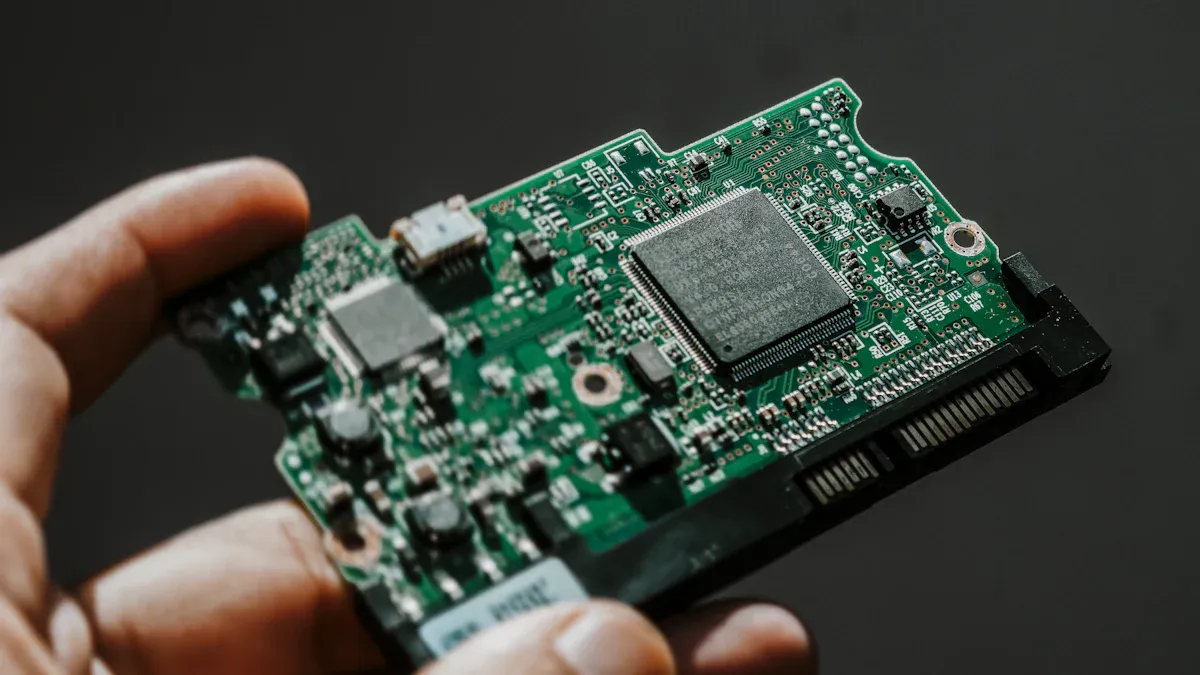

How to Find the Right Prototype PCB Assembly Service for Your Needs

Selecting the right prototype pcb assembly partner requires careful consideration of several key factors. You should evaluate their technical expertise, quality assurance processes, and responsiveness in communication. Industry experts recommend choosing a prototype pcb assembly provider who offers:

Extensive experience in prototype pcb assembly with the capability to scale up to larger production runs if needed

Robust quality control measures, such as automated optical inspection (AOI) and advanced manufacturing equipment

It’s also important to choose a prototype pcb assembly service that prioritizes quality and delivers excellent customer support. Focusing on these essential aspects will help you find the ideal prototype pcb assembly partner for your project.

Key Takeaways

Pick a prototype PCB assembly service that has lots of experience, the right certifications, and up-to-date equipment. This helps make sure you get good quality and results you can trust.

Make sure you know what your project needs and what technical things are important. This helps you find a partner who can finish on time, work with hard boards, and give great help.

Find providers who work fast, show clear prices, and talk well with customers. This keeps your project moving and helps stop any delays.

Define Your Prototype PCB Assembly Needs

Project Requirements

Before picking a prototype pcb assembly partner, you should list what your project needs. This helps you find the best provider for your job. Think about these important things:

Find someone who has worked with small production runs. This helps make sure your prototypes are good.

See if they can finish work fast. Meeting your deadlines is very important.

Look at how much they charge. Good prices help you stay on budget.

Make sure they know how to design pcb prototypes. This helps your prototypes work well.

Check if they can handle different board types like multilayer, flex, or rigid-flex.

Ask if they have used materials like epoxy, polyamides, and acrylic.

See if they test and check their boards. Board tests, solder tests, and X-ray checks help keep quality high.

Make sure they have strong quality control. Good quality means your prototype will meet your needs.

Tip: If you know what your project needs, you can find a pcb assembly partner who gives you the right solutions.

Technical Specifications

Technical details are very important when picking a prototype assembly service. You should see if the provider can handle hard jobs like fine pitch, BGA assembly, and multi-layer boards. Providers with good machines and skilled workers can do tough printed circuit board assembly jobs.

Pick pcb assembly services that do DFM analysis. This step helps your design get ready for making.

Choose a partner who tests in-house, like AOI and X-ray checks, to make sure quality is good.

Look for certifications like ISO 9001 and IPC-A-610. These show they follow industry rules.

Good pcb manufacturing and assembly services should offer fast prototyping and be flexible for rush orders.

Strong supply chain management and clear communication help projects go well and build good partnerships.

When you know your technical needs, you can work better with your pcb assembly partner.

Evaluate Prototype Assembly Service Providers

Experience and Expertise

When you check a pcb assembly service, look at their experience first. Companies with many years in prototype pcb assembly can do hard projects. They can also learn new technology fast. You want a partner who knows both surface mount technology (SMT) and through-hole assembly. They should pick the right parts and follow design for manufacturability (DFM) rules.

A good turnkey pcb assembly service provider will give you:

Proof they finished many projects well

Workers who can handle single, double, and multi-layer boards

Help with both prototypes and small production runs

Strong skills in finding parts and managing supplies

Expertise Area | Description |

|---|---|

Skilled in SMT, through-hole, and turnkey services; can work with many PCB types; uses new machines. | |

Industry Experience | Has done many projects, is dependable, and can change to meet new needs. |

Customer Service & Support | Gives custom help, answers fast, and delivers on time. |

Certifications & Compliance | Follows industry rules and has important certifications for trust and quality. |

LTPCBA is a turnkey pcb assembly service provider with lots of experience. They have strong technical skills and always aim for high quality. Their team can build simple prototypes or very complex, multi-layer printed circuit board assembly projects.

Tip: Picking an experienced provider helps you avoid delays, bad quality, and extra costs.

Quality Assurance and Certifications

Quality assurance is very important for any pcb assembly service provider. You should pick companies that use strong quality checks at every step. This means they use automated optical inspection (AOI), X-ray checks, and tests to make sure everything works. These steps find problems early and make sure your boards are good.

Some important certifications and standards to look for are:

IPC-A-610: Sets rules for assembly quality and checking.

ISO 9001: Shows they have a good quality system.

IATF 16949: Focuses on quality for cars.

UL Listing: Proves the product is safe for big markets.

RoHS: Makes sure they follow environmental rules.

A top turnkey pcb assembly service provider like LTPCBA has ISO, IATF, and UL certifications. Their quality system includes always getting better, training workers, and checking suppliers. This helps them get a 99.5% pass rate and use good materials in every order.

Note: Always check certifications and quality standards before you choose a provider.

Technology and Equipment

Modern machines and tools are very important for fast and accurate pcb assembly services. You want a provider who buys the newest machines, like automated pick-and-place systems, high-precision drills, and laser direct imaging. These tools help with quick turn pcb assembly and careful work with tiny parts.

Look for these things in a turnkey pcb assembly service provider:

Automated SMT lines for fast and repeatable work

AOI and X-ray checks for strong quality control

Can build very small parts and tricky boards

Can work with HDI, flex, rigid-flex, and multilayer PCBs

Quick turn pcb assembly for fast prototypes

LTPCBA uses new machines and automated systems to give quick turn pcb assembly with great results. Their technology lets them do many pcb assembly services, from SMT to BGA and mixed assembly. They also give 24-hour technical help and fast price quotes, so they are a quick turnkey pcb provider.

New machines help place parts right and lower mistakes.

Automated checks find problems early and help finish jobs faster.

Skilled workers and machines together make quality even better.

Quick turn pcb assembly and new technology help you finish your ideas faster and with fewer errors.

Choose a Reliable PCB Prototype Manufacturer

Reputation and Reviews

When you look for a reliable pcb prototype manufacturer, reputation is very important. You want a company that has done good work before. Good manufacturers use new machines and test their boards carefully. They follow steps like design, drilling, plating, and testing to make sure your board works. Customer reviews help you see if the company does what it says. Good reviews talk about fast service, helpful support, and fair prices. Bad reviews might say the company is slow or makes mistakes with orders. Here is a table that shows what people often say in reviews:

Positive Comments | Negative Comments |

|---|---|

Excellent fulfillment | Slow turnaround times |

Quality customer service | Occasional order mix-ups |

Cost effectiveness | Unexpected fees |

Good solder mask quality | Incorrect parts supplied |

You should always read reviews and testimonials before picking a pcb prototype manufacturer.

Customer Support and Communication

Good customer support helps your project go well. A reliable pcb prototype manufacturer gives updates and answers your questions fast. Clear communication helps you avoid mistakes and keeps your project moving. Look for a company that has 24-hour technical support and easy ways to talk to them. LTPCBA is known for quick replies and strong customer support. They deliver on time and help fix problems quickly. Great support means you get help that fits your needs and builds trust.

Tip: Talking early and often with your manufacturer helps you get better results and fewer problems.

Turnaround Time and Pricing

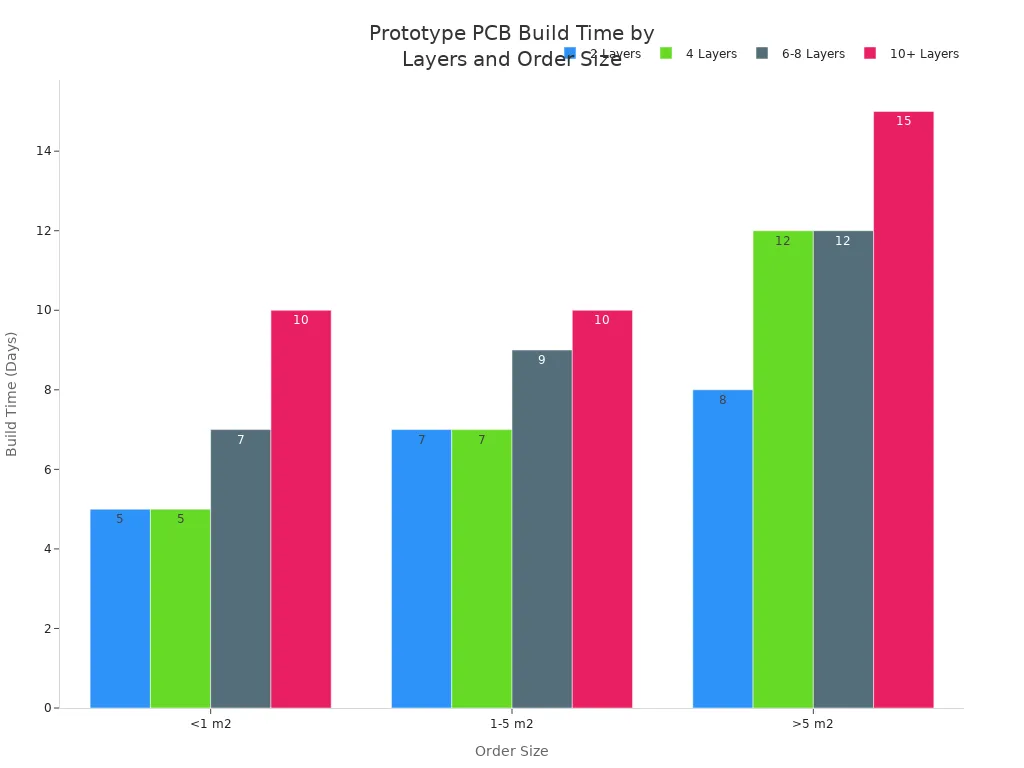

Fast turnaround time is important for quick prototyping. Most good pcb prototype manufacturers finish boards in 5 to 10 days. Some can do it even faster for simple boards. Quick service lets you test ideas and meet deadlines. Here is a chart that shows how long different boards take to build:

Good prices matter too. Top companies give clear quotes and flexible prices. You should compare costs, but do not pick low price over quality. LTPCBA offers fast pcb assembly, fair prices, and a 99.5% pass rate. Their ISO, IATF, and UL certifications show they care about quality and on-time delivery. When you pick a manufacturer with fast service and good support, your project is more likely to succeed.

To pick the best PCB assembly partner, you should do a few things. First, look at how much experience they have. Next, make sure they have the right certifications. Then, see what kind of machines and tools they use. Also, check how they test their boards. Match what the provider is good at with what your project needs. This helps your prototype move easily to manufacturing. Companies like LTPCBA have high pass rates and answer questions fast. They help you get good results you can trust. You can start checking providers today.

FAQ

What certifications should you look for in a PCB assembly provider?

You should look for ISO, IATF, and UL certifications. These show the company cares about quality and safety. They follow important rules to make sure your boards are good.

How fast can you get a prototype PCB assembled?

Most companies can finish a prototype in 5 to 10 days. Some, like LTPCBA, can work even faster if you need it soon.

Why does quality assurance matter in prototype PCB assembly?

Quality assurance helps stop mistakes and slowdowns. It makes sure your prototype works right and fits what your project needs.

See Also

Finding The Ideal All-In-One PCB Assembly Provider

Tips For Picking A PCBA Supplier That Fits Requirements

Guide To Choosing The Best Turnkey PCBA Manufacturer

Boosting Project Speed With Quick-Turn PCB Assembly Prototypes

Selecting The Best Through-Hole PCB Assembly For Industrial Use