When to choose lead-free solder paste in SMT assembly production

Lead-free solder paste is important in making modern electronics. It helps follow strict rules like the EU’s RoHS law. This law limits lead in electronics to 0.1%. Around 78% of lead-free solder is used in RoHS areas. This shows it is widely used. Lead-free materials also make recycling easier. They improve recovery by up to 15% during recycling.

Key Takeaways

Lead-free solder paste follows global rules like RoHS for safer devices.

It helps recycling by boosting recovery rates up to 15%.

LTPCBA offers expert help and tools for easy switching to lead-free paste.

The role of lead-free solder paste in SMT assembly

What is lead-free solder paste?

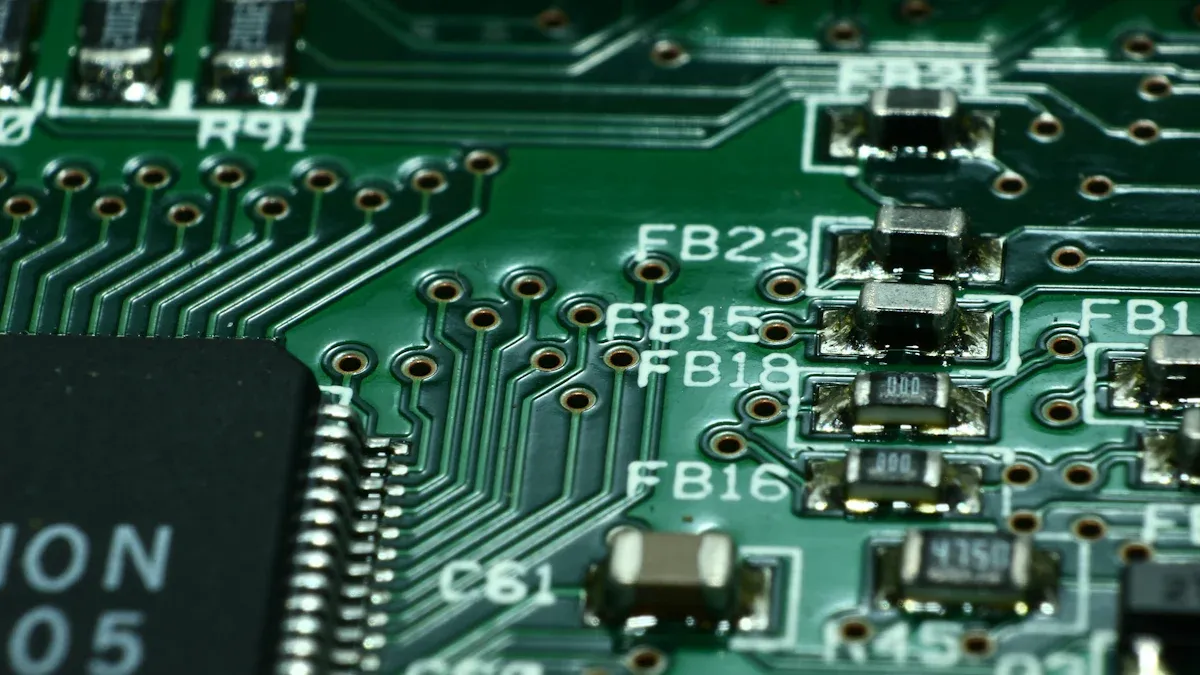

Lead-free solder paste connects electronic parts to PCBs in SMT assembly. Unlike older solder paste, it has no lead. This makes it safer for people and the planet. The most common type is SAC305. It is made of 96.5% tin, 3% silver, and 0.5% copper. SAC305 melts at a low temperature, between 217°C and 220°C, and sticks well.

Composition | Melting Temperature (℃) | Peak Reflow Temperature Range (℃) | Cost Level |

|---|---|---|---|

Sn/Ag/Cu (SAC305) | 217°C – 220°C | 240°C – 250°C | $ |

Since it has no lead, it meets global safety rules. This makes it a top choice for making modern electronics.

Why is lead-free solder paste critical for modern electronics?

Lead-free solder paste is very important in electronics today. It follows strict rules like RoHS, which limits harmful materials in products. Following these rules is key to selling in global markets, especially in the EU.

More people want safe and eco-friendly electronics, increasing the need for lead-free solder paste. It lowers the risk of lead exposure, especially in devices used daily. New technology has also made lead-free solder paste better and more reliable.

Market Drivers | Description |

|---|---|

Rules like RoHS require lead-free solder in electronics. | |

Environmental Concerns | People want eco-friendly electronics, boosting demand for lead-free solder. |

Consumer Safety | Reduces lead risks, keeping electronics safer for users. |

Technological Advancements | Research improves lead-free solder, making it work better. |

Using lead-free solder paste helps create safer, greener products. It also meets the needs of eco-conscious buyers.

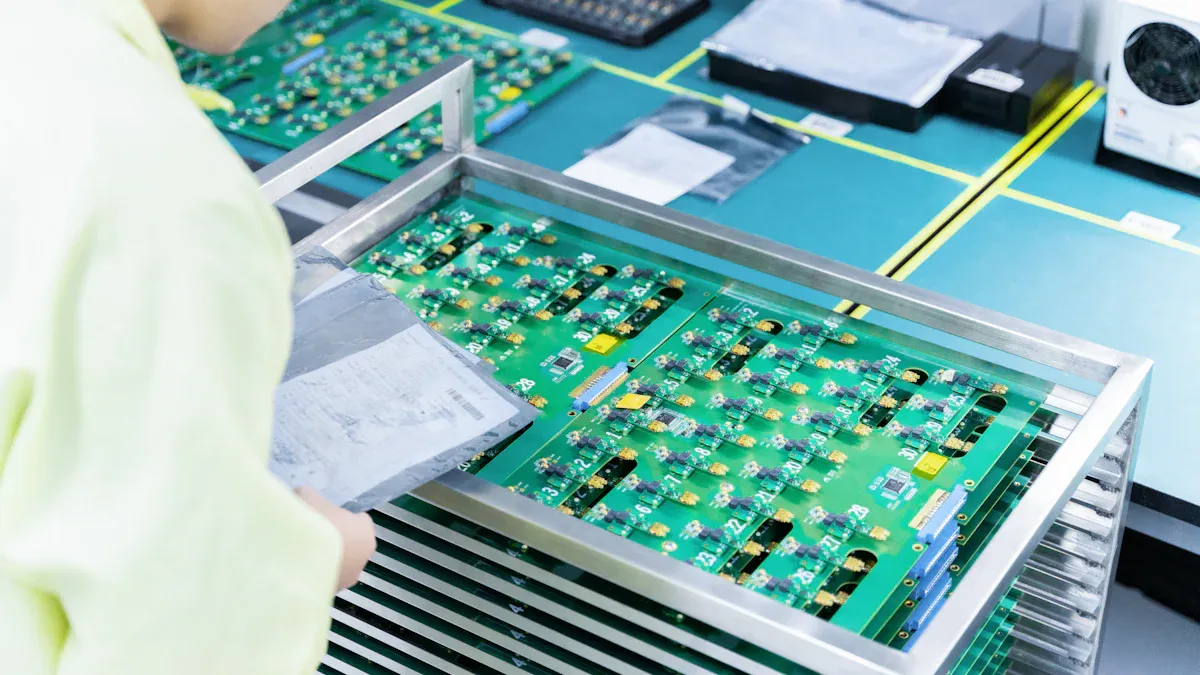

LTPCBA's approach to lead-free solder paste in SMT production

At LTPCBA, we focus on quality and new ideas in SMT assembly. We use advanced SAC305 solder paste for reliable and high-performing electronics. Our modern tools work perfectly with lead-free solder paste, ensuring top production quality.

We know switching to lead-free solder paste can be hard. That’s why we offer custom solutions to fit your needs. Whether you need special formulations or process help, our experts are ready to assist. With LTPCBA, you can easily switch to lead-free solder paste. This ensures you meet global rules and produce excellent products.

Tip: Work with LTPCBA to get expert help and the best tools. Switching to lead-free solder paste will be easy and effective.

Factors to consider when choosing lead-free solder paste

Regulatory compliance and environmental impact

When picking lead-free solder paste, follow environmental rules. Laws like the EU’s RoHS limit harmful materials like lead in electronics. Following these rules is key to selling worldwide and avoiding fines. Using lead-free solder paste also helps protect the environment.

Helpful tools can guide you in staying compliant:

Community Multiscale Air Quality Modeling System (CMAQ): Tracks air pollution levels.

FACT SHEET: Environmental Issues in Contracting: Explains why compliance matters.

Here’s a table of important regulatory resources:

Source | Description |

|---|---|

Unified Agenda of Regulatory Actions | Updates on rules, including EPA regulations. |

State Regulations | Links to state agencies for environmental compliance info. |

Combustion Portal | Tools for managing emissions in factories. |

By following these resources, your products can meet rules and help the planet.

Application-specific requirements and industry standards

Different industries need different solder paste features. For example, consumer electronics need fast production. Aerospace needs materials that are very strong and reliable. Knowing these needs helps you pick the best lead-free solder paste.

The table below shows industry needs:

Application Area | Description |

|---|---|

Consumer Electronics | Needs fast and reliable soldering for large production. |

Automotive | Electric cars need strong and high-performing solder paste. |

Aerospace | Needs solder paste that handles heat and pressure well. |

Industrial | Robots and machines need precise and eco-friendly soldering. |

To meet industry rules, use resources like data sheets and certifications. These give details about solder paste types and how they work. Examples include:

Choosing the right solder paste ensures your products work well and last long.

Cost and performance trade-offs

Balancing price and quality is important when choosing solder paste. High-quality solder paste costs more but works better and lasts longer. Small businesses often focus on keeping costs low. Bigger companies may pay more for better performance.

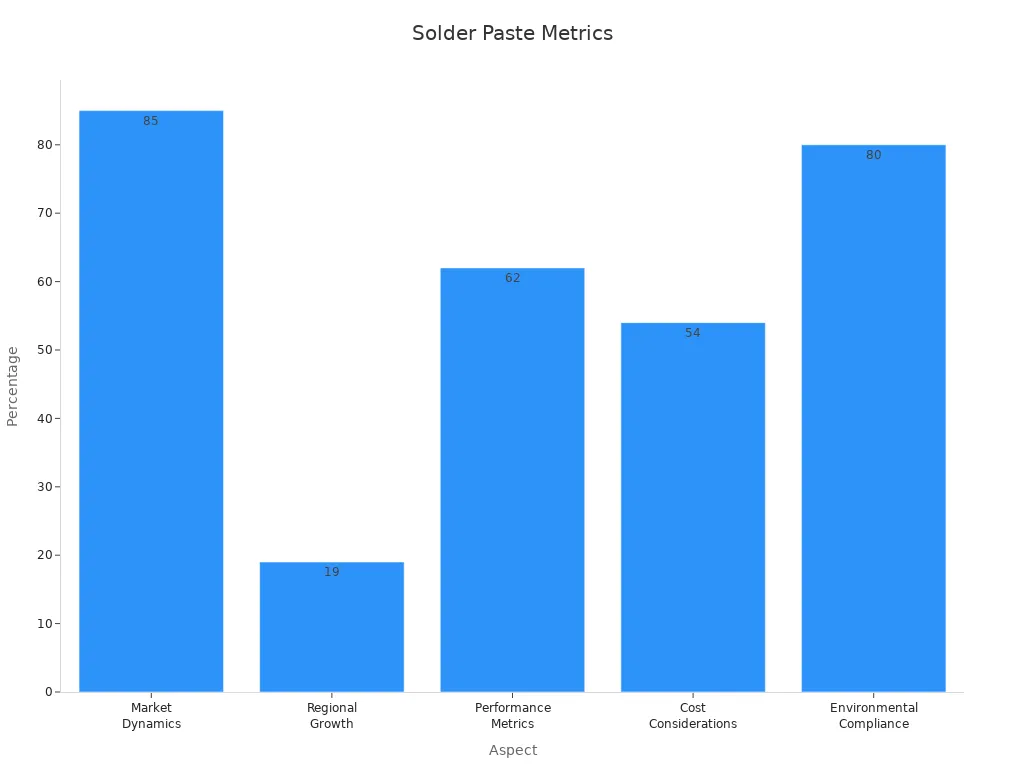

The chart below shows market trends and performance details:

Key points to think about:

Market Dynamics: Military and aerospace boost demand in North America.

Regional Growth: Brazil uses more high-temperature solder, up by 19%.

Performance Metrics: 62% of makers value thermal stability the most.

Cost Considerations: 54% of small businesses focus on low costs, while big companies pay more for quality.

By weighing these factors, you can choose solder paste that fits your budget and needs.

Lead-free vs. lead-based solder paste: A comparison

Key performance differences

Lead-free and lead-based solder paste have clear differences. Lead-based solder melts at a lower temperature, about 183°C. Lead-free solder needs more heat, melting around 217°C. This means lead-free solder uses more energy during production. Lead-based solder conducts electricity better, but lead-free solder has improved a lot.

Lead-free solder is safer and better for the environment. It removes the dangers of lead, protecting workers and users. It also follows global rules like RoHS, which are important for electronics and medical devices. Lead-based solder used to be cheaper, but lead-free options are now more affordable.

Melting Point: Lead-free solder needs higher heat to melt.

Health Impact: Lead-free solder is safe and non-toxic.

Cost: Lead-based solder was cheaper but is less popular now.

Practical challenges in transitioning to lead-free solder paste

Switching to lead-free solder paste can be tricky. You might need to change processes and upgrade tools for higher heat. Making sure parts work well with lead-free solder can also be hard. Quality checks must be updated to meet new rules.

Costs are another challenge. While production costs may not rise much, buying new tools can be expensive. Companies that don’t switch to lead-free solder could lose money in the future. Even with these challenges, the long-term benefits of safety and following rules are worth it.

Technical Adjustments: Higher heat and process changes are needed.

Economic Impact: New tools can cost a lot upfront.

Reliability Concerns: Keeping quality and performance steady is important.

How LTPCBA ensures seamless integration of lead-free solder paste

LTPCBA makes switching to lead-free solder easy. Our advanced tools handle the higher heat needed for lead-free soldering. This ensures your products are reliable and high-quality.

Our team helps you solve problems like process changes and part compatibility. We create custom solutions to fit your needs. With LTPCBA, you can switch to lead-free solder without losing quality. This keeps you competitive in the electronics market.

Tip: Work with LTPCBA to meet rules and get great results with lead-free solder paste.

Best practices for using lead-free solder paste

Equipment compatibility and process optimization

Lead-free solder paste needs tools that can handle more heat. Reflow ovens and soldering tools must work at higher temperatures. Components and board finishes should match the paste to avoid problems like weak joints or bad wetting.

To make your process better, focus on key areas. The paste should stick well to parts and boards when heated. Adjust your tools to keep performance steady. For example:

Solderability: Make sure the paste sticks to all surfaces.

Reliability: Test joints to see if they last under stress.

Compatibility: Check if your tools and materials work with the paste.

These steps help you get good results and avoid issues.

Storage and handling guidelines

Store lead-free solder paste in a cool place, between 0°C and 10°C. Refrigeration keeps it fresh for up to 6 months for no-clean paste and 3-6 months for water-soluble types. Before using, let the paste warm to room temperature (19°C-25°C). Avoid heat above 29°C, which can ruin its quality. Keep humidity between 40%-60% during use.

Aspect | Temperature Range (°C) | Notes |

|---|---|---|

Shipping | 0-29 | Paste is made to be shipped within this range. |

Long-term Storage | 0-10 | Refrigeration works best; shelf life depends on paste type. |

Room Temperature Storage | 19-25 | Use within 2 weeks; longer exposure lowers quality. |

Exposure to High Temperatures | >29 | Shortens the paste's useful life. |

Best Practices for Usage | 22-29 | Keep printer temperature steady; 40%-60% RH is ideal. |

Follow these rules to keep the paste working well and avoid defects.

Tips for achieving reliable results with LTPCBA's expertise

Getting good results with lead-free solder paste takes care and skill. LTPCBA suggests focusing on PCB support, squeegee settings, and stencil quality. For example, keep the PCB flat against the stencil to stop defects like bridging. Adjust squeegee speed, pressure, and angle for better paste transfer.

Key Factor | Description |

|---|---|

PCB Support | Keeps the PCB flat to avoid defects like bridging. |

Squeegee Parameters | Speed, pressure, and angle affect paste transfer quality. |

Stencil Characteristics | Thickness and cleanliness of the stencil matter for printing. |

Solder Paste Properties | Paste type and thickness impact printing and results. |

Working with LTPCBA gives you expert help and advanced tools. This ensures your production meets global rules and delivers top-quality products.

Lead-free solder paste has great benefits for modern SMT assembly. It follows global rules and helps protect the environment.

Main benefits include:

New ideas in production methods.

Evidence Type | Statistic/Impact |

|---|---|

Meets RoHS 3 rules | |

Fewer rework problems | 34% less rework reported by Class 3 certified makers. |

Working with LTPCBA ensures easy use and excellent outcomes.

FAQ

What are the benefits of using lead-free solder paste?

Lead-free solder paste follows global rules like RoHS. It is safer for people and better for the planet. This makes it great for making modern electronics.

Can lead-free solder paste work with all SMT equipment?

Some tools can't handle lead-free solder paste's higher heat. You might need to upgrade ovens or change settings for it to work well.

How does LTPCBA help with lead-free solder paste integration?

LTPCBA offers custom help, advanced tools, and expert advice. They make switching to lead-free solder easy while keeping quality high and following rules.

See Also

Impact of Solder Paste Quality on PCB SMT Soldering

Essential Tips for Controlling Solder Paste Screen Printing Quality

Choosing the Right Materials for PCB SMT Assembly