A Guide to Designing Industrial Controller PCBs

Designing and manufacturing industrial controller PCBs requires a strong emphasis on reliability. This is crucial to ensure they perform effectively in challenging environments that often experience extreme heat, vibrations, and electrical noise. Therefore, the PCBs must be robust. You can address these challenges with intelligent strategies. One effective method is implementing first article inspections, which enhances quality checks and reduces defects by half. Additionally, optimizing solder paste usage can resolve 75% of rework issues.

Key Takeaways

Make sure industrial controller PCBs are reliable. This helps them work well in harsh conditions.

Use first article inspections to make quality checks better and lower defects a lot.

Pick strong materials and improve heat control to make PCBs last longer and work better.

Understanding Industrial Controller PCBs

What Are Industrial Controller PCBs

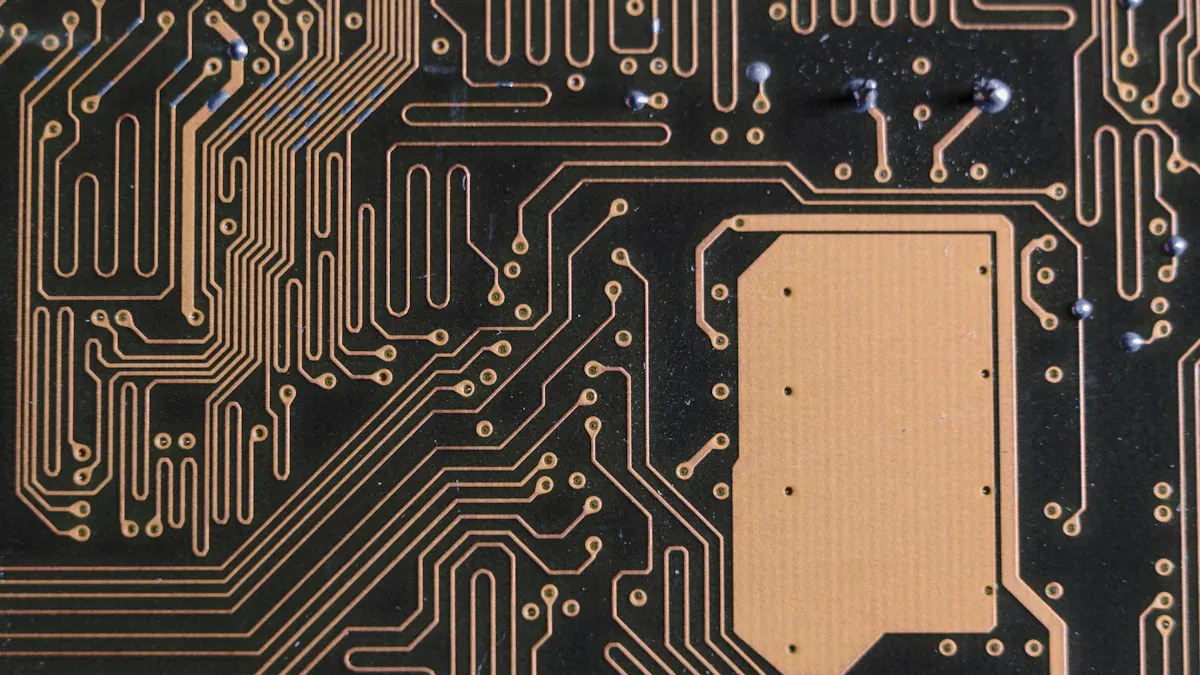

Industrial controller PCBs are the core of modern machines. They connect parts and help them work together. These boards are tougher than regular PCBs. They can handle heat, shaking, and electrical problems without breaking.

As automation grows, these PCBs are more important than ever. By 2035, the PCB market could grow from $70.44 billion in 2024 to $122.8 billion. Rigid PCBs might make up about 39% of this market. This shows how vital industrial controller PCBs are for many uses.

Role of Industrial Controller PCBs in Automation

Industrial controller PCBs are like the brain of machines. They send signals, control actions, and keep things running smoothly. For instance, in factories, they manage robotic arms, conveyor belts, and monitors. Their ability to handle hard tasks makes them key in industries like cars, planes, and healthcare.

These PCBs do more than basic jobs. They allow advanced features like live monitoring, fixing problems early, and saving energy. This makes them crucial for boosting work speed and cutting downtime in industries.

Key Features for Reliability in Industrial Controller PCBs

Making reliable industrial controller PCBs needs focus on key things:

Thermal Management: Good heat control keeps the PCB working in hot places.

Signal Integrity: Clear signals stop errors in communication.

Durable Materials: FR4 material, with 43% market share, is strong and heat-resistant.

Compliance with Standards: Following IPC rules ensures quality and performance.

Testing and Validation: Tests like optical checks and heat tests prove the PCB works well.

By focusing on these features, you can create PCBs that handle tough industrial needs.

Step-by-Step Guide to Designing Reliable Industrial Controller PCBs

Conceptualizing the Design PCB Controller

The first step in making industrial controller PCBs is planning the design. This step sets the stage for the whole process. You should:

Decide what the PCB controller will do. Know its purpose and how it will work to match its use.

Check the materials, tools, and methods needed. Make sure they fit the PCB's job and environment.

Pick the right microcontroller. Choose one that fits the power and performance needs.

Collect all the parts. Ensure they meet the controller's needs, like power use and efficiency.

Plan how to test it. Testing ensures the PCB works well in real-life situations.

By following these steps, you can make a clear plan. This helps avoid mistakes and saves time.

Material Selection for Durability and Thermal Management

Choosing the right materials is key for making strong and heat-resistant PCBs. Materials like glass fiber-reinforced polymers (GFRPs) work well. They handle heat better and expand less, which is important for tough jobs.

When picking materials, think about these:

Add heavy copper, heat sinks, or thermal vias to cool the PCB.

Pick parts with tight tolerances (1-2%) for high current.

Match the expansion rates of parts to reduce stress from heat.

Also, check temperature limits early and run heat tests. This ensures the PCB can handle tough conditions. These steps make the PCB better for industrial use.

Strategic Component Placement for Reliability

Placing parts in the right spots makes the PCB more reliable. Good placement keeps the PCB cool, reduces problems, and makes assembly easier. Follow these tips:

Keep hot parts away from sensitive ones to manage heat.

Put connectors near the edges for easy access.

Group similar parts together to reduce interference and improve function.

Keep important signal paths short to avoid signal issues and interference.

Place high-power parts where they can cool down easily.

Organizing parts well makes the PCB work better and easier to build and test.

PCB Layout Design Best Practices

A good PCB layout helps it last longer and work better. Follow these tips:

Use strong materials and connections to keep it working over time.

Match how much parts expand with heat to avoid cracks.

Fill vias to stop dirt and solder problems.

Adjust the heat settings during soldering for lead-free solder.

These choices help your PCB handle tough jobs while staying reliable.

Testing and Validation for Industrial Standards

Testing is important to make sure your PCB meets industry rules. Use these methods:

What It Does | |

|---|---|

In-Circuit Testing (ICT) | Checks if each part on the PCB works. |

Automated Optical Inspection (AOI) | Finds problems with soldering and part placement. |

Functional Testing | Tests the PCB in real-life conditions to see if it works. |

IPC-2221, IPC-A-610 | Ensures the PCB is made with top quality and follows rules. |

ISO Certifications | Confirms the PCB meets global quality standards. |

Using these tests proves your PCB is reliable and works well for industrial needs.

Critical Factors for Reliability in Industrial Controller PCBs

Thermal Management and Heat Dissipation

Good thermal management keeps a pcb controller working well. If heat builds up, parts can fail or wear out faster. You can use these methods to manage heat:

Thermal Vias: Move heat away from parts to keep them cooler.

Heat Sinks: These tools, with pads or paste, send heat into the air.

Substrate Materials: Copper spreads heat evenly across the pcb.

Bad heat control is a top reason electronics break. Using these ideas makes your pcb controller last longer, even in tough places.

Ensuring Signal Integrity and Connectivity

Good signals help a pcb controller work without errors. Weak signals can cause problems and stop systems from working. Follow these tips for better connections:

What It Does | |

|---|---|

Impedance Control | Keeps signal paths steady to avoid bouncing signals. |

Proper Grounding | Reduces noise by using strong grounding methods. |

Trace Length Matching | Makes paired signal paths the same length to fix timing issues. |

Crosstalk Mitigation | Spaces out paths to stop signals from mixing. |

Power Supply Decoupling | Adds capacitors near power pins to keep power steady. |

These steps make your pcb controller more reliable and prevent signal problems.

Adhering to Industrial Standards and Protocols

Following rules ensures your pcb controller is high quality. It also avoids fines and product recalls. Important standards include:

MIL-STD-810: Tests how military gear handles tough conditions.

ISO 16750-3: Checks car electronics for safety and durability.

FCC Part 15: Controls electronic emissions in the USA.

CISPR 22/32: Sets limits for IT equipment emissions worldwide.

IEC 61000-4-x: Tests how electronics handle disturbances.

Meeting these rules makes your pcb controller reliable and easier to sell.

Environmental Protection and Durability

Industrial machines face dust, water, and extreme temperatures. Protect your pcb controller with these ideas:

Cover the pcb with coatings to block water and dirt.

Use sealed cases to keep out dust.

Pick materials that resist expanding and shrinking from heat.

Test the pcb in harsh conditions to check its strength.

These steps help your pcb controller survive tough environments and work for a long time.

LTPCBA’s Skill in Making Industrial Controller PCBs

Modern Tools and Quality Checks

LTPCBA uses modern tools to make top-quality PCBs. They use advanced tests to ensure everything works well. For example, wave soldering makes strong connections and stops rust. This method also controls flux and gives steady results.

To keep quality high, LTPCBA runs strict tests like:

Test Type | What It Checks | Passing Score |

|---|---|---|

Edge Dip Test | Checks how well solder sticks | |

Wave Solder Test | Tests soldering in waves | No visible defects |

Wetting Balance Test | Measures solderability with numbers | At least 95% wetting |

MIL-STD-883 Method 2003 | Full solderability test | 95% coverage, under 5% flaws |

These tests make sure your PCBs are strong and ready to use. LTPCBA finds 99% of issues in just 7 seconds. This makes their process 30% faster.

Focus on Trust and Happy Customers

LTPCBA focuses on making reliable PCBs. They produce 60,000 square meters of PCBs and 240 million SMT points monthly. With a 99.5% quality pass rate, you can count on their products.

They also care about customers. LTPCBA replies quickly and gives quotes in 2-3 days. This helps you finish your projects on time.

Why Pick LTPCBA for Your PCBs

Choosing LTPCBA means working with experts in PCB making. They mix modern tools, strict checks, and great customer care. Whether you need a few PCBs or many, LTPCBA meets your needs. Their skill ensures your PCBs work well, even in tough conditions.

Making industrial controller PCBs needs a focus on being reliable. This helps them work well in tough conditions. Use strong parts, control heat properly, and follow IPC rules. Begin by setting clear goals. Focus on sturdy designs and work with trusted companies like LTPCBA for great results.

FAQ

What makes industrial controller PCBs different from regular PCBs?

Industrial controller PCBs are built for tough conditions. They can handle high heat, strong vibrations, and electrical noise. This makes them reliable and long-lasting for industrial use.

How can you improve the thermal management of a PCB?

You can add thermal vias, heat sinks, or copper layers. These tools help remove heat, protect parts, and keep the PCB working well.

Why is testing important for industrial controller PCBs?

Testing checks if the PCB meets industry rules. It proves the PCB works, lasts long, and won’t fail in real-life industrial jobs.

See Also

Comprehensive Overview of PCBA Manufacturing for All Skill Levels

Exploring Industrial Serial Screen PCBA Applications in Today’s Market

Designing PCB Boards for Effective SMT Processing Needs

Choosing the Right PCBA Supplier for Your Specific Requirements

Effective Strategies for Optimizing SMT Lines in PCBA Production