How to Identify Reliable Fast-Track PCBA Services for Medical Device Manufacturing

Speed matters in medical device manufacturing. If you choose a fast track pcba medical partner, you reduce delays that can slow device production and impact profitability.

Short lead times help you bring innovative solutions to market faster.

Quick delivery improves patient care and keeps your company competitive.

A systematic approach lets you minimize risk and achieve successful outcomes.

Key Takeaways

Prioritize quality and certifications like ISO 13485 and FDA regulations when choosing a PCBA partner. This ensures compliance and reduces product recalls.

Select a partner that uses advanced technology, such as automated systems and 3D X-ray inspection. This leads to higher quality and fewer defects in medical PCB assemblies.

Evaluate lead times and scalability. A reliable partner should deliver within 1-5 days and adapt to changing production needs, ensuring timely product launches.

Fast Track PCBA Medical Criteria

Quality & Certifications

You must prioritize quality and certifications when selecting a fast track pcba medical partner. Medical pcb assembly demands strict compliance with international standards. These certifications and standards ensure your devices meet regulatory requirements and perform reliably in clinical settings.

Certification | Description | Key Aspects |

|---|---|---|

ISO 13485 | Quality management for medical devices | Risk Management, Process Validation, Traceability |

IEC 60601 | Safety for medical electrical equipment | Dielectric Strength, EMI Control |

FDA Regulations | U.S. compliance for medical devices | Design Controls, Material Safety, Traceability |

UL Certification | Safety and reliability | Market Acceptance, Risk Reduction |

You reduce product recalls and errors by choosing a partner with these certifications and standards. ISO 13485 enforces strict quality controls, leading to fewer malfunctions and longer product lifespans. This consistency boosts customer satisfaction and strengthens your brand reputation.

LTPCBA holds industry-recognized certifications, including ISO 9001, IATF, UL, and IPC-A-610. These credentials demonstrate LTPCBA’s commitment to compliance and quality management. You benefit from a 99.5% pass rate in product delivery, which reflects rigorous quality control and reliable medical pcb assembly.

Tip: Always verify your PCBA partner’s certifications and standards before starting a project. This step protects your business and ensures compliance with healthcare regulations.

Advanced Technology

Advanced technology drives the success of fast track pcba medical. You need a partner who uses cutting-edge equipment and processes to deliver high-quality medical pcb assembly. Modern PCBA lines feature automated systems, precise placement, and comprehensive testing protocols.

Technology Type | Description |

|---|---|

Surface Mount Technology (SMT) | Mounts components directly onto PCB surfaces |

Through-Hole Technology (THT) | Inserts leads into holes and solders to the opposite side |

Ultra-fine pitch placement | Places components with very small spacing for compact designs |

HDI PCB | High-density interconnect for more functions and reduced trace routing |

Flex and rigid-flex boards | Flexible PCBs for non-standard shapes and reduced weight |

N₂-enabled reflow soldering | Uses nitrogen to improve soldering quality |

3D X-ray inspection | Detects defects in PCB assemblies |

Automated conformal coating | Applies protective coating for durability |

You gain a competitive edge by working with a partner who invests in these technologies. Advanced PCBA technology leads to defect rates below 2%, compared to 10% in manual facilities. Design for Manufacturability (DFM) checks reduce design iterations by 70%, improving efficiency and turnaround time. Controlled production environments and multi-stage inspections ensure your medical pcb assembly meets strict compliance standards.

LTPCBA demonstrates superior capabilities in handling advanced PCBA technology, especially with BGA components. You benefit from precise placements, strong solder connections, and reliable performance. LTPCBA’s equipment aligns with industry standards, supporting high-quality output for fast track pcba medical projects.

Note: Innovations in PCBA, such as IoT connectivity and flexible electronics, are shaping the future of medical devices. You should choose a partner who stays ahead of industry trends.

Lead Times & Scalability

Turnaround time is critical in fast track pcba medical. You must select a partner who delivers rapid results without sacrificing quality. Medical pcb assembly projects often require quick prototyping and scalable production to meet market demands.

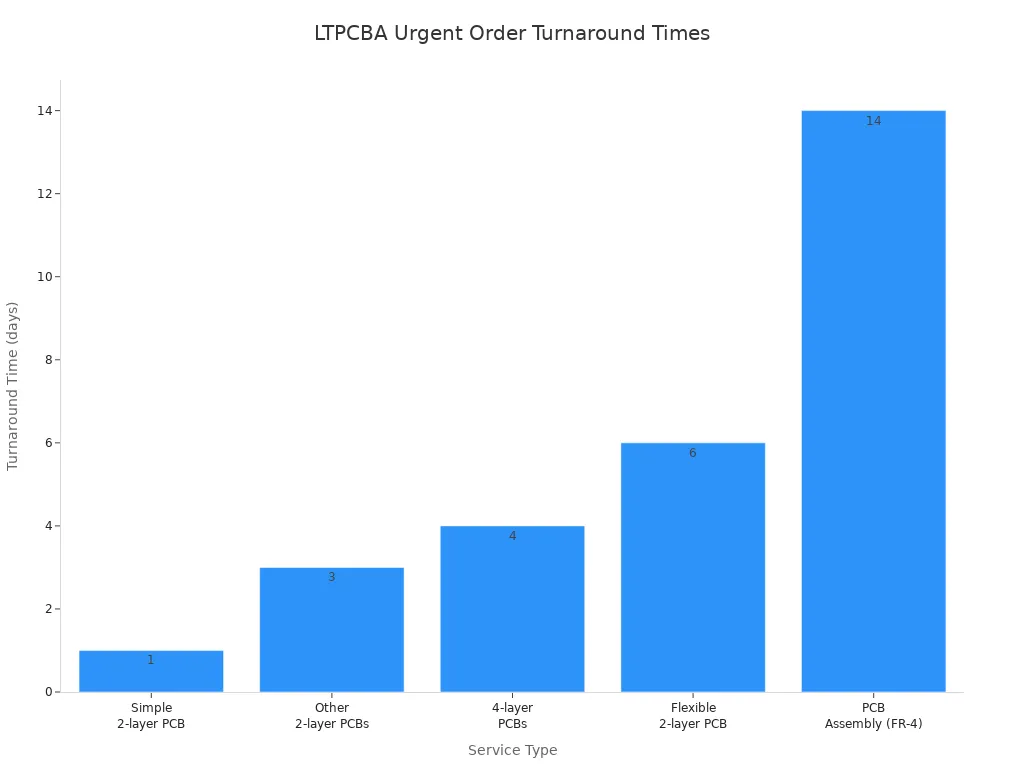

Fast-track PCBA services in the medical device sector offer lead times ranging from 1 to 7 days.

LTPCBA typically delivers orders within 1-5 days, depending on complexity and volume.

Normal procurement and assembly lead times are 1-5 days for assembly alone and 1-5 days for turnkey assembly.

Scalable solutions contribute to successful product launches. You benefit from high-quality output, timely delivery, and cost-effective manufacturing. LTPCBA’s quick response service provides quotations within 2-3 working days and 24-hour technical support, ensuring you meet tight deadlines and adapt to changing production needs.

Tip: Evaluate your partner’s scalability and turnaround time before committing. Reliable fast track pcba medical services help you launch products on schedule and maintain compliance throughout the process.

Trust & Support in PCB Assembly Services

LTPCBA PCB Assembly Services

You need trust and support when choosing pcb assembly services for medical device manufacturing. Trust comes from strong supply chain management, robust data security, and a proven quality control system. LTPCBA builds trust by maintaining industry certifications, communicating clearly, and collaborating early in the design phase. These factors help you optimize manufacturability and ensure regulatory compliance.

Certifications such as ISO and UL guarantee safety and quality standards.

Consistent communication keeps your needs and expectations clear.

Early collaboration with suppliers improves design and compliance.

Supply chain management plays a vital role in pcb assembly services. LTPCBA uses supplier qualification and diversification to maintain quality and compliance. Risk assessment and mitigation strategies help you avoid delays and disruptions. Inventory management ensures you have the right components when you need them. Traceability and transparency allow you to track materials and devices, making recalls swift and effective. Communication and collaboration with stakeholders keep your projects on track.

Strategy | Description |

|---|---|

Supplier Qualification and Diversification | Ensures quality standards and compliance by thoroughly vetting suppliers and diversifying sources. |

Risk Assessment and Mitigation | Proactively identifies potential risks and develops contingency plans. |

Inventory Management | Maintains optimal stock levels to buffer against disruptions through effective forecasting. |

Traceability and Transparency | Utilizes tracking systems to monitor materials and devices, ensuring swift action during recalls. |

Communication and Collaboration | Establishes clear channels with stakeholders to foster transparency and quickly address issues. |

LTPCBA’s supply chain reliability stands out in the medical device sector. You benefit from an on-time delivery rate above 98%, which exceeds industry benchmarks. Fast prototyping turnaround in 24 hours and customer support response in less than 24 hours give you confidence in project timelines.

Metric | LTPCBA Value | Industry Benchmark |

|---|---|---|

On-Time Delivery Rate (OTDR) | > 98% | 90–95% |

Fast Prototyping Turnaround | 24 hours | N/A |

Customer Support Response | < 24 hours | N/A |

Data security is essential in pcb assembly services for medical devices. LTPCBA uses watermarking to trace unauthorized sharing of design files. Secure data transmission and encryption protect your intellectual property. Tamper-detection circuits add another layer of security. Two-factor authentication and biometric authentication restrict access to sensitive information. Secure communication protocols guard patient data against cyber threats.

AES 256-bit encryption for data protection

Tamper-detection circuits in PCBs

Two-factor and biometric authentication for access control

Data encryption at rest and in transit

Secure communication protocols for patient data

You face challenges such as meeting safety requirements, ensuring reliability in data transmission, and managing product recalls. LTPCBA’s quality control system and supply chain management help you overcome these obstacles. You maintain reliability and compliance under demanding conditions.

Quick-Turn PCB Manufacturer

You need a quick-turn pcb manufacturer when speed and flexibility are critical. Quick-turn pcb assembly service delivers prototypes and urgent orders in 24 to 72 hours, while standard pcb assembly services take 2–4 weeks. You gain high flexibility for design changes and rapid iterations without sacrificing quality.

Feature | Quick-Turn PCB Manufacturing | Standard PCB Manufacturing |

|---|---|---|

Lead Time | 24 to 72 hours | 2–4 weeks |

Optimized for | Prototypes and urgent orders | Large-volume orders |

Flexibility for Design | High | Low |

Quality | Maintained | Maintained |

Quick-turn pcb manufacturer supports rapid design modifications and agile development. You can test and refine devices quickly, which helps you stay ahead in the competitive medical device market.

Increased design flexibility allows for rapid prototyping and testing.

You can make design modifications without significant production setbacks.

The development process becomes more agile and adaptable.

Quality control processes remain strong in quick-turn pcb assembly services. Automated Optical Inspection (AOI), X-ray inspection, and functional testing ensure prototypes meet specifications. Design-for-manufacturability reviews align designs with fabrication constraints, minimizing errors. LTPCBA maintains certifications such as ISO 13485, ISO 9001, and UL standards, so you receive reliable and compliant pcb assembly services.

Quality Assurance Method | Description |

|---|---|

Automated Optical Inspection (AOI) | Ensures prototypes meet specifications through automated checks. |

X-ray Inspection | Detects hidden defects in PCB assemblies. |

Functional Testing | Validates the performance of the prototypes under operational conditions. |

Design-for-Manufacturability (DFM) Reviews | Aligns designs with fabrication constraints to minimize errors. |

You avoid common project delays by choosing a quick-turn pcb manufacturer with a robust quality control system. LTPCBA’s on-time delivery and fast response times help you manage documentation, supplier quality, and risk management efficiently.

Customer Support & Reputation

Customer support and reputation are crucial in pcb assembly services for medical device manufacturing. You need a partner who responds quickly, maintains high quality, and supports you throughout the project lifecycle. LTPCBA provides quotations in 2-3 working days and technical support within 24 hours. You benefit from a 99.5% pass rate on product delivery, which reflects a strong quality control system.

Feature | Description |

|---|---|

Compliance with Industry Standards | Robust Quality Management Systems (QMS) certified to ISO 13485:2016 and compliance with IEC 60601-1. |

Quality Assurance Protocols | Testing protocols such as AOI, ICT, and others to ensure product quality. |

After-sales Support | Technical support responsiveness, warranty terms, and repair policies for long-term partnerships. |

LTPCBA collaborates early with clients, offering design insights during the prototype phase. You receive support for remote monitoring and home healthcare solutions. LTPCBA commits to being a strategic partner invested in your success.

You value pcb assembly services that deliver reliability, quality, and support. LTPCBA’s reputation for on-time delivery, strong manufacturing capabilities, and advanced quality control processes sets it apart. You can trust LTPCBA to help you meet regulatory compliance and achieve successful outcomes for your medical devices.

Tip: Choose a pcb assembly services provider with a proven track record, responsive support, and a robust quality control system. These qualities ensure reliability and long-term success in medical device manufacturing.

You improve outcomes by choosing a local medical pcb manufacturer with strong delivery and service. Use a checklist to compare providers on certifications, quality control, and communication. Track key performance indicators for ongoing evaluation.

KPI | Medical Benchmark |

|---|---|

Defect Rate | <100 PPM |

On-Time Delivery Rate | 97-99% |

Customer Complaint Rate | <0.5% |

Clear communication helps you forecast accurately, manage risks, and find cost-saving opportunities.

FAQ

What certifications should you look for in a medical PCBA partner?

You should verify ISO 13485, UL, and IPC-A-610 certifications. These ensure quality management, safety, and compliance for medical device manufacturing.

How fast can LTPCBA deliver prototypes for medical devices?

LTPCBA delivers prototypes within 24 hours for urgent orders.

Standard turnaround for most projects is 1–5 days.

How does LTPCBA protect your design and patient data?

Security Feature | Benefit |

|---|---|

AES 256-bit encryption | Protects your files |

Watermarking | Tracks unauthorized use |

Two-factor authentication | Secures access |

See Also

Understanding PCBA Processing Needs for Medical Devices

Choosing the Ideal Turnkey PCBA Manufacturer for Electronics

Finding a PCBA Supplier That Fits Your Requirements

Essential Strategies to Enhance PCBA Reliability Over Time

Sourcing Electronic Components for Effective PCBA Production