The implementation method of double-sided reflow soldering in PCBA production

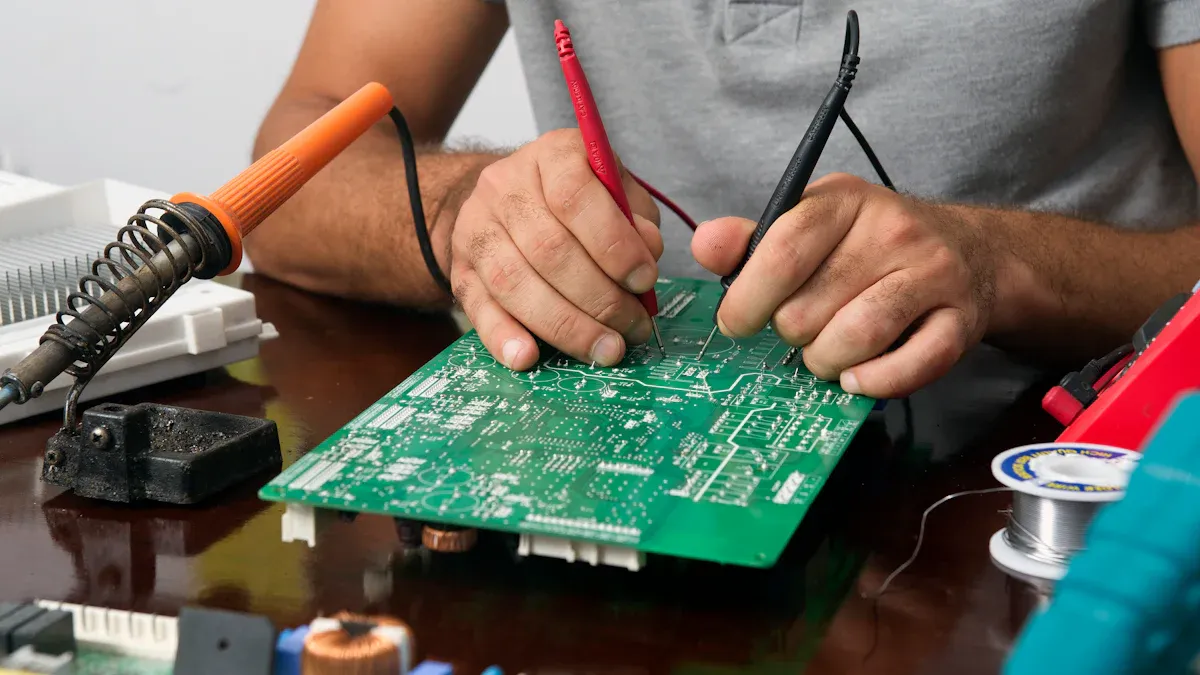

You use double-sided reflow soldering to put parts on both sides of a pcb. You need to watch each reflow step closely to stop problems. You must keep parts steady as the pcb goes through each reflow zone. Quality checks help make sure your double-sided reflow soldering works well.

Key Takeaways

Pick the best double-sided reflow soldering method for your PCB parts. This helps keep all parts steady and safe during making. Watch the temperature closely at each reflow step. This keeps solder joints safe and makes strong connections on both sides of the PCB. Do quality checks like automated optical inspection after each reflow. This helps find mistakes early and makes sure the PCB is good and works well.

Double-Sided Reflow Soldering Methods

When you do double-sided reflow soldering in pcb manufacturing, you must pick the best method for your job. Each method has its own steps and works best for certain projects. LTPCBA uses modern machines and strict quality checks to make sure your pcb turns out great. Here are the main ways you can do double-sided reflow soldering.

Solder Paste on Both Sides

The solder paste on both sides method is common for regular pcb manufacturing. This way works best if both sides of your pcb have similar parts. First, you put solder paste on one side of the pcb. Then you place the parts on that side and run the pcb through the reflow oven. The solder paste melts and holds the parts in place.

After the first reflow, you flip the pcb over. Next, you put solder paste on the second side and add the rest of the parts. The pcb goes through the reflow oven again. You must watch the temperature during the second reflow. This keeps the first side’s solder joints from getting damaged. Conveyor-type convection reflow ovens help hold the pcb steady and stop it from sagging in the heat. These ovens use special fans and supports to keep the heat even. Careful control makes this method work well for double-sided reflow soldering.

Tip: Use adhesives or low-temperature solder paste for small or light parts on the second side. This helps keep them from moving during the second reflow.

Tests show that how voids form in solder joints changes their strength. Small, spread-out voids can help solder joints last longer. Big voids near the edge can cause damage faster. You need to check for these problems during soldering to keep your pcb strong.

Red Glue and Solder Paste

The red glue and solder paste method is good when your pcb has both heavy and light parts. This way helps stop parts from falling off during reflow soldering. First, you put red glue on the pcb where the heavy parts go. Then you place the heavy parts on the glue. After that, you put solder paste on the same side for the lighter parts.

You run the pcb through the reflow oven. The glue holds the heavy parts while the solder paste melts and bonds the light parts. After the first reflow, you flip the pcb and do the same steps for the other side. This method is great for double-sided reflow soldering in pcb manufacturing when you need extra support.

Note: Make sure the glue dries all the way before reflow. This stops parts from moving during soldering.

LTPCBA uses automated optical inspection (AOI) after each reflow soldering step. This checks for any parts that are missing or in the wrong place. You get a high pass rate and reliable pcb manufacturing with this process.

Different Melting Point Solder Paste

Sometimes you need to use different melting point solder paste if your pcb has parts that are sensitive to heat. This way uses two kinds of solder paste: one melts at a high temperature and one melts at a low temperature. First, you put the high melting point solder paste on one side of the pcb. You add the parts and run the pcb through the reflow oven. The high melting point solder paste melts and makes strong joints.

Next, you flip the pcb and put the low melting point solder paste on the other side. You add the rest of the parts and run the pcb through the reflow oven again. The lower heat keeps the first side’s solder joints safe from melting again. Studies show that low temperature solder pastes, like tin-bismuth alloys, can work as well as standard SAC alloys sometimes. But these low temperature pastes can be brittle and may not work well for pcbs that get a lot of stress.

Tip: Use this way for consumer electronics or protected parts where the pcb does not get much shock or shaking.

LTPCBA’s advanced reflow soldering machines let you set exact temperatures for each solder paste type. This makes sure both sides of your pcb get strong, reliable solder joints. You can trust LTPCBA to do complex double-sided reflow soldering with high quality and speed.

Double-Sided PCB Process Control

Preventing Component Fall-Off

You must keep all parts steady on your double-sided pcb. Small or light parts might move or fall off during the second reflow. Using adhesives or special solder paste can help hold them in place. LTPCBA uses smart machines to put each part carefully. You should check the size and weight of each part before making the pcb. Heavy parts should be placed on the first side. This lets the solder paste hold them tight in the second reflow. Good planning helps stop problems and keeps your pcb safe.

Temperature and Reflow Profile

Having the right temperature is very important for double-sided pcb work. You need to control each reflow step to protect both sides. Here is a table that shows the best settings for each reflow phase:

Reflow Phase | Key Parameters & Effects | Recommended Values & Notes |

|---|---|---|

Preheat | Gets pcb ready, removes flux, lowers shock | Ramp rate: 1–1.5°C/sec; ΔT <40°C |

Pre-reflow | Soak makes temperature even, lowers voids | Soak for big pcbs and special parts |

Reflow | Solder paste melts, makes strong joints | Peak: 20–30°C above liquidus; TAL: 30–90 sec |

Cooling | Sets solder grain, stops cracks | Cooling: ~4°C/sec |

You should use a ramp rate of 1–1.5°C per second. This helps stop graping and other problems. Always watch the highest temperature and time above liquidus. This keeps the solder paste from burning and makes solder joints strong. LTPCBA sets each oven to fit your pcb’s needs. This makes sure every double-sided pcb is high quality.

Quality Assurance at LTPCBA

You want your double-sided pcb to pass every test. LTPCBA uses special machines to check for missing or wrong parts after each reflow. The team follows ISO, IATF, and UL rules for every job. You get a high pass rate and a good pcb every time. LTPCBA’s experts watch every reflow and solder paste step. You can trust them to make strong, reliable double-sided pcb assemblies for you.

You get the best double-sided reflow soldering results by doing these things:

Pick the best soldering method for your project.

Use careful stencil printing and good pick-and-place machines.

Watch the temperature closely at every step.

Work with LTPCBA to get expert help and strong double-sided PCB assembly.

FAQ

What is double-sided reflow soldering?

Double-sided reflow soldering puts parts on both sides of a PCB. You use two reflow steps to make sure all parts stay in place.

How do you stop parts from falling off during the second reflow?

You can use glue or special solder paste with a low melting point. LTPCBA’s machines put each part in the right spot and keep them steady.

Why should you choose LTPCBA for double-sided PCB assembly?

Reason | Benefit |

|---|---|

Modern machines | Great quality every time |

Careful checks | 99.5% pass rate |

Fast help | Quick support and answers |

See Also

Real-Time Temperature Monitoring Techniques For PCBA Reflow Soldering

Why Nitrogen Reflow Soldering Matters In Automotive SMT Manufacturing

Essential Process Guidelines For Reflow Soldering In SMT Production

Step-By-Step Guide To Reflow Soldering Through-Hole Parts Post SMT

Techniques Used To Achieve Double-Sided Mounting In SMT Assembly