Effective Ways to Waterproof Your PCBA in 2025

If you’re looking to achieve a waterproof PCBA in 2025, there are several highly effective solutions available. Popular methods for creating a waterproof PCBA include applying conformal coatings such as epoxy, urethane, silicone, and parylene. Potting with epoxy resins provides a robust barrier, while using sealed enclosures with gaskets and O-rings enhances airtightness and prevents water from reaching sensitive components. Nano-coatings can be used to form ultra-thin hydrophobic layers, and options like three-proof paint and parylene nano-coating offer additional protection for your waterproof PCBA. Sealing connectors and solder joints is another important step to further waterproof your electronics. A waterproof PCBA ensures your devices remain reliable and have an extended lifespan. At LTPCBA, we utilize advanced technology and rigorous quality control to deliver top-quality waterproof PCBA solutions. By protecting your PCB boards with these methods, you can be confident that your waterproof PCBA will perform reliably in any environment.

Key Takeaways

Use conformal coatings like urethane or parylene for strong moisture protection on your PCBA.

Potting with epoxy or silicone creates a tough barrier but may limit repair options.

Nano-coatings offer ultra-thin, fast-drying waterproof layers without affecting signals.

Sealed enclosures with gaskets and o-rings prevent water entry and extend device life.

Always clean and dry your PCBA before applying waterproof materials and test thoroughly to ensure reliability.

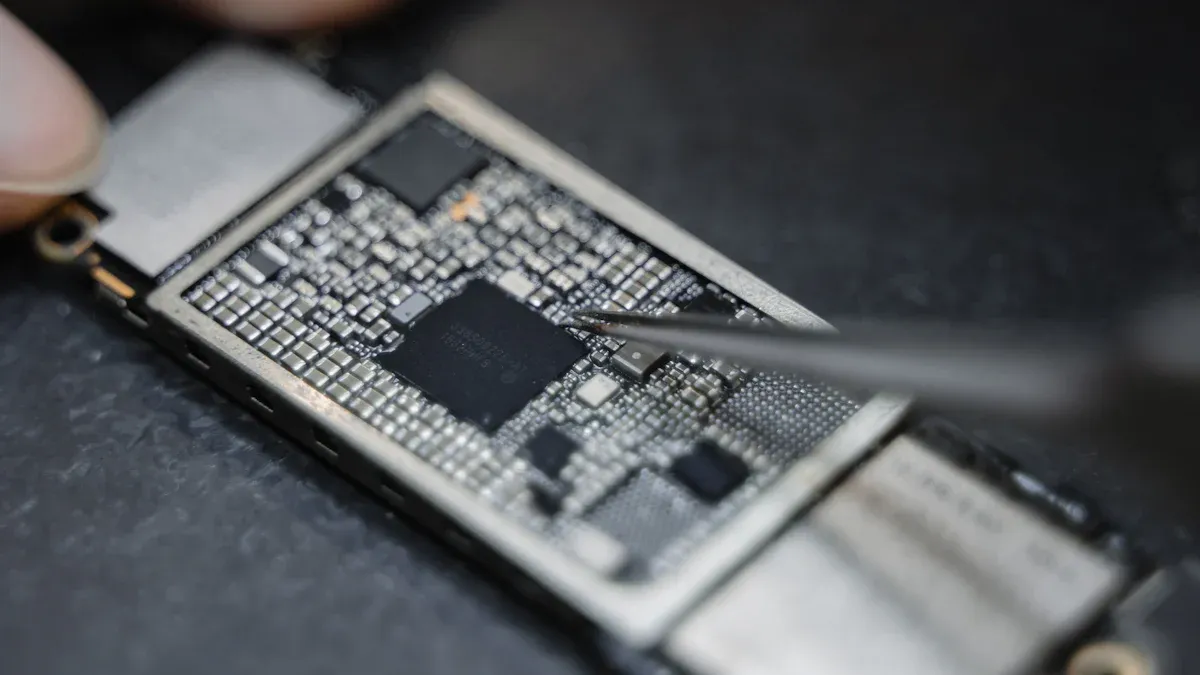

Waterproof PCBA Methods

Waterproofing PCBs is essential for protecting electronics in harsh environments. You have several circuit board waterproofing methods to choose from, each offering unique benefits for waterproof pcbs. LTPCBA uses advanced assembly and quality assurance practices to ensure your waterproof pcba meets the highest standards. Let’s explore the main waterproof coating options and selective pcb encapsulation techniques available in 2025.

Conformal Coating

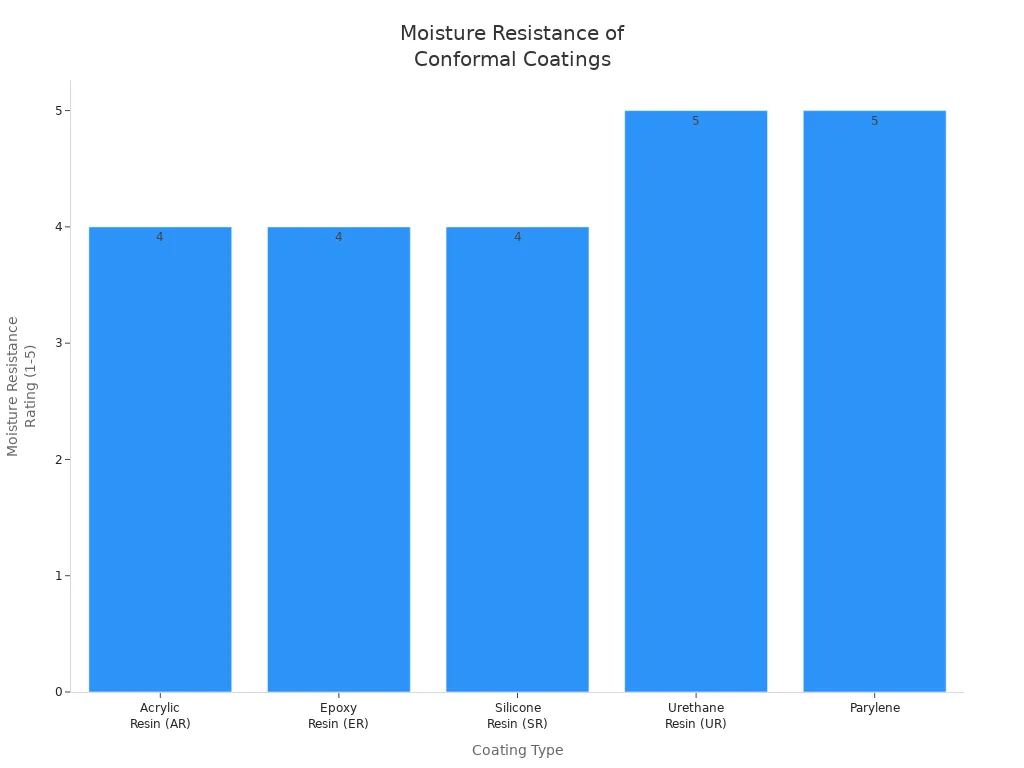

Conformal coating is one of the most popular circuit board waterproofing methods. You apply a thin, protective waterproof coating to the surface of your pcba. This layer shields components from moisture, dust, chemicals, and vibration. You can choose from several types of conformal coating, including acrylic, epoxy, silicone, urethane, and parylene nano-coating protection. Each type offers different levels of moisture resistance and durability.

Conformal Coating Type | Moisture Resistance Rating (1-5) | Key Characteristics |

|---|---|---|

Acrylic Resin (AR) | 4 | Reliable moisture protection, easy application, economical |

Epoxy Resin (ER) | 4 | Hard coating, good adhesion, hydrophilic, may swell with moisture |

Silicone Resin (SR) | 4 | Hydrophobic, flexible, good humidity resistance |

Urethane Resin (UR) | 5 | High moisture and chemical resistance, abrasion resistant |

Parylene | 5 | Ultra-thin, pinhole-free, superior moisture barrier |

You should apply conformal coating at thicknesses between 1 to 5 mils (25 to 127 microns) for optimal waterproofing pcbs. UV curable soldermask is a new waterproof coating that cures in seconds and provides strong protection. Parylene nano-coating protection offers ultra-thin, pinhole-free coverage, making it ideal for complex geometries and advanced electronics. LTPCBA uses automated optical inspection to verify coating integrity and ensure reliable waterproof pcbs.

Tip: For automotive and industrial applications, you should select urethane or parylene coatings for the highest moisture resistance.

Potting

Potting is another effective waterproof coating method for waterproof pcbs. You encapsulate the entire pcba in a solid or gel-like material, such as epoxy, silicone, or polyurethane. Potting waterproof techniques provide robust protection against water, chemicals, vibration, and temperature extremes. You can use potting compounds to fill gaps and seal components, creating a barrier that prevents moisture ingress.

Epoxy-based potting waterproof compounds offer high strength and chemical resistance.

Silicone-based potting waterproof compounds provide flexibility and wide temperature tolerance.

Polyurethane-based potting waterproof compounds balance strength and flexibility.

Potting or casing pcb encapsulation is ideal for harsh environments, such as marine or industrial settings. You should consider selective pcb encapsulation for areas that need extra protection. LTPCBA’s advanced assembly ensures precise application of potting waterproof materials, maximizing long-term reliability.

Note: Potting waterproof methods can extend the operational lifespan of waterproof pcbs to 5-10 years or more.

Nano-Coating

Nano-coating is a cutting-edge waterproof coating for waterproof pcbs. You apply an ultra-thin, hydrophobic layer that repels water and blocks moisture. Advanced nanoGUARD coatings cover the entire pcba, including connectors and contacts, without the need for masking. Nano-coating dries quickly at room temperature and allows easy rework.

Nano-coating exceeds IPX7/8+ standards, protecting against liquids, condensation, and humidity.

The process maintains signal integrity and does not interfere with heat sinks or antennas.

Nano-coating complies with environmental and safety standards.

Traditional Conformal Coatings | Nano-Coatings (e.g., Aculon NanoProof®) | |

|---|---|---|

Thickness | 10-200 microns | ~400 nm (nanometer scale) |

Water Ingress Protection | Effective moisture barrier | Strong water repellency, meets IPX7+ |

Application | Masking required, long cure | No masking, rapid drying |

Durability | Robust, inflexible | May need thicker application for harsh environments |

You should use nano-coating for selective pcb encapsulation in advanced electronics, IoT devices, and wearables. LTPCBA offers parylene nano-coating protection for maximum waterproofing pcbs performance.

Enclosures

Enclosures provide mechanical waterproof coating protection for waterproof pcbs. You place your pcba inside a sealed box made from materials like polycarbonate, ABS plastic, or aluminum. You use gaskets, o-rings, and adhesive bonding to create a watertight seal. Industry standards recommend achieving IP65, IP66, or IP67 ratings for waterproof pcba enclosures.

Description and Use Case | |

|---|---|

NEMA 1 | Indoor, basic dust protection |

NEMA 3 | Outdoor, protects against rain and snow |

NEMA 4 | Watertight, industrial outdoor use |

NEMA 4X | Watertight, corrosion resistance |

NEMA 6/6P | Temporary or extended submersion |

You should also use water-resistant substrates, three-proof paint, and special pcb varnish inside enclosures for extra protection. LTPCBA tests enclosures for static and dynamic water pressure to ensure compliance with waterproof pcba standards.

Tip: Add desiccants and humidity control features inside enclosures to further prevent moisture-related failures.

Connector Sealing

Connector sealing is vital for waterproofing pcbs. You use waterproof gaskets, o-rings, and overmolded seals to block water ingress at connection points. You should select connectors with IP66 or IP67 ratings and ensure proper alignment during installation. Materials like silicone, thermoplastic elastomers, and rubber provide durable waterproof coating for connectors.

Use waterproof gaskets and o-rings in connector designs.

Employ overmolded seals made from silicone or thermoplastic elastomers.

Ensure correct connector alignment to prevent gaps.

Choose connectors with high IP ratings for reliable waterproof pcbs.

Use sealing features such as gasket grooves and overmolded housings.

You can also use waterproof electrical tape, silicone sealant, and waterproof connection boxes for selective pcb encapsulation at connectors. LTPCBA’s quality assurance team verifies connector sealing through rigorous testing.

Note: Proper connector sealing prevents corrosion, electrical shorts, and insulation degradation in waterproof pcbs.

Materials & Steps

Choosing Materials

You need to select waterproofing materials based on your environment and the demands of your application. For waterproof pcbs, common choices include conformal coating, potting compounds, greases, gaskets, and silicone sealants. Each material offers a different level of water resistance. The table below shows how IP ratings relate to water protection:

IP Rating | Water Resistance Description |

|---|---|

IPx0 | No protection from water |

IPx1 | Protection against vertically falling water drops |

IPx3 | Protection against spraying water |

IPx5 | Protection against water jets |

IPx7 | Protection against temporary immersion in water |

IPx8 | Protection against continuous immersion in water |

You should consider the nature of your product, budget, and the specific waterproofing requirements. For example, silicone-based conformal coating works well for moisture and UV resistance, while potting with epoxy provides robust protection in harsh conditions. Moisture-resistant substrates like polyimide or PTFE help minimize absorption, supporting circuit board structure waterproof.

Tip: Parylene coatings offer uniform film thickness and excellent edge coverage, making them ideal for advanced waterproof pcbs.

Application Process

You must follow best practices when applying waterproofing materials to protect pcb boards. Start by sealing vias and exposed areas with epoxy, polyurethane, or silicone. Use spraying, dipping, or brushing methods for conformal coating, depending on the coverage you need. Apply multiple thin coats instead of one thick layer to avoid bubbles and defects. For potting, embed the pcba in the compound and allow it to cure fully.

Always use proper equipment for even application.

Cure coatings at recommended temperatures and times.

Allow adequate drying between coats to prevent cracking or delamination.

Note: Qualification testing, such as leak tests and insulation resistance checks, ensures you are protecting a circuit effectively.

Cleaning & Drying

Before you apply any waterproofing, clean the pcba thoroughly. Remove oils, flux residues, and fingerprints, as contamination can cause defects like de-wetting and delamination. Use isopropyl alcohol or specialized cleaning agents. Dry the board completely before starting the application process. After coating, let each layer dry fully before adding another. This step supports structural waterproofing and helps maintain the integrity of waterproof pcbs.

Proper cleaning and drying prevent common mistakes and ensure long-term reliability for your waterproof pcbs.

Pros & Cons

Method Comparison

When you choose a waterproofing method for your PCBA, you need to weigh the advantages and disadvantages of each option. The table below helps you compare the most common materials and methods. This comparison will help you select the right solution for your project and ensure a good waterproof effect.

Waterproofing Method/Material | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

Acrylic Conformal Coating | Easy to apply, repairable, good waterproof effect | Not for high heat or solvents | Automotive, communication devices |

Polyurethane Coating | Solvent resistant, easy to apply | Hard to repair, long cure time | Salt spray, solvent resistance |

Silicone Coating | High temperature resistance, flexible | Expensive, hard to remove | Mining, high heat equipment |

Epoxy Potting | Good moisture and chemical resistance, strong effect | Not flexible, hard to remove | Industrial, marine |

Paraxylylene Nano-coating | Excellent protection performance, thin, covers complex shapes | Expensive, complex process | High-reliability electronics |

Fluoropolymer Nano-coating | Ultra-thin, low cost, good dielectric effect | Low abrasion resistance | Specialized coatings |

Tip: If you need a good waterproof effect and easy repair, acrylic coatings work well. For the best protection performance in harsh environments, consider potting or parylene nano-coating.

Environmental Suitability

You must match your waterproofing method to the environment where your PCBA will operate. Each method offers a different level of protection performance and effect against water, chemicals, and temperature.

In high humidity, silicone-based coatings give you flexibility and a good waterproof effect.

For saltwater or corrosive settings, use corrosion-resistant finishes like immersion gold and sealed enclosures.

Potting and encapsulation protect your PCBA in deep water or extreme moisture, but you cannot repair the board after application.

Gasket and enclosure sealing with IP65 or higher ratings prevent water from entering, especially when you use strong materials like stainless steel or high-grade plastics.

Regular maintenance, such as cleaning and reapplying coatings, extends the life of your waterproof PCBA.

Sealing connectors with gaskets or O-rings is critical for keeping water out at connection points.

Note: Always test your waterproofing with IP, salt spray, or humidity tests to confirm the effect matches your needs.

Testing & Quality

Effectiveness Tests

You need to verify the waterproofing effect of your PCBA before you trust it in the field. Testing helps you confirm that the protection performance meets your requirements. You can follow a series of steps to check the overall protection performance:

Clean your PCB and use ionograph testing to find any ionic contaminants. This step prevents trapping unwanted materials under the conformal coating.

Dry your test specimen at 50°C for 24 hours. This prepares the board for accurate testing.

Measure the initial insulation resistance by applying 100 VDC. You should see a minimum resistance of 100 MΩ.

Place your specimen in a humidity and temperature cycling chamber. Set the humidity to 85% and apply a 10 VDC bias to alternating daisy chains. This helps you detect corrosion or dendritic growth by monitoring voltage drops.

Run 10 cycles of temperature and humidity stress. Each cycle raises the temperature from 25°C to 85°C over 2 hours, holds at 85°C for 4 hours, cools back to 25°C over 2 hours, and holds at 25°C for 4 hours. Repeat this process 4 times per cycle.

Monitor voltage drops every 60 seconds during cycling. This step helps you spot electrochemical migration.

After every second thermal cycle, perform insulation resistance tests with 100 VDC. Complete a final test after all cycles at 25°C and 50% relative humidity.

These procedures follow IPC and JEDEC standards. You can use them to confirm the waterproofing effect and ensure your PCBA resists moisture, corrosion, and electrochemical migration.

Tip: Regular testing helps you maintain high protection performance and avoid unexpected failures.

Quality Control by LTPCBA

You want your waterproof PCBA to deliver reliable results. LTPCBA uses strict quality control measures to guarantee the effect of every waterproofing process. The team inspects each board with automated optical inspection (AOI) to catch defects early. You benefit from advanced testing equipment that checks insulation resistance, verifies coating thickness, and confirms the overall protection performance.

LTPCBA follows international standards like ISO, IATF, and UL. You receive PCBA products that meet industry benchmarks for durability and safety. The company’s engineers monitor every step, from cleaning and coating to final testing. You can trust LTPCBA to deliver consistent protection performance and long-lasting waterproof PCBA solutions.

Note: LTPCBA’s commitment to quality ensures your PCBA works reliably in any environment.

You can achieve reliable waterproof pcba by following proven best practices. Select materials and methods that fit your environment and performance needs. The table below compares common waterproofing materials:

Material | Thickness Range | Flexibility | Temperature Range | Rework Difficulty |

|---|---|---|---|---|

Acrylic | Low | -40°C to +125°C | Easy | |

Silicone | 50-200µm | High | -55°C to +200°C | Moderate |

Epoxy | 0.5-2mm | None | -50°C to +150°C | Impossible |

Polyurethane | 25-100µm | Medium | -40°C to +130°C | Difficult |

Choose the right solution for waterproof your electronics by considering these steps:

Define your performance and maintenance needs.

Match the method to your design and budget.

LTPCBA delivers high-quality solutions and expert support for every project.

FAQ

What is the best waterproofing method for outdoor PCBAs?

You should use a combination of conformal coating and sealed enclosures. This approach gives you strong protection against rain, humidity, and dust. For extra safety, select materials rated for outdoor use.

Can you repair a PCBA after potting?

You cannot easily repair a potted PCBA. Potting materials harden around components. If you need to fix something, you often must remove the entire potting, which can damage the board.

How do you test if your PCBA is waterproof?

You can perform an IPX7 or IPX8 water immersion test. Place your PCBA in water for a set time and check for leaks or failures. You should also measure insulation resistance before and after testing.

Does nano-coating affect signal quality?

Nano-coating does not affect signal quality. The layer is ultra-thin and non-conductive. You can use it on sensitive electronics, including antennas and sensors, without worrying about interference.

See Also

Essential Methods To Enhance PCBA Durability Over Time

Advantages Of Using Conformal Coating In PCBA Assembly

Primary Materials Required For Effective PCBA Manufacturing