Comprehensive PCBA Services: From PCB Manufacturing to Final Assembly Testing

Comprehensive PCBA services include all steps of making electronics. These services help create high-quality and reliable electronic products. Automation helps make work faster and lowers mistakes. Companies like LTPCBA use smart technology and strict testing for great results. Finding problems early and testing designs prevent failures. This saves money and makes products work better. With LTPCBA’s skills, you get smooth manufacturing that focuses on quality and happy customers.

Key Takeaways

Complete PCBA services make electronics production easier and better. They ensure good quality and reliable products from making PCBs to final assembly.

Picking reliable suppliers and smart buying methods is important. It helps get good parts, which improves how products work and last.

LTPCBA focuses on quality with a 99.5% on-time delivery rate. They follow global rules to keep customers happy and products dependable.

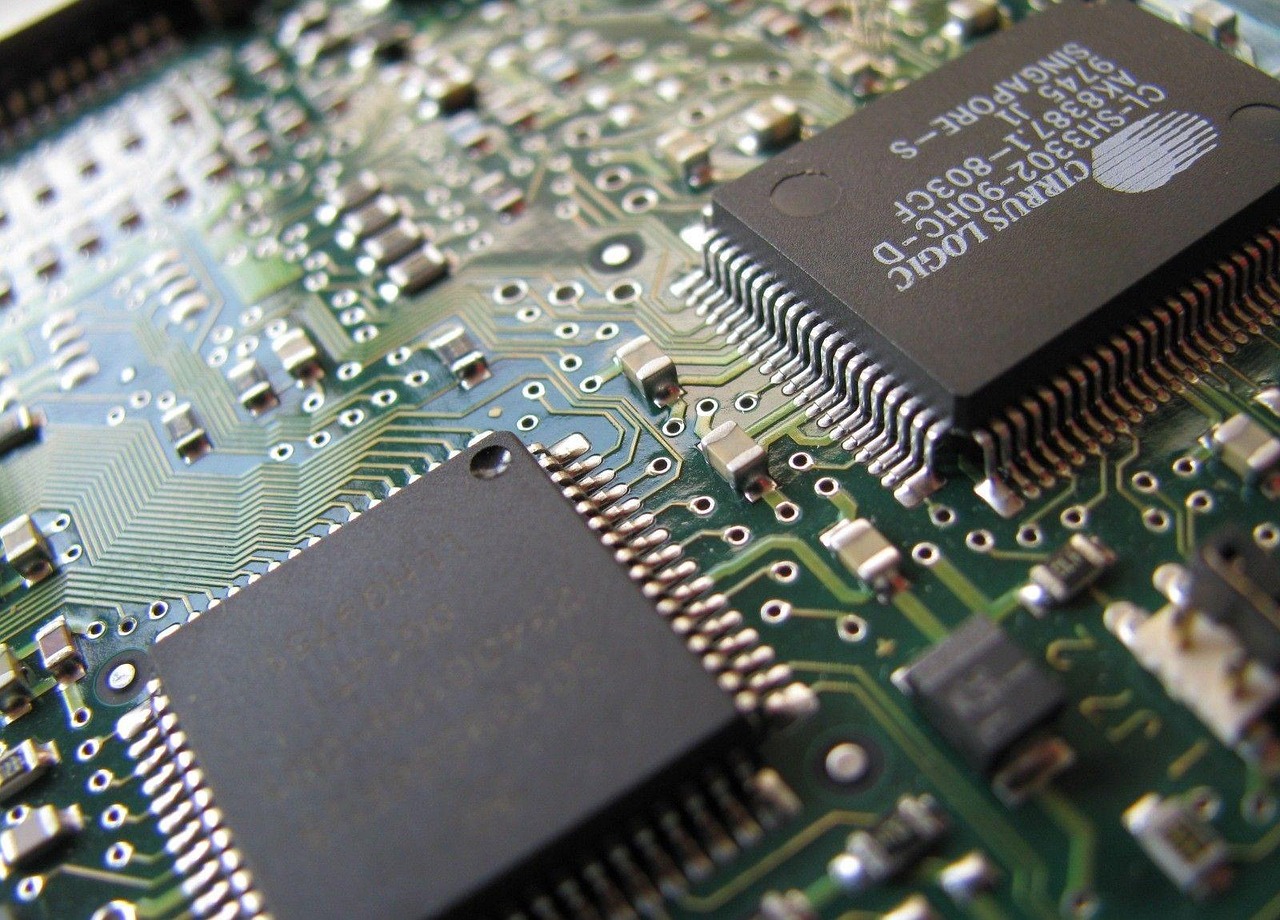

PCB Manufacturing: The Base of PCBA Services

Making printed circuit boards (PCBs) is the heart of PCBA work. Every gadget you use depends on a well-made PCB to work right. This process affects how well your product works, lasts, and costs. Knowing the steps, materials, and checks helps you see how PCBA ensures great results.

Main Steps in PCB Making

Making PCBs involves careful steps to turn raw stuff into working boards. Each step is key to making sure the board works as planned. Here’s a simple look at the steps:

Design and Layout Setup: Engineers make a detailed plan showing circuits and parts.

Material Choice and Lamination: Makers pick materials like FR4 and add copper layers.

Etching and Circuit Making: Chemicals remove extra copper, leaving the needed circuits.

Drilling and Coating: Tiny holes are drilled for parts, then coated for connections.

Solder Mask Adding: A protective layer stops short circuits and shields copper lines.

Silkscreen Printing: Labels and marks are printed to help with assembly and fixes.

Final Touches and Testing: Finishes like HASL are added, and tests check the board.

Tests make sure these steps work. For example:

Electrical Testing checks if circuits connect properly.

Impedance Testing ensures signals flow as planned.

Automated Optical Inspection (AOI) spots errors like broken circuits or misaligned parts.

Materials and Tools Used

The materials and tools you pick affect how the PCB works. Good choices make sure the board fits your needs. Common materials include:

FR4: A cheap, all-purpose option for most boards.

Polyimide: Great for high heat or flexible uses.

Metal Core: Helps boards handle heat better.

New tools make PCB making even better. For example:

HDI tech allows smaller designs with tiny parts.

Flexible and Rigid-Flex PCBs mix bendable and strong features.

Controlled Impedance Design keeps signals steady in fast circuits.

Future trends focus on special materials for new tech. For example, 5G and IoT need materials that handle heat and signals well.

Quality Checks in PCB Making

Quality checks make sure your PCB works well and meets rules. Makers use strict checks at every step. Key checks include:

BOM and MPN Checks: Makes sure parts match the design.

Visual and Automated Checks: Finds mistakes like wrong holes or bad circuits.

Supplier Checks: Ensures raw materials come from trusted sources.

Rules like IPC standards guide these checks. For example, IPC asks for sample tests to check solder joints and other parts. Makers also track performance with key measures. Here’s a quick look:

Measure | What It Tracks |

|---|---|

Percent of boards passing all checks without fixes. | |

Defect Rate | Percent of bad boards, showing areas to improve. |

Cycle Time | Time to make a board, showing how fast the process is. |

Throughput | Number of boards made in a set time, showing efficiency. |

Supplier Performance | Tracks how good suppliers are to keep quality high. |

By following these checks, makers like LTPCBA deliver top-quality PCBs you can trust.

Component Sourcing: Ensuring Quality and Reliability

Getting good parts is key to making reliable electronics. The parts you pick affect how well your product works and lasts. By choosing trusted suppliers and smart sourcing methods, you can avoid problems and keep quality high.

Why Trusted Suppliers Matter

Good suppliers are important for getting quality parts. They deliver on time and provide materials you can trust. For example, Multichem Sourcing supplies safe pharmaceutical ingredients. They follow strict rules like GMP and GDP to ensure quality. In electronics, trusted suppliers give parts that meet your needs and keep your assembly process smooth.

Tips for Getting High-Quality Parts

Using smart methods can help you get better parts. Here are some tips:

Look at the total cost, not just the price. Think about long-term use.

Set clear rules for quality to check parts meet standards.

Build good relationships with suppliers to work better together.

These steps improve part quality and lower risks from supply chain issues.

LTPCBA’s Supply Chain Success

LTPCBA carefully manages its supply chain for great results. They deliver 99.5% of orders on time, beating the 98% top industry rate. This ensures your projects stay on track without losing quality.

Metric | LTPCBA's Performance | Industry Benchmark |

|---|---|---|

On-Time Delivery Rate | 99.5% | >98% |

Industry Average | N/A | 90% to 95% |

By using trusted suppliers, smart sourcing, and strong management, LTPCBA makes sure every assembly is high-quality and reliable.

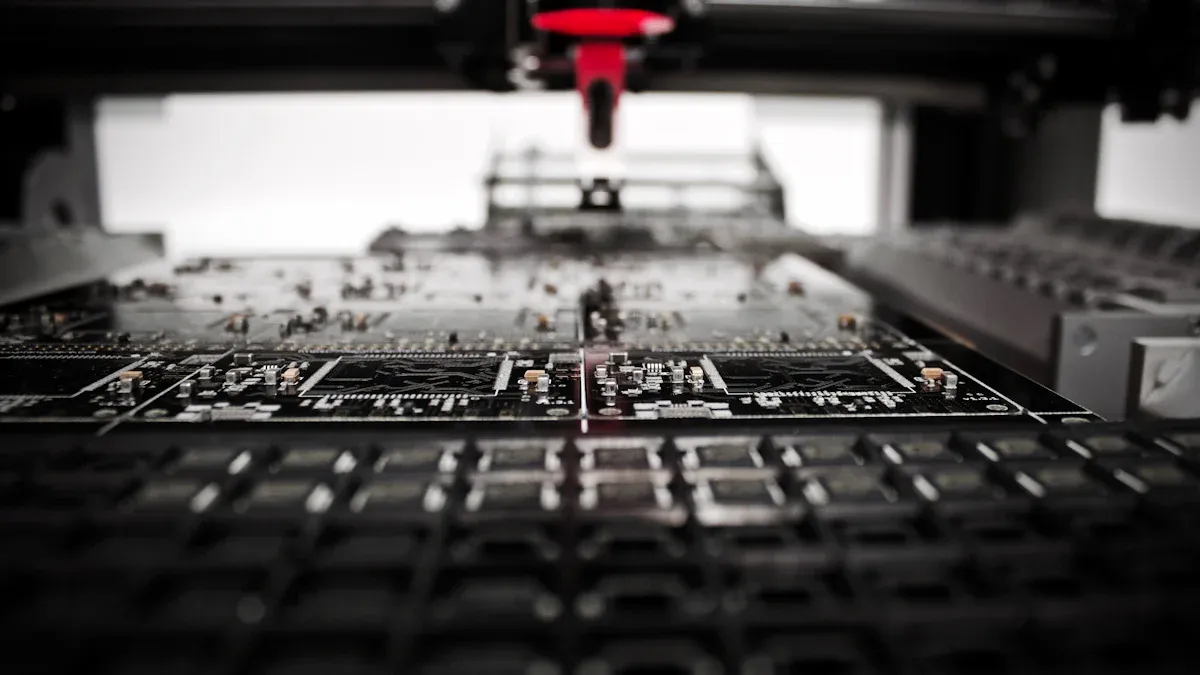

PCB Assembly Techniques at LTPCBA

Surface Mount Technology (SMT) Assembly

SMT is a fast and efficient way to build PCBs. At LTPCBA, machines handle every step, like adding solder paste, placing parts, and soldering them. This process is quick and reduces mistakes, helping meet deadlines without losing quality.

Fast SMT lines are key for making many electronics quickly. In 2023, they made up 46.66% of the market, worth USD 2,707.03 million, and are growing at 8.50%. LTPCBA uses smart systems to find defects during inspections. This ensures great results and fewer false alarms.

Tip: SMT is perfect for small designs needing speed and accuracy. It’s used in modern gadgets like smartphones and IoT devices.

Through-Hole Technology (THT) Assembly

THT is a strong method for attaching parts to PCBs. It involves putting parts into drilled holes and soldering them for strength. This method works well for products that face stress or heat, like industrial tools and car electronics.

LTPCBA uses advanced tools for drilling and soldering, lowering the chance of mistakes. This method is great for projects needing durability and long-lasting performance.

Mixed Technology Assembly for Complex Designs

Mixed technology combines SMT and THT for tricky designs. It allows using different parts, making it good for reliable and high-performing products. LTPCBA uses this for items like medical tools and aerospace systems that need both types of parts.

This method is more detailed than standard ones. It costs more but offers flexibility and reliability. LTPCBA uses digital tools to improve setups and fix problems, ensuring smooth production and top-quality results.

Aspect | Mixed Technology Assembly | Standard Techniques (SMT/THT) |

|---|---|---|

Component Flexibility | Uses both SMT and THT parts | Limited to one type |

Complexity of Assembly | More detailed process | Simpler process |

Cost | Higher costs for tools and labor | Lower costs |

Application Suitability | Best for complex, reliable designs | Good for specific needs |

Note: Mixed technology is best for projects needing both precision and strength. It’s often used in industries where reliability is critical.

Testing and Quality Assurance in PCBA Services

Testing and quality checks are key to making sure PCBA products work well. Using advanced tests helps find problems early, improves production, and meets industry rules. Let’s look at the main testing methods used in PCBA.

Automated Optical Inspection (AOI) and Its Role

AOI is important for spotting errors during PCBA production. It uses cameras and smart software to check for issues like misplaced parts, solder mistakes, or missing components. AOI is great for large-scale production where manual checks are too slow.

Benefits of AOI:

Quick Checks: AOI inspects during production, cutting human mistakes and saving time.

Error Spotting: It finds problems like solder bridges and misplaced parts with accuracy.

Smart Insights: AI-powered AOI tools study data to improve manufacturing.

Evidence Type | Description |

|---|---|

Market Growth | |

Industry Adoption | AOI is widely used in cars and gadgets industries. |

Real-time Inspections | AOI boosts speed and lowers errors with live monitoring. |

Tip: Adding AOI to your process ensures better quality and meets industry rules.

In-Circuit Testing (ICT) for Electrical Integrity

ICT is a strong method to check if PCBA circuits work correctly. It tests each part and connection to ensure they perform as planned. ICT happens early in production, helping catch and fix problems quickly.

Key Advantages of ICT:

Covers Many Errors: ICT finds issues like broken or short circuits.

Early Problem Solving: Fixing issues early saves money and avoids bad products.

Better Reliability: Ensures parts meet standards, vital for industries like healthcare.

Aspect | Description |

|---|---|

High Fault Coverage | |

Early Defect Detection | Early testing cuts costs and stops problems from growing. |

Improved Product Reliability | Ensures parts work well, crucial for industries needing safety. |

Note: ICT improves product quality and builds customer trust by delivering reliable PCBA.

Functional Testing to Ensure Performance

Functional testing is the last step to check if the PCBA works in real-life conditions. Engineers test the product as it would be used to make sure all features work properly.

Why Functional Testing Matters:

Fewer Failures: It lowers failure rates to just 0.0003%, compared to 0.03% without it.

Full Check: Complements other tests by confirming the PCBA works as a whole.

Saves Money: Catching problems early avoids costly fixes and recalls.

Functional testing ensures the PCBA meets design needs and works well in its real use. Engineers simulate real-world use to check durability and performance.

Callout: Functional testing is crucial for high-quality PCBA. It ensures your product is ready for use without issues.

Final Assembly and Packaging: Ready-to-Use Products

Adding PCBAs to Final Products

Putting PCBAs into finished products is an important step. This makes sure the product works well and meets needs. By adding PCBAs early, you can find and fix problems. This saves money and improves how the product works.

It avoids costly fixes or recalls, saving time and cash.

Problems are found sooner, speeding up product launches.

Fewer risks mean more reliable and better products.

This step also helps bring new ideas to market faster. By making sure PCBAs work perfectly in the product, you meet customer needs and industry rules.

Safe Packaging for Delivery

Good packaging keeps products safe while being shipped. It protects PCBAs and finished items from damage. LTPCBA uses strong, safe, and approved packaging methods.

The packaging shields electronics from water, static, and bumps. LTPCBA uses anti-static bags and foam to keep PCBAs safe.

Clear labels on packages make handling easier and safer. This lowers the chance of mistakes during shipping. LTPCBA’s packaging ensures your products arrive in great shape.

LTPCBA’s Focus on Following Rules

LTPCBA follows global rules to make high-quality products. They meet standards that ensure safety, quality, and eco-friendly practices.

Certification | What It Ensures |

|---|---|

ISO9001 | Consistent quality in products and services. |

ISO13485 | Safe and effective medical devices. |

ISO14001 | Environmentally friendly practices. |

IPC standards | Reliable and high-quality electronics. |

UL | Products meet safety rules. |

SGS | Testing and certification for quality. |

RoHS | Limits harmful materials in electronics. |

These certifications show LTPCBA’s promise to deliver great PCBA services. By following these rules, LTPCBA makes products that meet industry needs and make customers happy.

Comprehensive PCBA services simplify making electronics, from PCBs to assembly. These services focus on quality, speed, and dependability. Picking LTPCBA gives big advantages, like delivering 99.5% of orders on time and following global rules.

Industry | Reasons for Growth |

|---|---|

More people want gadgets like phones, tablets, and smartwatches needing better PCBs. | |

Automotive | New tech like 5G and IoT needs advanced PCBs for cars. |

Healthcare | Medical tools need strong PCBs for safe and important uses. |

Using LTPCBA’s skills helps you make creative, top-notch products faster.

FAQ

What is the difference between SMT and THT assembly?

SMT puts parts on the PCB's surface, great for small designs. THT pushes parts through holes, making them strong for tough uses.

How does LTPCBA ensure product quality?

LTPCBA uses smart tests like AOI, ICT, and functional checks. These tests make sure products are high-quality and work well.

Why choose LTPCBA for PCBA services?

LTPCBA gives full services, quick delivery, and 99.5% on-time success. They follow global rules to make safe and reliable products.

See Also

Understanding Full Turn-Key PCB Manufacturing And Assembly Services

Selecting The Ideal One-Stop PCB Assembly Solution

Defining PCBA And Its Essential Components Explained