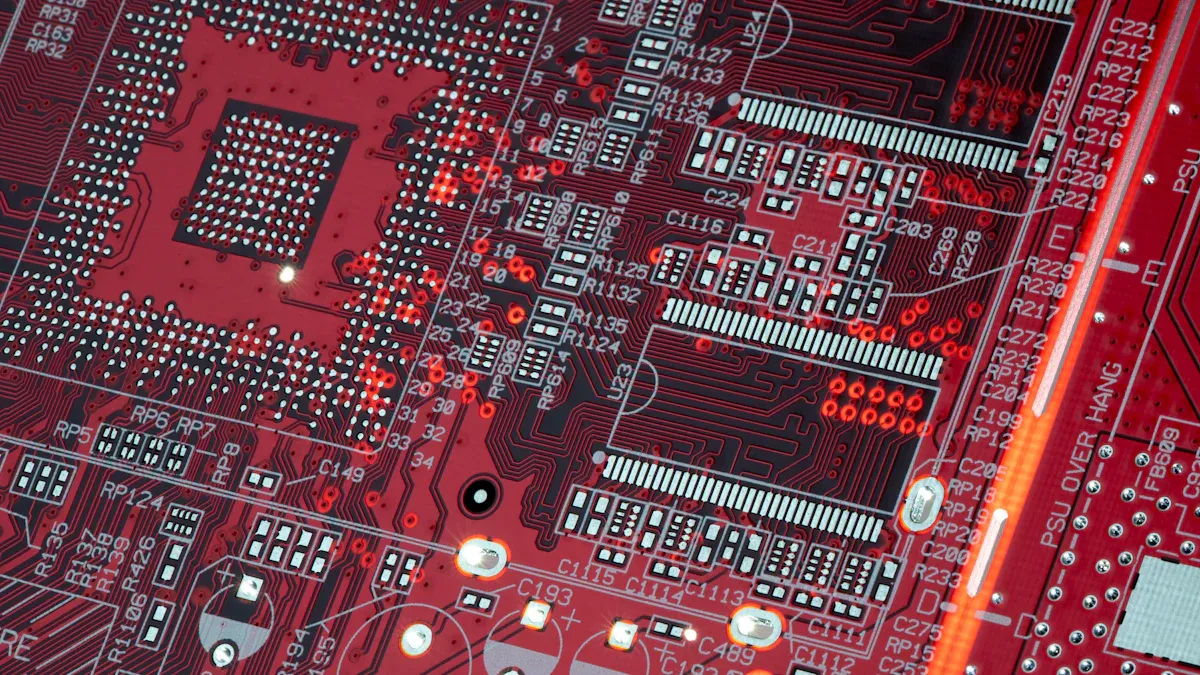

Common reflow soldering defects in SMT assembly and processing and preventive measures

Reflow soldering defects can lead to significant challenges in SMT assembly. Issues such as bridging, tombstoning, and solder balling can negatively impact PCB performance. Effective soldering ensures robust connections and reduces the risk of failures. Implementing advanced techniques helps prevent these reflow soldering defects and maintains high assembly quality.

Key Takeaways

Knowing common soldering problems like bridging, tombstoning, and solder balls improves circuit board work.

Using solder paste correctly and keeping surfaces clean stops problems and makes strong connections.

Taking care of tools and teaching workers good methods reduces errors and makes better assemblies.

Overview of Common Reflow Soldering Defects

Reflow soldering problems can harm how well your PCBs work. Knowing these issues helps you fix them during SMT assembly. Below are some common soldering problems you might face.

Bridging

Bridging happens when too much solder connects two nearby pads. This can cause short circuits and stop your PCB from working properly. It often occurs if too much solder paste is used or parts are not placed correctly.

To avoid bridging, apply solder paste carefully and align parts properly. Using a stencil with the right size holes can control solder paste amounts.

Insufficient Solder Joints

This defect happens when there isn’t enough solder to make a strong connection. Weak joints can break easily or fail to carry electricity well.

Reasons for this include not enough heat, bad solder paste, or dirty surfaces. Contaminants can stop solder from sticking properly.

Problem | What Happens |

|---|---|

Not enough solder | Joint isn’t fully covered with solder. |

Reflow process doesn’t reach the needed temperature. | |

Bad solder paste | Poor-quality paste makes weak joints. |

Cooling issues | Problems during cooling weaken the joint. |

Dirty surface | Dirt or oils stop solder from sticking. |

To fix this, use good solder paste and enough heat. Keep the PCB clean before soldering.

Tombstoning

Tombstoning happens when one side of a part lifts up, looking like a tombstone. Small parts like resistors or capacitors are most affected. Uneven heating or uneven solder paste causes this problem.

To stop tombstoning, heat the PCB evenly and apply solder paste carefully. Adjusting the reflow settings can also help.

Solder Balling

Solder balling creates tiny solder balls near the joint. These can cause short circuits or stop the PCB from working. Too much solder paste, bad reflow settings, or dirt can cause this.

Reduce solder balling by using the right amount of paste and keeping the area clean. Set the reflow oven correctly to avoid this issue.

Dewetting

Dewetting happens when solder doesn’t spread evenly on the pad or lead. Instead, it pulls back, leaving bare spots. This weakens the joint and can be caused by dirt, low flux, or bad reflow temperatures.

To fix dewetting, clean the PCB well and use solder paste with enough flux. Check the reflow temperature to ensure proper solder flow.

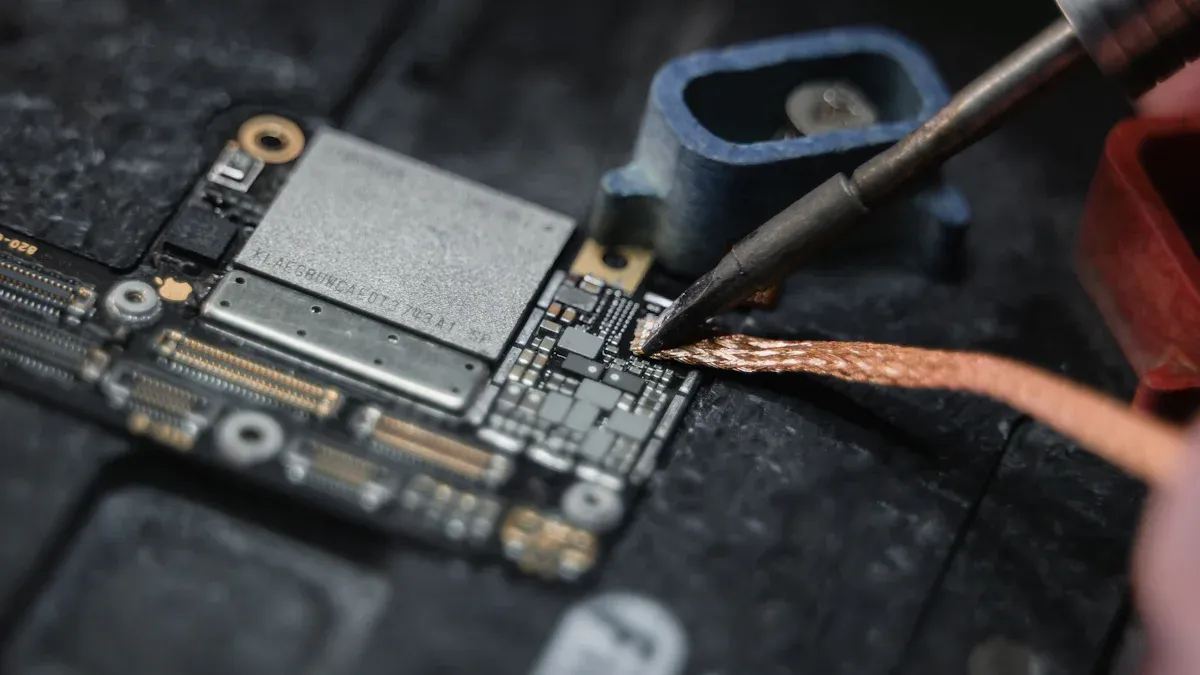

Cold Solder Joints

Cold solder joints form when solder doesn’t get hot enough to bond well. These joints look dull and are weak. Low heat or moving the PCB during cooling can cause this.

Prevent cold solder joints by ensuring the reflow oven heats evenly. Don’t move the PCB while it cools to keep joints strong.

Tip: Check and test your work often to catch these problems early.

Causes of Reflow Soldering Defects

Knowing why reflow soldering defects happen helps improve SMT assembly. Below are the main reasons for these problems.

Wrong Solder Paste Application

How you apply solder paste is very important. If too much or too little is used, defects like bridging or weak joints can occur. Problems often come from bad stencil printer settings or humid air. To avoid this, align stencils properly and control the environment.

Bad Reflow Temperature Settings

Reflow soldering needs the right heat levels. Wrong settings can cause issues like tombstoning, voids, or head-in-pillow defects. Uneven heat might lift one side of a part, causing bad connections. For example:

Uneven heat makes solder melt poorly, causing tombstoning.

Poor heat control worsens voids, weakening joints.

Trapped gas bubbles make joints weaker under stress.

Check and adjust oven settings to keep heating steady.

Misaligned Parts

Parts that are not placed correctly can cause weak joints. Mistakes during placement or movement during transport often lead to this. Using automated machines can help place parts accurately and reduce errors.

Dirty Surfaces

Dirt or oils can stop solder from sticking well. Contaminants weaken joints and make solder spread unevenly. Studies show dirt changes solder properties and reduces its stickiness. Clean the PCB and work in a clean area to prevent this.

Bad PCB Design

A poorly designed PCB can cause more defects. Pads too close together may lead to bridging, while uneven pad sizes can cause tombstoning. Following good design rules helps reduce these problems.

Tip: Check your tools and processes often to fix problems early.

Preventive Measures for Common Soldering Defects

Optimizing solder paste application

Applying solder paste correctly helps avoid problems like bridging. Focus on key settings during the paste printing process. For example, keep the table gap at 2.0 mm. Set the squeegee speed to 50 mm/s for better results. Use the right squeegee pressure, like 0.15 Pa, for even paste. Adjust the table speed to 2.0 mm/s for volume and 2.5 mm/s for height.

Good solder paste printing reduces defects and improves joint quality. Check your machines often and watch for humidity changes. These steps make the process more reliable.

Ensuring proper reflow oven settings

The reflow oven is important for avoiding soldering problems. Make sure the oven settings are correct for even heating. Place thermocouples to check temperature across the PCB. Adjust the time-temperature curve to improve solder joints. For example, changing conveyor speed by 5 mm/s can adjust heat by 10–15 °C·s.

Using nitrogen gas during reflow helps solder stick better. It reduces defects like bridging and tombstoning by up to 20%. Regularly check and fine-tune oven settings to keep results consistent.

Using Design for Manufacturing (DFM) principles

Designing PCBs with DFM principles helps prevent soldering issues early. Think about pad sizes, spacing, and part placement during design. Work with your assembly provider to match designs with their tools. This reduces mistakes during production.

For example, one company cut defects by 60% using DFM rules. Another study showed an 18% boost in product quality with DFM. Planning ahead makes soldering more reliable.

Implementing thorough inspection and testing protocols

Testing and inspecting early catches soldering problems before they grow. Watching the process closely helps stop defects from happening. Tools like AOI and X-ray inspection find issues like solder balling. Comparing past and current data shows if changes are working.

Regular checks and audits ensure high-quality assembly. Focus on preventing problems instead of just fixing them later.

Maintaining a clean and controlled environment

A clean workspace reduces soldering problems like weak joints. Dirt and oils can stop solder from sticking properly. Sorting defects during inspections keeps the area cleaner. This also cuts waste and helps the environment.

Use cleanrooms and control humidity and temperature for better results. A clean space lowers defect risks and makes PCBs more reliable.

Best Practices for SMT Assembly by LTPCBA

Regular maintenance of equipment

Taking care of your machines is very important. It keeps them working well and avoids sudden problems. Regular checks make machines last longer and work better. For example:

Clean and working machines cause fewer soldering mistakes.

Routine checks find problems early and save repair costs.

By maintaining equipment, you get better results and fewer defects.

Training personnel on proper techniques

Teaching your team the right skills is very important. Trained workers know how to use tools and follow rules. This lowers mistakes and makes solder joints stronger.

Benefit of Training | What It Helps With |

|---|---|

Knowing Equipment | Workers learn to use and fix tools correctly. |

Following Rules | Teams meet quality standards more easily. |

Less errors mean better assembly results. |

Training helps your team improve and keeps the process smooth and reliable.

Using high-quality materials and components

Good materials make better solder joints. Using quality paste, stencils, and finishes reduces problems. For example:

Material | Why It’s Important |

|---|---|

Solder paste | Works well with the process for good results. |

Stencil quality | Helps apply paste evenly and accurately. |

Surface finish compatibility | Makes solder stick better and last longer. |

Using the best materials avoids issues like bridging and tombstoning.

Conducting regular process audits

Checking your process often helps fix problems early. Audits like 5S checks keep workspaces clean and organized. Calibration checks ensure machines work correctly.

Audit Type | What It Does |

|---|---|

Makes sure processes are followed properly. | |

5S Workplace Checks | Keeps work areas tidy and efficient. |

Calibration Audits | Ensures tools are accurate. |

Regular audits improve quality and reduce mistakes, keeping assembly standards high.

Fixing soldering problems in SMT assembly means knowing their causes. Using methods like careful solder paste application helps reduce mistakes. Keeping the workspace clean also lowers errors. Improving processes, like using automated soldering, works well. One study showed fewer defects with new methods.

New tools, like automatic heat profiling and live data tracking, help prevent issues. These steps save money and make products work better. LTPCBA focuses on making reliable PCBs by using smart ideas, quality checks, and constant improvements.

FAQ

What causes bridging in reflow soldering?

Bridging happens when too much solder paste is used. Misaligned parts can also cause this problem. Use the right stencil and place parts carefully to avoid it.

How do you stop tombstoning in SMT assembly?

To stop tombstoning, heat the PCB evenly. Apply solder paste properly and adjust reflow settings to lower the risk.

Why should you clean the PCB before soldering?

Dirt and oils stop solder from sticking well. Cleaning the PCB makes solder joints stronger and prevents defects like dewetting.

Tip: Check your work often and keep the area clean for better soldering results.

See Also

Importance Of Nitrogen Reflow Soldering In Automotive And PCBA

Key Considerations For VIPPO PCB Boards In SMT Assembly

Critical Points To Consider In Rigid-Flex PCB SMT Assembly

Essential Guidelines For Wave Soldering In SMT Processes

Effects Of Reflow Soldering Temperature Zones On PCB Quality