How to Select a PCBA Supplier That Meets Your Needs

Choosing a PCBA supplier impacts how well your project goes. You need to match their skills to your project needs. This helps production run smoothly. For example:

Checking part costs helps keep designs affordable.

Looking at BOM data finds supply chain problems.

Checking failure rates ensures good quality.

Studying performance data makes designs better.

LTPCBA uses smart technology and cares about customers to give great results.

Key Takeaways

Focus on quality when picking a PCBA supplier. Check for certifications like ISO 9001 and ISO 13485 to confirm they follow industry rules.

Check the supplier's ability to make your product. Look at their tools, technology, and experience to ensure they can do a good job.

Learn about pricing and ask for clear details. Compare prices and make sure you balance cost and quality to keep your project successful.

Quality and Certifications

Why Quality Standards Matter

When picking a PCBA supplier, quality should come first. Good quality ensures the product is safe, reliable, and works well. In fields like aerospace, defense, and medical devices, following IPC rules is required. Even small mistakes can cause big problems. For example, a faulty PCBA in a medical device could harm a patient.

To meet these strict rules, manufacturers use strong quality checks. These checks make sure every PCBA meets industry rules, protecting people and the planet. IPC rules give a clear list for manufacturers to follow. This list includes choosing materials, packing parts, and making the product. By following these steps, suppliers can make great PCBAs that meet your needs.

Certifications to Look For in a Supplier

Certifications show a supplier cares about quality. When picking a PCBA supplier, look for certifications that follow global standards. Two important ones are:

Certification | What It Means |

|---|---|

ISO 9001:2015 | Sets up a system for improving quality and keeping customers happy. |

ISO 13485:2016 | Lists rules for making medical devices safely and managing risks. |

These certifications prove the supplier works hard to make reliable products. They also show the supplier meets customer and legal needs.

LTPCBA’s Commitment to Quality Assurance

LTPCBA stands out for its focus on quality. The company uses advanced methods to ensure every step is precise. Here’s how LTPCBA keeps its high standards:

Thorough Testing: LTPCBA tests products to find and fix problems early.

Design Checks: The team reviews designs to catch issues before making products.

Top Materials: Only the best materials that meet industry rules are used.

LTPCBA also follows a careful inspection process:

Material Checks: All materials are inspected before assembly starts.

Component Checks: Tools like X-rays confirm parts are real and correct.

Final Checks: Each product is tested before shipping to ensure quality.

LTPCBA’s results show its dedication to quality. For example, they ensure perfect soldering and part placement. They test prototypes to see how they perform in real conditions. They also make sure every batch meets the same high standards. LTPCBA follows rules like ISO 9001 and IPC-A-610, proving it’s a trusted supplier.

Choosing a PCBA supplier like LTPCBA means working with a partner who values quality at every step.

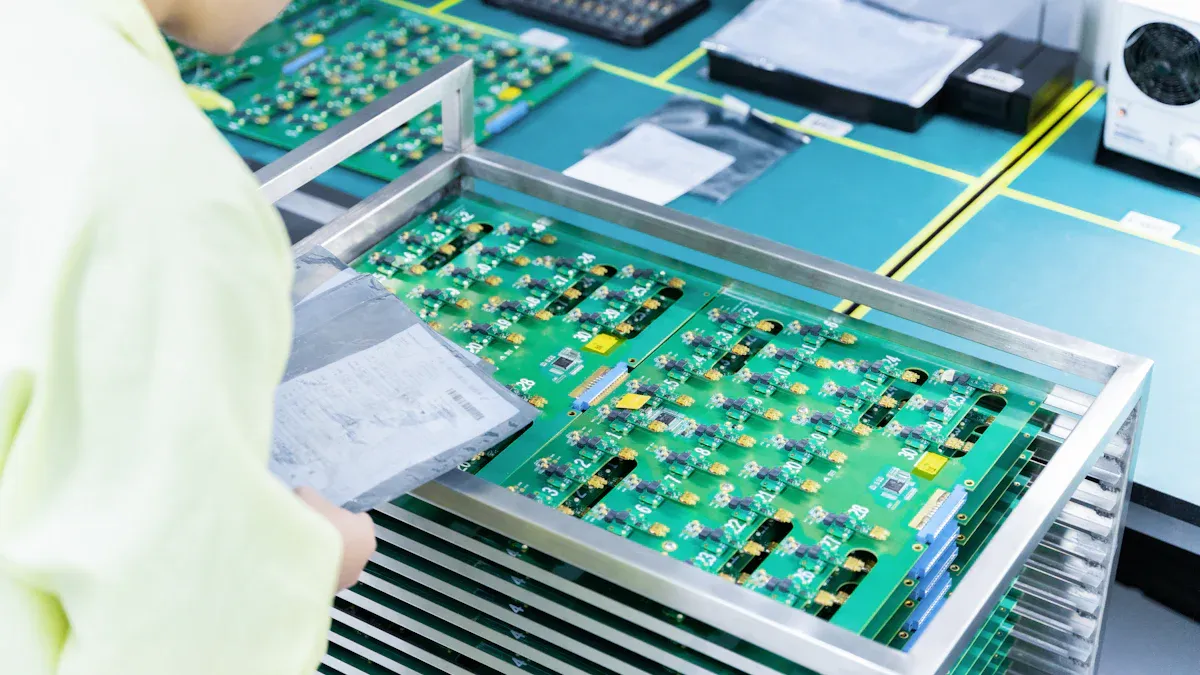

Manufacturing Capabilities and Technology

Checking a Supplier’s Tools and Machines

When picking a PCBA supplier, check their tools and machines. Modern equipment helps make better products with fewer mistakes. Suppliers with advanced tools can handle tricky designs and tight spaces. Here are some important things to look at when checking a supplier’s abilities:

Capability Category | Importance | |

|---|---|---|

PCB Types Supported | See if they know how to make your type of PCB. | High |

Material Expertise | Make sure they understand materials and how to choose them. | High |

Manufacturing Technology | Check if they can work with very small details. | High |

Layer Count Capability | Find out the highest number of layers they can make. | High |

Tolerances and Precision | Look at how well they control tiny spaces and sizes. | High |

Surface Finish Options | See if they can do the right finishes for your project. | Medium |

Special Processes | Check if they have experience with unique technologies. | Medium |

Testing and Inspection | Make sure they test boards to catch problems. | Medium |

Prototype and Small Batch | See if they can make small amounts for testing. | Medium |

Project Complexity Handling | Check if they’ve worked on projects like yours before. | High |

Also, check if they have tools like precise solder printers, pick-and-place machines, and AOI systems. These tools help place and solder parts correctly.

Matching Your Project Needs

Not all suppliers can handle your project’s special needs. Make sure their skills match what you need. This includes handling your design, materials, and production size. A good supplier should also be ready to grow with your needs.

Here’s what to check:

Criteria | What It Means |

|---|---|

Process and Technological Capability | See if they have the tools and skills for now and the future. |

Quality Capabilities | Make sure they have strong quality checks and stay consistent. |

Management Capability | Look for experienced leaders who care about customers. |

Financial Stability | Check if they have enough money to handle long projects. |

IT Capability | See if they can connect with your systems and use new tech. |

Employee Capabilities | Check if their workers are skilled and happy. |

Environmental Regulation Compliance | Make sure they follow rules to protect the environment. |

Infrastructure and Assets | Look at their buildings, tools, and how well they maintain them. |

It’s also important that they can handle small tests, small orders, and big productions. This flexibility helps as your business grows.

LTPCBA’s Top Manufacturing Skills

LTPCBA is great because of its advanced tools and methods. They use the best machines to make high-quality PCBAs. Here are some of LTPCBA’s strengths:

Metric | Value |

|---|---|

60,000 square meters | |

SMT monthly production capacity | 240 million points |

Quality assurance pass rate | 99.5% |

Quick response time for quotes | 2-3 working days |

LTPCBA uses tools like AOI, X-ray, and ICT machines. These tools make sure every step is accurate and reliable. They can handle tricky designs, small spaces, and many layers. This makes them a trusted choice for many industries.

By choosing LTPCBA, you get a supplier that focuses on new technology and quality. Their advanced tools help your project succeed, whether it’s a small test or a big order.

Cost and Pricing Transparency

Understanding Pricing Models

When picking a PCBA supplier, knowing their pricing is important. Suppliers use different ways to set prices. Comparing these helps you find the best deal. Here are key things to check:

Strategy/Component | What It Means |

|---|---|

Complete BOM | Needed to compare costs between suppliers accurately. |

RFQ Analysis | Look at quotes from many suppliers to save money. |

Component-level Pricing | Check if each part has a fair price and source. |

OEM Model | Compare part prices using supplier quotes. |

Lowest-cost Tactics | Focus on getting the cheapest parts available. |

By checking these, you can save money and meet your project needs.

Balancing Cost and Quality

Finding the right mix of cost and quality is key. Cheaper options might hurt product reliability. To balance both, think about these points:

Factor | What It Means |

|---|---|

Assembly Method | Different methods cost more or less (THT vs. SMT). |

Turnaround Time | Faster work may cost more due to extra resources. |

Quantity of PCBs | Making more lowers the cost per board. |

Design Complexity | Harder designs take more time and cost more. |

Labor Costs | Costs depend on worker skills and location. |

PCB Size and Layers | Bigger boards with more layers need more materials and time. |

Look at these to get good quality without overspending.

How LTPCBA Ensures Transparent Pricing

LTPCBA makes pricing clear and easy to understand. They give detailed quotes showing costs for materials, labor, and testing. This helps you see where your money goes. LTPCBA also uses smart tools to cut extra costs. They reply to quote requests fast, usually in 2-3 days. Choosing LTPCBA means fair prices and great quality for your project.

Lead Times and Delivery

Why Turnaround Times Matter

Turnaround times are key to your project’s success. Faster delivery helps test ideas and improve designs quickly. Quick-turn PCB services can deliver prototypes in just 24 hours. Regular production, however, might take two to eight weeks. Speed is crucial when you need fast changes or face tight deadlines. Picking a PCBA supplier with fast processes helps you stay ahead and meet goals on time.

How to Avoid Delays

Delays in PCB assembly can mess up schedules and raise costs. To prevent this, use strategies that make production smoother. Here are some tips:

Keep designs simple and use common parts to avoid issues.

Work with suppliers early to check material availability.

Share your plans so suppliers can prepare properly.

Use quality checks during production to catch problems early.

Have a clear process for handling design changes.

Improve teamwork to avoid confusion among everyone involved.

Handle rules and regulations early to avoid delays.

Plan shipping carefully to prevent delivery problems.

These steps can help ensure smooth production and on-time delivery.

LTPCBA’s Strong Delivery Record

LTPCBA is known for delivering projects on time. Their on-time delivery rate is better than most in the industry, which is usually 90% to 95%. LTPCBA’s numbers show they are reliable:

Metric | Industry Benchmark |

|---|---|

On-Time Delivery Rate (OTDR) | Top performers > 98% |

With smart planning, efficient processes, and strong logistics, LTPCBA keeps your project on track. Their focus on being on time makes them a dependable choice for PCB assembly.

Customer Support and Communication

Checking How Fast and Easy They Respond

When picking a PCBA supplier, see how fast they reply. Quick replies show they can handle your needs and fix problems fast. Here’s what to look for:

Check if they answer questions within 24 hours or less.

See if they use tools like online systems for urgent updates.

Make sure you know who to contact for specific issues.

Suppliers who respond quickly help avoid delays and keep things running well. Watching how they communicate helps you build a strong partnership.

Why Clear Communication Matters

Good communication is key for successful PCB projects. It makes sure everyone understands the goals and limits. It also helps solve problems early and keeps work on track. Think about these points:

What to Check | Why It Helps |

|---|---|

Shared Goals | Keeps everyone working toward the same objectives. |

Feedback Options | Fixes problems quickly during production. |

Instant Updates | Shares changes with everyone right away. |

Regular Meetings | Tracks progress and keeps things consistent. |

Open and clear communication improves teamwork and project success.

LTPCBA’s Always-Available Support

LTPCBA stands out with its great customer service. They offer help 24/7, so you can always get expert advice. Whether fixing a problem or making quick changes, LTPCBA’s team is ready to help. Their fast replies and clear systems make them a trusted partner. With LTPCBA, you can focus on your project, knowing help is just a call or message away.

Experience and Reputation

Understanding Industry Knowledge

When picking a PCBA supplier, check their industry knowledge. A skilled supplier uses smart methods and creative ideas for your project. You can measure their skills by looking at important numbers, called KPIs. These numbers show how good a supplier is:

KPI | What It Shows |

|---|---|

Production Efficiency | Tracks speed, meeting deadlines, costs, and quality checks. |

Customer Satisfaction | Looks at reviews, repeat buyers, and how fast they fix issues. |

Product Innovation | Measures how quickly they create new designs and test ideas. |

Environmental Impact | Checks waste reduction, recycling, energy use, and rule-following. |

Financial Health | Focuses on profits, steady cash flow, and smart spending on tools. |

By studying these KPIs, you’ll know if the supplier can handle your project well.

Looking at Reviews and References

Reviews and references help you learn about a supplier’s reputation. Read customer stories, online reviews, and case studies to see how they perform. Ask for references from past clients to hear their experiences. Talking to other customers shows the supplier’s strengths and weaknesses. A supplier with good reviews and strong references is more likely to meet your needs.

LTPCBA’s Strong Reputation

LTPCBA is well-known in the PCB assembly field. They use advanced tools like IoT and AI to ensure top quality. Their process includes strict checks and testing prototypes for reliability. This leads to smooth production and happy customers. LTPCBA’s focus on new ideas and accuracy makes them a reliable choice for any project size.

Customization and Scalability

Handling Custom Requirements

Every project has special needs. Your PCBA supplier must adjust to meet them. A supplier good at customization can manage tricky designs, special materials, and unique processes. For example, LTPCBA has finished over 1,000 custom PCB projects. This shows they can deliver solutions made just for you. Their team includes IPC-certified designers with 30+ years of experience. They use advanced tools like Altium Designer to make great layouts.

Here are two examples of LTPCBA’s skills:

Multi-Processor Vital Controller for Wayside Rail Application: This project needed expert PCB layout for an important use.

Embedded Monitoring for Grid-Scale Energy Storage: This design showed their skill with high-frequency circuits and memory systems.

These examples prove LTPCBA can handle custom needs and help your project succeed.

Scaling Production for Future Needs

As your business grows, your PCBA supplier must grow too. A good supplier should manage small tests and big orders without losing quality. LTPCBA offers flexible production runs, from single units to thousands. This flexibility means they can grow with your business.

Their scaling ability is backed by strong numbers:

Production Cycle Time: 12 hours

First Pass Yield: 95%

On-Time Delivery Rate: 97%

These stats show LTPCBA’s focus on being efficient and reliable. They are a trusted partner for growing your operations.

LTPCBA’s Flexible and Scalable Solutions

LTPCBA uses smart tools and fast processes to offer flexible solutions. They have cut lead times by 60% and defects by 86%. Their production capacity has grown by 300%. This means they can deliver quick and high-quality results, whether for one prototype or many units.

Choosing LTPCBA gives you a partner ready for your current and future needs. Their focus on customization and scalability keeps your project successful, no matter its size or complexity.

Picking a PCBA supplier means looking at important things like quality, communication, and growth ability. These help your project meet design goals, stay on schedule, and work well.

Key Factor | Why It Matters |

|---|---|

Meeting Design Needs | Makes sure the supplier can handle your design and materials. |

Quality Checks | Prevents problems and ensures the circuit boards work correctly. |

Staying on Schedule | Keeps the project on time, making customers happy and building trust. |

LTPCBA has a 99.5% success rate and answers quickly. They are a reliable choice for fast and high-quality PCB assembly. Their all-in-one services save time and money, helping every project succeed.

FAQ

What matters most when picking a PCBA supplier?

Quality is the top priority. The supplier must follow industry rules. They should make reliable PCBAs without defects. Their products must match your project needs.

How do I check a supplier’s certifications?

Ask for proof of certifications like ISO 9001 or IPC-A-610. Look on their website or request references. This confirms they meet global standards.

Why does scalability matter for a PCBA supplier?

Scalability means handling small tests and big orders. It helps your business grow while keeping quality high and deliveries on time.

See Also

Understanding PCBA: Key Components And Their Functions

Choosing The Right PCB Materials For SMT Assembly

Enhancing Project Efficiency With Quick-Turn PCB Prototypes