How to Choose the Right Through Hole PCB Assembly Service for Industrial Control Applications

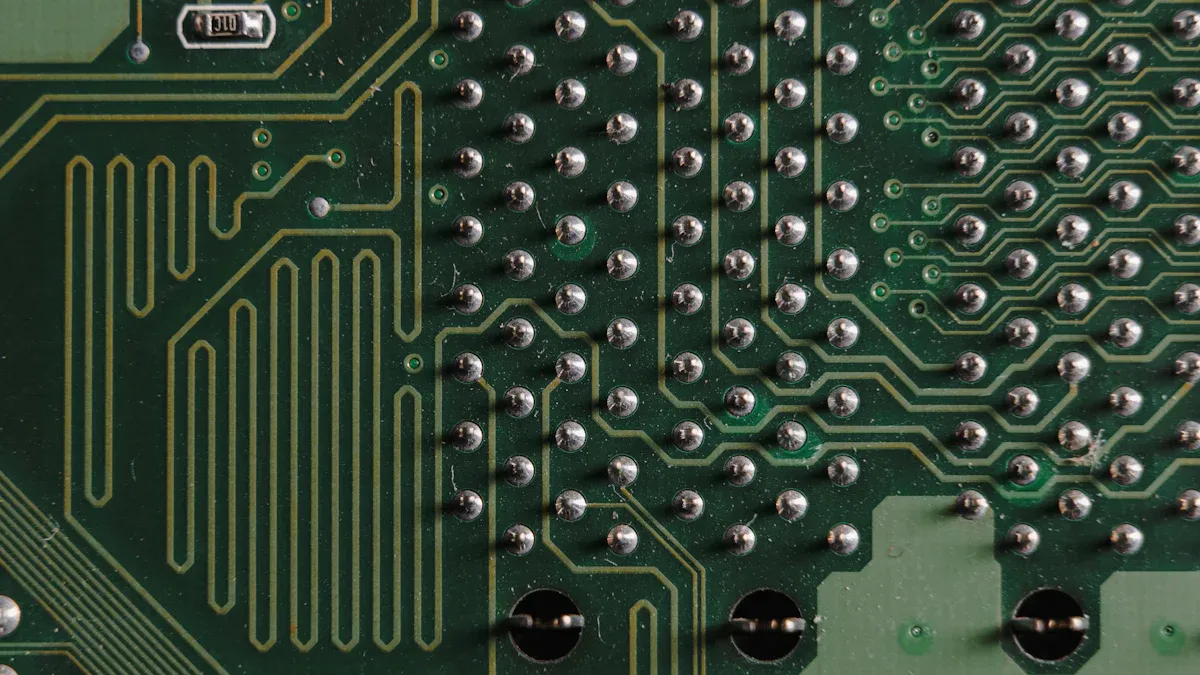

Choosing the right PCB assembly service is crucial. Through Hole PCB Assembly is essential for industrial systems due to its strength. It features robust solder bonds that perform well in challenging environments. Additionally, it is easy to repair and solder, which saves time. LTPCBA employs excellent techniques and advanced tools to create durable PCBs for various industries. With a strong commitment to quality and customer satisfaction, they have become a trusted choice for Through Hole PCB Assembly.

Key Takeaways

Picking the right PCB service is important for factories. Good through-hole connections make systems strong and long-lasting in hard conditions.

Find a PCB company with good quality checks and approvals. This ensures high quality and lowers chances of system problems.

Quick samples and timely delivery are very important. A reliable service like LTPCBA can give test PCBs in a day, helping you finish projects on time.

Why the Right Through Hole PCB Assembly Service Matters

The important role of PCBs in industrial control systems

PCBs are key parts of industrial systems. They help parts communicate smoothly. Signals move correctly and quickly, keeping systems stable. Through-hole assembly is strong and lasts long, perfect for tough jobs. These PCBs handle heat, shaking, and rough conditions well. This makes them reliable in hard environments. Good PCBs improve system work and reduce downtime. This is vital for industries that need constant operation.

Factor | How It Helps Systems |

|---|---|

Mechanical Strength | Through-hole connections are stronger than surface mount ones. |

Reliability | Through-hole PCBs are better for products needing high reliability. |

Heat Tolerance | They resist heat, great for military and aerospace uses. |

Compression Resistance | They handle stress, ideal for high-power systems. |

Ease of Prototyping | Easy to replace or adjust, making testing faster. |

Durability | Strong bonds mean they survive tough conditions better. |

Problems with bad PCB assembly in industrial settings

Bad PCB assembly can cause big problems. Weak connections or poor materials may lead to system breakdowns. This can delay work or create safety risks. Quality checks like Lot Reject Rate (LRR) and Risk Priority Number (RPN) show why good assembly matters. For example:

Lot Reject Rate (LRR): Improved from 5500 PPM to 900 PPM with better quality checks.

Risk Priority Number (RPN): Helps find risks and fix them using FMEA.

Fault Reduction: Dropped by 0.76% thanks to better quality control.

Picking a service with strict quality rules lowers these risks. It ensures systems work well even in tough conditions.

Benefits of working with a trusted PCB company like LTPCBA

Choosing a reliable PCB company like LTPCBA has many perks. They follow global rules like ISO 9001 and IPC. This ensures every PCB is safe and high-quality. LTPCBA uses advanced tools for quick testing. They can make test PCBs in just 24 hours. Their delivery rate is 99%, and first-pass yield reaches 98%.

Benefit | Details |

|---|---|

Cheaper than older SMT methods. | |

Fast Prototyping | Test PCBs ready in 24 hours. |

On-time Delivery Rate | 99% of orders arrive on time. |

First Pass Yield (FPY) | Between 95% and 98%. |

Scrap Rate | Kept below 5%. |

With LTPCBA, you get a trusted partner known for top-quality PCB services. They meet industrial needs with proven success.

Key Factors to Consider When Picking a PCB Assembly Service

Experience and Skill in Through-Hole PCB Assembly

Experience is very important when picking a PCB assembly service. A company with lots of practice in through-hole assembly knows how to handle tricky designs. Many years in business show they are stable and have good processes. This leads to better quality work.

Evidence Type | What It Shows |

|---|---|

Company History | |

Industry Knowledge | Knowing industry rules helps meet project needs better. |

Years in Business | More years mean steady work and better ways of doing things. |

Working with a company like LTPCBA gives you their proven skills. They have years of experience and a strong name in the industry.

Quality Checks and Certifications

Good quality checks are key for reliable PCB assembly. Certifications like IPC-A-610 and UL prove the company follows strict rules for quality.

IPC Standards - Guides for making PCBs at every step.

UL Certification - Makes sure products are safe and meet electrical rules.

LTPCBA also uses checklists, reviews, and monitors their processes. These steps help reduce mistakes and make sure the PCBs are dependable.

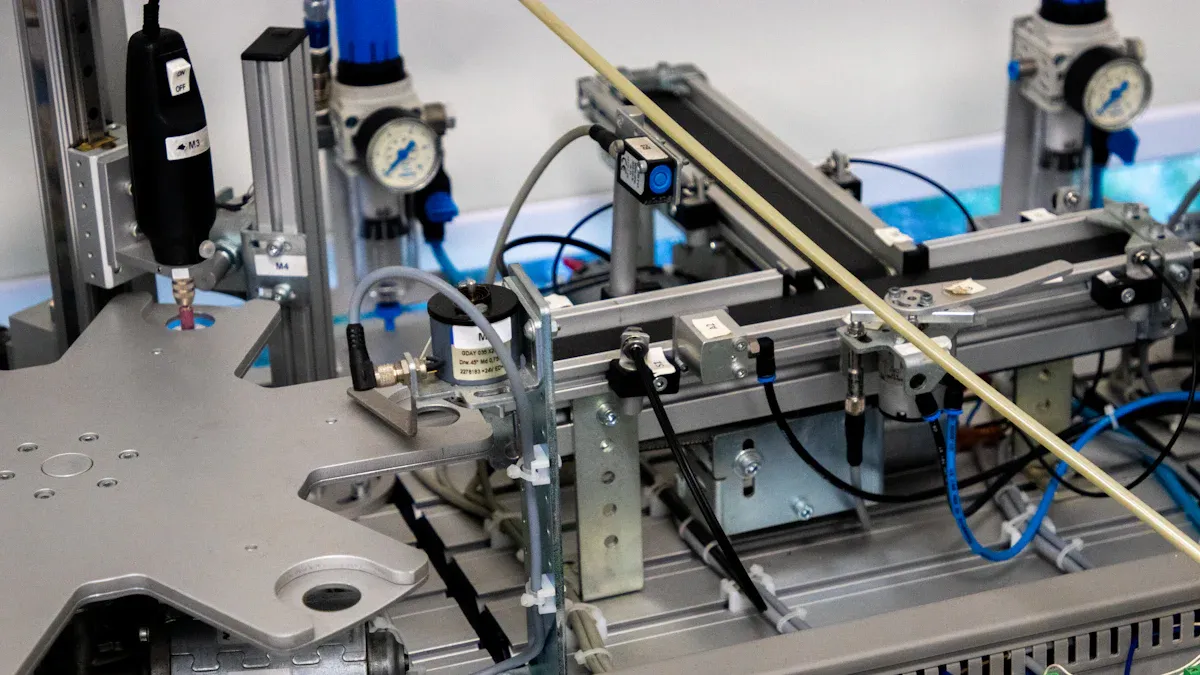

Testing and Checking for Industrial PCBs

Testing is important to make sure industrial PCBs work well. Advanced tools like optical and X-ray inspections find problems. Other tests check if the PCB works as it should.

Test Type | What It Does |

|---|---|

Optical Inspection | Looks for visible problems on the PCB. |

X-Ray Inspection | Finds hidden issues inside multi-layer PCBs. |

Electrical Testing | Checks if the PCB meets electrical needs. |

Burn-In Testing | Tests how the PCB handles long-term use. |

LTPCBA uses modern tools like Flying Probe testers for small jobs and special testers for big ones. These tools ensure the PCBs meet high standards and work reliably.

Affordable Options for Small Orders

Keeping costs low is important, especially for small orders. Special methods can make small production runs cheaper. Using standard materials and automation also helps save money.

Looking at long-term costs, like repairs, helps plan better.

Picking the right materials keeps costs down.

LTPCBA offers fair prices for small orders without losing quality. Their smart processes make them a good choice for affordable PCB assembly.

Good Customer Service and Quick Help

Good customer service makes the PCB process easier. Things like fast delivery and quick answers show a company cares about its customers.

Great service makes customers happy and loyal.

Fast delivery times improve the overall experience.

LTPCBA stands out with 24-hour tech support and fast replies. Their focus on customer happiness makes them a trusted PCB assembly partner.

Specific Considerations for Industrial Control Applications

Durability and Reliability Under Harsh Operating Conditions

Industrial systems often work in tough environments. These conditions can test the strength of their parts. Through-hole manufacturing makes PCBs strong enough to handle these challenges. It’s perfect for systems that need to last in extreme settings. Choose a PCB service that focuses on reliability with strict testing. For instance, stress tests mimic real-world conditions like heat, moisture, and vibrations. These tests show how well the PCB performs under pressure.

Testing Method | Purpose | What it Shows |

|---|---|---|

Environmental Stress Testing | Mimics real-life conditions | Strength against heat, moisture, and physical stress |

Temperature Cycling | Tests repeated temperature changes | Solder joint strength and thermal expansion issues |

Humidity Testing | Checks resistance to water and rust | Weaknesses from moisture or corrosion |

Vibration Testing | Measures strength during shaking or movement | Stability of solder joints and overall structure |

Shock Testing | Tests sudden impacts or drops | Strength of parts and connections |

Electrical Stress Testing | Checks electrical performance under stress | Power stability and heat resistance |

Power Cycling | Tests repeated power on/off cycles | Reliability of solder joints and heat handling |

Through-hole assembly passes these tests with flying colors. It offers great strength and heat resistance. This makes it the best choice for systems needing long-lasting performance.

Compliance with Industry Standards and Regulations

Following industry rules is a must for industrial systems. Make sure your PCB company meets global certifications. These prove the PCBs are safe and high-quality. They also ensure the boards meet strict industry needs.

Standard | Use Case | What It Ensures |

|---|---|---|

Automotive | Quality and performance for rigid PCBs | |

AS9100 | Aerospace | Top standards for aviation and defense systems |

ISO 13485 | Medical | Safety and compliance for medical devices |

A company like LTPCBA follows these rules, including IPC and AS9100. This guarantees your PCBs meet all safety and quality needs. It also boosts your product’s reputation in the market.

Customization and Scalability for Industrial Needs

Industrial systems often need special designs to work well. Through-hole manufacturing allows PCBs to be customized for unique tasks. Whether you need one prototype or many units, the right service should handle both.

Customization helps create PCBs that fit perfectly into your system. Scalability means the company can grow with your needs without losing quality. LTPCBA excels at both. They offer advanced tools and a strong history of delivering custom solutions.

Tip: Pick a service that handles both small prototypes and large orders. This ensures they can support your needs as your business grows.

Steps to Assess and Compare PCB Assembly Companies

Researching and Shortlisting Providers

Begin by finding PCB assembly companies using trusted websites. Sites like ThomasNet, Global Sources, and Digi-Key Electronics list many providers. These platforms let you search by skills, certifications, and experience in through-hole manufacturing.

Resource Name | What It Offers | Website Link |

|---|---|---|

ThomasNet | Helps find suppliers and manufacturers, including PCB services. | |

Global Sources | Connects buyers with suppliers, mainly in Asia. | |

Digi-Key Electronics | Lists suppliers for electronics and PCB assembly services. |

Pick companies that focus on through-hole PCB assembly and have good results in industrial projects.

Evaluating Quotes and Proposals

When looking at quotes, don’t just check the price. Think about the value each company offers. Look for clear pricing details, including costs for materials, labor, and testing. Use tools like RFPs (Requests for Proposals) and RFIs (Requests for Information) to get detailed offers.

Method/Technique | What It Does |

|---|---|

Helps gather detailed offers from providers. | |

Market Research | Collects data about industry prices and services. |

One-on-One Meetings | Allows direct talks about project needs and terms. |

Compare prices while checking the company’s quality and skills. This helps you choose a service that is both affordable and reliable.

Conducting Audits or Site Visits

Visiting a company or doing an audit gives you a closer look. Check their tools, testing methods, and if they follow standards like ISO 9001 and IPC-A-610. Testing methods like In-Circuit Testing (ICT) and Automated Optical Inspection (AOI) show their focus on quality.

Testing Method | What It Checks | Quality Standard Followed |

|---|---|---|

In-Circuit Testing (ICT) | Tests electrical performance and solder strength. | ISO 9001, IPC-A-610, UL certified |

Automated Optical Inspection (AOI) | Finds visible problems on the PCB. | ISO 9001, IPC-A-610, UL certified |

Audits help confirm the company can meet your project’s needs.

Reviewing References and Customer Feedback

Customer reviews can tell you how reliable a company is. Ask for references and talk to past clients about their experiences. Online reviews and testimonials also show how well the company handles problems and deadlines. Choose companies with a strong record in through-hole manufacturing.

Tip: Look for positive feedback on delivery, quality, and support. This helps you pick the best PCB assembly service.

Picking the right PCB assembly service keeps systems working well. The service should match your project needs to prevent issues. Through-hole manufacturing is strong and can be customized for tough jobs. LTPCBA uses advanced tools, strict quality checks, and great support to provide dependable solutions made just for you.

FAQ

1. What certifications should a PCB assembly service have?

Look for certifications like ISO 9001, IPC-A-610, and UL. These show the company makes safe and reliable products.

2. How can you check if industrial PCBs are strong?

Ask about tests like vibration, temperature changes, and moisture checks. These tests show if the PCB can handle tough conditions.

3. Why does customer support matter for PCB assembly services?

Good support solves problems fast and keeps you informed. It also helps you track production and delivery updates.

See Also

Finding The Ideal Comprehensive PCB Assembly Provider

Essential Tips For Designing Industrial Controller PCBs

Tips For Choosing A PCBA Supplier That Fits You