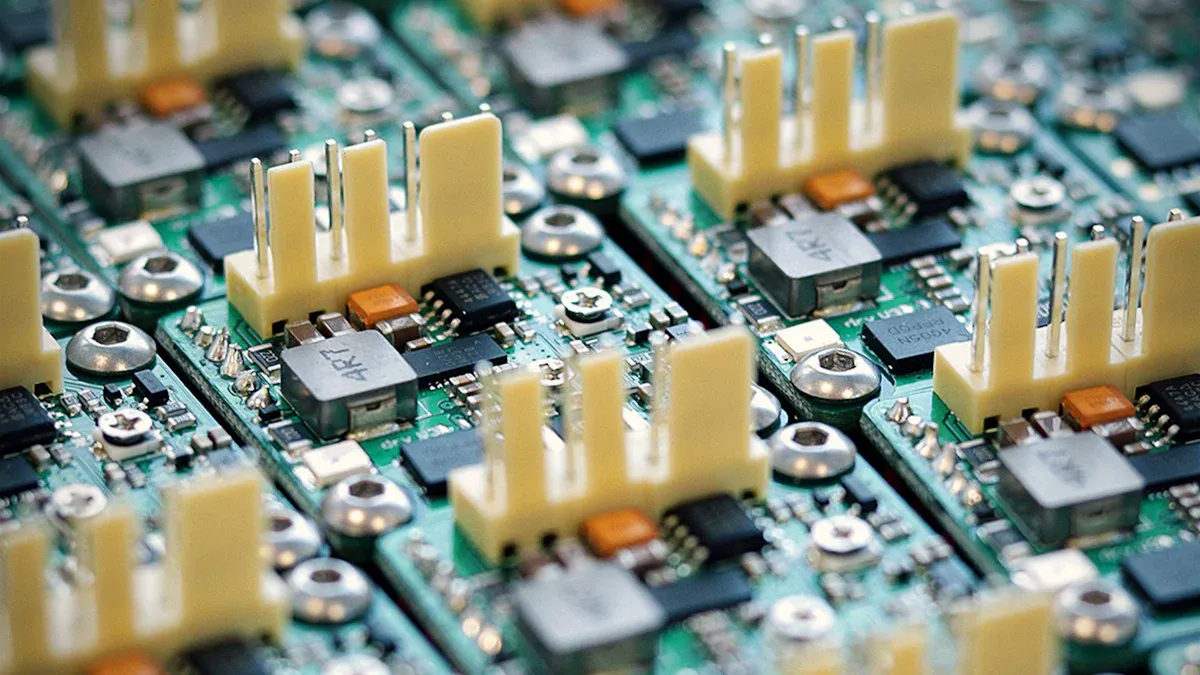

Why components may fall off during wave soldering in smt assembly production

Components falling off during wave soldering in smt assembly production often result from adhesive failure, oxidation, improper process control, or mechanical stress. Technicians in smt assembly production must check each step to protect component placement and ensure quality. LTPCBA experts address these challenges in smt assembly production by using advanced inspection methods.

Key Takeaways

Keep component leads clean and free from oxidation to ensure strong solder joints and prevent parts from falling off during wave soldering.

Use the right adhesive with proper application and storage to hold components firmly in place through the soldering process and thermal stress.

Maintain strict process control and inspection, including flux application and soldering parameters, to catch errors early and ensure reliable SMT assembly quality.

Causes of Components Falling Off

Poor Solderability and Oxidation

Poor solderability often leads to components falling off during wave soldering. When the leads or pads have oxidation, the solder cannot form a strong bond. Oxidized component leads resist wetting, which means the solder does not flow evenly over the metal surfaces. This lack of wetting causes weak joints and increases the risk that components come off the board during the soldering process. In smt assembly production, technicians must ensure that all leads remain clean and free from oxidation. They use flux to remove oxides and promote wetting, but insufficient or degraded flux can leave areas unprotected. For example, if a batch of through-hole parts arrives with oxidized leads, even the best flux may not achieve proper wetting, resulting in poor solder joints. LTPCBA’s quality assurance team inspects incoming components and verifies that all leads meet strict standards for solderability.

Adhesive and Glue Issues

Adhesive and glue problems can cause significant component displacement during pcb wave soldering. If the adhesive cures too long or at the wrong temperature, its peel strength drops below the industry standard of 1.0 pounds per inch for rigid PCBs. Peel strength testing measures how much force is needed to separate the adhesive bond. Failures can occur within the adhesive layer, at the interface, or even in the substrate itself. These failures directly relate to components falling off the board. In smt assembly production, engineers select adhesives with the right rheology to hold surface mount components in place during the soldering process. Acrylic and epoxy adhesives must withstand the reflow and wave soldering temperatures without losing grip. If the adhesive cannot handle the thermal load, components may shift or detach. LTPCBA uses advanced adhesive testing and process controls to ensure consistent component positioning and minimize component quality issues.

Tip: Always verify adhesive shelf life and storage conditions to maintain optimal performance during the process.

Process Control in SMT Assembly Production

Precise process control prevents many defects in smt assembly production. Incorrect process parameters, such as conveyor speed, preheat temperature, or flux application, can lead to component displacement and poor solder joints. For example, if the flux does not cover all leads, wetting will not occur uniformly, and some components may not bond properly. Excess solder or insufficient solder can both cause problems. Too much solder may create bridges or lift components, while too little solder leaves joints weak. Shadowing effects, where taller components block solder flow to smaller parts, also contribute to components coming off the board. LTPCBA’s process engineers monitor every stage, from flux application to soldering, using automated inspection systems to catch errors early. They adjust process settings in real time to maintain high quality and reduce the risk of components falling off.

Mechanical and Thermal Stress

Mechanical and thermal stress play a major role in component displacement during wave soldering. When the board heats up, different materials expand at different rates. This mismatch in expansion, known as the coefficient of thermal expansion (CTE), creates strain on solder joints and adhesives. Studies using strain gauges and digital image correlation show that these stresses can cause die cracking, bond fractures, and even component lift-off. Tensile testing and optical microscopy reveal that repeated thermal cycling changes the toughness of solder joints and adhesives. At first, toughness may increase, but after many cycles, weak points develop, making components more likely to detach. In smt assembly production, engineers design the process to minimize thermal stress and use materials with compatible CTE values. LTPCBA’s quality assurance team reviews every board for signs of thermal or mechanical damage after the soldering process.

Design and Board Factors

Design and board layout influence the risk of component displacement and soldering defects. Incorrect lead length can prevent proper wetting and solder flow. Leads that are too short may not reach the solder wave, while leads that are too long can create excess solder buildup. Poor pad design or insufficient spacing between components can cause shadowing, where solder does not reach all areas. The placement of through-hole parts and surface mount components must allow for even solder distribution and effective flux coverage. If the board design does not support good wetting and surface tension balance, components may shift or detach during the process. LTPCBA’s design review process checks for these issues before production begins, ensuring that every board meets strict quality standards.

Note: Good board design, proper flux selection, and careful process control all work together to prevent components from coming off the board during wave soldering.

Prevention and Best Practices

Improving Solderability

Technicians improve solderability by ensuring all leads remain clean and free from oxidation. They use good flux coating to promote wetting and prevent defects. Enhanced soldering techniques, such as balanced stencil designs and uniform heating profiles, have increased production speed and improved the quality of solder joints. Operators now focus on inspection rather than multitasking, which reduces mistakes. Consistent wetting and proper solder paste application help prevent component displacement and ensure strong bonds during the soldering process.

Optimizing Adhesive Application

Engineers optimize adhesive application by controlling viscosity and adjusting dispensing parameters. They select the right nozzle diameter and print speed to achieve even adhesive coverage. Stencil design, including aperture size and shape, controls adhesive volume and spread. Studies show that optimized adhesive application reduces the risk of components jumping out during wave soldering. Proper adhesive placement ensures mechanical stability and prevents component displacement, even under thermal stress.

Process Control with LTPCBA

LTPCBA maintains strict process control throughout SMT assembly. Their inspection protocols detect problems at a 99% rate, with inspection times as fast as 7 seconds per PCB. They require at least 95% wetting in all tests and enforce high standards for solder and flux. These measures ensure that leads receive proper coverage and that the soldering process produces reliable joints. LTPCBA’s process control reduces defects and supports consistent quality control.

Inspection and Quality Checks

Advanced automatic optical inspection (AOI) systems play a key role in quality control. AOI uses high-resolution cameras to detect issues like misaligned components, poor wetting, and solder joint flaws. These systems work quickly and accurately, reducing costly rework and improving documentation. AOI adapts to different production needs, supporting high-quality standards as SMT assembly evolves. LTPCBA integrates AOI at multiple stages, ensuring early detection of defects.

Staff Training and Documentation

Staff receive regular training on process parameters, flux handling, and solder paste application. They learn to identify signs of poor wetting, oxidation, and thermal stress. Detailed documentation supports traceability and continuous improvement. This approach helps prevent component displacement and maintains high quality throughout the soldering process. LTPCBA’s commitment to training and documentation ensures every technician understands the importance of surface tension, reflow, and proper handling of leads and components.

Technicians see components fall off during wave soldering due to poor solderability, adhesive issues, and process errors. Strong process control and inspection help prevent these problems.

LTPCBA’s expertise ensures reliable SMT assembly production.

Quick Checklist:

Inspect for oxidation

Use proper adhesive

Monitor process parameters

Train staff

FAQ

What causes components to jump out during wave soldering?

Technicians see components jump out due to poor adhesive, excess solder, or rapid conveyor movement. LTPCBA uses process control to prevent this issue.

How does LTPCBA ensure high-quality SMT assembly production?

LTPCBA uses automated inspection, strict process monitoring, and staff training. These steps help maintain a 99.5% pass rate for every production batch.

Can design changes reduce the risk of components falling off?

Engineers improve pad layout and lead length.

Good design supports even solder flow.

LTPCBA reviews every board design before production.

See Also

Essential Wave Soldering Techniques For Successful SMT Assembly

Identifying And Preventing Typical Reflow Soldering Defects In SMT

Key Technical Standards For Wave Soldering In DIP Assembly

Challenges Faced During Conformal Coating In SMT Assembly

Step-By-Step Guide To Reflow Soldering Through-Hole Parts Post SMT