Essential Considerations for PCB Manufacturing and Assembly Projects

You need to pay attention to some main things for a good pcb manufacturing project:

Correct Gerber files help guide the pcb manufacturing steps.

A full Bill of Materials keeps pcb assembly going smoothly.

DFM analysis lets you find design problems early.

Environmental needs help you pick the right pcb.

Quality, speed, and trust are important at every step. Good testing, industry certifications, and the right materials help the pcb work well. You should think about both technical needs and service quality when picking a pcb manufacturing partner.

Key Takeaways

Make sure your design files are correct and your Bill of Materials is complete. This helps stop mistakes and makes PCB manufacturing and assembly go smoothly.

Pick a manufacturing partner who checks quality well, has certifications, and delivers fast. This helps you get good PCBs when you need them.

Use automated inspections and turn-key services to save time. These steps help lower mistakes and keep your PCB project moving from start to finish.

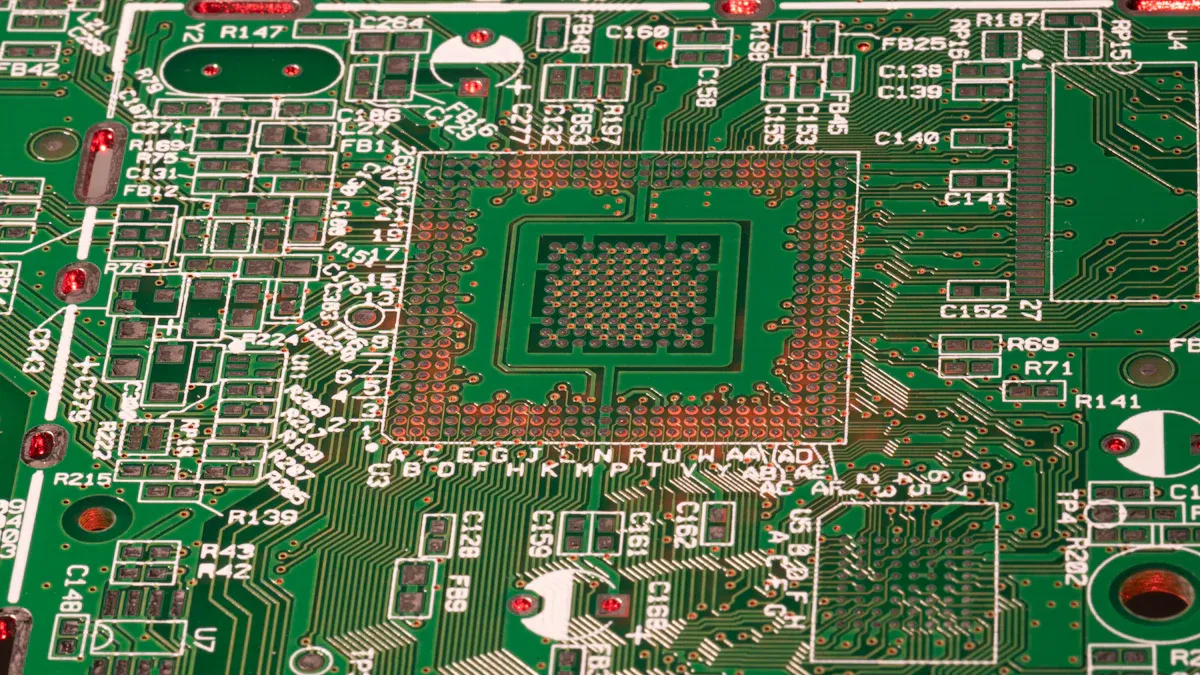

PCB Manufacturing Essentials

Design Files and DFM

Every good pcb manufacturing project starts with correct design files. These files tell the manufacturer how to make your pcb. You need to make sure your Gerber files, Bill of Materials, and centroid files are right. If you make mistakes in these files, problems can happen. You might get layers that do not line up. Parts could be put in the wrong place. Soldering might not work well.

Here are some important things to put in your pcb design files to help make them better and avoid mistakes:

Ask your manufacturing partner for help early in the design. This helps you find problems before making the pcb.

Leave enough space between parts and the edge of the board. This keeps the board safe during manufacturing.

Do not put too many parts on the board. This makes the board easier and cheaper to make.

Only use surface mount technology (SMT) on both sides if you really need to. This makes building the pcb easier.

Pick the right pcb finish, like ENIG, to help with soldering and save time.

Use IPC standard footprints for all your parts. This makes sure the parts fit right.

Do not leave open copper spots or sharp corners in your traces. This helps stop signal and manufacturing problems.

Always check your design rules and look over your files before sending them to be made.

Tip: Automated DFM checks help you find and fix problems early. These checks give you feedback right away. You can change your design before the pcb is made. This step helps stop mistakes and makes your circuit board better.

PCB Fabrication Process

The pcb fabrication process turns your design into a real board. Each step follows strict rules, like IPC standards. You should know these steps to make sure your board works for you.

The main steps in the pcb fabrication process are:

Pre-production engineering: You send your files, and the manufacturer checks for mistakes.

Inner layer imaging: The manufacturer puts on photoresist and uses lasers to make the circuit pattern.

Etching: Chemicals take away extra copper, leaving the circuit lines.

Photoresist stripping: The manufacturer takes off the extra photoresist.

Inspection and post-etch punch: Machines check for mistakes and line up the layers.

Alternative oxide coating: A special layer protects the copper and helps layers stick together.

Lamination: Heat and pressure press the layers together to make a multilayer board.

Drilling: Machines make holes for vias and part leads.

Metallization: Copper is put in the holes to make them conduct electricity.

Copper and tin plating: More copper and tin are added for protection.

Photoresist stripping (post-plating): The manufacturer takes off the photoresist again.

Final etching: Chemicals remove extra copper, leaving clean paths.

Tin stripping: The tin layer is taken off to show the copper.

Solder mask application: A solder mask covers the board and stops shorts.

Surface finish: The manufacturer adds a finish to protect the copper and get ready for soldering.

Note: Each step in the pcb fabrication process uses new technology to make sure everything is right. Machines check for mistakes early and help keep quality high.

LTPCBA Technology and Quality

LTPCBA uses new technology to make more accurate and better pcbs. You get tools like laser via drilling, laser direct imaging, and fine line/space features. These tools help make hard circuit boards with great detail.

Advanced Technology | Benefit for Your PCB Project |

|---|---|

Laser via drilling | Makes small holes for better layer connections |

Laser direct imaging (LDI) | Fast, flexible mask making for custom and test boards |

Fine line/space capabilities | Lets you have lots of small parts close together |

Flexible and rigid-flex fabrication | Gives you more ways to design and better product performance |

Automation and 100% inspection | Keeps quality the same and helps most boards pass the first time |

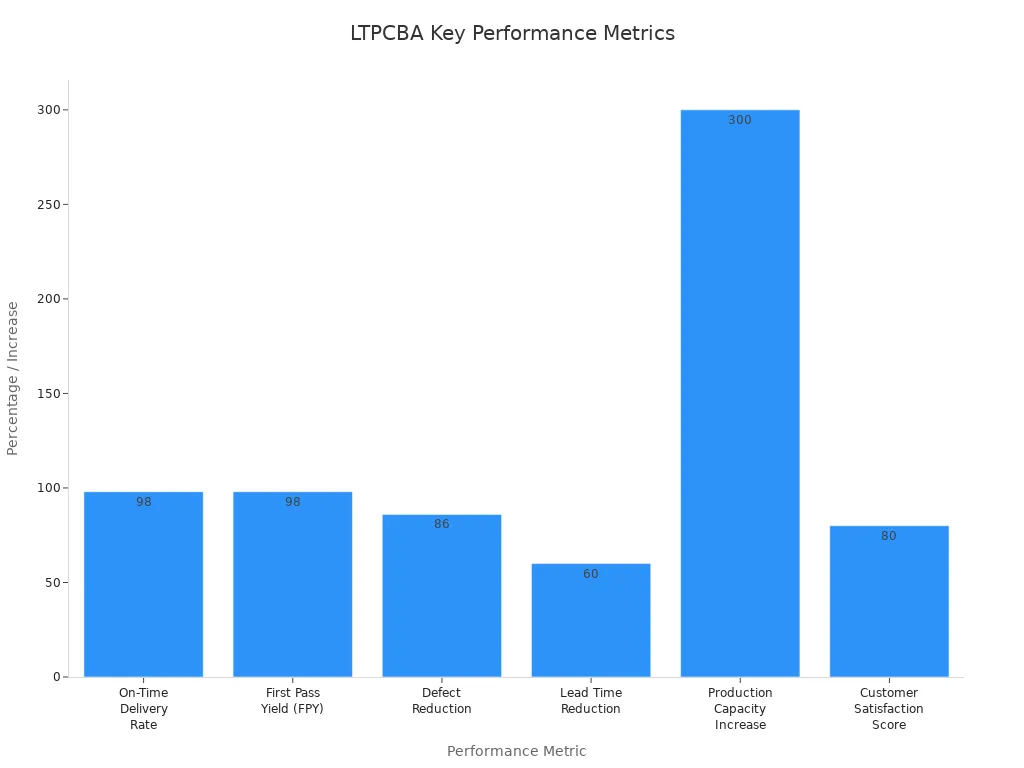

You can count on LTPCBA to give you good boards on time. The company has important certifications like ISO, IATF, and UL. These show LTPCBA meets tough quality and safety rules. For example, ISO 9001 means strong quality management. UL standards mean the boards are safe and reliable.

LTPCBA delivers on time more than 98% of the time. This is better than most other companies. Most pcb projects take 10-12 weeks, but LTPCBA can finish full projects in just 4-5 weeks. The company also has a 99.5% pass rate, which shows they care about quality.

When you pick LTPCBA, you get a partner who cares about quality, speed, and making you happy. The company uses new ways to make boards and checks quality at every step to make sure your board is just right.

Assembly and PCB Assembly Process

Component Sourcing

You need the right parts to make a good circuit board. Getting parts affects how fast and well your board is made. If you plan early, you can avoid waiting a long time and paying more. Sometimes, it is hard to get microcontrollers or capacitors because of shortages. You might have to wait up to a year for some parts. If you cannot find what you need, you may have to change your board or use different connectors. This can slow your project down by weeks or months.

Fake parts from bad sellers can break your board and are not safe. To stop this, you should:

Buy only from trusted sellers.

Ask for papers that prove the parts are real.

Use special tests, like X-ray, to check parts.

Work with top suppliers for better prices and help.

Order early to avoid waiting and higher costs.

Companies like LTPCBA buy in large amounts and check other parts to help you get what you need faster. They also look at every part before putting it on your board to make sure it is right.

Tip: Always check your Bill of Materials and design files before you start assembly. This helps stop mistakes and keeps your project moving.

Assembly Methods

There are different ways to put your circuit board together. Each way has its own good points. The main ways are Surface Mount Technology, Through-Hole Technology, and mixed assembly. Most new electronics use Surface Mount Technology for almost all boards. This way puts small parts right on the board’s surface. Machines do this fast and place parts very well.

Through-Hole Technology puts part leads through holes in the board. People or machines then solder the leads on the other side. This way makes strong bonds and is good for parts that need to handle stress or high power.

Mixed assembly uses both Surface Mount and Through-Hole. You use this when you need both small size and strong parts. Mixed assembly is harder but gives you more ways to design your board.

Here is a table to help you see the differences:

Assembly Method | Cost | Speed | Reliability |

|---|---|---|---|

SMT | Lower cost for many boards; less work needed | Fastest because of machines | Good for most uses; not as strong under stress |

Through-Hole | Higher cost; more work and time | Slower because of hand work | Best for boards that need to handle stress or power |

Mixed | Highest cost; uses both ways | Slower than SMT, faster than Through-Hole for some parts | Has both strengths for hard designs |

Machines help a lot in the assembly process. Pick-and-place machines put parts on the board quickly and very well. Automated soldering makes sure the joints are even and strong. Machines like AOI and X-ray find problems early, so your board works well every time.

Note: Using machines in assembly saves time, stops mistakes, and keeps quality high.

LTPCBA Turn-Key Services

LTPCBA gives you turn-key assembly services for every step. You send your design files and Bill of Materials, and LTPCBA does the rest. They get parts, kit them, make the board, put it together, and test it. You talk to one person, so it is easy and fast.

LTPCBA answers your quote in 2–3 business days. You get answers to questions in one day. You can see your project’s progress any time. Their smooth process and good communication help finish projects about 30% faster. You can count on LTPCBA to deliver on time, with a 99% on-time rate.

Save time by letting experts do the work.

Avoid mistakes and missing parts.

Get good parts, even when there are shortages.

Find design or file mistakes early.

Control costs with clear prices and less shipping.

Move from samples to bigger runs easily.

Quality checks happen at every step of assembly. LTPCBA uses machines to inspect, test circuits, and check if the board works. They follow strict rules like ISO, IATF, and UL. This focus on quality helps you avoid big mistakes and makes sure your board meets all needs.

When you pick LTPCBA for your assembly, you get a partner who helps you from start to finish. You can focus on your design while LTPCBA handles the rest, delivers on time, and meets top quality standards.

Quality Assurance and Delivery

Inspection and Testing

You want your pcb to work well the first time. Inspection and testing help find problems early. LTPCBA uses many ways to check each pcb. Here is a table that shows some important inspection and testing methods:

Method | Purpose / Focus | Application Context / Notes |

|---|---|---|

Automated Optical Inspection | Finds surface problems, checks part placement and solder joints | Used after printing and soldering in assembly |

Automated X-ray Inspection | Looks for hidden problems, especially in BGAs and hard parts | Used for places you cannot see in advanced fabrication |

Functional Circuit Testing | Checks if the whole pcb works in real life | Last test before shipping; makes sure the circuit works as planned |

In-Circuit Testing | Tests each part for shorts, opens, and wrong parts | Fast and exact; good for big runs in manufacturing |

LTPCBA’s careful checks help reach a 99.5% pass rate. This is much better than most companies. You get fewer problems and more boards that work.

Certifications and Compliance

Certifications show a company follows strict rules. LTPCBA has important certifications like ISO 9001, UL, and IATF 16949. These prove your pcb meets high standards for quality and safety. For example, ISO 9001 means the company always tries to get better and keep customers happy. UL checks for electrical safety. IATF 16949 is important for car pcb fabrication. These certifications help your products meet rules in North America, Europe, and Asia.

Tip: Always ask your manufacturing partner about their certifications. This helps you avoid problems with rules and shipping.

Packaging and Logistics

Good packaging keeps your pcb safe when shipped. LTPCBA uses best ways to protect every board. You can expect these steps:

Clean each pcb before packing.

Put the pcb in an antistatic bag.

Wrap with bubble wrap or foam for extra safety.

Seal in a moisture barrier bag.

Use a strong box with shock-absorbing material.

Label the box with handling instructions and details.

Add all needed papers and tracking info.

LTPCBA works with trusted shipping partners to deliver your boards on time. You get updates and help until your boards arrive safely.

You can do well in pcb projects by using good habits. Check your Bill of Materials early. Use strong quality control. Talk openly with your team. Working with LTPCBA means your boards arrive on time. You also get fewer mistakes, as shown here:

Metric | LTPCBA Value |

|---|---|

On-Time Delivery Rate | |

First Pass Yield | Up to 98% |

Keep your pcb working well by focusing on quality. Work together as a team. Always try to make things better. This helps your project stay on track.

FAQ

What files do you need to start a PCB project with LTPCBA?

You need to send Gerber files, a Bill of Materials, and a pick-and-place file. These help LTPCBA build your board correctly.

How fast can LTPCBA deliver assembled PCBs?

You can get assembled PCBs in as little as 4–5 weeks. LTPCBA works quickly and keeps you updated during the process.

Does LTPCBA support prototype and mid-volume runs?

Yes, you can order both prototypes and mid-volume batches. LTPCBA helps you at every stage, from small samples to larger production.

See Also

Comprehensive Overview of PCBA Production Techniques for All

Essential Criteria for PCB Boards Used in SMT Assembly

Critical Methods to Enhance PCBA Durability Over Time

Sourcing Electronic Parts for Efficient PCBA Production

Primary Materials Required for Successful PCBA Manufacturing