How to Evaluate Turnkey PCBA Manufacturing Partners for Quality and Speed

To evaluate pcba turnkey manufacturing partners, you should focus on end-to-end process management, certifications, technical capabilities, supply chain strength, customer service, and proven fast delivery. Top turnkey pcb assembly providers achieve higher quality and speed than industry averages.

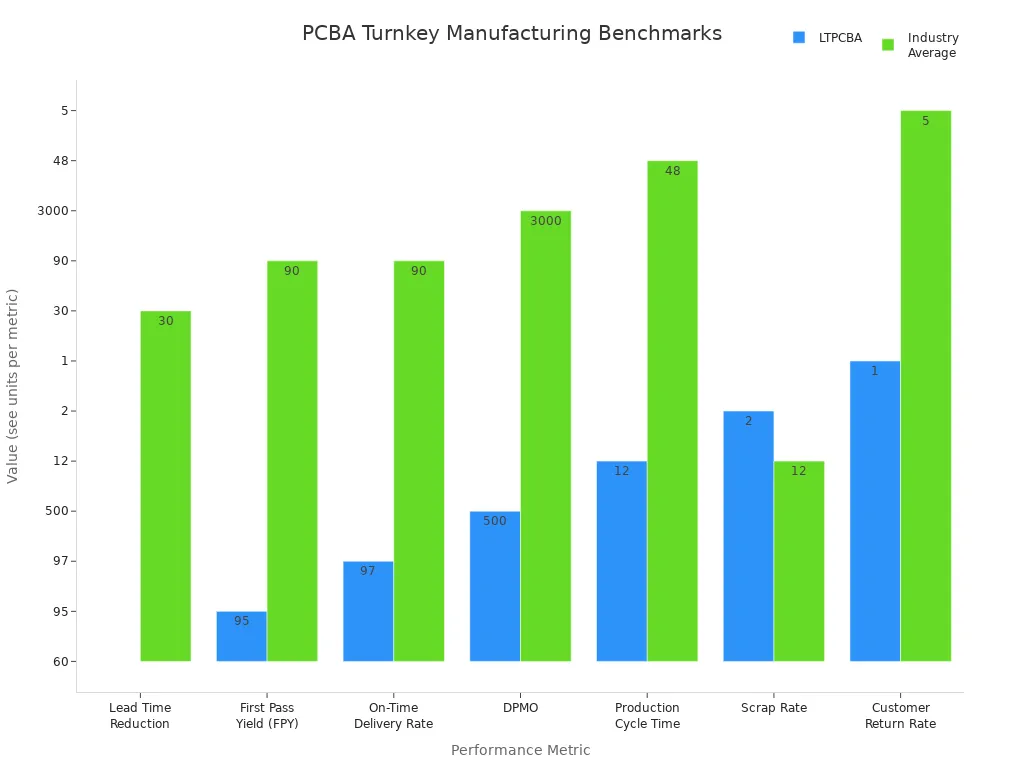

Metric | LTPCBA Performance | Industry Average |

|---|---|---|

Lead Time Reduction | Up to 60% faster | 20–30% faster |

First Pass Yield (FPY) | 95–98% | 85–90% |

On-Time Delivery Rate | 97% | 85–90% |

Defects Per Million Opportunities (DPMO) | 500–1000 | 2000–3000 |

Production Cycle Time | 12 hours | 24–48 hours |

Scrap Rate | 2–5% | 8–12% |

Customer Return Rate | <1% | 3–5% |

Before you choose a turnkey partner, define your expected quality, speed, project volume, and complexity. Balance both speed and quality to avoid compromising your results in pcba turnkey manufacturing.

Key Takeaways

Define your project needs clearly. List your expectations for quality, speed, volume, and complexity to find the best manufacturing partner.

Choose a partner with end-to-end capabilities. This ensures faster coordination and better quality control throughout the entire process.

Check certifications and quality standards. Look for ISO 9001, RoHS, and UL certifications to ensure compliance with safety and quality regulations.

Choose a Partner for PCBA Turnkey Manufacturing

Define Project Needs

Before you choose a partner for pcba turnkey manufacturing, you need to clarify your project requirements. Start by listing your expectations for quality, speed, volume, complexity, cost, and privacy or security. Each of these factors will shape your decision and help you find the best pcb manufacturer for your needs.

Aspect | Description |

|---|---|

Quality | Ensures every printed circuit board meets technical, quality, and regulatory requirements. |

Speed | Streamlined processes reduce lead times and enhance product consistency. |

Volume | Capable of managing high volume production and high-mix batches efficiently. |

Complexity | Adopts a turnkey model to significantly reduce operational complexity and improve supply chain control. |

You should also consider how your project’s complexity and volume will affect your choice. Higher complexity in pcba turnkey manufacturing requires advanced capabilities and technologies. Volume impacts pricing and lead time. Quick-turn services work best for simple prototype circuit board projects, while complex or large orders need longer timelines.

Tip: Write down your must-have requirements and nice-to-have features. This list will help you compare potential partners and make a confident decision.

Assess End-to-End Capabilities

A strong manufacturing partner manages every step of the process, from design to delivery. This end-to-end approach is a critical factor in achieving both speed and quality standards. The best pcb manufacturer will offer a full turnkey solution, handling everything from pcb fabrication to final assembly and shipping.

Step | Description |

|---|---|

Material Procurement | Management of components based on gathered requirements, including PCB boards and assembly materials. |

PCB Fabrication | Involves creating the bare board according to design through etching, laying, and drilling. |

Component Assembly | Utilizes SMT and THT methods for accurate component placement using automated instruments. |

Testing and Quality Control | Conducts various tests to ensure the board meets required parameters and identifies defects. |

Final Assembly | Integrates the board with large assemblies, ensuring the final product functions correctly. |

Delivery | Ensures proper packing and timely delivery while meeting legal transportation requirements. |

When you choose a partner with turnkey pcb assembly capabilities, you benefit from faster coordination and better quality control. One team manages the entire process, so there are no delays from handoffs between vendors. You also get a single point of contact, which makes communication easier and reduces the risk of errors.

A full turnkey approach streamlines procurement and reduces risk. For example, a medical device company avoided a three-week delay by qualifying a substitute part early, allowing them to source it in just two days. An IoT startup reduced their production cycle from 28 days to 16 days by using turnkey services.

Evaluate Supply Chain and Sourcing

Supply chain strength is essential in pcba turnkey manufacturing. The best pcb manufacturer builds strong relationships with component distributors, which leads to faster and cheaper part acquisition. Local sourcing ensures quicker delivery and fewer disruptions. Rigorous quality controls help minimize defects and lower costs.

Common risks in supply chain and sourcing include component delays, quality issues, shipping disruptions, and regulatory complexities. Top partners use clear communication and responsive support to avoid costly disruptions. They also optimize batch planning to enhance resource efficiency and reduce setup time.

Disruption Type | Description |

|---|---|

Shortages can lead to delays in pcb assembly production, resulting in missed deadlines and lost sales opportunities. | |

Increased Costs | Higher prices for components due to supply and demand imbalances can increase overall costs for manufacturers. |

Quality Issues | Use of alternative components or design changes due to shortages can affect the reliability of the final product. |

Cost is another important factor. Producing a multilayer pcb in China can cost 30%–60% less than in the West. High-quality production is possible without sacrificing quality when you work with certified manufacturers. Turnkey services often provide volume discounts and better coordination, which can save you money and time.

Privacy and security also matter. Trusting a partner with your designs and Bills of Material requires strong protection of intellectual property and personal information. Compliance with legislative requirements is essential to ensure privacy and security. Theft of pcb designs can cause financial and reputational damage, and even lead to bankruptcy if products are illegally replicated.

Note: Always ask about your partner’s data protection policies and how they handle sensitive information.

By focusing on these areas, you can select a turn-key pcb partner who meets your needs for quality, speed, and reliability.

Turnkey PCB Assembly: Quality and Speed Factors

Check Certifications and Standards

You should always check the certifications and quality standards of any pcba turnkey manufacturing partner. Certifications show that a company follows strict rules for quality and safety. The best pcb manufacturer will display these certifications clearly. Here are some of the most important ones:

Certification | Description |

|---|---|

ISO 9001:2015 | A globally recognized standard for quality management systems, demonstrating commitment to quality. |

RoHS | Ensures responsible manufacturing by restricting harmful materials in electronics production. |

ITAR | Compliance allows for the manufacturing of defense products while protecting intellectual property. |

UL Certified | Signifies adherence to rigorous safety standards for PCBAs set by Underwriters Laboratories. |

You should also ask about process controls. Top turnkey pcb assembly providers use methods like automated optical inspection (AOI), in-circuit testing (ICT), and real-time monitoring. These controls help catch problems early and keep quality high. Prototyping and design for testability (DFT) also play a big role in reducing errors and costs.

Tip: Always request proof of certifications and ask about their testing and inspection process.

Review Turnaround and Quickturn

Speed matters in turnkey pcb assembly. You want a partner who can deliver your boards fast without sacrificing quality. The best pcb manufacturer will offer a quick turnaround time for both prototypes and production runs. Here is what you can expect from leading companies:

Assembly Type | Lead Time |

|---|---|

Prototype Assembly | 1–5 working days |

Low-Volume Production | 5–10 working days |

Medium to High Volume | 10–20 working days or more |

Turnkey with Component Sourcing | 10–25 working days |

Quickturn pcbs help you get your products to market faster. These services work best for prototype circuit board projects and custom designs. The table below shows how quickturn services compare to traditional pcb fabrication:

Aspect | Quick Turn Services | Traditional PCB Manufacturing |

|---|---|---|

Lead Time | Significantly shorter | One to several weeks |

Project Types | Prototypes, custom designs, limited runs | Standard production runs |

Industries Benefiting | Consumer electronics, medical devices, telecommunications | Various industries |

You should look for a partner with experience in quickturn pcbs. This ensures you get low lead time and reliable delivery, even for urgent projects.

Assess Technical and Customer Support

Technical support is a key part of any full turnkey service. You want a partner who can handle everything from component sourcing to final assembly and testing. This makes project management easier and keeps quality consistent. Reliable pcb assembly providers manage the supply chain, making sure all parts are authentic and available.

Customers value these services because they:

Avoid risks associated with coordinating multiple vendors.

Control overhead costs and eliminate delays.

Reduce turn times and get products to market quickly.

You should also check the equipment and scalability of your partner. Turnkey services can move from small test runs to mass production without losing quality. Modern equipment and large facilities help with high-mix projects and ensure process efficiency.

Customer support matters, too. Fast response times and clear communication lead to higher satisfaction. Here is how some top companies perform:

Manufacturer | On-time Delivery | Reorder Rate | Response Time |

|---|---|---|---|

Shenzhen JS Technology | 100% | 41% | <2 hours |

Hongrong Electronics | N/A | 78% | N/A |

Wonstron Technology | N/A | N/A | <2 hours |

Note: Newer manufacturers often have higher quality ratings because they use modern equipment. For high-mix or complex projects, choose a partner with a large facility and proven technical support.

Verify References and Track Record

You should always check references, testimonials, and case studies before choosing a turn-key pcb partner. Real stories from other customers show how a company handles challenges and meets deadlines. Reviews give you insight into their problem-solving skills and how well they stick to quality standards.

Testimonials and case studies build confidence by showing real results.

Reviews highlight operational performance, including timeliness and quality.

High customer satisfaction scores (above 80%) show strong performance.

Tip: Ask for recent case studies and contact references directly. This helps you confirm the company’s claims about quality and speed.

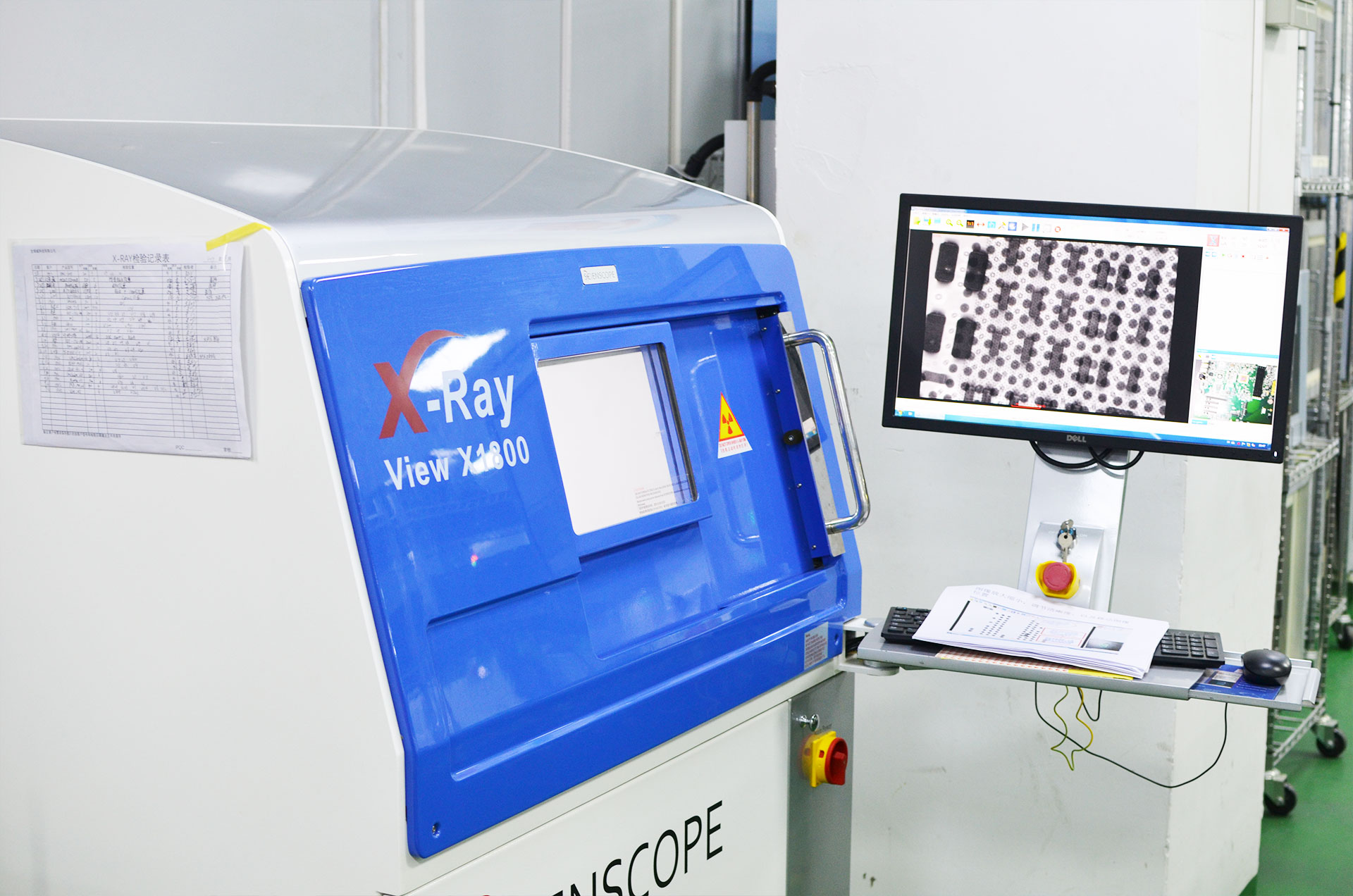

Industry experts agree that the most critical factors for turnkey pcb assembly are managing complex supply chains, balancing cost and quality, and adapting to new technologies. Leading companies use strict quality control at every stage, including pcb fabrication, assembly, and testing. They use advanced inspection methods like AOI and X-ray testing to keep standards high, even for fast turn projects.

By following these steps, you can find a pcba turnkey manufacturing partner who delivers both quality and speed. Look for full turnkey services, strong technical support, and a proven track record. This approach helps you get reliable pcb fabrication, affordable pricing, and quickturn services for your next project.

To choose the right turnkey PCBA partner, follow these steps:

Define your project needs.

Research and shortlist candidates.

Request quotes, visit sites, and check references.

Ask about certifications, process control, and support.

What to Avoid | |

|---|---|

Transparent factory tour | No QC reports |

Real-time production updates | No RoHS documentation |

Compare offers by quality, reliability, and service—not just price. Comprehensive services help you launch faster and reduce costs.

FAQ

What certifications should you look for in a turnkey PCBA partner?

You should check for ISO 9001, RoHS, and UL certifications. These show the partner meets global quality and safety standards.

How can you verify a partner’s speed and reliability?

Ask for recent delivery records.

Request customer testimonials.

Review case studies that show on-time performance.

Why does end-to-end process management matter?

Benefit | Description |

|---|---|

Faster Delivery | One team handles all steps. |

Fewer Errors | Clear communication reduces mistakes. |

Better Quality | Consistent standards at every stage. |

See Also

Choosing The Best Turnkey PCBA Manufacturer For Your Project

Ensuring Quality Production Through Advanced Turnkey PCBA Factories

Boosting Project Efficiency With Quick-Turn PCB Assembly Prototypes

Finding A PCBA Supplier That Fits Your Requirements

Enhancing Business Efficiency Through PCBA Contract Manufacturing