How Top PCBA Manufacturers Stack Up on Quality and Cost

Leading pcba providers set industry benchmarks for quality, speed, and cost, according to recent user reviews. Many engineers choose a provider based on the specific needs of prototyping, production, or high reliability. Fast turn pcb services now play a key role in reducing time to market. LTPCBA stands out for consistent quality, rapid turnaround, and strong customer support. Fast turn pcb options from top providers help teams meet tight time requirements for both pcb prototyping and full-scale production. High reliability remains essential for critical pcb applications, while fast turn pcb and quick turnaround drive efficiency in every stage of production.

Key Takeaways

Top PCBA manufacturers differ in quality, speed, and pricing, so choose one that fits your project needs.

LTPCBA excels in quality control, fast turnaround, and customer support, making it ideal for prototyping and mid-volume production.

Fast turn PCB services help reduce time to market and adapt quickly to design changes, benefiting all production stages.

Understanding cost factors like materials, complexity, and volume helps manage your PCB project budget effectively.

High-reliability projects need providers with strict quality standards and proven inspection methods to ensure long-term performance.

Top PCBA Providers

Selecting the right pcba providers can shape the success of any electronics project. Engineers and businesses often evaluate providers based on quality, speed, turnaround, and pricing. Each manufacturer brings unique strengths to the table, making it important to match their capabilities with project requirements.

Quality Comparison

Quality stands at the core of every successful pcb manufacturing process. Top pcba providers invest in advanced inspection systems, strict process controls, and international certifications. LTPCBA, for example, maintains a 99.5% pass rate in product delivery. The company follows ISO, IATF, and UL standards, ensuring consistent quality across all pcb assembly projects.

Other leading pcba providers, such as JLCPCB, Advanced Circuits, and MacroFab, also focus on quality. JLCPCB uses automated optical inspection and X-ray testing for complex assemblies. Advanced Circuits emphasizes in-house quality checks and traceability. MacroFab leverages digital manufacturing platforms to monitor quality throughout the production cycle.

Note: High quality reduces the risk of defects, lowers rework costs, and increases reliability in both prototyping and full-scale production.

The table below compares the quality features of top pcba providers:

Provider | Quality Certifications | Inspection Methods | Pass Rate | Notable Strengths |

|---|---|---|---|---|

LTPCBA | ISO, IATF, UL | AOI, X-ray, Functional Test | 99.5% | Fast turn pcb, customer support |

JLCPCB | ISO, UL | AOI, X-ray | 98% | Low pricing, fast turnaround |

Advanced Circuits | ISO, UL | AOI, In-house QC | 98.5% | North American fast turn pcb manufacturers, reliability |

MacroFab | ISO | AOI, Digital Monitoring | 98% | Flexible production, digital platform |

Speed and Turnaround

Speed and turnaround times have become critical in modern electronics manufacturing. Fast turn pcb services help teams reduce time to market and adapt quickly to design changes. LTPCBA delivers quotations within 2-3 working days and offers 24-hour technical support. The company specializes in fast turn pcb assembly, supporting both rapid prototyping and mid-volume production.

JLCPCB and MacroFab also provide fast turn pcb options. JLCPCB can complete pcb assembly in as little as 24 hours for standard orders. MacroFab uses a digital platform to streamline order processing and minimize turnaround times. Advanced Circuits stands out among north american fast turn pcb manufacturers, offering same-day and next-day pcb manufacturing for urgent projects.

Tip: Choosing a provider with fast turnaround can save valuable time during both prototyping and production phases.

The following table highlights speed, turnaround, and pricing for leading pcba providers:

Provider | Fast Turn PCB Services | Typical Turnaround Times | Pricing Level | Production Capacity |

|---|---|---|---|---|

LTPCBA | Yes | 1-5 days | Competitive | Prototype to mid-volume |

JLCPCB | Yes | 1-3 days | Low | Prototype to high-volume |

Advanced Circuits | Yes | Same-day to 5 days | Moderate | Prototype to production |

MacroFab | Yes | 3-7 days | Moderate | Prototype to production |

Pricing varies based on order size, complexity, and required turnaround. LTPCBA offers competitive pricing for both fast turn pcb and standard production runs. JLCPCB attracts customers with low pricing and quick delivery. Advanced Circuits and MacroFab provide moderate pricing, balancing speed and quality for a wide range of manufacturing needs.

When evaluating pcba providers, teams should consider how speed, turnaround, and pricing align with their project timelines and budget. Fast turn pcb services from top manufacturers help companies stay agile in a fast-paced market, while strong quality controls ensure reliable pcb production every time.

LTPCBA Overview

Services and Capabilities

LTPCBA stands out as a custom pcb manufacturer with a strong focus on innovation and efficiency. The company offers a wide range of pcb assembly services, including SMT assembly, BGA assembly, through-hole assembly, and mixed assembly. LTPCBA supports both rapid prototyping and mid-volume production, making it a reliable manufacturer for diverse project needs. Their technical capabilities include handling complex components such as BGA, Micro-BGA, and QFN. LTPCBA also provides rigid flex pcb assembly and full turn-key solutions, managing every step from component sourcing to final shipment.

Fast turn pcb services form the backbone of LTPCBA’s operations. The company delivers quick quotations, often within 2-3 working days, and supports 24-hour technical assistance. This approach helps customers achieve rapid prototyping and meet tight project deadlines. LTPCBA’s flexible production lines allow for fast turn pcb assembly, ensuring that both custom pcbs and standard orders receive the same attention to quality and speed. Many engineers choose LTPCBA for its ability to combine technical capabilities with fast turnaround and dependable support.

Note: LTPCBA’s commitment to fast turn pcb services helps teams reduce time to market and adapt quickly to design changes.

Quality Assurance

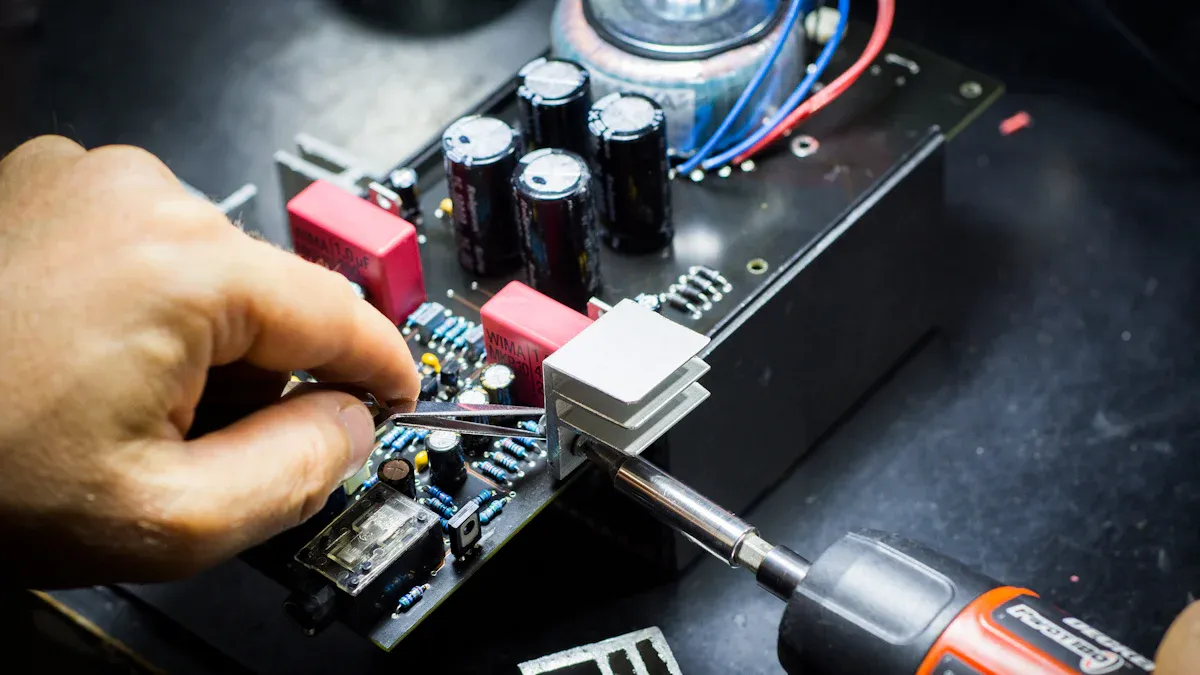

Quality remains a top priority at LTPCBA. The company implements strict quality control measures at every stage of pcb assembly. Automated optical inspection, X-ray testing, and functional tests ensure that each pcb meets high standards. LTPCBA follows international certifications, including ISO, IATF, and UL, which demonstrates its dedication to quality and reliability.

A 99.5% pass rate in product delivery highlights LTPCBA’s good quality control and attention to detail. The company’s quality control team monitors every process, from incoming materials to final inspection. Fast turn pcb projects receive the same level of quality assurance as larger production runs. Customers benefit from consistent quality, fast turnaround, and responsive support. LTPCBA’s reputation as a custom pcb manufacturer grows stronger with each successful project.

Tip: Choosing a manufacturer with strong quality control and fast turn pcb services can make a big difference in project success.

Industry Trends

Global Market

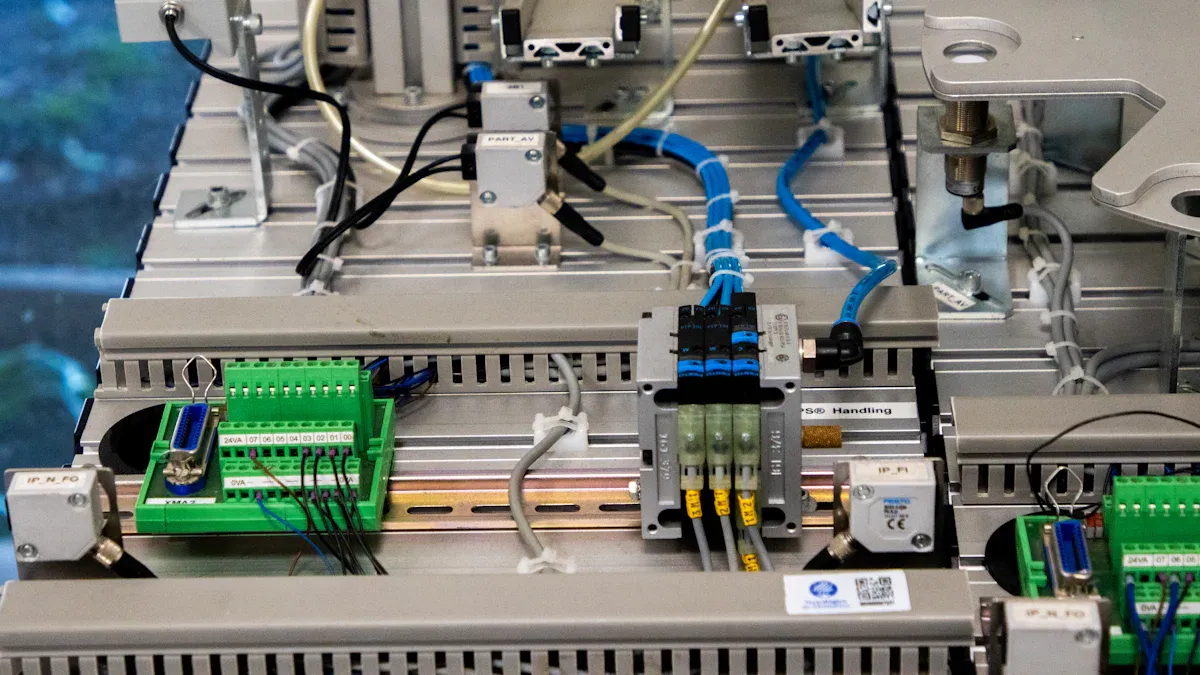

The global market for pcb manufacturing continues to expand as technology advances. Companies in Asia, North America, and Europe compete to deliver high-quality pcb solutions. Many global fast turn pcb manufacturers invest in automation and smart factories. These investments help them meet the rising demand for quick delivery and reliable products.

Manufacturing hubs in China and Southeast Asia lead in volume production. North American and European providers focus on specialized services and rapid prototyping. Customers now expect fast response times and flexible manufacturing options. The market also sees a shift toward environmentally friendly processes. Manufacturers adopt green practices to reduce waste and energy use.

Note: Global competition drives innovation and improves service standards across the pcb manufacturing industry.

Cost Factors

Pricing remains a key concern for businesses planning pcb projects. Several factors influence the final cost of manufacturing. Material selection, board complexity, and order volume all play important roles. Fast turn services may increase pricing, but they help companies meet tight deadlines.

A clear understanding of manufacturing costs helps teams manage their budget. Many providers offer online calculators to estimate pricing before placing an order. Companies often compare quotes from multiple manufacturers to find the best fit for their budget and project needs.

Cost Factor | Impact on Pricing |

|---|---|

Material Type | High-quality materials raise costs |

Board Complexity | More layers or features increase pricing |

Order Volume | Larger runs lower unit cost |

Turnaround Time | Faster delivery may add to pricing |

Manufacturing efficiency and automation help reduce costs over time. Providers that streamline their manufacturing processes can offer better pricing and faster delivery. Teams that understand these cost factors can make informed decisions and keep projects within budget.

Quick Turn PCB Assembly

Fast Turn PCB Services

Quick turn pcb assembly has become essential in modern electronics manufacturing. Companies rely on fast turn pcb services to reduce time to market and respond quickly to design changes. Speed plays a critical role in every stage of pcb manufacturing, from prototyping to full-scale production. Fast turn pcb options allow engineers to test new ideas and move projects forward without delay.

Top providers, such as LTPCBA, JLCPCB, and MacroFab, focus on delivering fast turn pcb solutions. LTPCBA stands out by offering rapid quotations and 24-hour technical support. Their advanced manufacturing systems handle both small prototype runs and larger production batches. JLCPCB and MacroFab also provide fast turn pcb services, supporting customers who need quick results. These companies use automation and streamlined processes to maintain high quality while meeting tight time requirements.

Note: Fast turn pcb services help teams stay competitive in a fast-paced industry.

Lead Times

Turnaround times have a direct impact on project success. Fast turn pcb assembly reduces waiting periods and helps companies meet strict deadlines. LTPCBA delivers most orders within 1-5 days, depending on the complexity and volume of the pcb. JLCPCB often completes standard orders in 1-3 days, while MacroFab offers flexible turnaround times for different production needs.

The table below compares typical turnaround times for leading providers:

Provider | Typical Turnaround Times | Fast Turn PCB Availability | Production Range |

|---|---|---|---|

LTPCBA | 1-5 days | Yes | Prototype to mid-volume |

JLCPCB | 1-3 days | Yes | Prototype to high-volume |

MacroFab | 3-7 days | Yes | Prototype to production |

Fast turn pcb services shorten the time from design to finished product. This speed supports rapid prototyping and enables faster production cycles. Companies that choose providers with reliable turnaround times gain an advantage in manufacturing and product development. Quick turn pcb assembly ensures that teams can adapt to changes and deliver results on schedule.

Choosing for Your Needs

Prototyping

Prototyping forms the foundation of every successful electronics project. Engineers often require pcb prototype services that deliver fast results and maintain strict quality control. Many teams select a provider that offers rapid pcb prototype service to reduce development time. LTPCBA supports rapid prototyping with advanced equipment and experienced staff. Their pcb prototype services help engineers test ideas quickly and refine designs before moving to production. A budget-friendly pcb maker can help teams manage costs during early development. Affordable custom pcb order options allow for flexibility and experimentation. Reliable quality control ensures that pcb prototypes meet design requirements and function as intended.

Tip: Choose a provider with strong quality control and fast turnaround for pcb prototyping. This approach saves time and reduces costly errors.

Low/Medium Volume

Low and medium volume production requires a balance between cost, speed, and reliability. Many companies transition from pcb prototypes to small batch production as projects progress. LTPCBA offers scalable solutions for these needs. Their production lines handle both small and mid-sized orders efficiently. Teams benefit from consistent quality control and on-time delivery. Providers that offer flexible production schedules help companies stay within budget and meet market demands. A clear understanding of production costs and timelines supports better planning. LTPCBA’s experience with low and medium volume production ensures reliable results at every stage.

Need | Key Considerations | LTPCBA Solution |

|---|---|---|

Low/Medium Volume | Cost, reliability, timing | Scalable production, quality control, on-time delivery |

High-Reliability

High-reliability applications demand strict standards. Industries such as medical, aerospace, and automotive require pcb assemblies that perform under challenging conditions. LTPCBA implements rigorous quality control processes for these projects. Their team uses advanced inspection methods to ensure reliability in every unit. Production for high-reliability applications often involves additional testing and documentation. LTPCBA’s commitment to reliability gives customers confidence in mission-critical products. Teams that prioritize reliability and quality control reduce the risk of failure and improve long-term performance.

Note: High-reliability production benefits from providers with proven quality control systems and a track record of dependable results.

Top PCBA manufacturers each bring unique strengths. LTPCBA leads in quality assurance and fast turnaround. JLCPCB stands out for low pricing and quick delivery. MacroFab and Advanced Circuits offer flexible production and reliability. Readers should match their project needs—such as prototyping, volume, or high-reliability—to the right provider.

For dependable service and expert support, LTPCBA remains a strong choice. Visit LTPCBA’s official website to request a quote or learn more.

FAQ

What is PCBA and why does quality matter?

PCBA stands for Printed Circuit Board Assembly. Quality matters because it ensures reliable performance, reduces defects, and supports long-term product success. High-quality PCBA minimizes rework and helps companies meet industry standards.

How fast can LTPCBA deliver assembled PCBs?

LTPCBA delivers most orders within 1-5 days, depending on complexity and order size. The company also provides rapid quotations and 24-hour technical support for urgent projects.

Which industries benefit most from fast turn PCB assembly?

Industries such as consumer electronics, automotive, medical devices, and aerospace benefit most. Fast turn PCB assembly helps these sectors accelerate prototyping and meet tight production deadlines.

What certifications does LTPCBA hold?

LTPCBA holds ISO, IATF, and UL certifications. These standards demonstrate the company’s commitment to quality, safety, and reliability in every project.

How can customers request a quote from LTPCBA?

Customers can visit LTPCBA’s official website and use the online quote form. The team responds quickly, usually within 2-3 working days.

See Also

Ensuring High Quality Production In Modern Turnkey PCBA Plants

Choosing The Right PCBA Supplier To Fit Your Requirements

Understanding PCBA And The Key Components Involved

Defining PCBA And Its Meaning Within Electronics Industry

Boosting Business Efficiency Through PCBA Contract Manufacturing Services