What Is Full Turn-Key PCB Manufacturing and Assembly

Full turn-key PCB manufacturer services provide a comprehensive solution for your needs. One company manages everything, including design, sourcing parts, assembly, testing, and delivery. This approach eliminates the need to coordinate with multiple companies, saving you both time and energy.

Choosing a full turn-key PCB manufacturer benefits your business in numerous ways. It accelerates production while maintaining consistent quality. Additionally, you can save money through bulk discounts and reduced unexpected costs. By allowing a full turn-key PCB manufacturer to handle the entire process, you can concentrate on innovation and addressing customer demands. Your partner ensures that the final product meets your exact specifications.

Key Takeaways

Full turn-key PCB manufacturing handles design, parts, assembly, and delivery together.

This process makes production faster, cutting lead times by 60%.

Using full turn-key services saves money with bulk buying and fewer extra costs.

Strict quality checks ensure reliable PCBs with fewer problems and happy customers.

Working with one provider avoids confusion, so you can focus on new ideas and customer needs.

What Does a Full Turn-Key PCB Manufacturer Offer?

PCB Design and Prototyping

A full turn-key PCB manufacturer helps with design and prototypes. They use their skills to turn your ideas into working designs. Their support ensures your printed circuit board meets standards and works well. Prototyping lets you test and improve your design before production. This step reduces mistakes and ensures the product fits your needs.

Evidence Type | Description |

|---|---|

Collecting data from production to check important dimensions. | |

Process Capability Studies | Studying data to see how tool wear or workers affect results. |

Continuous Improvement | Updating tolerances to match better manufacturing methods. |

Industry Implementation | Using these methods to improve quality and save costs. |

These steps make products more reliable and give you confidence in the outcome.

Component Sourcing and Procurement

Turnkey PCB assembly handles finding and buying parts. Manufacturers work closely with suppliers to get quality components. They also help suppliers improve with new technologies. Digital tools make the supply chain easier to manage, avoiding delays. This process ensures you get the right parts on time, keeping your project moving.

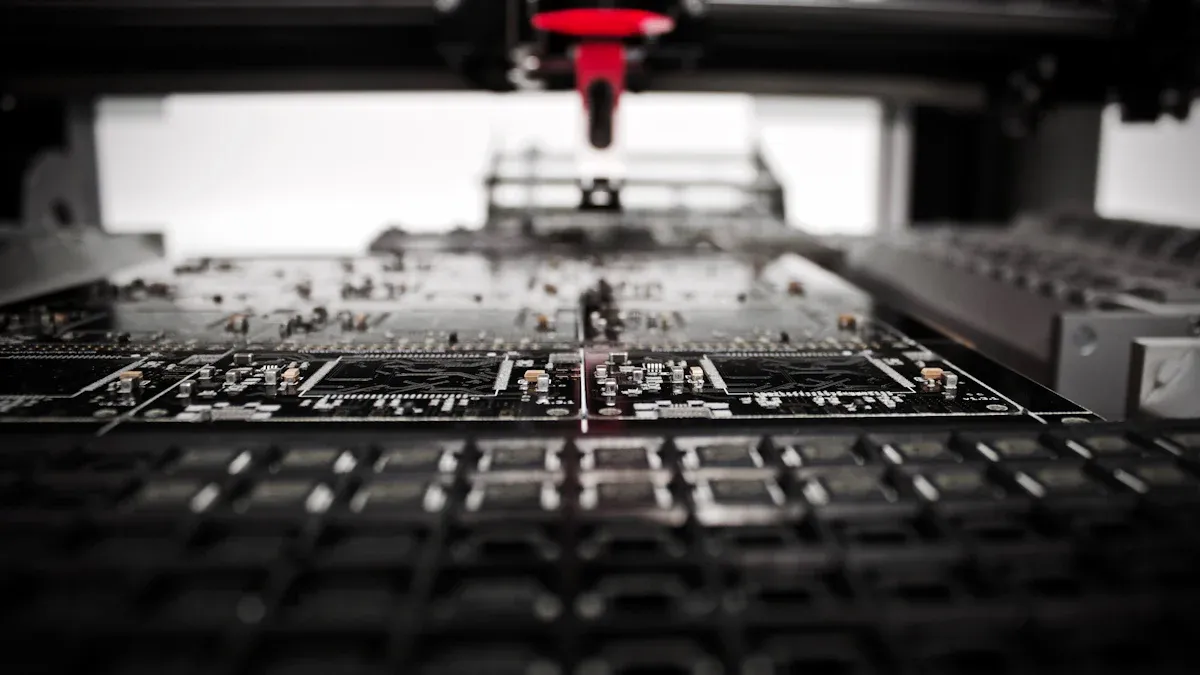

PCB Fabrication and Assembly

The PCB assembly process combines making and assembling in one place. This setup saves time and makes moving from design to production smoother. Advanced methods ensure good quality and consistency. Unlike older methods, turnkey PCB assembly allows faster updates, easier scaling, and better accountability. Whether you need quick prototypes or large orders, this method works best.

Aspect | Turnkey PCB Assembly | Traditional Separated Processes |

|---|---|---|

Lead Times | Shorter, all done in one place | Longer, due to switching between vendors |

Design to Production | Faster with early feedback | Slower due to back-and-forth communication |

Revisions and Changes | Quick updates across the process | Delays from working with multiple vendors |

Scaling Production | Easy scaling from small to large runs | Requires finding new vendors or deals |

This method is great for businesses needing fast, high-quality results.

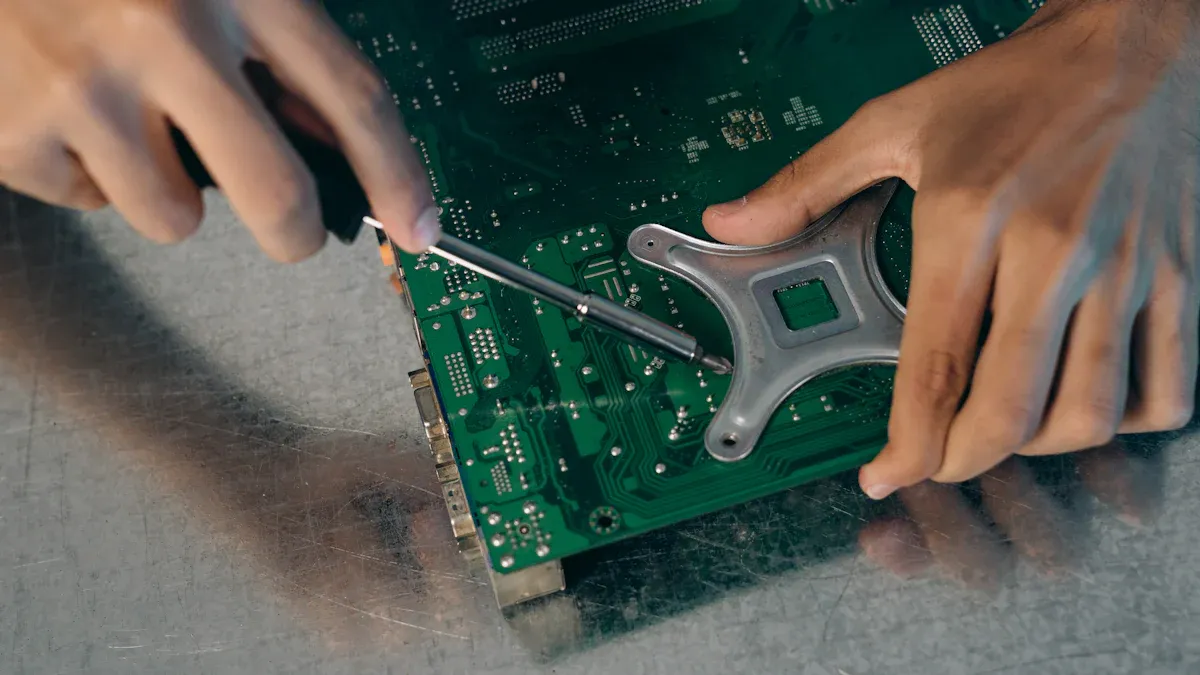

Testing and Quality Assurance

Testing ensures your PCB works well and meets top standards. Full turn-key PCB makers use advanced tests to check performance. These include in-circuit testing, functional testing, and optical inspection. Each test makes sure your PCB works in real-life situations.

Quality checks show how effective this process is. For example:

Metric | Value Range |

|---|---|

Order Fulfillment Rate | |

Scrap Rate | Below 5% (as low as 2%) |

First Pass Yield (FPY) | 95% to 98% |

These numbers prove the accuracy of full turn-key PCB work. Low scrap rates and high first-pass yields save money and reduce waste. Also, defects per million opportunities (DPMO) stay between 500 and 1000. This shows the high quality of production.

Choosing a full turn-key PCB maker gives you strong testing systems. This ensures your PCB works as planned and is reliable in its environment.

Packaging and Delivery

Packaging and delivery keep your PCB safe during shipping. Full turn-key PCB makers use special materials to protect products. Anti-static bags, foam, and custom boxes stop damage from shocks or moisture.

Delivery stats show how dependable this process is:

Metric | Industry Benchmark |

|---|---|

On-Time Delivery Rate (OTDR) | 90% to 95% (Top performers > 98%) |

Customer Satisfaction Score (CSAT) | 70% to 90% (Excellent > 80%) |

First Pass Yield (FPY) | 70% to 90% (High performers > 90%) |

High on-time delivery rates keep your project on track. Great customer satisfaction scores show care in packaging and shipping. These make full turn-key PCB services a smart choice.

By improving packaging and delivery, full turn-key PCB makers avoid delays. They ensure your products arrive safely and in perfect condition.

How Turnkey PCB Assembly Differs from Other Approaches

Full Turn-Key vs. Partial Turn-Key

Full turn-key and partial turn-key PCB assembly differ in responsibility. In partial turn-key, you handle some tasks like buying parts. The manufacturer takes care of the rest. Full turn-key means the provider does everything, from sourcing parts to delivery.

Aspect | Partial Turn-Key PCB Assembly | Full Turn-Key PCB Assembly |

|---|---|---|

Definition | You manage part of the process | Provider handles the entire process |

Responsibilities | You supply parts; provider does the rest | Provider sources and assembles everything |

Advantages | More control over specific parts | Faster and simpler process |

Challenges | Needs more effort and coordination | Less control, higher upfront costs |

Full turn-key is ideal if you lack time or skills. It lets you focus on your business while ensuring smooth production.

Full Turn-Key vs. Contract Manufacturing

Contract manufacturing and full turn-key PCB assembly differ in organization. Contract manufacturing involves working with many vendors for parts and assembly. This can cause delays and errors. Full turn-key combines everything under one company.

Aspect | Turnkey PCB Assembly | Contract Manufacturing |

|---|---|---|

Lead Times | Shorter, with one team handling all tasks | Longer, due to switching between vendors |

Quality Consistency | High, with one quality control system | Varies depending on the vendor |

Accountability | One company is responsible | Responsibility is shared among vendors |

Hidden Costs | Few, most costs are included | More, like shipping and vendor fees |

Turnkey PCB assembly avoids miscommunication and delays. It ensures better quality and fewer hidden costs.

Advantages of Turnkey PCB Assembly Over Other Models

Turnkey PCB assembly has many benefits compared to other methods. It simplifies work by giving you one contact for everything. This reduces the hassle of managing multiple vendors. It also speeds up production and improves quality.

Key Performance Indicator | Turnkey PCB Assembly | Traditional Separated Processes |

|---|---|---|

Higher upfront cost, but saves money later | Lower upfront cost, but more expensive long-term | |

Time Efficiency | Faster production | Slower production |

Quality Outcomes | Consistent, with early error detection | Inconsistent, with late error detection |

Turnkey PCB assembly reduces mistakes and saves time. Its streamlined process makes it a smart and cost-effective choice.

Benefits of Choosing a Full Turn-Key PCB Manufacturer

Cost Efficiency

Picking a full turn-key PCB maker saves you money. One company handles everything, so no extra shipping costs. This reduces transportation and handling fees. They buy parts in bulk, getting lower prices. These savings are passed on to you. For instance, TechInnovate cut costs by 23% using turnkey services.

Combining design, sourcing, and assembly avoids repeated steps. This makes production smoother and cheaper. Fewer mistakes mean less money spent fixing errors. Faster timelines, from 10-12 weeks to 4-5 weeks, help you sell products sooner. This boosts your profits and saves time.

Simplified Communication

Using one provider for turnkey PCB work makes talking easier. You don’t need to manage many vendors. One contact person handles everything, reducing confusion. Miscommunication is less likely, so there are fewer delays or mistakes.

Turnkey providers handle everything, from making PCBs to final assembly.

This clear communication ensures your needs are met. It also makes finding parts simpler and faster. With one company in charge, you can focus on your business. You won’t need to worry about the details of PCB production.

Faster Production Timelines

Turnkey PCB services speed up production by doing all steps together. Design, sourcing, assembly, and testing happen in one place. This avoids delays from switching between vendors. It helps you meet deadlines and satisfy customers quickly.

Quick prototype creation is another benefit. Finding design problems early saves time and money. Turnkey providers can also adjust production size easily. Whether you need a few or many, they can deliver on time. This flexibility keeps your project on track, no matter its size.

Superior Quality Control

Top-notch quality control is key in full turn-key PCB manufacturing. Every step includes checks to ensure the final product works well. Manufacturers use advanced tests and systems to create reliable, high-performing PCBs.

Important practices like Design for Manufacturability (DFM) and internal reviews help make error-free boards. These steps make sure your PCB design is ready for production and works as planned.

DFM makes production easier and reduces mistakes.

Internal checks find problems early, keeping quality steady.

Here’s how full turn-key PCB services compare in quality:

Metric | Quick Turn PCB | Traditional PCB |

|---|---|---|

First Pass Yield | 98-99% | |

Defects Per Million Opportunities (DPMO) | 500-1000 | 50-500 |

Customer Return Rate | <1% | <0.5% |

These numbers show how effective full turn-key PCB quality control is. While traditional methods may slightly excel in some areas, turn-key services offer a smooth and reliable process.

With strong quality control, your PCB will work as expected, lowering the chance of costly failures.

Reduced Risk of Errors

Full turn-key PCB manufacturing lowers errors by managing all steps in one place. This setup avoids problems and ensures design, production, and assembly work together smoothly.

One company handles everything, making communication simple and clear. This teamwork ensures your PCB design becomes a working product without issues.

Unified production prevents delays from switching between vendors.

Expert engineers fix design problems early.

Quality checks at every step keep standards high.

Turnkey services also speed up production, helping you launch products faster. Fixing issues early makes your PCB more dependable.

Lead times shrink by skipping vendor handoffs.

Quality stays consistent with one team in charge.

Choosing full turn-key PCB services saves time and ensures fewer mistakes for a smoother production process.

Steps to Begin with Turnkey PCB Assembly

Picking the Best Full Turn-Key PCB Manufacturer

The first step is finding the right manufacturer. Choose one with good skills, quality materials, and enough capacity for your project. Check their testing methods and prototype services to match your needs.

Criteria | Description |

|---|---|

Can handle different needs like reliable PCBs and advanced designs. | |

Material Quality | Uses materials that meet performance and reliability standards. |

Production Capacity | Can manage your project size and deadlines without losing quality. |

Quality Control | Follows strict testing to ensure products work well. |

Turnkey Services | Offers combined services to make managing the project easier. |

Prototyping Help | Lets you test and improve designs early in the process. |

A dependable manufacturer makes your project easier. They provide all-in-one services and keep quality steady. This helps your PCB production stay smooth and meet your goals.

Sending Design Files and Details

After choosing a manufacturer, send them your design files and needs. Share a complete Bill of Materials (BOM) and Gerber files. These show the PCB layout and parts needed. Add testing rules, order amounts, and delivery dates.

Documentation Type | Description |

|---|---|

Lists what the device must do, including use, performance, and risks. | |

Design Outputs | Includes drawings, specs, and plans approved for use. |

Verification | Proves outputs match input needs through tests and checks. |

Validation | Shows the device meets user needs before selling it. |

Change Control | Tracks and manages design changes to keep quality high. |

Design Reviews | Checks done after each stage to ensure quality and rules are followed. |

Clear documents help avoid mistakes. They also make sure your PCB design fits your project’s needs.

Checking Prototypes and Starting Production

Prototypes are small test versions of your PCB. Manufacturers make these to find and fix problems. Look over the prototypes to see if they meet your needs. Only approve production when the prototype works well.

PPAP Elements | |

|---|---|

Test Production Run | Part Submission Warrant (PSW) |

Measurement Study Results | Design Records |

Process Studies | Engineering Change Documents |

Validation Testing | Design FMEA (DFMEA) |

Packaging Check | Process Flow |

Control Plan | Process FMEA (PFMEA) |

Quality Sign-Off | Dimensional Results |

Approval at Gateway | Performance and material tests |

Prototypes help you improve your design. They ensure the final product works as planned. This step lowers risks and leads to a successful production run.

Tracking Progress and Getting Final Products

Keeping track of your project helps it stay on time. It also ensures your PCBs meet quality standards. Full turnkey PCB providers use smart tools to give updates. This keeps the process clear and easy to follow.

Modern systems use IoT, AI, and automated checks. IoT watches production in real-time. AI finds problems and makes work faster. Automated Optical Inspection (AOI) spots defects early. These tools work together to improve speed and quality.

Key performance indicators (KPIs) measure how well things are going. They show if the process is fast and accurate. Here are some common KPIs for PCB production:

KPI Name | KPI Average |

|---|---|

Production Cycle Time | |

First Pass Yield | 95% |

On-Time Delivery Rate | 97% |

Short cycle times mean quicker delivery. A high first-pass yield means fewer mistakes. A 97% on-time rate shows the service is dependable.

When you get your final products, they are handled with care. Smart factories and automation make production smooth. Green methods reduce waste and help the environment.

Using these tools and methods, you can trust the process. Your PCBs will arrive on time, meeting your needs and high-quality standards.

Full turn-key PCB manufacturing makes production easier. One provider handles design, parts, assembly, and delivery. This method cuts lead times by 60% and reduces defects by 86%. It also boosts production capacity by 300%. These changes save money and speed up product launches.

Picking a full turn-key PCB maker gives great results. Communication is simple, and you can focus on new ideas. Experts take care of the technical work. Try this smart solution to improve your PCB process. Reach out to a reliable provider to get started today.

FAQ

What is the difference between full turn-key and partial turn-key PCB services?

Full turn-key handles everything like design, parts, and delivery. Partial turn-key means you do some tasks, like buying parts. Full turn-key makes things easier, while partial gives more control.

How long does full turn-key PCB manufacturing take?

The time depends on order size and complexity. Full turn-key cuts lead times by 60%. Products are ready in 4-5 weeks, unlike 10-12 weeks with older methods.

Can I request changes after submitting my design?

Yes, you can make changes during the prototype stage. Full turn-key lets you adjust designs before production. Early fixes ensure the final product meets your needs.

Are full turn-key PCB services cost-effective?

Yes, they save money by combining steps and avoiding mistakes. Bulk buying and smooth processes lower costs. Full turn-key is a smart and affordable option.

What quality checks are included in full turn-key PCB manufacturing?

Full turn-key uses tests like in-circuit, functional, and optical checks. These tests ensure your PCB works well. Advanced systems reduce errors and improve reliability.

Tip: Ask your provider about their testing methods to match your project needs.