The technical process for double-sided mounting of BGA devices in PCBA products

Double-sided mounting lets engineers put parts on both sides of a printed circuit board. This helps make devices smaller and stronger.

Evidence Aspect | Details |

|---|---|

Market Size (2024) | |

Projected Market Size (2033) | USD 4.8 Billion |

CAGR (2026-2033) | 7.8% |

Key Growth Drivers | People want electronics that save energy and work well in many industries |

Technical Advantages | It cools better, is stronger, and works for high-power uses |

Emerging Applications | Used in electric cars, green energy, 5G, planes, and defense |

Quality checks are very important for double-sided mounting of BGA devices.

Key Takeaways

Double-sided mounting lets engineers put parts on both sides of a circuit board. This makes devices smaller and stronger. It also lets them add more features without making the device bigger.

LTPCBA uses special machines like AOI and X-ray inspections to check each step. This helps make sure the solder joints are good. It also helps make PCBA products that work well and have fewer mistakes.

Careful design and exact solder paste use are important. Controlled reflow and careful checks help with heat, alignment, and solder joint strength. These steps help double-sided BGA assembly work well.

Double-Sided Mounting Overview

What Is Double-Sided Mounting?

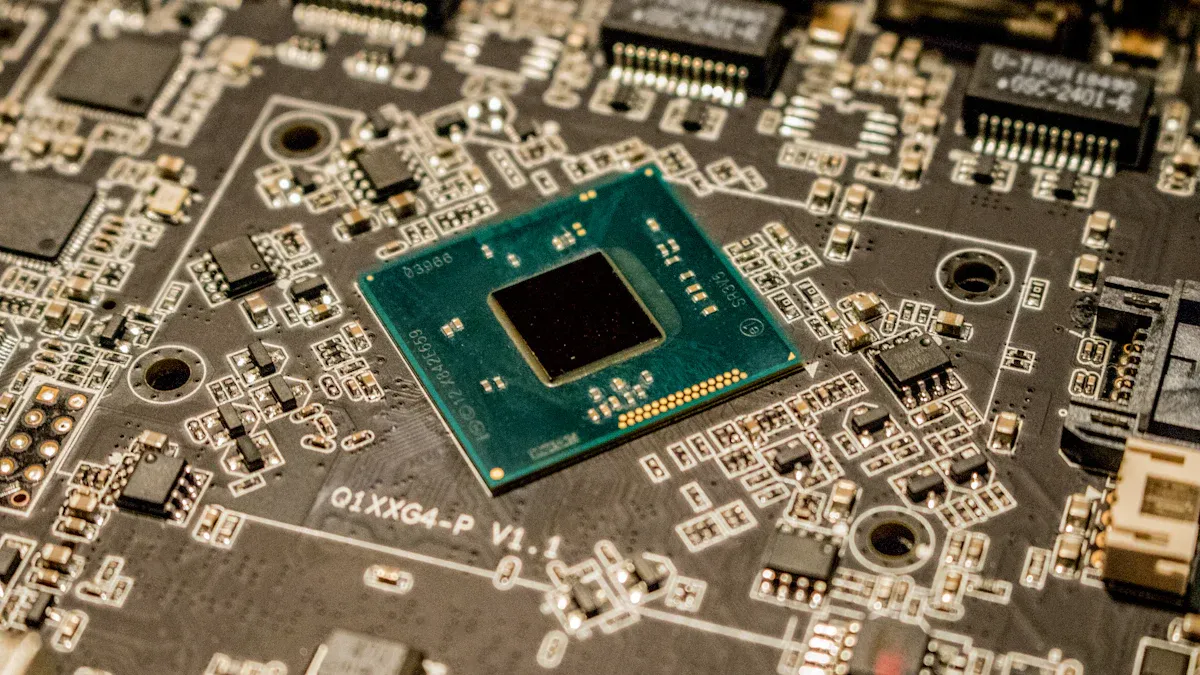

Double-sided mounting means engineers put parts on both sides of a PCB. This lets them fit more parts into a small space. LTPCBA uses special machines and follows strict rules to get good results. The company uses dual-camera AOI systems. These systems have clear cameras and bright lights. They take sharp pictures of both sides of the PCB. The AOI looks for missing parts, wrong placements, and soldering problems. It checks both sides at once. This saves time and makes the checks more accurate.

Note: Double-sided mounting helps engineers make small and strong devices. It also helps meet the need for tiny and complex electronics.

Benefits for PCBA Products

Double-sided mounting gives many benefits for PCBA products:

More parts fit: Putting parts on both sides lets boards be more complex.

Better performance: Devices can do more jobs without getting bigger.

Better checking: AOI systems check fast and well, so there are fewer mistakes and more good boards.

Saves money: The process cuts labor costs and makes things faster.

LTPCBA is skilled at double-sided mounting, so the assembly is steady and reliable. The company’s AOI technology helps with quality checks and tracking. This way, they meet the needs of industries that want small and powerful electronics.

Process Steps

Design Considerations

Engineers start by planning the double-sided mounting process. They pick the PCB stackup, drill sizes, and materials. They use special PCB design software to help avoid mistakes. Tools like Altium Designer let them do many steps in one place. This makes the work go smoothly and helps stop errors.

Designers set rules for via and mounting hole sizes. They keep the solder side simple with only basic parts. They do not use fine-pitch devices or BGAs on this side. Parts on the solder side must be shorter than 6mm. Heavy parts cannot be too heavy for their pads. This stops parts from falling off during reflow. Engineers leave extra space at the board edges for stiffeners. Stiffeners help keep the board straight during soldering.

Thermal simulations are very important. They help engineers pick the right solder joint size and pad thickness. These choices make solder joints last longer when heated and cooled. Substrate thickness and solder ball height also matter for strong boards.

Tip: Making a full bill of materials with sourcing info helps get ready for production.

Solder Paste Application

Solder paste application is a key step in double-sided mounting. LTPCBA uses machines to put solder paste on the board very carefully. The company tests many solder pastes before picking one. They look at print quality, wetting, slump, solder balls, and reflow. They use numbers like transfer efficiency to help choose.

AOI and X-ray imaging check the solder paste spots. These checks find problems that could cause bad solder joints. Good solder paste and inspection stop issues like voids and cold joints. This helps make sure BGA assembly works well.

First Side Placement and Reflow

After solder paste is on, engineers put parts on the first side. Fast pick-and-place machines put each part in the right spot. The board goes into a reflow oven next. The oven melts the solder paste to make strong joints.

Engineers watch the reflow profile closely. They use thermocouples to check the temperature. This makes sure the board heats evenly. This step is very important for good solder joints, especially for BGAs. LTPCBA’s process control keeps quality high.

Board Flipping and Second Side

When the first side cools, workers flip the board for the second side. They handle the board gently to protect the first solder joints. Fixtures or carriers hold the board and stop stress on parts.

Engineers limit the size and weight of parts on the second side. This keeps parts from moving or falling off in the next reflow. Sometimes they use things like Kapton tape to hold parts in place.

Second Side Placement and Reflow

The second side gets solder paste and parts just like the first. Engineers check datasheets to make sure parts can handle reflow. They look at temperature ratings and materials to avoid damage.

The board goes through a second reflow oven. Oven settings are very important now. Engineers change the profile for the board’s extra heat mass. They use thermocouples to watch the temperature and Time Above Liquidus. Good hole size and stencil design control solder amount and fill.

Some parts need special care. Connectors or plastic parts must survive reflow heat. Engineers may use lower temperature solder or supports to protect these parts.

Note: Solder joints may look different from old methods, but if holes are filled and joints meet IPC standards, the board is good.

Inspection and Quality Control at LTPCBA

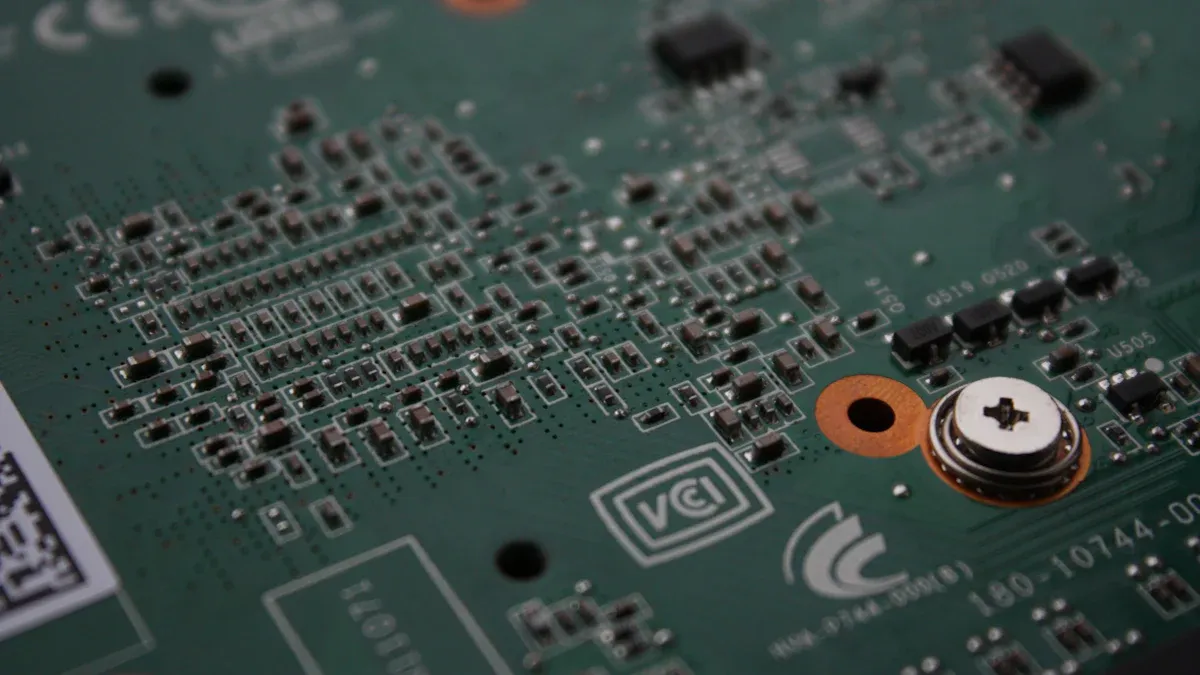

LTPCBA checks quality at every step of double-sided mounting. They use both manual and machine inspections to keep standards high.

Manual inspection: Workers use magnifiers and microscopes to find problems.

AOI: Machines with cameras check solder joints, part placement, and cleanliness fast.

X-ray inspection: This finds hidden problems under BGAs that eyes can’t see.

Functional testing: Engineers do continuity checks and ICT to test circuits.

Frequent inspection cycles: These help catch and fix problems early.

Careful rework: Workers fix tricky spots like fine-pitch parts with extra care.

Post-inspection cleaning: The team cleans off flux to keep boards reliable.

LTPCBA writes down all inspection results and tracks how tools and materials perform. This helps keep boards reliable and improves the process over time.

Quality assurance at LTPCBA uses advanced tools, strict controls, and a promise to deliver strong solder joints for every project.

Challenges and Solutions

Thermal Management

Engineers have tough problems with heat in double-sided mounting of BGA devices. Chips on both sides make more heat. This can make the inside of the chip too hot and hurt how long it lasts. Studies say it is important to control heat, coolant flow, and pressure at the same time. Here are some main points:

More chips on both sides make the chip hotter.

Coolant must move at the right speed to cool well and save energy.

Engineers use special materials and tools to measure heat.

It is important to spread heat and move coolant evenly.

LTPCBA uses computer models and real-time checks to keep heat safe.

Alignment and Placement

Putting BGA devices in the right spot is very important. The table below shows common problems and ways to fix them:

Aspect | Details |

|---|---|

Assembly success rate | |

Typical error margins | Less than 0.8 mm for position, 0.6 degrees for angle |

Key challenges | Mistakes in finding the right spot, matching in 3D, and limits of hand skills |

Using computer models, 3D cameras, and math methods |

LTPCBA uses smart machines and 3D cameras to help place parts better and make fewer mistakes.

Solder Joint Reliability

Good solder joints stop problems in double-sided mounting. LTPCBA puts on solder paste with machines and checks joints with AOI and X-ray. They control oven heat to stop small cracks and weak spots. The team follows IPC and ISO rules to make sure joints are strong and have no defects.

Best Practices

LTPCBA keeps quality high by:

Checking with many ways like AOI, X-ray, and electric tests.

Using math to find problems early.

Writing down checks and always trying to get better.

Training workers and using live data to change the process.

LTPCBA’s way gives a 99.5% pass rate and strong BGA assemblies for tough jobs.

Good assembly needs good planning and careful work. Parts must be put in the right place. Every step must be checked closely. LTPCBA uses important numbers to check their work:

How happy customers are

How they keep getting better

These things help LTPCBA give every customer strong and dependable PCBA products.

FAQ

What is the main advantage of double-sided BGA mounting?

Double-sided BGA mounting lets more parts fit on a board. This helps engineers make smaller and stronger devices for new uses.

How does LTPCBA ensure quality in double-sided assembly?

LTPCBA checks each board many times to find problems. They use AOI, X-ray, and follow strict rules to keep boards good.

Can all components handle double-sided reflow?

Some parts cannot go through double-sided reflow. Engineers read datasheets and pick parts that can take the heat and have the right materials.

See Also

Understanding The Process Of Double-Sided SMT Assembly Mounting

Effective Techniques For Double-Sided Reflow Soldering In PCBA

Through-Hole DIP PCBA Manufacturing, Quality, And Application Insights

Steps To Ensure Perfect BGA Assembly Through Quality Control

Critical Technical Aspects Of Conformal Coating In PCBA Production