Component Procurement Service and its role in reducing time-to-market for electronics manufacturers

Electronics factories need to work fast and be accurate. Many factories only utilize 20% of their SMT machines effectively, which can increase costs by up to four times compared to optimized setups. LTPCBA offers a comprehensive Component Procurement Service that helps factories avoid purchasing excess parts. Some factories end up with as much as 75% surplus components they don’t need. By using smart systems for component procurement, LTPCBA enables factories to streamline their operations, improve efficiency, and bring products to market faster.

Key Takeaways

Smart buying of parts helps factories save money and time.

They only buy what they need and watch parts closely.

Using up-to-date data and online tools makes buying faster.

This lowers problems and keeps work on track.

LTPCBA’s quick and trusted service helps companies get parts fast.

Their good supplier control lets products come out sooner than usual.

Component Procurement Service in Electronics Manufacturing

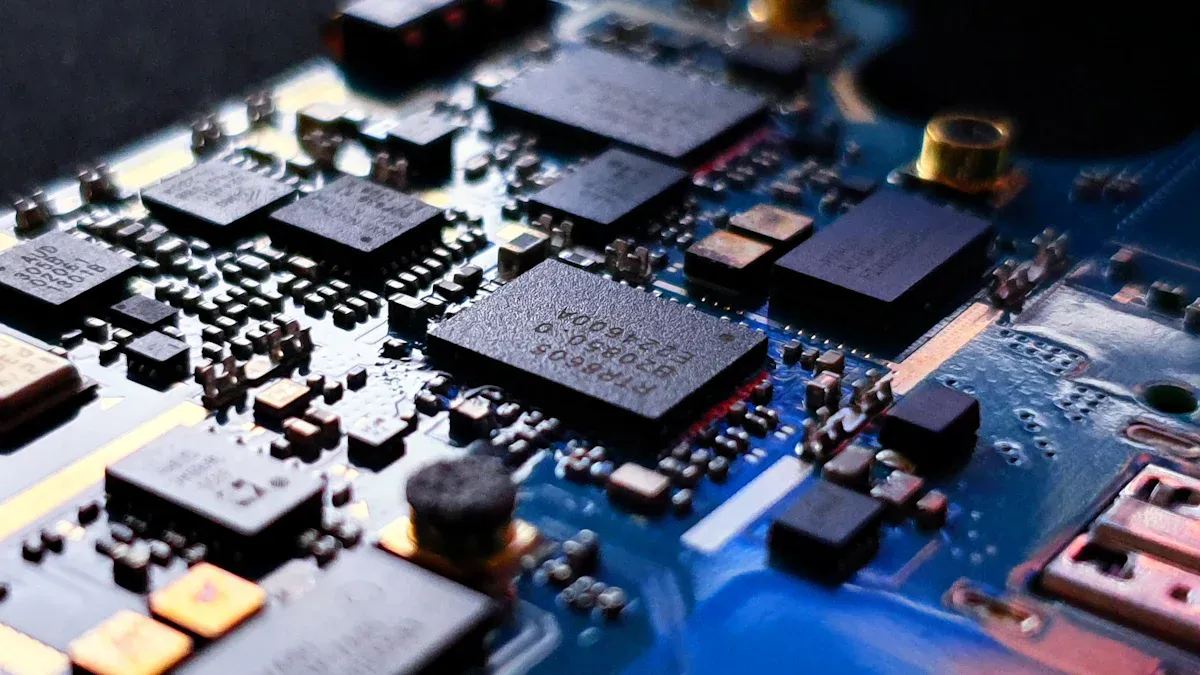

Component procurement service is very important in electronics. This service helps companies get the parts they need. It also helps them buy and keep track of these parts. Today, companies must get parts quickly and reliably. Fast part buying helps them build products on time. Good pcb component management services help companies avoid waiting and missing deadlines.

Key Challenges in Electronic Component Procurement

Electronics makers face many problems when getting parts.

Sometimes, the supply chain breaks and parts run out. This can stop production.

It is hard to check quality because some parts may be fake or not good.

Companies must follow rules for safety and trading.

Talking with suppliers can be hard if there are language or culture differences.

When suppliers join together, some parts may not be sold anymore. This can make it hard to find needed parts.

To fix these problems, companies use more than one supplier and plan carefully.

Real-time data lets companies see if parts are in stock. It also shows prices and how long it takes to get parts. This helps them make better choices and act fast when parts are low.

LTPCBA’s Approach to PCB Component Management Services

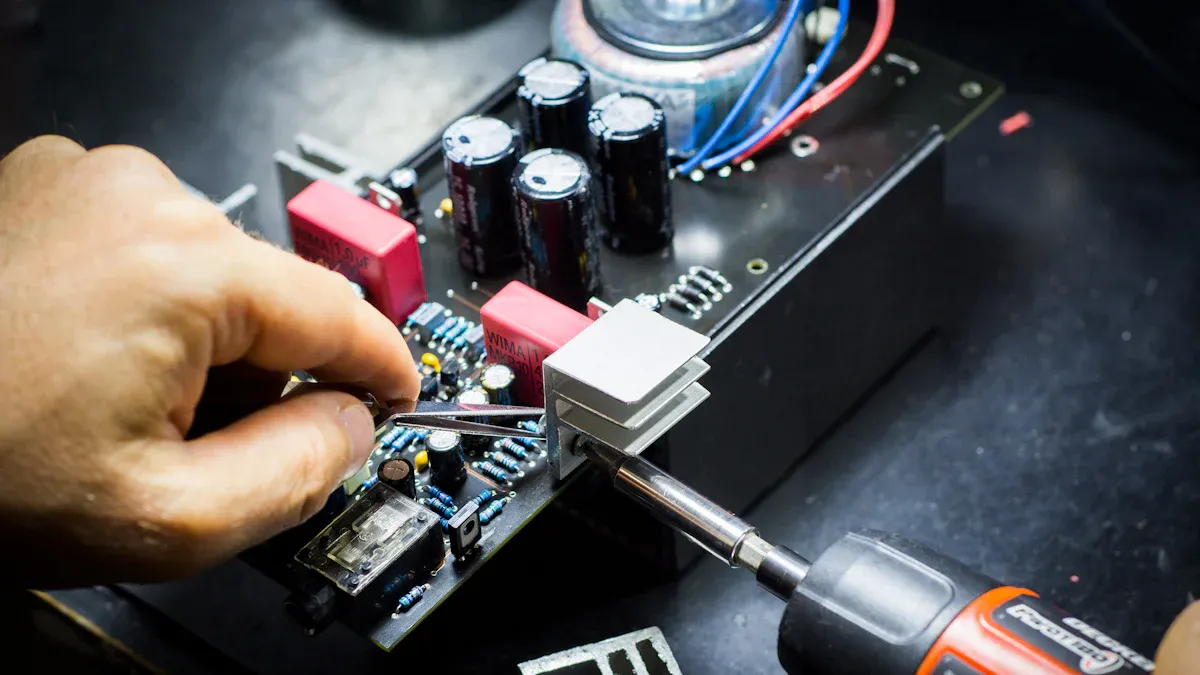

LTPCBA is a leader in managing pcb parts for electronics. They use new technology and check parts carefully. They look at BOM and MPN to make sure parts are right. LTPCBA keeps parts safe and dry in special storage. They follow world rules for storing and handling parts. Their team helps customers all day and night. They also track parts in real time to stop shortages.

Metric | LTPCBA Performance | Industry Average |

|---|---|---|

On-Time Delivery Rate | 90-95% |

LTPCBA gives reports when parts are low and manages inventory before problems happen. These steps help save money and keep the supply chain strong. By making sure parts are ready and risks are low, LTPCBA helps customers avoid running out of parts and keeps their work on time.

Reducing Time-to-Market with Procurement Solutions

Making Sourcing and Supplier Management Easier

Electronics makers need parts fast and on time. Procurement services help them find and buy parts quickly. Digital tools make buying parts easier. Companies use online platforms to talk to suppliers and order parts. In 2022, these online sales were over $1 trillion. This means many companies trust digital buying to work faster.

Supplier management systems help companies talk to suppliers and check how they do. These systems track if parts arrive on time and if they are good quality. They also see how fast suppliers fix problems. Companies use this information to pick the best suppliers. This helps stop delays and keeps parts from running out. Special software looks at old data to guess what parts are needed. It helps companies keep enough parts in stock. This makes sure they have what they need to build products.

Companies using automated quote tools and online auctions get prices faster and make fewer mistakes. Online platforms also check suppliers and give out contracts automatically. These steps make buying parts faster and help companies launch products sooner.

Practice/Tool | Measurable Impact | Example/Outcome |

|---|---|---|

Using data to buy smart | One company saved 15% on parts | |

Checking suppliers | Wait time cut by 25-40% | A big company got parts 25% faster |

Online buying tools | Buying time cut by 50% | Teams can do more important work |

Working with suppliers | Wait time cut by 15% | Supply chain got 30% better |

These new ways help companies avoid running out of parts and finish projects on time.

Real-Time Data and Lowering Risks

Real-time tracking lets companies see their parts and orders right away. This helps them spot problems early and act fast. Automation makes buying parts 66% quicker. Companies can check if parts are in stock, see prices, and know delivery times right away. This helps teams decide fast and avoid waiting.

Smart computer tools help guess what parts are needed and plan orders. These tools use tracking data to see trends and stop shortages. Companies using robots to help buy parts save money and work faster. For example, Walmart used new tech to track products in just 2.2 seconds instead of 7 days. This shows how digital tools make supply chains much faster.

Working with fewer, trusted suppliers also helps. It lowers risks and makes things run smoother. Data checks how well suppliers do and helps companies pick the best ones. This lowers the chance of running out of parts and keeps buying easy.

LTPCBA’s Help in Launching Products Faster

LTPCBA uses smart ways to get parts so customers can launch products sooner. They give price quotes fast, often in 2-3 days. Their team helps customers all day and night. LTPCBA delivers on time 99.5% of the time, which is better than most.

LTPCBA uses trusted suppliers and smart buying to stop delays and bad parts. Automated machines make building products faster and better. They can handle hard designs without slowing down. LTPCBA uses special tests to find problems early. This saves time and stops extra work.

Using PCBAs early in products helps find problems before they get big. LTPCBA follows world rules, so customers always get good quality. These steps help customers avoid running out of parts and launch products faster. LTPCBA’s strong supply chain and fast delivery help companies stay ahead.

LTPCBA’s focus on real-time tracking, smart buying, and digital tools gives customers a big advantage. They can avoid shortages, keep parts ready, and launch products faster.

Getting parts through special services helps electronics companies make more money. It also helps them finish products faster. LTPCBA uses computers and tracking to get parts to factories quickly. Big companies like GE, Shell, and Amazon use these new ways too. They launch products faster and work better with their suppliers.

Products are made quicker

Companies spend less money

Suppliers and companies work together better

Electronics companies should look at how they get parts now. They might want to work with a trusted company. To learn more, check out LTPCBA’s website.

FAQ

What does a component procurement service do?

A component procurement service helps companies get parts. It finds, buys, and keeps track of electronic parts. This service makes sure factories have the right parts when needed.

How does LTPCBA help companies launch products faster?

LTPCBA gives quick price quotes and tracks orders live. They use trusted suppliers to get parts fast. These steps help customers get parts and launch products sooner.

Why do we need quality checks in getting parts?

Quality checks make sure every part is safe and works well. This stops delays and keeps products working for customers.

See Also

Sourcing Electronic Parts Essential For PCBA Production

PCBA Solutions Managing All Phases From Build To Test

Rapid PCB Assembly Prototypes Boost Project Workflow Speed

EMS Providers Improve Efficiency In PCB Production Processes