How to Assemble Flex PCBs for Optimal Performance

Accuracy is key for flex PCB assembly to work well. Flexible materials need gentle care to avoid harm and stay reliable. Problems like moisture and exact soldering can be tricky. But flex PCBs are light and easy to use. Steps like drying, adding solder paste, and testing help them perform their best.

Key Takeaways

Flex PCBs are thin and bendable, perfect for small designs and tight spots.

Placing parts correctly and soldering carefully are key for good performance and dependability of flex PCBs.

Keeping your workspace tidy and neat helps avoid errors and speeds up assembly.

Understanding Flex PCB Assembly

What Makes Flex PCBs Unique?

Flex PCBs are special because they can bend and twist. They don’t break when folded, unlike rigid boards. These boards use polyimide film, which is strong and flexible. Their thin design and rolled copper make them great for small spaces. Flex PCBs work well where space is tight or vibrations occur. They handle stress and fit into unique shapes, making them important in modern gadgets.

Advantages of Flex PCBs in Modern Applications

Flex PCBs save space and make designs more compact. They reduce connections, improving signals and cutting down interference. These boards absorb shocks, so they work in tough conditions. You’ll see them in medical devices like wearables and implants. They’re also used in tiny surgical tools like cameras and catheters. Flex PCBs are key for building reliable and efficient technology.

Key Considerations for Flex PCB Design

To make flex PCBs work well, follow some rules. Keep 20 mil space between holes and bends. Use smooth bends instead of sharp angles to avoid damage. Place small wires inside the bend’s center and leave 10 mil space near bends. Tear guards make bends stronger and last longer. Thin materials and polyimide layers add stability. By following these tips, you can create flex PCBs that work well in tough situations.

Getting Ready to Assemble Flexible PCBs

Checking Design and Details for Accuracy

Before starting, check the design and details carefully. This step makes sure the circuit meets standards and fits the process. Begin with a full design review and rule check. These steps find problems early, saving time and effort.

Use clear drawings and a complete list of parts (BOM) to guide you. Good documents stop mistakes and save time. Working with trusted makers can improve results. Testing prototypes and picking the right materials are also very important for success.

Tools and Parts Needed for Flex PCB Assembly

Having the right tools and parts is very important. Follow these steps to get ready:

Check all parts to make sure nothing is missing. Missing parts can slow you down.

Look at the PCB closely and test it for problems.

Use a stencil to add solder paste correctly for placing parts.

Plan where parts go, thinking about signals and heat.

Get all tools ready, like soldering irons, tweezers, and lamps, before starting.

These steps follow safety and quality rules, making the process smooth and reliable.

Creating a Safe and Tidy Workspace

A clean workspace helps you work faster and make fewer mistakes. Arrange tools and parts neatly to save time. Use trays or boxes to keep parts organized and reduce mess. Keep items you use often close by to work faster.

Tips for Organizing Your Workspace | Why It Helps |

|---|---|

Arrange tools and parts neatly | Saves time and avoids searching for items. |

Use trays or boxes for parts | Keeps things tidy and easy to find. |

Keep often-used items nearby | Speeds up work and reduces movement. |

A tidy workspace not only helps you work faster but also keeps you safe. It lowers the chance of accidents while assembling your flex PCB.

Step-by-Step Assembly Process for Flex PCBs

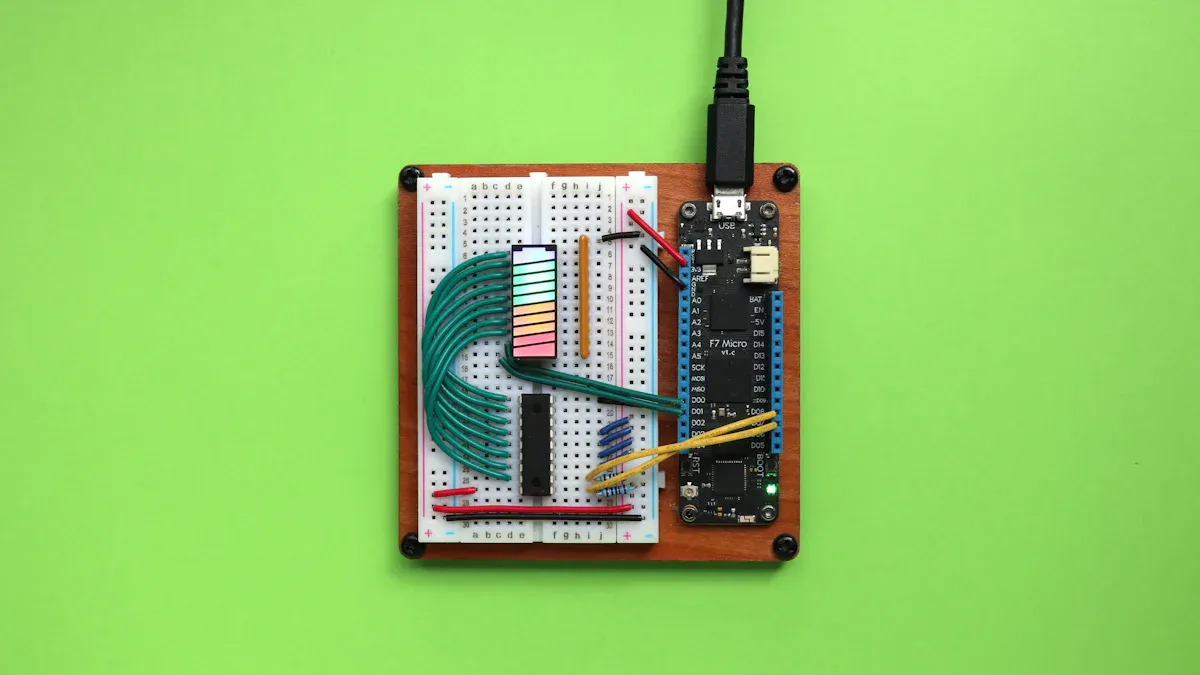

Techniques for Accurate Component Placement

Placing parts correctly is very important for flex PCB success. Start by checking the layout and marking where each part goes. Use a stencil to carefully add solder paste to the right spots. This helps hold parts in place during assembly.

Use tools like tweezers or vacuum pick-up devices to place parts. Handle the flexible board gently to avoid bending or breaking it. Arrange parts to reduce signal problems and keep heat spread out evenly.

Tip: Always check the direction of special parts like diodes and capacitors. If they’re placed wrong, the circuit won’t work.

By following these steps, you can place parts accurately and make your flex PCB work well.

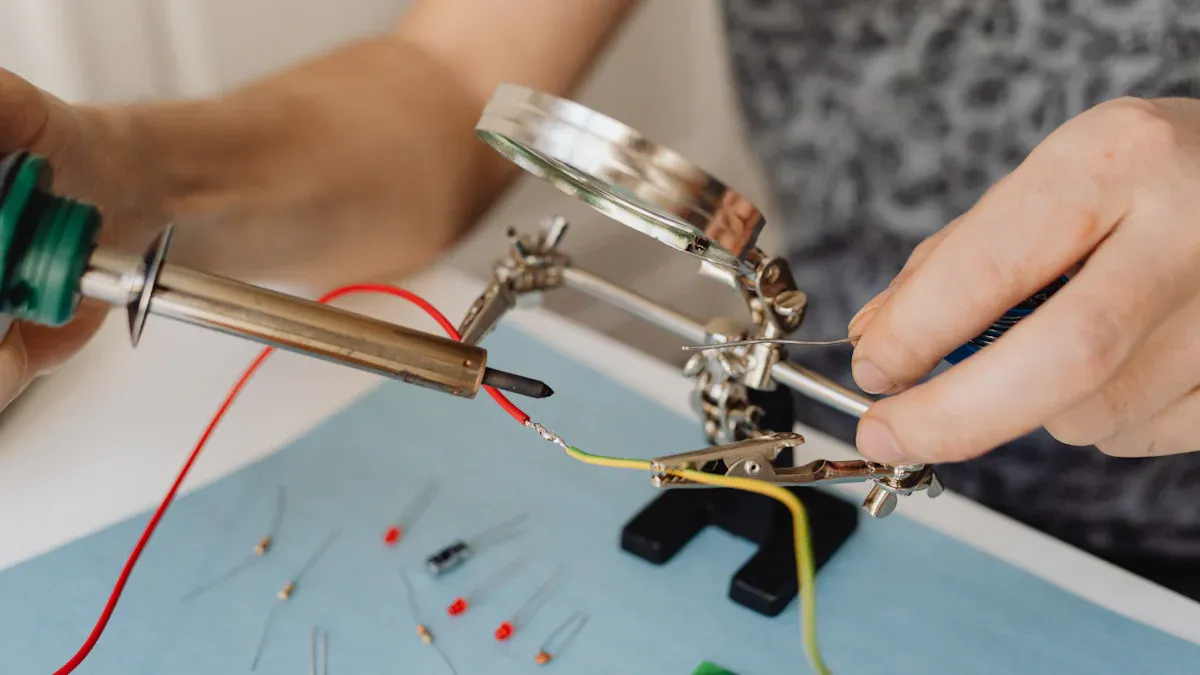

Soldering Methods for Flexible Materials

Soldering flexible boards needs careful handling to avoid damage. Pick a soldering iron that lets you adjust the heat. Use low-heat solder to protect the board from getting too hot.

When soldering by hand, heat the area evenly and don’t hold the iron too long. Add flux to help the solder flow and make strong connections. For reflow soldering, set the heat levels to match the board’s needs.

Note: Flexible boards can get damaged by too much heat. Watch the temperature closely while soldering to keep the board safe.

After soldering, check the joints to make sure they’re strong and even. Good soldering makes the board last longer and work better.

Inspection and Testing for Quality Assurance

Checking and testing are important to make sure the flex PCB works well. Start by looking at the board to find soldering mistakes, misplaced parts, or damage. Machines like AOI can spot problems like missing parts or solder bridges.

Electrical tests check if the board works and signals are clear. Use in-circuit tests to confirm connections and signal quality. Keeping tight controls helps avoid waste and ensures the board works consistently.

Use tools like charts and measurements to track how well the process is working. The table below shows helpful tools:

Description | Why It Helps | |

|---|---|---|

Control Charts | Show data changes over time | Find problems early |

Process Capability Indices (Cp, Cpk) | Check if outputs meet limits | Ensure good results |

Six Sigma Techniques | Reduce mistakes to very low levels | Improve process quality |

Tip: Use visual checks, AOI, and electrical tests together for the best quality control.

By using these testing methods, you can make sure your flex PCB is reliable and high-quality.

Best Practices for Flex PCB Assembly with LTPCBA

Using Carrier Plates for Stability During Assembly

Carrier plates help keep flexible circuit boards steady during assembly. These plates stop the board from bending or twisting while you work. Without them, parts might not align properly, or soldering could go wrong.

Using a carrier plate keeps the flex PCB flat and stable. This is very important when placing parts or soldering. Pick carrier plates made of heat-resistant materials like aluminum or stainless steel. These materials are strong and spread heat evenly, protecting the board from heat damage.

Tip: Make sure the carrier plate is clean before use. Dirt can cause problems and mess up the assembly process.

Managing Reflow Temperatures for Optimal Results

Reflow soldering is a key step in flex PCB assembly. Controlling the temperature carefully makes sure solder joints are strong and parts stay safe. Flexible materials like polyimide need exact heat control to avoid damage.

Watch the heat levels closely during reflow. Track things like peak temperature, soak time, and stability (PWI). The table below explains these terms:

Key Metric | Description |

|---|---|

Peak Temperature | Keeps heat within safe limits for the board. |

Soak Time | Ensures soldering happens without overheating parts. |

Process Window Index (PWI) | Shows how stable the process is in real time. |

Think about material type, board thickness, and part size when setting heat levels. Thicker boards or bigger parts may need more heating time. The table below shows how these factors affect heat control:

Factor | Impact |

|---|---|

Material Type | Changes how much heat the board can handle. |

Board Thickness | Affects how much heat the board absorbs. |

Component Size | Bigger parts need more heat and time. |

Note: Use SPC tools to check the reflow process. This helps reduce mistakes and keeps quality high.

Applying Adhesives to Secure Components

Adhesives hold parts firmly on a flexible circuit. They give extra support, especially in areas that move or face stress. Proper adhesive use stops parts from shifting and makes the board last longer.

To test adhesive strength, use proven methods. For example, the peel strength test checks how well the adhesive sticks to the board. The table below lists common tests:

Testing Method | Description |

|---|---|

Peel Strength Test | Checks how strong the adhesive bond is. |

Thermal Exposure Test | Tests how heat affects adhesive strength over time. |

Aged Sample Test | Simulates long-term use to see if the adhesive weakens. |

Apply adhesives in a thin, even layer to avoid extra material. Pick adhesives that can handle high heat during reflow soldering.

Tip: Let the adhesive fully dry before moving to the next step. This ensures it sticks well and avoids problems later.

Quality Control and Final Steps in the Assembly Process

Visual and Electrical Testing for Reliability

Testing makes sure your flex PCB works well in real life. Start by looking at the board to find scratches, misplaced parts, or bad soldering. Use magnifying tools to see small problems that might affect how it works.

Electrical tests check if the circuit works as planned. Machines measure things like resistance and capacitance to ensure the board meets its design. Reliability tests speed up aging to find weak spots that might fail later.

Testing Method | What It Does |

|---|---|

Finds visible problems like scratches, misaligned parts, or bad soldering. | |

Electrical Testing | Checks resistance and capacitance with machines to confirm design specs. |

Reliability Testing | Speeds up aging to find weak areas that could fail over time. |

Tip: Use all three tests—visual, electrical, and reliability—to make sure your flex PCB is high quality.

Proper Packaging to Prevent Damage

Packaging keeps your flex PCB safe during shipping. Anti-static bags stop static electricity from harming the board. Moisture barrier bags protect it from water damage. Bubble wrap cushions the board from bumps and shakes.

Pack the board tightly so it doesn’t move during shipping. Add labels to show how to handle it carefully. These steps keep your board safe until it arrives.

Anti-static packaging: Stops static electricity from damaging the board.

Moisture Protection: Keeps water away using special barrier bags.

Cushioning and shock absorption: Uses bubble wrap to protect from bumps.

Proper Labeling: Helps handlers know how to care for the shipment.

Secure Packaging: Stops the board from moving during shipping.

Note: Test your packaging to meet safety rules like MIL-STD-2073.

Continuous Improvement with LTPCBA's Expertise

LTPCBA helps improve flex PCB assembly with smart methods. Bend tests find weak spots in early designs to make them stronger. Automated machines make assembly faster and more accurate. Special reflow soldering methods work best for flexible boards.

They also use coatings to protect circuits from damage. Advanced tools check quality, and environmental tests make sure the board works in tough conditions.

Bend Testing: Finds weak areas in early designs to fix them.

Automation: Uses machines to make assembly faster and better.

Tailored Reflows: Adjusts soldering for flexible boards.

Environmental Testing: Tests boards in tough conditions to ensure reliability.

Continuous Improvement: Always works on making assembly better.

Tip: Work with LTPCBA to get expert help and better results for your flex PCB assembly.

Making flex PCBs work well needs careful planning and checks. Follow these steps for the best results:

Use tools like DRC and ERC to check designs early.

Inspect each layer with AOI to catch mistakes fast.

Do DFM checks early to avoid problems during production.

Why It Helps | What It Does |

|---|---|

Reduces assembly mistakes | Checking parts against BOM stops errors and saves time. |

Ensures good quality | Automated checks make sure prototypes work as planned. |

Early DFM checks | Fixing design issues early keeps production smooth and reliable. |

Focus on checking designs, materials, and quality during assembly. Working with LTPCBA gives you expert help and better tools for flex PCB success.

FAQ

What are the common mistakes to avoid during flex PCB assembly?

Parts placed in the wrong spots

Too much heat while soldering

Not enough glue to hold parts

Tip: Check part placement and heat settings to avoid problems.

How can you ensure the durability of flex PCBs?

Use strong materials, add protective layers, and test for tough conditions. These steps help the board last longer and work better.

Why is reflow soldering preferred for flex PCBs?

Reflow soldering spreads heat evenly and makes strong connections. It lowers the chance of harming the flexible board.

See Also

Key Considerations for SMT Assembly of Rigid-Flex PCBs

Effective Strategies for Optimizing SMT Lines in PCBA

Tips to Enhance Hardware Assembly for Improved Outcomes