How Through Hole PCB Assembly Works and What You Should Expect from a Service Provider

You work with PCBs every day, finding them in radios, alarms, and computers. Through-hole technology gives your PCB a strong, reliable connection. With LTPCBA’s advanced tools and expertise, every job receives careful attention. Our through hole PCB assembly service ensures you get the highest quality and durability for your projects. Through-hole technology supports your PCB in demanding environments, providing the strength you need. LTPCBA thoroughly checks every PCB, so you can trust your board to last.

Key Takeaways

Through-hole PCB assembly provides strong, reliable connections, making it ideal for demanding environments.

Choose a service provider that follows strict quality standards and offers transparent communication to ensure a smooth assembly process.

Always inquire about inspection and testing methods to guarantee the reliability and performance of your assembled PCB.

Through Hole PCB Assembly Process

You want your pcb to last. You want every connection to stay strong, even in tough conditions. That’s why the pcb assembly process for through hole technology matters so much. Let’s walk through each step so you know what to expect from a reliable provider like LTPCBA.

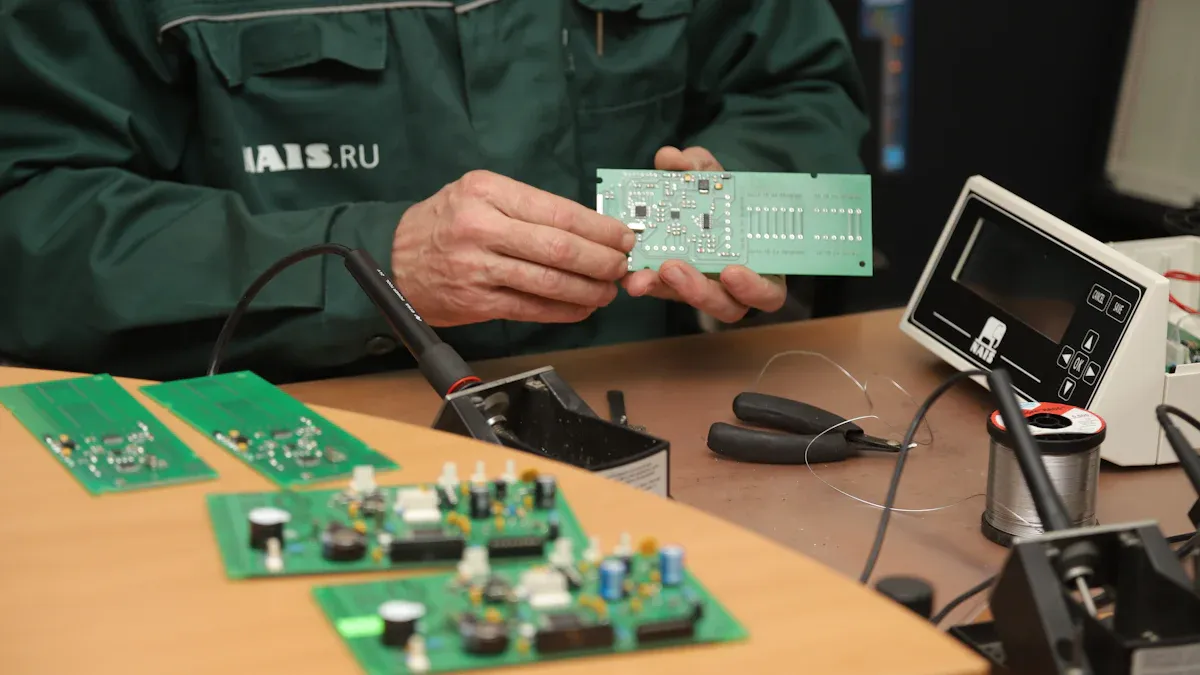

Component Placement in PCB

The first step in the pcb assembly process is placing components onto the pcb. You start with a clean, prepared board. Each hole in the pcb lines up with a specific component lead. You or a technician insert the leads of resistors, capacitors, or connectors into these holes. This step can be manual or automated, depending on the size and complexity of your pcb.

Manual placement works well for prototypes or small batches. You get careful attention to detail. For larger runs, automated machines handle the job. These machines pick and place components quickly and accurately. LTPCBA uses advanced pick-and-place systems to make sure every component sits exactly where it should. This precision helps your pcb perform better and last longer.

You might notice that through hole components stand out compared to surface-mount parts. They have longer leads and go all the way through the pcb. This gives your board extra mechanical strength. If you build devices for harsh environments or high-stress uses, you want this kind of reliability. That’s why many engineers still choose traditional pcb assembly for mission-critical projects.

Soldering Methods in PCB Assembly

Once you finish placing components, the next step in the pcb assembly process is soldering. Soldering locks each lead in place and creates a solid electrical connection. You can use different methods, but wave soldering is the most common for through hole boards.

In wave soldering, you pass the pcb over a wave of molten solder. The solder flows up through the holes and around each lead. This method works fast and gives you consistent results. Before the soldering wave, the pcb goes through a preheating stage. Preheating helps prevent thermal shock and ensures the solder joints come out smooth and strong.

Here’s a quick look at the typical temperature profiles and materials used in wave soldering for through hole pcb assembly:

Technique | Temperature Range (°C) | Notes |

|---|---|---|

Wave Soldering | Preheating minimizes thermal shock and ensures quality joints. | |

Through-Hole Soldering | 250 - 300 | Used for larger components needing strong connections. |

You might also see hand soldering in the pcb assembly process, especially for prototypes or special components. Skilled technicians use soldering irons to make precise joints. This method takes more time but gives you flexibility for unique designs.

LTPCBA uses both automated and manual soldering, depending on your project’s needs. Their quality assurance team checks every joint to make sure your pcb meets the highest standards. This attention to detail sets LTPCBA apart from other providers.

Inspection and Testing Steps

After soldering, you want to make sure your pcb works perfectly. The inspection and testing steps in the pcb assembly process catch any problems before your board ships out. You can use several methods to check your pcb.

Visual inspection is the first line of defense. Technicians look for solder bridges, missing components, or misaligned parts. Automated Optical Inspection (AOI) systems scan the pcb for defects. These machines use cameras and software to spot even tiny issues.

You also want to test the electrical performance of your pcb. In-circuit testing checks each connection and component. Functional testing simulates real-world use to make sure your pcb does its job. LTPCBA uses advanced testing equipment to verify every board. Their team follows strict quality control procedures, so you get a pcb you can trust.

If you need a high-reliability product, you want a provider who takes inspection seriously. LTPCBA’s commitment to quality assurance means your pcb assembly process includes multiple checks at every stage. This reduces the risk of failure and gives you peace of mind.

Tip: Always ask your provider about their inspection and testing steps. A thorough pcb assembly process saves you time and money in the long run.

You can see why the pcb assembly process for through hole boards stands out. You get mechanical strength, reliable connections, and careful quality control. Whether you need traditional pcb assembly for a prototype or a full production run, LTPCBA has the technology and expertise to deliver.

Choosing a Through Hole PCB Assembly Service

When you look for a through hole pcb assembly service, you want more than just a finished board. You want a partner who understands your needs and delivers quality every time. Let’s break down what you should expect from a top-tier provider like LTPCBA.

LTPCBA Quality Standards

You deserve a through hole pcb assembly service that puts quality first. LTPCBA follows strict international standards, including ISO, IATF, and UL certifications. These certifications show you that the company meets global requirements for pcb assembly. You can trust that every pcb meets high standards for safety and performance.

LTPCBA uses advanced inspection tools and automated systems. These tools catch even the smallest issues during the pcb assembly process. You get a pcb that works right the first time. The company’s 99.5% pass rate proves its commitment to quality. When you choose LTPCBA, you know your pcb assembly will meet your expectations.

Here’s a quick look at what LTPCBA’s quality standards mean for you:

Quality Feature | What You Get |

|---|---|

ISO, IATF, UL Certified | Reliable and safe pcb assembly |

99.5% Pass Rate | Fewer defects, less rework |

Automated Inspection | Consistent quality on every pcb |

Skilled Technicians | Careful handling of your pcb assembly |

Note: Always ask your provider about their certifications. This step helps you avoid problems later.

Service Transparency and Communication

You want clear answers and fast support from your through hole pcb assembly service. LTPCBA stands out because of its open communication and quick response times. You can get a quote in just 2-3 working days. If you have questions, the support team answers you within 24 hours.

Good communication means you always know the status of your pcb assembly. LTPCBA keeps you updated at every stage. You never feel left in the dark. If you need changes or have special requests, the team listens and responds quickly.

Here’s what you should expect from a transparent through hole pcb assembly service:

Clear pricing with no hidden fees

Regular updates on your pcb assembly progress

Fast answers to your questions

Support for changes or special needs

Tip: Choose a provider who values your time and keeps you informed. This approach saves you stress and helps your project succeed.

Material and Board Specifications

You need a through hole pcb assembly service that understands your material and board requirements. LTPCBA works with a wide range of pcb materials and can handle complex designs. Whether you need a simple single-layer pcb or a multi-layer board, the team has the skills and equipment to deliver.

You can specify the type of components, board thickness, and finish you want. LTPCBA sources high-quality parts for every pcb assembly. The company checks each material before use, so you get a reliable pcb every time.

Here’s how LTPCBA handles your pcb assembly needs:

Accepts custom board sizes and shapes

Supports various pcb materials (FR4, Rogers, etc.)

Handles both leaded and lead-free pcb assembly

Offers mixed assembly for boards with both through hole and surface-mount parts

You get flexibility and quality with every pcb assembly. LTPCBA’s experience means your board meets your exact needs, whether you build prototypes or full production runs.

Callout: Always share your material and design specs early. This step helps your through hole pcb assembly service deliver the best results.

When you choose LTPCBA, you get more than just a pcb. You get a partner who cares about your success. The company’s focus on quality, transparency, and technical skill makes it a top choice for any pcb assembly project.

You now know the key steps in the through-hole pcb assembly process. Look for a provider with strong pcb quality checks, clear support, and trusted certifications. Always ask about their pcb experience. Ready to start? Choose LTPCBA for reliable service and customer satisfaction every time.

FAQ

What makes through-hole PCB assembly stronger than surface-mount?

You get more strength because the leads go through the board. This helps your PCB handle stress and vibration better than surface-mount.

How fast can LTPCBA deliver my assembled PCB?

You usually get a quote in 2-3 days. LTPCBA works quickly to ship your finished PCB on time.

Can I order both prototypes and large batches from LTPCBA?

Yes, you can. LTPCBA supports small prototypes and mid-volume production runs. You get flexibility for any project size.

See Also

Ultimate Resource for Understanding Through Hole PCB Assembly

Choosing Between SMT and Through-Hole for Your Project

Selecting the Best Through Hole PCB Assembly Service for Industry

Understanding Full Turn-Key Solutions for PCB Manufacturing

Evaluating Reliability: Through Hole PCB Assembly versus SMT