times are 24 hours for quick-turn prototypes and 2-4 weeks for full projects.

Things that change delivery speed include:

How hard the design is and number of layers.

How easy it is to get parts.

Board size and what it is made of.

Testing and quality steps.

Order size and how much they can make.

Use of new manufacturing tech.

Top pcb assembly companies like LTPCBA use machines and good supplier networks to work faster. They also give clear updates and manage your order well. The best companies deliver on time 97% of the time or more, which is very reliable.

Tip: Pick a partner who delivers on time and can grow with your needs.

By looking at these key things—quality, process controls, technical skill, customer support, and delivery—you can pick the best turnkey pcb assembly partner for your project.

Turnkey PCB Assembly Process

The turnkey pcb assembly process gives you help from start to finish. You only need to share your design and what you want. The manufacturer does all the steps for you. They make sure you get a good product that fits your needs.

Component Sourcing

You want good parts for your project. In turnkey pcb assembly, the company handles the bill of materials. They pick trusted vendors and check each part for quality. They use supplier checks, incoming tests, and standard tests to keep quality high. Good teams watch inventory, use just-in-time systems, and check delivery speed. They also work closely with suppliers to stop delays and lower risks. This focus on quality at the start helps stop problems later.

Assembly and Inspection

During assembly, skilled teams use machines to place and solder parts. They follow strict quality rules at every step. Automated Optical Inspection (AOI) looks for surface problems and placement mistakes. X-ray Inspection (AXI) finds hidden issues in hard parts. Solder Paste Inspection (SPI) checks if the right amount of solder is used. In-Circuit Testing (ICT) and Flying Probe Testing check connections and if parts work. These steps catch problems early and keep quality high.

Tip: Regular checks and automated systems help you reach a 99.5% pass rate in turnkey pcb assembly.

Final Testing

Final testing is the last step before shipping. Functional testing acts like real use to see if your board works. Other tests, like burn-in and reliability checks, push the board hard to find early failures. In-Circuit Testing and Automated X-ray Inspection make sure every part meets industry rules. This focus on quality makes sure your turnkey pcb assembly is safe, reliable, and ready to use.

Test Type | Purpose |

|---|---|

Functional Test | Checks if the board works as planned |

Burn-in Test | Finds early failures when stressed |

ICT | Tests each part for correct values |

AXI | Looks at hidden solder joints and inside layers |

Reliability Test | Checks long-term use and service life |

You can trust the turnkey process to give you high quality and reliable results every time.

Evaluate Turnkey Partners

Research and Shortlist

Start by looking up companies that do pcb assembly services. Write down what your project needs and how many you want. Tell the companies when you need your project done. Check if each company has worked in your field, like medical or cars. Find companies with good reviews and the right certifications.

See what each company can do and their experience.

Look at their certifications and quality rules.

Make sure they offer full turnkey pcb assembly services.

Create a table to compare their skills, services, and reviews.

A company like LTPCBA works with many types of customers. This shows they are flexible and know a lot about different jobs.

Request Quotes

When you ask for prices, give clear details. Tell them your board type, how many layers, size, and what it is made of. Share your BOM, Gerber files, and other important papers. Ask about costs for parts and work, how long it takes, and how they test. Find out about shipping, if they can handle bigger orders, and how they talk with you. This helps you compare companies and pick the best one for your pcb assembly services.

Check References

Check references to make sure the company is good and knows what they are doing. Read what other customers say and look at case studies. These show if the company can do hard jobs and finish on time. LTPCBA has many clients, which shows they give good quality and help. Look for reviews from other places for more info. If you can, visit the company or talk to experts. You can see their machines, how they check quality, and what services they have. Doing these things helps you find a company that is skilled, honest, and gives reliable pcb assembly services.

Start Your Turnkey Project

Define Requirements

You need to be clear about what you want. First, write down your technical needs like board size and layers. List the types of parts you need. Give your design files and bill of materials to your partner. This helps your partner know what you expect. Tell them when you need the project finished. Say if you need any special tests. Giving all the details helps your partner plan better. They can find problems early or suggest ways to improve. A good partner will ask questions to make sure they understand. They will also give ideas that fit your project. Working together like this helps you get the results you want.

Set Communication Channels

Talking clearly with your partner is very important. Pick a partner who gives you one main contact. This makes things less confusing and keeps your project on track. Your partner should tell you what is happening at each step. If you tell your partner about changes, you avoid delays and extra costs. Many projects have problems because people do not talk enough. So, make good communication a top goal. A good partner will use email, phone, or online tools to stay in touch. You should always know who to ask if you have questions. When you and your partner talk well, you trust each other more and get better results.

Tip: A partner who talks openly helps you avoid problems and keeps your project moving.

Picking a turnkey PCB assembly partner is the first step to doing well. A partner with good technical skills, strong quality, and helpful support can help you reach your goals. If you check your partner carefully, you get better quality, save money, and your project lasts longer. Begin by talking to a partner you trust today.

FAQ

What should you look for in a turnkey PCB assembly partner?

You need to check if they have certifications. Make sure they use strong process controls. Look for a team with good technical skills. They should answer your questions quickly. A reliable partner helps you get good quality. They also help you save money and finish faster.

How does a partner handle urgent PCB assembly projects?

A good partner uses smart systems and skilled workers. You get a price quote fast. They start making your order quickly. They tell you what is happening at each step. This helps your urgent project stay on schedule.

Can your partner support both small and large production runs?

Yes. A flexible partner can make just a few boards or many. You get the same good quality every time. They deliver your order on time, no matter how big or small.

See Also

Finding The Ideal All-In-One PCB Assembly Provider

Tips For Picking The Perfect Turnkey PCBA Manufacturer

Guide To Choosing A PCBA Supplier That Fits You