How to Find a Reliable Through Hole Assembly Service Partner

When searching for through hole assembly services, it's essential to choose a partner who demonstrates reliability. Make sure they hold key industry certifications such as IPC-A-610, ISO 9001, and UL, which reflect their commitment to quality and safety. Opt for through hole assembly services providers who prioritize customer support, have extensive experience, and utilize advanced technology to ensure the best results for your projects.

Key Takeaways

Pick a through hole assembly partner with lots of experience. Make sure they have important certifications like ISO 9001 and IPC-A-610. This helps make sure you get good and reliable work.

Find companies that do careful testing and checks at every step. This helps find problems early. It also helps make strong products that last a long time.

Choose a company that talks with you quickly and clearly. Good customer support helps your project stay on track. It also helps stop mistakes from happening.

Key Criteria for Through Hole Assembly Services

Experience and Certifications

When you look for through hole assembly services, experience is very important. Companies with many years in pcb assembly do better work. They can handle hard projects without problems. Experts say you should pick a pcb assembly company with 15 to 20 years of experience. This much experience means your projects get good processes and strong technical skills.

Provider | Years of Experience |

|---|---|

Suntronic | 27 |

Jingfuyin Technology Co., Ltd. | 15 |

Estimated Average | 21 |

You also need to check for industry certifications. Certifications like ISO 9001, IPC-A-610, and UL show a company cares about quality and safety. These certifications mean the pcb assembly company follows strict rules and meets world standards. LTPCBA has ISO, IATF, and UL certifications. This shows they work hard to make high quality and reliable through-hole products.

Tip: Always check a company’s certifications and how long they have been in business before you start your project. This helps you stay away from bad partners and makes sure your pcb assembly services are what you want.

Quality Assurance in PCB Assembly

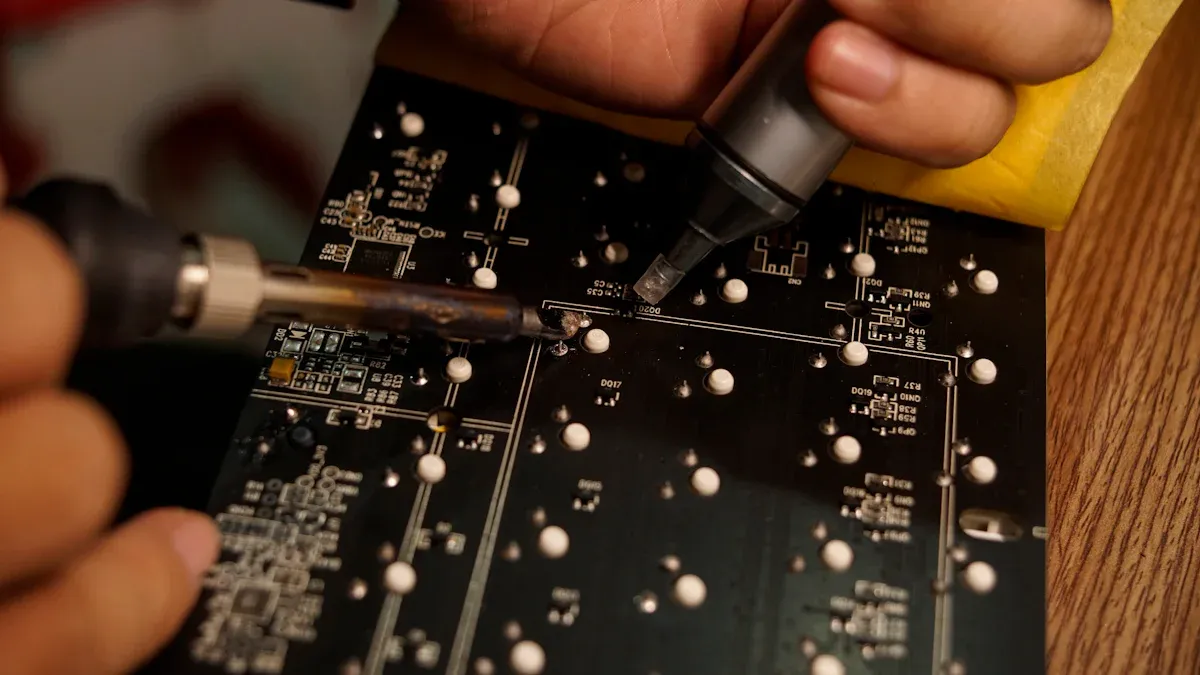

Quality assurance is very important for pcb assembly projects. You need a pcb assembly company that checks quality at every step of through-hole manufacturing. Good companies use in-circuit testing, flying probe tests, functional tests, AOI, and X-ray inspection. These tests help find problems early and keep quality high.

In-Circuit Testing (ICT): Finds open or short circuits and checks if parts work.

Flying Probe Test: Looks for loose connections and shorts without turning on the board.

Functional Test: Makes sure the pcb assembly works right.

AOI: Uses cameras to find missing or wrong parts and solder mistakes.

X-Ray Inspection: Looks inside for hidden problems.

LTPCBA has a 99.5% pass rate for product delivery because of its strong AOI and quality checks. The company follows IPC and ISO standards, so every assembly meets tough quality rules. When you ask about testing, find out the company’s defect rates and how they check for problems. Good pcb assembly services will share their quality data and explain their tests.

Customer Support and Communication

Good customer support makes your pcb assembly experience better. You want a pcb assembly company that answers questions fast, gives clear updates, and fixes problems quickly. The best companies answer customers in 24 hours and let you contact them by email, phone, or live chat.

LTPCBA gives 24-hour technical help and quick price quotes in 2-3 days. This good service keeps you updated during the assembly process. Clear communication helps you avoid mistakes and keeps your project moving. When you pick through hole assembly services, choose companies known for good customer support and clear communication.

Note: Look at online reviews and what other people say to see if a company has good customer support. Lots of good reviews mean the pcb assembly company is reliable.

Technology and Capabilities

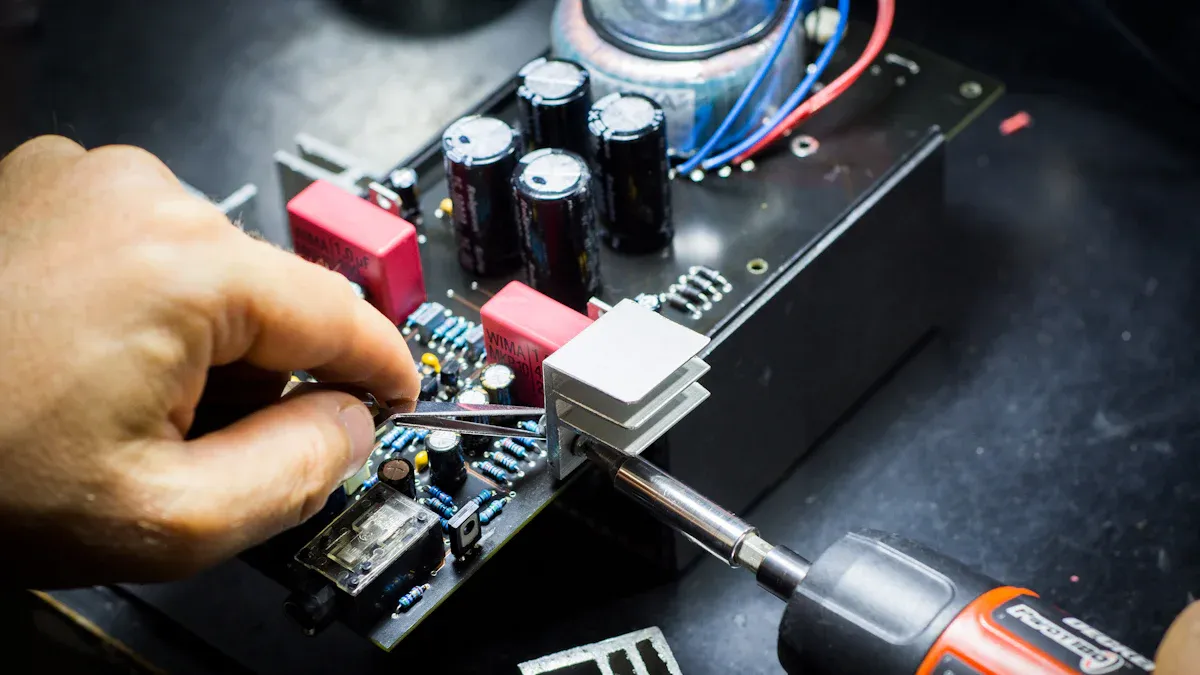

Modern through-hole manufacturing uses advanced technology and strong skills. You should check a company’s equipment, how much they use machines, and if they can do easy and hard assemblies. The best pcb assembly companies use automated insertion machines, wave soldering, selective soldering, and hybrid assembly. These tools help make pcb assembly services more accurate and faster.

LTPCBA uses the latest equipment and skilled workers to give full pcb assembly services. The company’s skills include SMT, BGA, and rigid flex pcb assembly. This makes them a good partner for many types of projects. When you check a pcb assembly company, look at their manufacturing skills and technical knowledge. Ask if they have done hard assemblies and how they check quality.

Automated insertion and soldering systems help make more boards and fewer mistakes.

AOI and X-ray inspection make sure assemblies have no defects.

Hybrid assembly uses both through-hole and surface-mount technologies for better results.

By looking at technical skills and manufacturing abilities, you make sure your pcb assembly project is high quality and reliable.

How to Choose a PCB Assembly Company

Evaluate PCB Assembly Services

Start by checking how much experience the pcb assembly company has. Companies with lots of years in business know how to do hard projects. They also make fewer mistakes. Ask how long the company has worked in this field. Find out about the leaders and their skills. This helps you see if the company is trustworthy.

Next, look at their certifications. Check for ISO 9001, IPC-A-610, and UL. These show the company follows strict rules for quality. Ask what tests they use. Good companies use automated optical inspection, in-circuit testing, and functional testing. These tests help find problems early and keep your boards working well.

Customer support is also important. Fast answers and helpful support make your project easier. Ask how fast they reply and if they have 24-hour help. LTPCBA gives quick quotes in 2-3 days and offers help all day and night.

Check what machines and tools the company uses. Advanced machines like automated insertion and soldering systems help make boards faster and better. Make sure the company can do both small and medium-sized jobs. See if they can handle SMT, through-hole, and mixed assembly. This means they can do many kinds of projects.

Tip: Ask for examples of past work. This lets you check their quality and see if they can do your job.

Key Criteria | |

|---|---|

Products | Quality control, industry specialization, cost transparency |

Capabilities | Certifications, equipment, technical expertise |

Service | Lead time reliability, communication, support |

Compare Quotes and Value

When you get quotes from pcb assembly companies, do not just look at price. Think about the whole offer. Quality, speed, and service matter too. The cheapest choice can cost more later if there are problems.

Read each quote carefully. See if testing, inspection, and extra services are included. These extras can save you time and money. Check how fast each company can finish your boards. Quick turn pcb assembly helps with tight deadlines, but speed should not lower quality.

See if the company can buy parts at good prices. Good buying saves money and avoids delays. Ask about discounts for bigger orders. LTPCBA gives clear prices and shows what you pay for.

Quality: Board material, part placement, and soldering accuracy.

Assembly expertise: Experience with SMT, through-hole, and hard designs.

Manufacturing capabilities: Modern machines and flexible production.

Turnaround time: Speed for both small and big orders.

Customer support: Fast, clear answers and technical help.

Extra services: Testing, programming, and DFM reviews.

Note: Value is a mix of price, quality, and service. Always check what is in the quote before you decide.

Check References and Reviews

Before picking a pcb assembly company, check their references and reviews. A good reputation means the company does quality work. Ask for names of past customers. Talk to them about their experience with the company’s work, support, and delivery.

Look for reviews that talk about quality, speed, and support. Good comments about quick turn pcb assembly and technical skills are a good sign. You can also ask for case studies or finished project examples. This helps you see if the company can do your job.

Check how the company controls quality. Ask about their checks, like visual checks, AOI, X-ray, and functional testing. Companies with strong quality steps and certifications usually do better work. LTPCBA has a 99.5% pass rate and many good reviews, showing they care about quality.

Red Flags to Avoid

Watch for warning signs when picking a pcb assembly company. Bad communication or slow replies can cause problems. If a company cannot explain their quality checks, this is a big problem.

Be careful if the company has no certifications or will not give references. Rushing or only looking at price can lead to bad results. Stay away from companies with unclear quotes or unclear project plans.

Common warning signs are:

Slow replies or bad communication

Not willing to help or answer questions

Long delays without good reasons

No certifications (ISO, IPC, UL)

No testing or inspection steps

No references or bad reviews

Unclear prices or hidden fees

Warning: If you see these problems, look for another company. Good companies like LTPCBA have clear prices, strong support, and proven skills.

If you follow these steps, you can pick a pcb assembly company that fits your needs. Always check quality, compare value, and look at the company’s reputation before you choose.

Picking a good through hole assembly partner takes time and care. You should look at how much experience they have. Check if they have the right certifications. Make sure they do strong testing and give quick help when needed.

Why It Matters | |

|---|---|

Experience | Helps make sure the assembly is always good |

Certifications | Shows they follow important quality rules |

Testing & Inspection | Makes sure the work lasts and works well |

Customer Support | Gives you answers and help when you need it |

If you want good results, reach out to LTPCBA for a quote or to talk.

FAQ

What should you look for when you choose a pcb assembly company?

Check if the company has industry certifications. Make sure they have good quality checks. See if their customer support is helpful and fast. Look at their technical skills too. These things help you know if the company does good work.

How do you evaluate quality in through hole assembly services?

Ask what tests the company uses, like AOI, X-ray, and functional tests. Find out how they check for mistakes. Look at what other people say about their work. This helps you know if they do a good job.

Why does turnaround time matter in pcb assembly services?

Turnaround time changes how fast your project gets done. Quick turn pcb assembly helps you finish on time. Fast service and good support make your experience better.

See Also

Selecting The Ideal Through-Hole PCB Assembly For Industrial Use

Finding The Most Reliable One-Stop PCB Assembly Provider

An In-Depth Overview Of Through-Hole PCB Assembly Processes

Evaluating Reliability Between Through-Hole And SMT PCB Assembly

Choosing Between SMT And Through-Hole For Your Electronics Build