Full Turnkey PCB Assembly Versus Partial Assembly What’s the Real Difference

The main difference between full turnkey PCB assembly and partial turnkey service in PCB assembly lies in the level of control, cost, and convenience. With full turnkey PCB assembly, LTPCBA manages the entire process, from sourcing components to assembling the printed circuit boards, providing a seamless and hassle-free experience. In contrast, partial turnkey assembly allows customers to supply some of their own components, giving them more involvement in the project. LTPCBA offers both full turnkey PCB assembly and partial turnkey options for printed circuit board projects, ensuring top-quality results for every order.

Aspect

Partial Turnkey Assembly

Full Turnkey PCB Assembly

Customer Involvement

High

Low

Cost

Lower

Higher

Time

Longer

Shorter

Quality

Variable

Generally higher

Key Takeaways

Full turnkey PCB assembly does every step. It gets parts, puts them together, and tests them. This makes things fast and easy. It is also more reliable. Customers do not have to do much.

Partial assembly lets customers bring their own parts. This gives them more control. It can help save money. But it takes more work. Customers must watch their parts closely.

You should pick full turnkey or partial assembly based on your project. Think about how hard your project is. Think about your budget and time. Also, think about how much control you want over parts and quality.

Quick Comparison

Key Differences

You pick full turnkey PCB assembly or partial assembly based on what you need. It depends on how much control and convenience you want. The table below shows the main differences:

Aspect | Full Turnkey PCB Assembly | Partial Turnkey PCB Assembly |

|---|---|---|

Scope of Services | The provider does everything from start to finish. This includes design, getting parts, making the PCB, putting it together, testing, packing, and delivery. | The customer gives some parts or PCBs. The provider does the rest, like putting it together, testing, and checking at the end. |

Customer Involvement | The customer does not do much. The provider handles the whole job. | The customer does more. They get some parts or PCBs themselves. |

Ideal For | This is good for people who want an easy process. They do not want to be involved much. | This is good for people who want to pick their own parts or save money. |

Benefits | It is easy, saves money, has good quality, is fast, and you only talk to one company. | You get to pick special parts, keep your ideas safe, and save money. |

Full turnkey PCB assembly makes it easy to work with vendors. You only need to talk to one company for the whole job. This helps stop mistakes and delays.

Turnkey PCB assembly lets you order any amount you need. LTPCBA can help with small or big orders.

Turnkey PCB assembly gives extra help. They can ship your boards and keep track of parts for you. This makes things easier.

Partial turnkey PCB assembly lets you give special or expensive parts. You have more control and can keep your ideas safe.

Partial turnkey PCB assembly can help you spend less and get your boards faster. Work can start with your parts while LTPCBA gets the rest.

LTPCBA does both turnkey PCB assembly and partial assembly. They use new technology and check quality carefully. The company makes customers happy by giving good printed circuit board solutions for every need.

Full Turnkey PCB Assembly

Process Overview

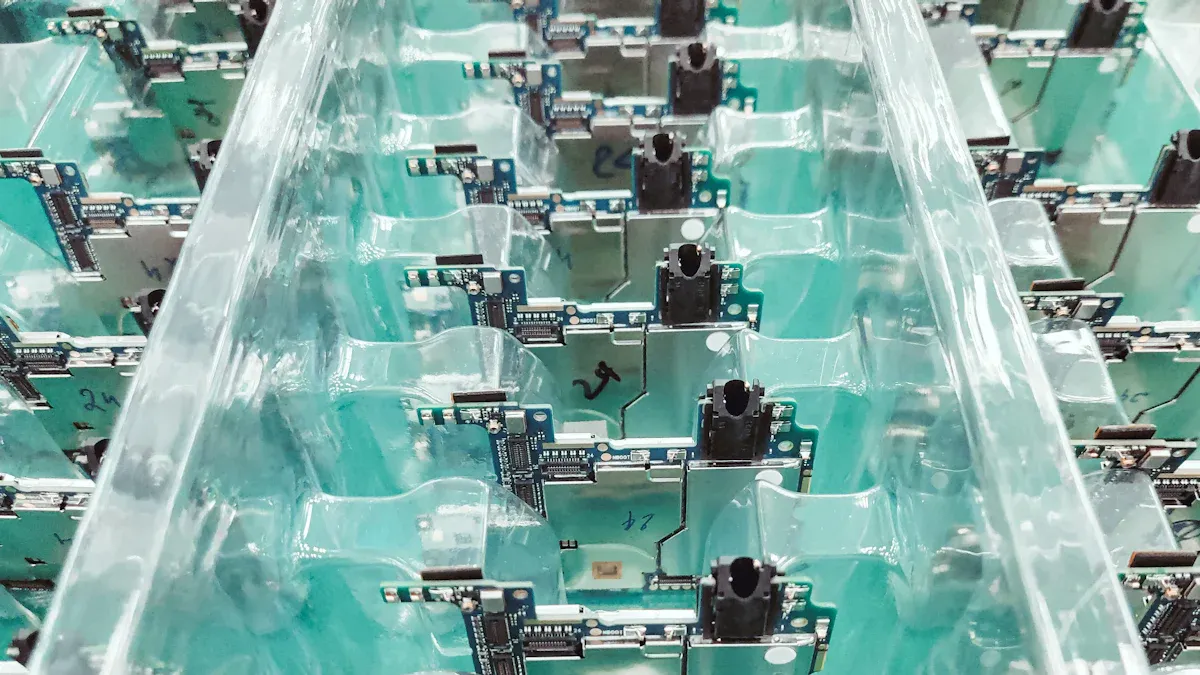

Full turnkey PCB assembly takes care of every step. It starts with checking the design to find mistakes early. LTPCBA uses new machines and checks quality at each step. The steps are:

They check the design with DFM and DFA to spot problems.

They make the PCB by doing lamination, drilling, copper etching, solder mask, and silkscreen printing.

They look at all parts before using them to make sure they are good.

They put on solder paste with special stencils.

Machines place the parts on the board.

They check and test the board at every step, using AOI and electrical tests.

LTPCBA uses modern tools like reflow ovens and inspection machines. Their full turnkey service helps make boards faster and better.

Benefits

Turnkey pcb assembly has many good points for customers. LTPCBA does all the work, so customers save time. They do not have to talk to many companies. This helps stop delays. Turnkey pcb assembly can cost less because services are combined. There are fewer mistakes. Customers only need to talk to one company. LTPCBA gives expert help for both small and big orders. They check quality carefully, so results are always good. Problems get fixed fast.

Note: Full turnkey pcb assembly lets customers see where their boards are and helps keep track of parts. This makes everything easy and smooth.

Drawbacks

Full turnkey pcb assembly is not best if you want to use your own special parts. Some people want more control over picking parts. But for most jobs, turnkey pcb assembly is better. LTPCBA’s full turnkey service gives great quality, works fast, and makes customers feel safe about their order.

Partial Assembly

Process Overview

Partial turnkey assembly is also called kitted pcb assembly. It lets customers have more control over their projects. In this process, customers give some or all parts to LTPCBA. LTPCBA does the rest of the work. Here are the steps:

The customer picks and sends special parts or PCBs.

LTPCBA checks all the parts to make sure they are good.

The team keeps the parts in safe places to protect them.

LTPCBA uses machines to put the boards together.

They test the boards to make sure they work well.

Partial turn key service is good for companies with extra parts. It is also good for those who want to use special parts. This way, people can make their boards just how they want.

Benefits

Partial turnkey services have many good points. Customers can control important parts. They can make sure the boards fit their needs. This way helps save money by using parts they already have. Customers can also check the quality of their own parts. Kitted pcb assembly lets work start faster. LTPCBA can begin with the parts you send while getting the rest. This option is best for projects that need special parts.

Tip: Partial turnkey services help companies waste less and keep track of their parts better.

Drawbacks

Partial turnkey needs more work from the customer. Customers must keep track of all the parts and send them on time. They are also in charge of making sure their parts are good. Kitted pcb assembly means customers and LTPCBA talk more. But having more control and choices is often worth it.

Turnkey PCB Assembly vs Partial

Cost

Cost is very important when picking between turnkey pcb assembly and partial assembly. Turnkey pcb assembly covers all steps, like getting parts, making the PCB, putting it together, and testing. This way usually costs more at first, but you can save money because they buy in bulk and work faster. Partial turnkey or kitted pcb assembly lets customers bring their own parts, which can make the starting price lower. But this means the customer has to find good parts and might pay more if parts are late or not good.

The table below shows how the costs compare:

Aspect | Full Turnkey Assembly | Partial Turnkey Assembly |

|---|---|---|

Service Scope | PCB fabrication, parts procurement, and assembly | Customer supplies some components or PCBs; assembly only |

Lead Time | Includes procurement and fabrication; typically 7-10 days or more | Starts after receipt of all components and PCBs from customer |

Cost Impact | Generally higher total cost due to component procurement and longer lead times | Potentially lower cost by using customer-supplied parts but shifts procurement risk to customer |

Expedited Service Cost | Increases cost by 30%-200% for shorter lead times | Similar cost increase if expedited, but depends on supplied parts availability |

Pricing Range (per panel) | $50 to $1,500 depending on complexity and volume | Varies, generally lower due to reduced procurement scope |

Customer Involvement | Low; turnkey vendor manages supply chain and procurement | High; customer responsible for parts procurement and risk management |

Many things change the total cost of turnkey pcb assembly services:

Getting parts through the manufacturer’s network can save money and make sure parts are real.

The bill of materials is the biggest cost. Using other parts can help save money.

The size, thickness, and how hard the PCB is to make changes the price.

Faster jobs cost more, but waiting longer can save money.

Making more boards at once makes each one cheaper.

Special materials and following rules can make it cost more.

Testing, packing, and shipping also add to the price.

Turnkey pcb assembly is often a good deal for many projects, especially when you think about getting all parts from one place and having less risk. Partial turnkey can also save money if you already have parts or need special ones, but you must watch everything closely.

Lead Time

Lead time is also very important. Turnkey pcb assembly makes things faster by handling everything from start to finish. This stops delays and helps keep the schedule on track. Full turnkey assembly usually takes 10 to 16 working days, from checking the design to shipping. Partial assembly, where the customer brings some or all parts, can make the building part faster, taking only 1 to 5 working days. But the whole job depends on how fast the customer sends the parts.

Assembly Type | Average Lead Time (Working Days) |

|---|---|

10 - 16 | |

Partial/PCB Assembly Alone | 1 - 5 |

Turnkey pcb assembly gives more steady lead times because the company controls everything. Partial turnkey jobs can be late if parts come late or are not right. LTPCBA’s turnkey services let customers track orders and get quick help, so they can meet tight deadlines.

Quality

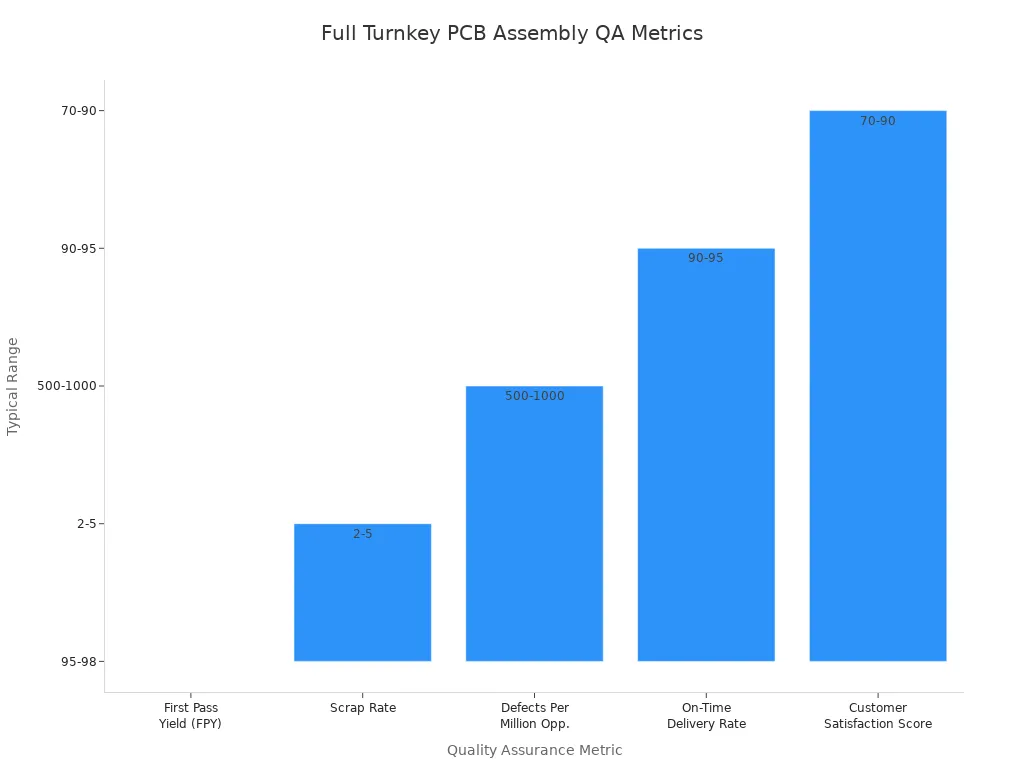

Quality is very important for every PCB project. Turnkey pcb assembly gives better quality by using strong tests and checking at every step. Full turnkey assembly uses in-circuit testing, functional testing, AOI, and X-ray inspection. These checks make sure each board is good and meets what the customer wants.

Full Turnkey PCB Assembly (Typical Range) | |

|---|---|

First Pass Yield (FPY) | 95% to 98% |

Scrap Rate | Below 5% (as low as 2%) |

Defects Per Million Opportunities (DPMO) | 500 to 1000 |

On-Time Delivery Rate (OTDR) | 90% to 95% (Top performers > 98%) |

Customer Satisfaction Score (CSAT) | 70% to 90% (Excellent > 80%) |

Turnkey pcb assembly from LTPCBA has a 99.5% pass rate, showing strong checks and happy customers. Partial turnkey projects depend on the customer for good parts, which can change the quality. Turnkey services give one company to talk to, making it easier to keep high standards and get a better product.

Flexibility

Flexibility is important for customers with special needs. Turnkey pcb assembly is simple, but you cannot pick every part yourself. Partial turnkey lets customers bring special or custom parts, so they can make boards just how they want. This mix of kitted and turnkey helps customers use rare or special parts and still get good assembly and checks.

Customers like being able to make more boards or just a few.

Clear updates and fast answers help customers know what is happening.

Good checks are always important, no matter who brings the parts.

Turnkey pcb assembly can change to fit new project needs, giving both ease and trust.

LTPCBA’s turnkey services can fit any project size or type. Whether you want full turnkey or partial, LTPCBA gives a good, high-quality answer for every need.

Choosing the Right Service

Project Needs

What your project needs will help you pick the right service. If your project is hard or has many parts, turnkey pcb assembly is best. This service does every step and checks quality all the way. If your project is simple or uses easy-to-find parts, partial turn key service might work better. People who want more control or have special parts often pick partial turn key for more choices.

Criteria | Full Turnkey PCB Assembly | Partial Turnkey PCB Assembly |

|---|---|---|

Best for complex builds | Best for simple builds | |

Component Sourcing | Provider manages all | Customer supplies some |

Customization | Limited | High |

Budget

How much money you have is important. Turnkey pcb assembly puts all costs together, so it is easier to plan. This way helps companies avoid surprise costs and problems with getting parts. Full turn key service makes it easier to know what you will spend and can save money by working with suppliers. Partial turn key service can cost less at first if you already have parts, but it can be risky and needs more checking. Companies should think about all costs, not just the first price.

Timeline

How fast you need your boards matters too. Turnkey pcb assembly is faster because one company does everything. This is good for projects that need to be done quickly or need fast samples. Partial assembly can take longer if customers are slow to send parts. Turnkey pcb assembly helps stop delays and makes sure boards arrive on time, which is important for busy companies.

Resources

What your company can do also helps you choose. If you do not have many workers or do not know much about pcb assembly, turnkey pcb assembly is a good choice. This service is easier to manage and checks quality for you. If your company is good at finding parts or wants more control, partial assembly gives you more choices. LTPCBA says it is smart to talk about your project early. Their team can help you pick the best service for your needs, money, and time, so you get good boards every time.

Tip: If you talk to LTPCBA early, you can find the best way to save money and get good boards that fit your project.

Real-World Scenarios

When to Choose Full Turnkey

Many companies pick turnkey pcb assembly for a simple process. For example, a tech startup wants to launch a smart electric meter. They have a short deadline and trouble finding chips. They choose turnkey pcb assembly so LTPCBA does every step. LTPCBA gets the parts and tests the boards. This saves time and lowers risk. The company uses LTPCBA’s strong supply chain and expert help. They get their boards on time, save 20% on costs, and avoid delays.

Turnkey pcb assembly is good for projects needing high quality and fast shipping. Medical device makers, like those making blood oxygen sensors, use turnkey services. They trust LTPCBA to keep their ideas safe and make great products. Customers say turnkey pcb assembly brings on-time delivery and good communication. There are fewer problems. Teams can work on design while LTPCBA handles the rest.

Tip: Turnkey pcb assembly is best for hard projects, big orders, or when you need top quality and trust.

When to Choose Partial Assembly

Partial assembly is for customers who want more control over parts. For example, a small electronics company has special parts for a three-phase electric meter. They pick partial assembly and send these parts to LTPCBA. This helps them save 15% on costs and get global certifications. Partial assembly lets them use rare or special parts and still get LTPCBA’s help.

Customers who want flexibility and to protect their designs often choose partial assembly. They can check their own parts and waste less. Reviews show that clear talks and strong support from LTPCBA help projects go well. Partial assembly is great for test boards, small orders, or custom jobs.

Customer Profile | Best Choice | Key Benefits |

|---|---|---|

Tech Startup | Full Turnkey | Fast delivery, risk reduction, high quality |

Medical Device Manufacturer | Full Turnkey | IP protection, strict quality control |

Small Electronics Firm | Partial Assembly | Cost savings, use of custom components |

Hobbyist/Student | Partial Assembly | Flexibility, hands-on involvement |

Full turnkey PCB assembly handles all the steps for you. It is fast and easy. The company checks quality at every step.

Partial assembly lets you make more choices. You get more control and can change things. But you have to do more work and keep track of parts.

The best choice depends on how hard your project is. It also depends on how much money and help you have.

LTPCBA’s team helps customers pick the best PCB assembly for any project.

FAQ

What is the main advantage of full turnkey PCB assembly?

Full turnkey PCB assembly helps save a lot of time. LTPCBA does every step, like getting parts and testing the boards. Customers get finished boards without doing much work.

Can customers supply their own components for assembly?

Yes, customers can send their own parts. LTPCBA offers partial assembly for this. The team will finish putting the boards together.

How does LTPCBA ensure quality in PCB assembly?

LTPCBA checks boards with special tools like AOI and X-ray. The company follows strict rules to make sure boards are always good and reliable.

See Also

Deciding Between Full Or Partial Turnkey PCB Assembly

Understanding Complete Turnkey PCB Manufacturing And Assembly

How To Select The Ideal One-Stop PCB Assembly Provider

All-Inclusive PCBA Solutions Covering Manufacturing To Testing

Boosting Project Speed With Quick-Turn PCB Assembly Prototypes