How to Choose the Right Through Hole Assembly Service Provider

Selecting the right pcb assembly company for through hole assembly is important. Start by picking a pcb manufacturer that cares about quality, experience, and following rules. You want a pcb assembly company that people trust. LTPCBA is a top pcb assembly company. They give great pcb assembly services. They find 98.7% of defects and make 120 boards each hour. This is better than most companies. The right pcb assembly service gives good and steady results. The best pcb assembly companies use smart testing like AOI. This makes sure every pcb assembly is made right. Working with a trusted pcb manufacturer like LTPCBA means you get good through hole assembly. You also get fast help from a company that cares about quality.

Metric | Industry Standard | LTPCBA Performance |

|---|---|---|

Defect Detection | 90-95% | 98.7% |

Throughput | 50-100 boards/hr | 120 boards/hr |

False Alarm Rate | <5% | <2% |

Key Takeaways

Pick a pcb assembly company that has lots of experience and good skills. This helps you get boards that work well and last long. - Find providers who have important certifications and use good testing steps. This makes sure there are fewer mistakes and your product is safer. - Choose a company that talks clearly and helps you fast. This keeps your project moving and fixes problems quickly.

Through Hole Assembly: Key Selection Criteria

Experience and Industry Expertise

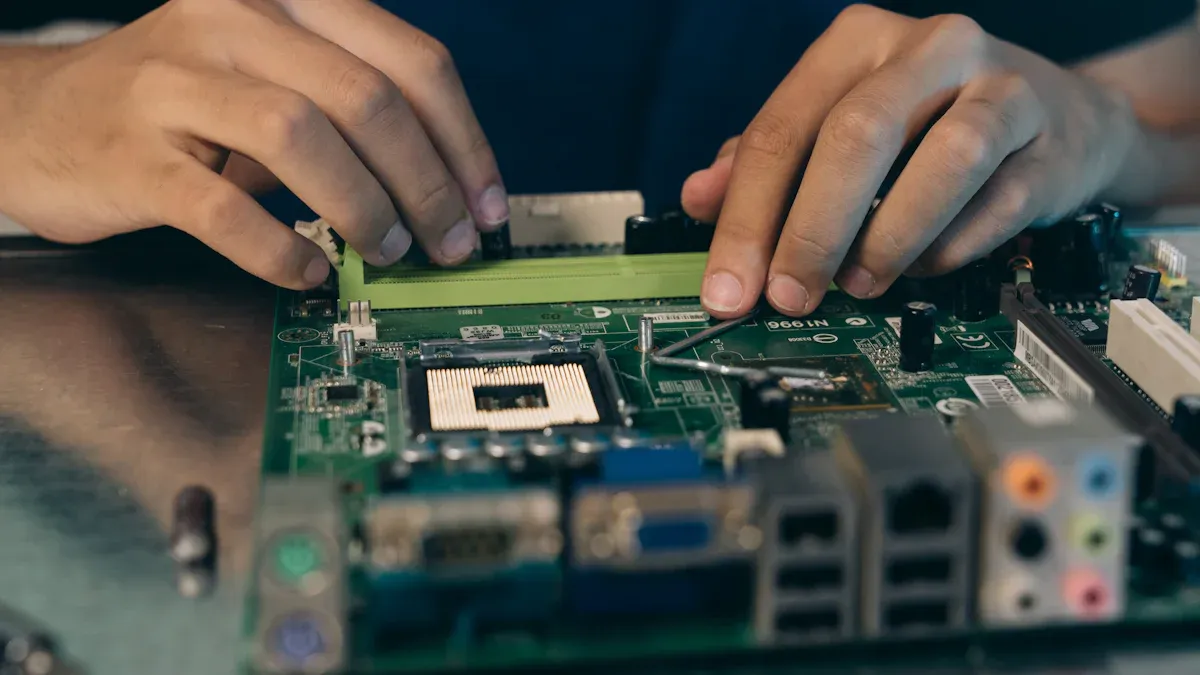

Pick a pcb assembly company with lots of experience. Companies that have worked for years know how to handle tough jobs. They can work with complex boards and hard projects. These companies know what strong and reliable products need. Many fields, like aerospace and medical, use through hole assembly because it is tough. Skilled teams can do tests like temperature and humidity checks. These tests help your boards last longer. If you choose a company with proven skills, you get better boards and fewer problems. LTPCBA has done through hole pcb assembly for a long time. They help clients who need strong and steady connections.

Tip: Ask if the company has worked on projects like yours. This helps you see if they can give you good results.

Quality Assurance and Certifications

Quality assurance is very important for pcb assembly services. You want a company that follows strict rules and has top certifications. Certifications like ISO, IATF, and UL show the company meets high standards. These also mean the company checks quality at every step. LTPCBA has a 99.5% pass rate, which is better than most. This shows they care about quality and careful checks.

Statistical Impact | |

|---|---|

Defect Trend Analysis (SPC) | 15% of reworks caused by tombstone effects |

Early Defect Detection (AOI, X-ray) | Over 50% reduction in rework rates |

Automation | Labor costs reduced by up to 40% |

Continuous Improvement & DFM | Lead times shortened by 15–30% |

Yield Rates | Increased up to 95% with cost reductions of 20% |

Having certifications and strong quality checks means fewer mistakes and lower costs. You can feel safe knowing your pcb assembly meets top standards.

Testing and Inspection

Testing is a big part of through hole pcb assembly. You need a company that uses smart testing to find problems early. AOI and X-ray testing can find defects that people might miss. These tools make your boards better and more reliable. LTPCBA uses AI-driven AOI systems. These can cut downtime by 20% and lower bad part costs by 30%. High-resolution imaging finds problems at every step. This makes sure your boards are always high quality.

Testing is more than just AOI. Good pcb assembly services also do process control, functional testing, and stress tests. These steps make sure every board is strong and lasts long. LTPCBA uses many testing steps, so you get better boards and fewer returns.

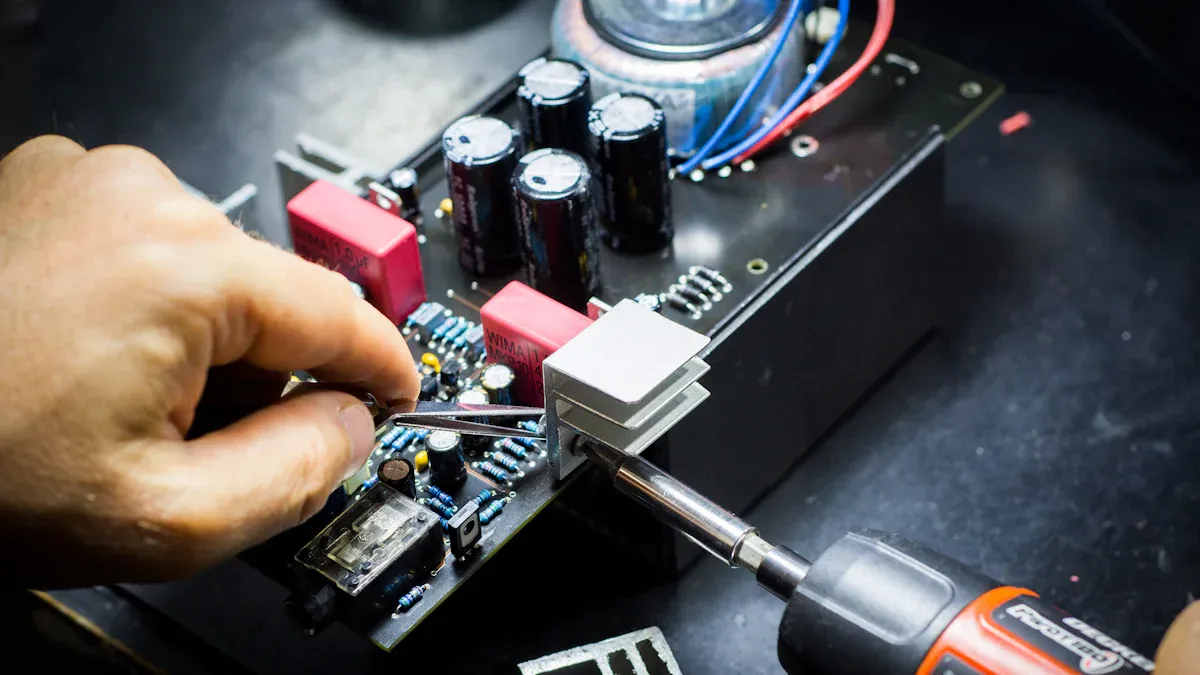

ROHS and Compliance

Following ROHS and other rules is very important for safety. ROHS rules limit dangerous materials. This makes your products safer for people and the planet. ROHS needs lead-free solders, which flow differently and need careful control. This helps make strong solder joints and stops problems. Millions of ROHS products work safely all over the world. This shows that following rules does not make boards weaker.

Check that your pcb assembly company follows all rules, like IPC and UL. These rules keep your boards safe and ready for use everywhere. LTPCBA follows all big rules, so you can trust their pcb assembly for safety and quality.

Customer Support and Communication

Good support and clear talk make the best pcb assembly companies stand out. You need a partner who answers fast and keeps you updated. Good talk helps fix problems quickly and keeps your project moving. A drilling manager from West Texas said regular talks with their provider led to fewer tool problems and less wasted time. This shows that strong support and open talk help you get better results.

LTPCBA gives 24-hour technical support and quick answers. This makes them a good choice for turnkey pcb assembly services. When you work with a team that listens, your projects go smoother and you are happier.

Note: Pick a pcb assembly company that listens to you and keeps you in the loop. This helps you get better results and a stronger team.

Evaluating a PCB Assembly Service Provider

Comparing Quotes and Turnaround Times

When you look at quotes for through hole pcb assembly, do not just look at the price. You should see what is included in each quote and how fast the company can finish your order. Fast answers and clear prices show a good pcb assembly service. LTPCBA is known for giving quick quotes and 24-hour help. You get answers fast and service that does not make you wait. Use the table below to check important things:

Description | |

|---|---|

Order Size | Bigger orders may cost more but can have lower prices for each board. |

Services Requested | Asking for through hole pcb assembly or extra work changes the total price. |

Components Provided | The cost changes if you give parts or let the company find them. |

Labor Costs | Harder jobs mean more money for labor. |

Shipping Costs | Delivery costs depend on how big, how far, and how fast you need it. |

Turnaround Time Factors | Fast pcb assembly needs a company that can work quickly and change plans. |

You want a pcb assembly company that gives you good value and delivers on time.

Assessing Manufacturing Capabilities

Check what each pcb manufacturer can do. You need a company that is good at both through hole pcb assembly and quick-turn pcb assembly. Look for new machines like AOI, X-ray, and reflow ovens. LTPCBA can make prototypes and medium-sized orders. They do SMT, through hole, and mixed assembly. Good machines and skills mean you get boards that work well and arrive on time. You should also look for certifications, good process controls, and the ability to make hard designs. These things help you avoid waiting and make your project go well.

Checking References and Past Projects

Ask for references and look at old projects. A good pcb assembly service will show you work from cars, medical, and factory jobs. You can see how they lower mistakes, deliver on time, and make more boards when needed. Look for proof of quality, like AOI and in-circuit testing. LTPCBA’s old projects show they are good at quick-turn pcb assembly and sending boards on time. Good references show the company can do what you need.

Site Visits and Communication

If you can, visit the company’s site. You will see their machines and how they send out boards. Talking in real time helps fix problems fast. Local pcb manufacturers can sometimes change your design the same day and fill emergency orders quickly. LTPCBA lets you visit and keeps you updated all the time. Good talk and visits show the company cares about sending your boards on time and making your project work.

When picking a through hole assembly manufacturer, look for experience and certifications. You should also check if they have good results. LTPCBA is a manufacturer that does strong testing and gives fast help. They are known for being reliable. Here is how LTPCBA does:

Metric | LTPCBA Result |

|---|---|

On-time Delivery Rate | 99% |

First Pass Yield | 95–98% |

Certifications | ISO, UL, IPC-A-610 |

24-hour Tech Support | Yes |

You can contact this manufacturer to get a quote or ask questions today.

FAQ

What certifications should you look for in a through hole assembly provider?

You should look for ISO, UL, and IATF certifications. These show the provider follows strict quality and safety standards.

How fast can you get a quote from LTPCBA?

You can receive a quote from LTPCBA within 2–3 working days. Their team responds quickly to your requests.

Why is ROHS compliance important for your PCB project?

ROHS compliance keeps your boards safe for people and the environment.

It ensures your products meet global safety rules.

See Also

Selecting The Ideal Through-Hole PCB Assembly For Industrial Use

An In-Depth Overview Of Through-Hole PCB Assembly Techniques

Comparing SMT And Through-Hole PCB Assembly For Electronics Projects

How To Find The Top One-Stop PCB Assembly Provider

Evaluating Reliability Between Through-Hole And SMT PCB Assembly