How to Select the Right Industrial PCBA Prototyping Partner for Your Business

Selecting the right partner for industrial pcba prototyping is crucial to your product’s success. You need a provider who offers rapid turnaround, exceptional support, and unwavering commitment to quality standards. LTPCBA leads the way in industrial pcba prototyping with industry-defining benchmarks:

Benchmark Type | What to Look For |

|---|---|

Turnaround Times | Fast industrial pcba prototyping delivery |

Pricing Models | Transparent, flexible pricing |

Support Quality | Responsive customer service |

Certifications | ISO, IATF, UL, RoHS compliance |

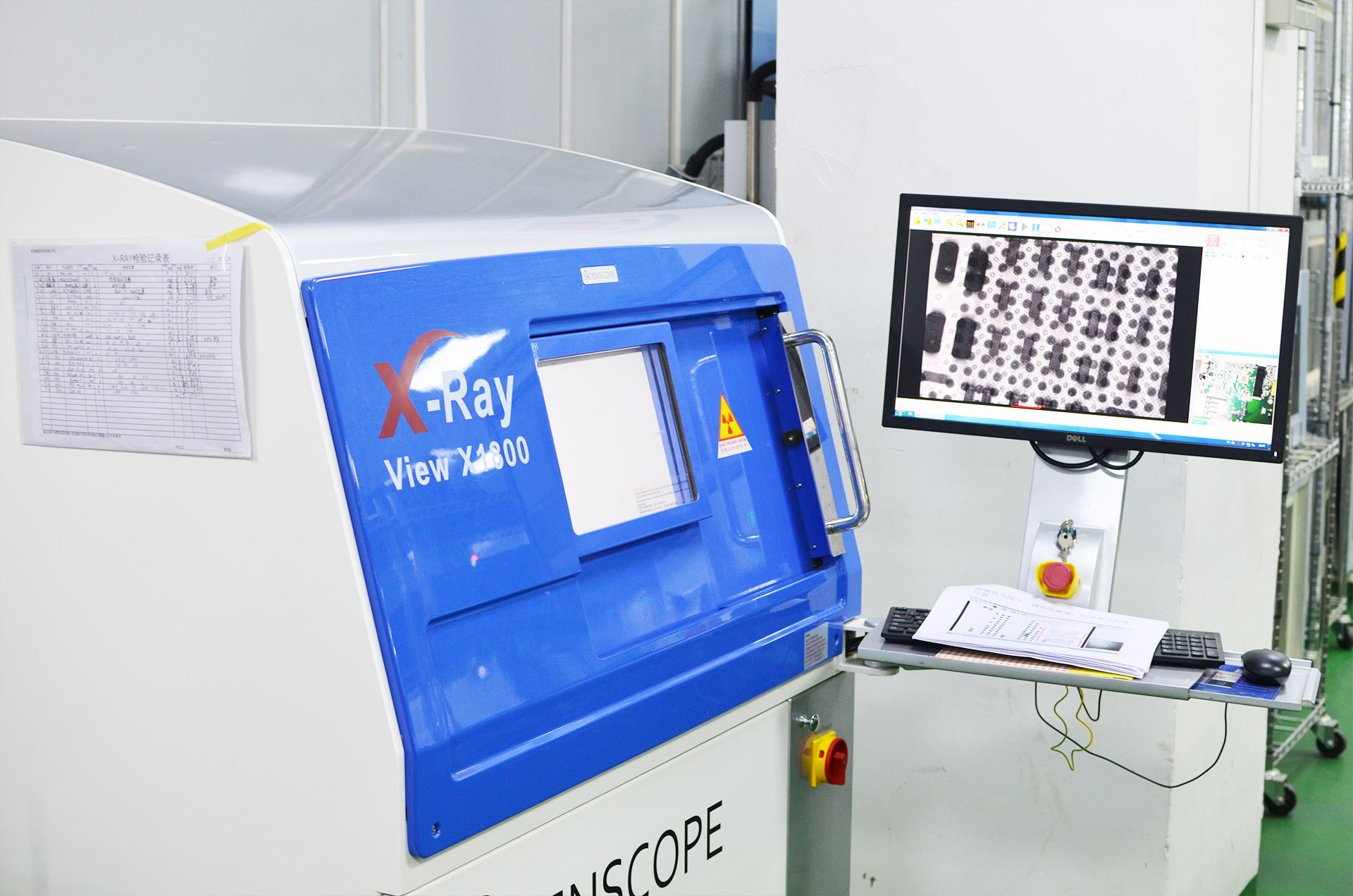

Quality Assurance | AOI and X-ray inspections |

Before making your choice, clearly define your project needs and goals for industrial pcba prototyping.

Key Takeaways

Define your project needs clearly to find the right PCBA prototyping partner. This helps avoid costly mistakes and ensures the provider can meet your specific requirements.

Look for a partner with strong quality assurance processes. Certifications like ISO and IATF indicate a commitment to high standards and reliability in manufacturing.

Choose a provider that offers transparent pricing and excellent customer support. This ensures you understand costs upfront and have assistance throughout the prototyping process.

Define Needs for Industrial PCBA Prototyping

Before you select a partner for industrial pcba prototyping, you need to define your project’s unique requirements. This step ensures you find a provider who can deliver the right solutions for your business and help you avoid costly mistakes later.

Project Requirements

Start by outlining the core goals and constraints of your project. You should:

Define project goals. Clarify what you want to achieve with your prototype. This sets the direction for your design and manufacturing process.

Understand operational constraints. Consider the environment where your product will operate. Factors like temperature, humidity, and vibration can affect material and component choices.

Address market and regulatory needs. Identify any certifications or standards your product must meet. Planning for compliance from the start saves time and resources.

Tip: Leading providers like LTPCBA help you navigate these requirements by offering guidance on certifications and regulatory standards.

When you consider production volume, you should know that industrial pcba prototyping providers handle a wide range of batch sizes:

Low-volume runs (under 1,000 units) work well for prototypes and specialized products.

High-volume runs (10,000 units or more) suit products ready for mass production.

Choosing a partner with flexible capacity, such as LTPCBA, ensures your project can scale as your business grows.

Technical Capabilities

You need a provider with the right technical capabilities to support your industrial pcba prototyping. The best partners offer a broad range of assembly services and advanced testing options. Here’s a comparison of essential capabilities:

Capability Type | Description |

|---|---|

Assembly Services | SMT, through-hole, BGA, lead-free, and hybrid assembly options. |

Testing Options | Flying probe, ICT, AOI, and other rigorous quality assurance protocols. |

Expert recommendations to improve design for manufacturability and reduce costs. | |

Flexibility in Prototyping | Ability to handle both basic and advanced prototypes for diverse project needs. |

Providers like LTPCBA stand out by offering custom circuit board design, robust supply capacity, and ISO certification. Their advanced technology supports complex assembly, including rigid-flex and multilayer PCBs. This ensures your prototypes match the quality and performance of your final product.

Note: Top industrial pcba prototyping companies use automation and Industry 4.0 integration to boost efficiency and accuracy. LTPCBA’s automated systems and rapid response times set a high standard in the industry.

Experience with Prototyping Services

Experience matters in industrial pcba prototyping. You want a partner who understands the challenges of component sourcing, design for manufacturability, and quality control. Providers like LTPCBA use strong vendor networks to secure components quickly and offer expert feedback to optimize your designs.

Common challenges in industrial pcba prototyping include:

Sourcing hard-to-find components

Managing thermal issues

Ensuring smooth production transitions

A reliable partner addresses these with advanced testing, careful planning, and flexible manufacturing solutions. LTPCBA’s experience with both small and large projects means you get support at every stage, from initial prototype to full-scale production.

Industry Trend: The demand for miniaturized electronics, IoT devices, and eco-friendly manufacturing is rising. LTPCBA keeps pace with these trends by investing in new technologies and sustainable practices.

When you define your needs clearly, you set the stage for a successful partnership in industrial pcba prototyping. Use LTPCBA’s comprehensive service offerings and advanced capabilities as a benchmark when evaluating potential providers.

Evaluate Quality and Reliability in PCBA Prototyping

When you select a partner for pcba prototyping, you need to focus on quality and reliability. These factors determine if your prototypes meet your expectations and perform well in real-world conditions. A reliable pcba prototyping manufacturer uses advanced technology, strict quality assurance, and proven reliability metrics to deliver consistent results. Let’s break down what you should look for.

Quality Assurance

Quality assurance is the backbone of any successful pcba prototyping project. You want your prototypes to match your design and function as intended. Reliable pcb prototype manufacturers use a series of checks and controls to guarantee prototype quality and accuracy.

Here are some standard quality assurance processes you should expect:

First Article Approval: The manufacturer inspects the first unit to confirm the process is set up correctly.

Precision Calibration Inspection: Each unit receives careful calibration checks to prevent defects.

Employee Training and Certification: Skilled workers follow industry standards for every step.

You should also look for these quality assurance steps in pcb assembly services:

Quality Assurance Process | Description |

|---|---|

Design for Manufacturing (DFM) Reviews | Identifies potential manufacturing challenges early in the design phase. |

Material Selection and Sourcing | Ensures high-quality substrates and components for durability. |

Manufacturing Process Control | Uses standardized procedures and automated systems for consistency. |

Final Inspection and Testing | Verifies functionality and finds defects before shipping. |

Automated Optical Inspection (AOI) | Scans PCBs for surface defects with high-resolution cameras. |

X-ray Inspection | Detects hidden defects in multilayer PCBs. |

In-Circuit Testing (ICT) | Checks electrical performance at test points. |

Functional Testing | Simulates real-world conditions to validate performance. |

Environmental Stress Testing | Tests durability under extreme conditions. |

Confirms compliance with safety and regulatory requirements. |

LTPCBA stands out as a reliable pcba prototyping manufacturer because they use advanced technology and automated systems for every stage of prototype circuit board manufacturing. Their quality assurance includes AOI, X-ray inspection, and functional testing. LTPCBA’s team receives regular training, so you can trust their expertise in pcb assembly services.

Certifications and Standards

Certifications show that a manufacturer meets global standards for quality and safety. When you choose a reliable pcb prototype manufacturer, check for these certifications:

ISO 9001:2015 for quality management systems

IATF 16949 for automotive industry standards

RoHS and REACH for environmental compliance

UL for safety and flammability

Certification |

|---|

ISO 9001:2015 |

IATF 16949 |

RoHS |

REACH |

UL |

LTPCBA holds ISO, IATF, and UL certifications. This means you get pcba prototyping that meets strict international standards. Their commitment to quality assurance and advanced technology ensures your prototype circuit board design meets all regulatory requirements.

You should also look for industry-specific standards like IPC-A-600 and IPC-6012. These guide defect tolerances and performance for rigid PCBs. LTPCBA follows these standards, which adds another layer of confidence in their pcb assembly services.

Reliable PCBA Prototyping Manufacturer

Reliability is more than just delivering on time. It means your prototypes work as expected and meet your project goals. You can measure reliability using several metrics:

Metric | Description |

|---|---|

First Pass Yield (FPY) | Percentage of products passing testing on the first attempt. |

Defect Rate | Percentage of products that fail; lower is better. |

Return Rate | Percentage of products returned by customers. |

Failure Rate | Frequency of product problems in use. |

Reliability Metrics | Includes MTBF (Mean Time Between Failures) and MTTR (Mean Time To Repair). |

Cost of Quality (COQ) | Measures costs related to quality, including prevention and failure costs. |

Process Capability Index | Measures stability and consistency of the manufacturing process. |

On-Time Delivery (OTD) is crucial for evaluating reliability.

Consistent OTD performance shows a manufacturer’s dependability.

Reliable suppliers meet delivery schedules every time.

LTPCBA has achieved a 99.5% pass rate for pcba prototyping. This high pass rate proves their commitment to quality and reliability. Their advanced technology and strict process controls help them maintain low defect rates and high first pass yields. As a reliable pcb prototype manufacturer, LTPCBA also provides fast turnaround and consistent on-time delivery.

Customer testimonials and case studies often highlight the value of consulting with a reliable pcba prototyping manufacturer early in the design process. This helps you avoid costly mistakes and ensures your prototype circuit board design meets all requirements. LTPCBA’s support team works with you from the start, guiding you through every step of circuit board manufacturing.

When you evaluate pcba prototyping partners, always check for quality assurance, certifications, and proven reliability. LTPCBA sets a high standard as a reliable pcb prototype manufacturer, making them a strong choice for your next project.

Assess Cost, Support, and Flexibility

When you select a partner for pcba prototyping services, you need to look at more than just technical skills. Cost, support, and flexibility are key factors to consider. These elements help you find the best pcb manufacturer for your needs and ensure you receive high-quality output every time.

Pricing Structure

You should always look for transparent pricing when choosing pcba prototyping services. Transparent pricing models give you clear cost estimates before you commit. This helps you plan your budget and avoid hidden fees. Many providers, including LTPCBA, offer no minimum order requirements, making their prototyping services accessible to both startups and established companies.

Common pricing factors include:

Materials: FR-4 is the most cost-effective, while Rogers and Polyimide offer specialized features.

Surface Finishes: Lead-free HASL, Immersion Silver, and ENIG each have different costs and benefits.

Production Quantity: Low-volume orders cost more per unit than high-volume runs.

LTPCBA’s fast quotations and clear pricing make them a top choice for businesses seeking customized solutions and fully tailored pcb solutions.

Customer Support

Strong customer support is one of the key factors to consider when evaluating pcba prototyping services. You want a provider who offers 24/7 technical support and personalized service. LTPCBA stands out as the best pcb manufacturer because their engineering staff guide you through every step of the process. Their team answers questions quickly and helps you with customization and design changes. This level of customer support builds trust and improves your experience.

Great customer support means you always have help when you need it, from the first quote to the final delivery.

Turnaround and Flexibility

Fast turnaround and flexibility in prototyping options are essential for meeting tight deadlines. The average turnaround time for standard double-layer pcba projects is 5 to 7 business days. More complex pcba assemblies may take 8 to 15 business days. LTPCBA offers quick response times and can handle urgent or custom orders with ease.

Feature | Description |

|---|---|

Quick Turnaround Time | Reduces go-to-market time and boosts your competitive edge. |

On-Demand Services | No minimum order, so you can request custom pcba without volume limits. |

Flexible PCB Turnkey | Full turnkey services, including part sourcing and assembly. |

LTPCBA’s customization capabilities and reputation and client feedback show their commitment to superior product quality and high-quality output. Their flexibility in prototyping options ensures you get the best pcb manufacturer for your project.

You can select the best custom pcba manufacturer by following these steps:

Define your pcb project needs.

Research each provider’s reputation and service.

Compare technology, turnaround, and price.

Check quality assurance and support.

Description | |

|---|---|

Quality Assurance | Providers with certifications ensure reliable pcb service. |

Technology | Advanced pcb tools improve accuracy. |

Turnaround | Fast service helps meet deadlines. |

Reach out to a provider like LTPCBA for a quote or more information.

FAQ

What certifications should you look for in a PCBA prototyping partner?

You should check for ISO, IATF, and UL certifications. These show the provider meets international quality and safety standards.

How fast can you expect a PCBA prototype from LTPCBA?

LTPCBA delivers most prototypes within 5 to 7 business days. You can request urgent orders for even faster turnaround.

What support does LTPCBA offer during the prototyping process?

You get 24-hour technical support and fast quotations. The team helps you with design changes and answers your questions quickly.

See Also

Tips for Choosing the Ideal Turnkey PCBA Manufacturer

Finding the Perfect PCBA Supplier for Your Requirements

Selecting the Best Through Hole PCB Assembly Service

Identifying the Top One-Stop PCB Assembly Provider

Ensuring Quality Production Through Advanced Turnkey PCBA Factories