ESD design for SMT assembly and processing workshops

Electrostatic discharge (ESD) is a big problem for SMT workshops. It can harm delicate parts and reduce product quality. Good ESD design helps avoid these issues. Using tools like optical checks, special heat settings, and frequent reviews improves reliability and cuts down mistakes. Keeping parts safe begins with solid ESD control.

Key Takeaways

Learn about electrostatic discharge (ESD) and its dangers. ESD can harm fragile electronic parts, causing delays and higher costs.

Manage your workshop setup. Keep humidity at 40-60% and use grounding tools to stop static electricity.

Take safety steps. Use anti-static items, tools, and careful handling to protect sensitive parts during assembly.

Understanding ESD and Its Impact on SMT Assembly

What is electrostatic discharge (ESD)?

Electrostatic discharge happens when stored energy leaves a charged object. This can happen by touching or being near another object. The charge depends on things like material type, speed of contact, and humidity. In SMT assembly, static discharge can harm electronic devices directly or indirectly. It may cause visible damage right away or hidden problems that show up later. These issues lower the reliability of the devices.

Note: People often use "electrostatic discharge" in technical writing. Some think "static electricity discharge" is a better term. This change shows how understanding of ESD has grown in electronics.

Sources of ESD in SMT workshops

Static electricity builds up in different ways. Friction, like walking on a carpet, is one common cause. Touching materials or being close to charged objects can also create static. In SMT workshops, static discharge can happen during making, testing, shipping, or handling items. All materials can hold a charge, which depends on humidity and how fast contact happens. Knowing these causes helps reduce ESD risks.

Consequences of ESD damage in SMT processes

ESD can cause big problems in SMT assembly. Sensitive parts may stop working because of static discharge. Machines may break down, slowing production and wasting time. Damaged parts might stick together, making them hard to handle. These problems can stop production, raise costs, and delay deliveries. Studies show ESD limits how much can be made. For example, if only three out of twenty machines are safe from ESD, production drops a lot. Ignoring ESD often leads to bigger problems that hurt manufacturing.

Key Principles of ESD Design for SMT Workshops

Environmental controls for electrostatic discharge prevention

Controlling the environment helps reduce ESD in SMT workshops. Start by managing humidity levels. Low humidity makes static discharge more likely. Keeping humidity between 40-60% helps stop static buildup. Air ionizers are useful tools. They release ions that remove static charges in the air. This protects delicate parts from damage.

Temperature control is also important. High temperatures can cause more static electricity. Keeping the workshop at a steady temperature helps protect your process. Use anti-static floors and mats too. These materials lower static electricity, making the workshop safer for assembly.

Tip: Use special sensors to check humidity and temperature often. This keeps conditions ideal.

Grounding systems and ESD protection circuits

Grounding systems are key to stopping ESD. Install a grounding system to safely remove static charges. This system connects all metal surfaces to one ground point. It stops static from building up. Workers should wear grounding wrist straps or heel straps. These keep them grounded while handling sensitive parts.

ESD protection circuits are also very important. These circuits protect your PCB by redirecting harmful static away. Add transient voltage suppressors (TVS) or diodes to your circuit design. These parts absorb extra voltage and protect your assembly from harm.

Note: Check grounding systems and protection circuits often. Broken systems can cause unexpected problems in your process.

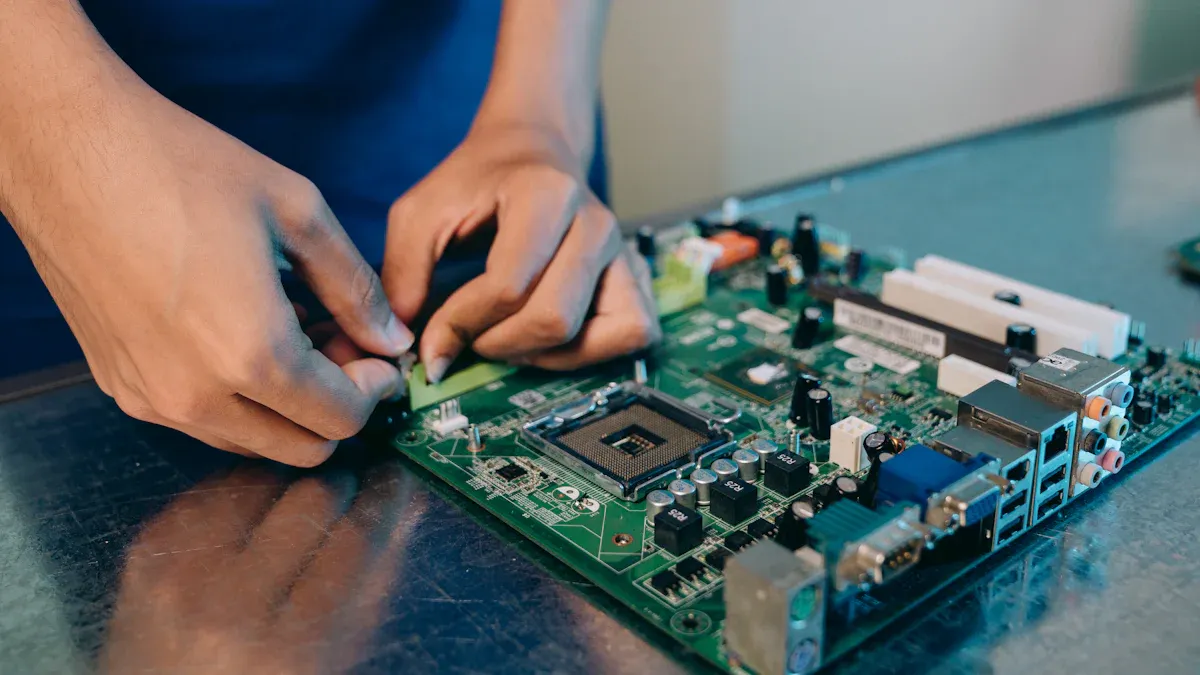

Use of protective materials and tools in SMT assembly

Static-safe materials are a must in SMT workshops. Use anti-static bags, trays, and containers to store parts. These items protect sensitive components from static damage. Workers should wear anti-static gloves and clothing. These stop static electricity from transferring during work.

Special tools also improve ESD safety. Use soldering irons with built-in grounding systems. These tools lower the risk of static discharge during soldering. Anti-static brushes and tweezers are helpful too. They let you clean and handle parts safely without adding static.

Best Practices for Designing: Pick high-quality static-safe materials and tools. Good products give better long-term protection for your assembly process.

Practical ESD Control Measures by LTPCBA

Personnel grounding techniques and tools

Keeping workers grounded helps stop electrostatic discharge (ESD) in SMT workshops. When handling sensitive devices, your body can build up static. This static can harm delicate PCB parts if transferred. To prevent this, use tools like wrist straps and foot straps. These tools safely send static charges to the ground.

Workstations also need proper grounding. Use special materials for tables and floors to make them safe. Teaching workers about ESD risks and correct handling is very important. Training should show how to use grounding tools like wrist straps properly.

Tip: Test wrist straps and grounding tools before using them. This ensures they work well.

Equipment grounding and maintenance in SMT workshops

Grounding equipment is key to controlling ESD in SMT assembly. Grounding systems safely remove static charges, protecting machines and PCB parts. For non-conductive items, use ionizers to neutralize static. This adds extra protection.

Equip workstations with these items:

Static-safe work surfaces

Grounding tools like wrist straps

A shared ground point

Signs showing ESD-safe zones

Check and fix grounding systems often to keep them working. Workstations with static-safe surfaces and grounding tools lower ESD risks. This keeps your SMT process smooth and reliable.

Note: If grounding isn’t possible for some machines, use voltage suppression tools to stop static damage.

Safe handling procedures for sensitive electronic components

Handling delicate parts needs careful ESD safety steps. Always wear grounded wrist straps and anti-static gloves. Avoid touching component pins directly. Use static-safe packaging to store and move parts. These packages should have resistance between 10^8 and 10^11 ohm-cm for best protection.

Set up an ESD control plan for your workplace. This plan should include rules, training, and checks. Following steps like grounding, safe handling, and using static-safe packaging protects parts from damage.

Best Practice | Description |

|---|---|

Grounding | Safely removes static charges, lowering ESD risks. |

Handling Guidelines | Wear wrist straps, avoid pin contact, and use gloves. |

ESD Packaging | Use static-safe materials for storing and moving parts. |

ESD Control Program | Includes rules, training, and checks for workplace safety. |

By following these tips, you can protect PCB parts and keep production quality high in SMT workshops.

ESD Standards and Testing for SMT Workshops

Overview of ESD standards relevant to SMT assembly

Knowing ESD standards helps protect delicate parts in SMT work. These rules explain how to control static and keep processes safe. ANSI/ESD S20.20 shows how to set up ESD control plans. It also explains how to label sensitive devices. JESD 625 focuses on safe ways to handle fragile parts during assembly. IEC 61340-5-1 gives general rules for shielding electronics from static electricity.

Standard | Description |

|---|---|

ANSI/ESD S20.20 | Explains ESD control plans and labeling for sensitive devices. |

JESD 625 | Gives rules for safely handling ESD-sensitive parts in assembly. |

IEC 61340-5-1 | Lists general rules for protecting electronics from static electricity. |

These standards help you create strong safety measures. They make sure your assembly process stays smooth and reliable.

Testing methods for ESD compliance in SMT environments

Testing for ESD keeps your assembly safe from static damage. Switching from air-gap to contact discharge improved testing accuracy. Older methods, like IEC801-2, used air-gap discharge. This caused errors because of environmental changes. Contact discharge, used in IEC61000-4-2, is more reliable. It measures static directly, reducing mistakes and protecting circuits better.

Regular testing finds risks and checks if you follow the rules. Tools like resistance meters and static locators measure static levels. Testing ensures your SMT process meets standards and protects fragile parts.

Monitoring and auditing ESD control systems

Watching and checking ESD systems keeps SMT workshops safe. Regular checks stop problems before they happen and show where to improve. Monitoring ensures ionizers are in the right spots and working well. Training workers to use tools like resistance meters helps confirm safety.

Benefit of Auditing and Monitoring Procedures | Description |

|---|---|

Problem Prevention | Stops issues early, avoiding bigger problems later. |

Corrective Action Identification | Finds problems quickly for fast fixes. |

Weakness Identification | Shows areas that need improvement. |

Resource Leveraging | Makes the best use of available tools and time. |

Employee Retraining Needs | Points out when workers need more training. |

Yield and Productivity Improvement | Boosts production and efficiency. |

Program Cohesion | Combines all parts of the ESD program into one system. |

By checking and improving your systems, you can work faster, protect parts, and keep your process running well.

Good ESD design protects your SMT assembly process. It reduces harm to delicate parts and keeps quality high. Use grounding systems, control the environment, and add protective tools. Following ESD rules and testing methods makes your system stronger. A full ESD plan increases reliability and helps your workshop work better.

FAQ

How can you stop ESD in SMT workshops?

Use grounding tools, anti-static items, and control humidity. These steps lower static and keep parts safe during assembly.

How often should ESD systems be checked?

Check systems every week to make sure they work well. Regular testing finds problems early and keeps the workshop safe.

Why does ESD compliance matter in SMT assembly?

Following rules keeps your workshop up to standards. It protects parts from harm and makes production more reliable.

See Also

The Importance Of Anti-Static Measures In Smt Workshops

Common Techniques And Workflow In SMT Assembly Processes

Essential Guidelines For Wave Soldering In DIP Assembly