Technical key points of conformal coating processing in the PCBA production process

Conformal coating processing protects your PCBA from elements like water and dust. This layer keeps it safe by preventing rust and damage. Industries such as automotive and aerospace utilize conformal coating to enhance the longevity of parts in challenging conditions. LTPCBA employs advanced tools and expertise to deliver top-quality conformal coating for your electronics.

Key Takeaways

Conformal coating keeps PCBA safe from water, dirt, and harm. It helps electronics last longer and work better.

Picking the correct coating, like acrylic or silicone, is key. It ensures the best protection for different surroundings.

Cleaning surfaces and applying coating properly, like spraying or dipping, is important. This makes the coating strong and long-lasting.

Purpose and Benefits of Conformal Coating

Protection against moisture, dust, and contaminants

Conformal coating adds a shield to protect your PCBA from harm. This layer stops water from causing rust or short circuits. It keeps your electronics working in wet conditions. Dust and dirt are also blocked, preventing overheating or problems. The coating also guards against power surges, keeping circuits safe and working well.

Tip: Use conformal coating to protect your PCBA from damage. It helps your electronics last longer and work better.

Prevention of corrosion and electrical failures

Rust can ruin your PCBA and cause costly problems. Conformal coatings stop rust by shielding the board from water and chemicals. Studies show that good adhesion and water-blocking features are key to stopping rust.

Research using special tests found elastomeric acrylate coatings work best. They protect circuits even in dirty or tough conditions, making them great for hard environments.

Enhanced durability and performance in harsh environments

Electronics often face tough conditions like heat or salty air. Conformal coatings make them stronger by keeping water out and handling heat well. They also lower stress on parts, helping them work better in rough places.

Performance Metric | Benefit Description |

|---|---|

Moisture Resistance | Stops water damage, making electronics last longer and work better. |

Thermal Stability | Handles big temperature changes, keeping devices working. |

Corrosion Protection | Blocks harmful elements, stopping parts from breaking down. |

Conformal coatings also help parts work better by insulating them and reducing stress. This makes them important for industries like aerospace and cars.

Contribution to operational integrity and dielectric resistance

Conformal coatings help keep electronics working well and improve insulation. They stop electricity from leaking and ensure circuits work properly. Coatings that meet military standards, like MIL-I-46058C, add a protective layer to prevent shorts and sparks.

Evidence Type | Description |

|---|---|

Electrical Insulating Properties | Stops electricity leaks, ensuring circuits work in tight spaces. |

Compliance with Military Specs | Adds a layer to prevent shorts and sparks. |

Resistance to Environmental Factors | Protects against damage from tough conditions, keeping electronics reliable. |

These coatings block chemicals, water, and humidity, protecting PCBs from harm. They also stop cracks in batteries, making electronics safer and last longer.

Types of Conformal Coatings in PCBA Manufacturing

Acrylic-based coatings

Acrylic coatings are great for UV protection and lasting use. They are simple to apply and remove, making repairs easy. These coatings don’t turn yellow and stay strong under sunlight. This makes them perfect for outdoor electronics. Acrylic coatings also block some moisture, so they work well for general PCBA needs.

Tip: Use acrylic coatings if UV light is a concern. They are easy to handle and popular with developers.

Silicone-based coatings

Silicone coatings work well in heat and humid conditions. They can handle temperatures over 120°C and resist water, chemicals, and rust. These coatings stick firmly to electronics, offering strong protection in tough places. Silicone coatings, like Konform SR-X, dry fast at room temperature. They also resist scratches, making them great for cars and planes.

Test Method | Description |

|---|---|

MIL-STD 810G salt spray | Tests how well coatings work in wet outdoor settings. |

MS941-04 | Checks performance in extreme conditions, often used in cars. |

Polyurethane-based coatings

Polyurethane coatings protect against tough environmental conditions. They work well in high humidity and changing temperatures. These coatings stop moisture from damaging parts, keeping them safe. But their curing process takes time, so they’re not ideal for small projects. Studies show they are great for long-term protection of PCBs.

Note: Polyurethane coatings are strong but need careful curing, which can make production harder.

Epoxy-based coatings

Epoxy coatings are strong and keep out moisture. They protect against rust and wear, making them good for factories. But they are stiff, which can be a problem if the board bends. Epoxy coatings must be mixed and used quickly because they harden fast. Special tools are needed for this process.

Advantages:

Very durable and resists chemicals well.

Stops rust and stress damage effectively.

Limitations:

Not flexible under heat changes.

Needs careful preparation and tools to apply.

Parylene coatings for high-performance applications

Parylene coatings cover PCBs evenly without gaps, offering top protection. They have strong insulation, handle heat well, and stop rust. This makes them perfect for military, medical, and aerospace uses. Parylene coatings are applied with Chemical Vapor Deposition (CVD), which ensures even coverage but is complex to do.

Feature | Description |

|---|---|

Dielectric strength | Provides strong insulation (6800-7000 volts/mil). |

Thermal stability | Works well in high heat (up to 290°C). |

Biocompatible | Safe for medical devices. |

Parylene coatings are the best choice for demanding jobs needing strong and reliable protection.

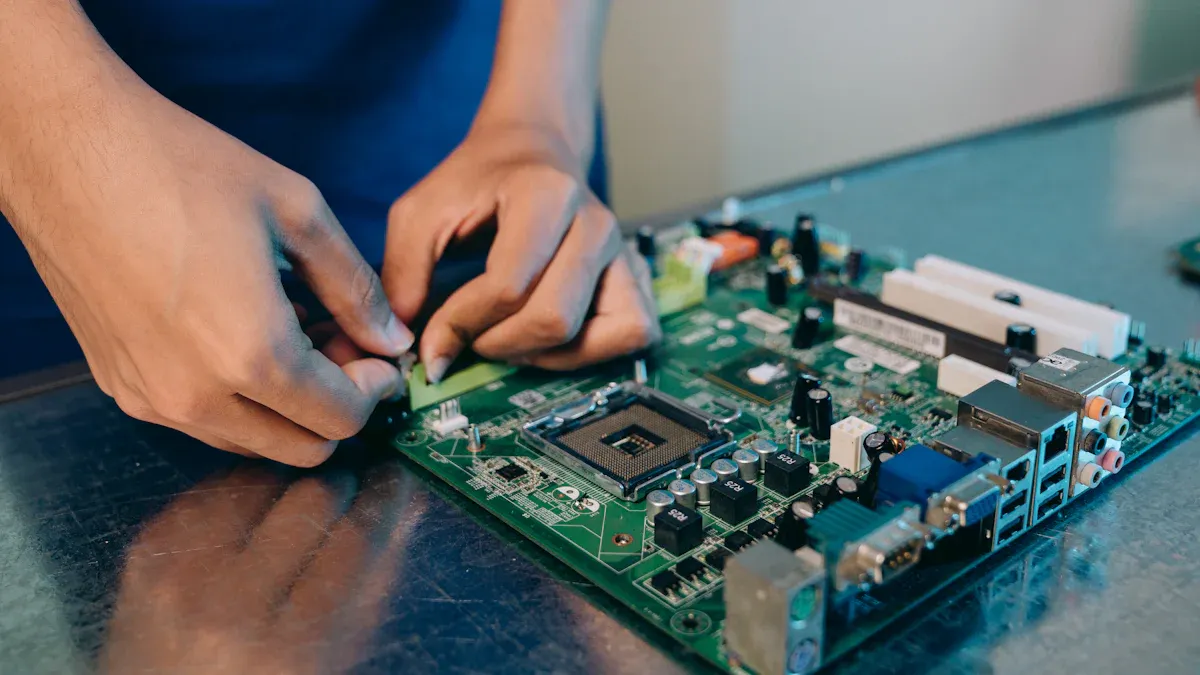

Step-by-Step Conformal Coating Process

Preparing the PCBA Surface

Getting the PCBA surface ready is the first important step. The board must be clean and free of dirt, oil, or flux. These can stop the coating from sticking well and protecting properly.

Use cleaners to remove dirt from soldering or handling.

Try advanced cleaning like plasma or ultrasonic methods for better results.

Make sure the board is fully dry before moving to the next step.

A clean and dry board makes the coating last longer and work better. It also helps avoid mistakes and saves time during production.

Tip: Never skip cleaning. It’s key to a strong and lasting coating.

Ways to Apply Coating (Spraying, Brushing, Dipping, Robots)

How you apply the coating depends on your PCBA needs. Each method has its own benefits:

Spraying: Great for smooth, even layers. Machines make it faster for big jobs.

Brushing: Good for small fixes but not ideal for large areas.

Dipping: Covers everything by dipping the board in the coating. Mask areas you don’t want coated.

Robotic Coating: Robots are precise and work well for tricky designs or high-quality needs.

Spraying, especially with machines, gives the best finish. Dipping is great for full coverage in tough conditions.

Curing Methods (Heat, UV Light, Chemicals)

Curing hardens the coating so it sticks to the PCBA. Different methods have different benefits:

Curing Method | How It Helps |

|---|---|

Heat Curing | Makes the coating strong and long-lasting. Works for heat-activated coatings. |

UV Light Curing | Dries fast and looks smooth. Perfect for quick production. |

Chemical Curing | Dries evenly on tricky shapes. Best for special coating formulas. |

UV curing is fast and efficient. Studies show more UV light improves heat resistance and insulation. Special UV bulbs help cure colored coatings better.

Note: Pick the curing method that matches your coating and production needs.

Checking and Testing for Quality

Testing ensures the coating is done right and works well. Here’s what to check:

Measure thickness and check for even coverage.

Test circuits to ensure the coating doesn’t affect performance.

Check durability with stress tests for heat, cold, or moisture.

Look for flaws like bubbles, cracks, or uneven spots.

Test moisture resistance by exposing the board to humidity.

These checks make sure the coating meets standards and protects your PCBA. Regular testing keeps quality consistent.

Following IPC Standards for Reliability (e.g., IPC-CC-830)

Following IPC rules like IPC-CC-830 ensures your coating is reliable. These rules set the bar for coatings used in electronics. Products like Humiseal 1B73 and Dymax 984LVUF meet these standards, proving they protect PCBs well.

By following these rules, you create high-quality coatings. This improves your PCBA’s reliability and earns customer trust.

Conformal coating keeps your PCBA safe in tough conditions. Picking the right coating improves protection and makes it last longer. Using correct methods to apply and dry the coating avoids problems. LTPCBA provides top solutions to ensure your electronics stay reliable and work well anywhere.

FAQ

How do I pick the right conformal coating for my PCBA?

Think about where your PCBA will be used. Check for heat, water, or chemicals. Choose a coating that matches these needs for the best protection.

Can I apply conformal coating without fancy tools?

Yes, you can use brushing or spraying methods. But machines are better for tricky designs or big projects. They make the process more accurate and consistent.

How can I make sure the coating sticks well to the PCBA?

Clean the board carefully to get rid of dirt or grease. Try ultrasonic cleaning for a deeper clean. Make sure the board is totally dry before adding the coating.

Tip: Test the coating after applying it to ensure it sticks properly.

See Also

Exploring The Advantages Of Conformal Coating For PCBA

Challenges Faced During Conformal Coating In SMT Assembly

Different Types Of Conformal Coatings: Pros And Cons