How to Find the Ideal Custom PCBA Partner for Your Next Project

Choosing the right custom pcba partner is essential for the success of your project. You need a custom pcba manufacturer who meets your technical requirements and consistently delivers high-quality products with excellent support. Many companies face challenges such as unclear lead times, inconsistent quality, or communication issues with their custom pcba suppliers.

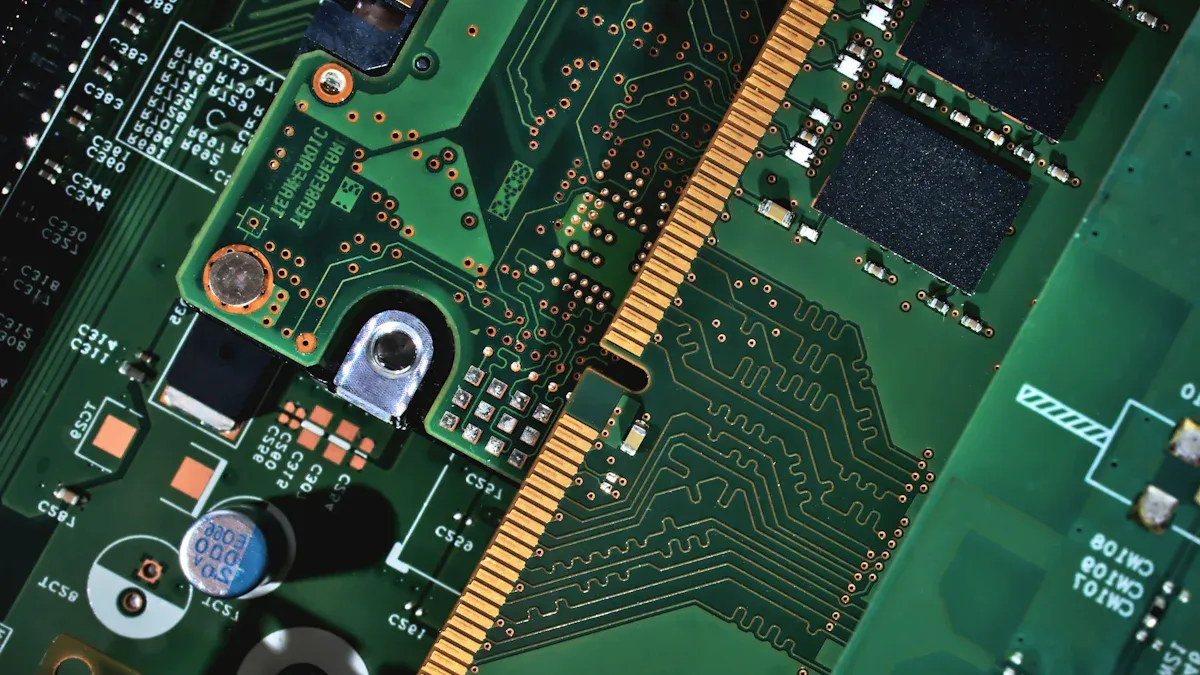

Look for a custom pcba manufacturer that owns advanced equipment, utilizes automated assembly processes, and implements rigorous quality control measures.

Verify their certifications and choose custom pcba providers who respond quickly and thoroughly test every product.

By prioritizing quality, reliability, and value from the start, you can avoid costly mistakes and ensure your custom pcba project is successful.

Key Takeaways

Make sure you understand your project needs before picking a PCBA partner. This includes knowing the technical specs, how many you need, your timeline, and your budget. This helps you avoid delays and extra costs.

Pick a manufacturer that has advanced equipment and strong quality control. They should also have the right certifications. This will help you get high-quality and reliable PCBA products.

Find a partner who communicates well and gives fast support. They should have clear pricing and a good reputation. This will help your project go smoothly and be successful.

Project Requirements

Technical Specs

Before you talk to any manufacturer, know what your project needs. Make a list of all the parts you need. Write down part numbers and other options. Give datasheets for any special parts. Say what size and type of printed circuit board you want. List how many layers, what material, thickness, copper weight, and surface finish you need. If your design needs high-speed, RF, or flexible pcb materials, say so.

Write down design rules like smallest trace width, spacing, drill sizes, and if you need impedance control.

Tell them if your circuits need special signal or power integrity.

Say which standards you must follow, like IPC, UL, or RoHS.

List what tests you need, like in-circuit testing and where test points go.

Give instructions for making the board, like the outline, slot sizes, and soldermask color.

If you need it, share how you want arrays or panels and where to put fiducials.

Give a technical contact so questions get answered fast.

The right pcb manufacturer depends on these details. If you need many layers or special materials, pick a manufacturer with strong skills and experience.

Volume and Timeline

Decide how many boards you need and when you need them. Prototypes are made faster than big orders.

Prototypes: 5-10 days

Low volume: 10-20 days

High volume: 4+ weeks

Quick-turn services can make simple boards fast. Big or tricky orders take longer. Match your order and build time to your project schedule so you do not fall behind.

Budget

Set your budget early. Planning your budget helps you balance speed, quality, and cost. If you work with your pcb assembly company from the start, you can plan better. This helps you avoid paying extra for rush jobs and makes sure you get your boards on time. A clear budget also helps with testing and quality checks, so you do not waste money fixing mistakes. Knowing your budget helps you pick the right materials, labor, and standards. This makes your project more likely to succeed.

Custom PCBA Manufacturer Evaluation

Capabilities and Technology

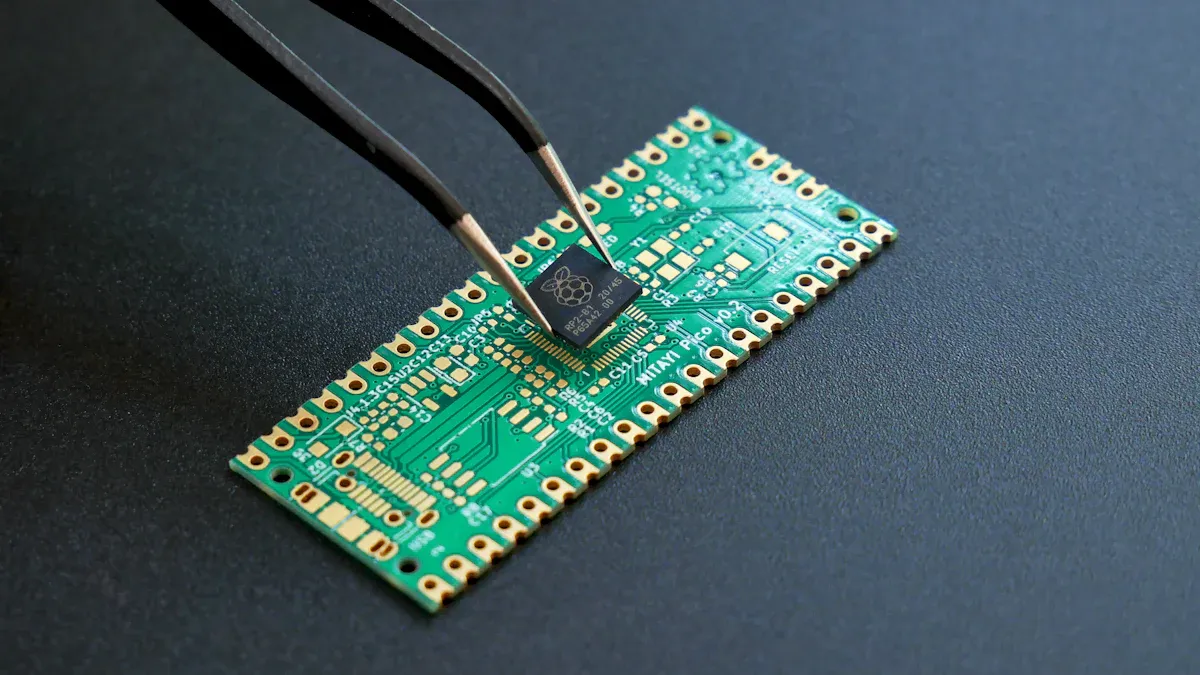

When picking a custom pcba partner, check what they can do. The right pcb manufacturer should have good machines and use automation. Modern pcb assembly companies use special machines. These include pick-and-place systems, reflow soldering, and automated optical inspection. These tools help them make hard pcb types fast and well. They can build rigid-flex, BGA, and SMT boards with high quality.

Here are some advanced technologies to look for in a pcb manufacturer:

Rigid, flex, and rigid-flex pcb assembly (1-22 layers)

RF and high-speed digital design support

Signal and power integrity design

Quick-turn manufacturing for fast delivery

Custom materials and advanced pcb fabrication

Automation Equipment Type | Impact on Quality and Complexity of PCBA Production | Benefits Related to Quality and Complexity |

|---|---|---|

Pick-and-Place Machines | Precise placement of components, supports complex board designs | Faster production, fewer errors, supports high-volume assembly |

Soldering Systems (Reflow, Wave) | Reliable connections, essential for SMT and mixed boards | Better solder joints, fewer defects, handles complex assemblies |

Automated Optical Inspection (AOI) | Detects defects quickly and accurately | Maintains high quality, reduces manual checks, catches problems |

Automated In-Circuit Testers (ICT) | Tests electrical function and connection integrity | Ensures performance, reduces faulty products, boosts reliability |

A good pcb assembly company buys these machines to get better results. Always check if your manufacturer can handle your pcb’s needs.

Quality and Certifications

Quality is very important in pcb assembly. You need a manufacturer who follows strict steps and has the right certifications. Look for pcb assembly manufacturers with ISO 9001, IATF, and UL certifications. These show the company meets world rules for quality and safety.

ISO 9001: Makes sure the manufacturer has a strong quality system.

IATF: Focuses on car industry standards.

UL: Proves the pcb meets safety and flammability rules.

Certifications help you check quality and lower risks. They also show the pcb manufacturer wants to improve and keep customers happy. Ask about their testing methods, like AOI, X-ray inspection, and functional testing. These steps find problems early and keep your pcb assembly process working well.

Tip: Always ask for proof of certifications and details about their quality steps. This helps you avoid problems and makes sure your project meets industry rules.

Reliable PCB Manufacturer: LTPCBA

LTPCBA is a reliable pcb manufacturer with strong skills and a focus on quality. LTPCBA is in Shenzhen and uses automated SMT, BGA, and rigid-flex assembly systems. They can handle hard pcb projects. The company follows strict quality steps, using AOI, X-ray inspection, and functional testing. This makes sure every pcb meets high standards.

Technology/Certification | Description | Impact on Differentiation |

|---|---|---|

SMT, BGA, Rigid-Flex Assembly | Automated systems for complex pcb assembly | High precision and flexibility |

AOI & X-ray Inspection | Multiple inspection technologies | Fewer defects, faster delivery |

IPC-6012, IPC-610D Standards | Global pcb manufacturing standards | Reliable and accepted worldwide |

ISO, IATF, UL Certifications | Quality, safety, and compliance | Reduces risk, builds trust |

ERP and MES Systems | Advanced planning and control | Flexible and scalable production |

Quality Assurance Process | Strict checks from start to finish | Consistent high quality and traceability |

LTPCBA gives turnkey pcb assembly services, from design review to shipping. You get fast quotes, 24-hour technical support, and clear order tracking. The company’s 99.5% pass rate shows its promise to high quality and reliability.

Communication and Support

Good communication and support make pcb assembly companies stand out. You need a manufacturer who listens, answers fast, and keeps you updated. LTPCBA gives one-to-one feedback, ERP-based order tracking, and expert engineering support.

Early teamwork helps fix design and manufacturing problems.

Account managers guide you from prototype to production.

Regular updates and clear messages stop confusion.

Ask about customer support before you start. A good pcb manufacturer will help with design, testing, and fixing problems. Watch for slow replies or unclear answers. Good support means fewer delays and better results.

Pricing and Value

Price matters, but value is more than just being cheap. A good pcb manufacturer gives clear prices, easy quotes, and no hidden fees. LTPCBA gives free instant quotes and flexible solutions for your budget and time.

When you compare pcb assembly companies, look at:

Prices for prototypes and big orders

Included services (testing, inspection, support)

Delivery times and on-time record

Cost and quality balance

Note: Watch for unclear prices, hidden fees, or bad communication about costs. Ask about customer support and make sure you know what is included.

A good pcb assembly company helps you plan, avoid extra costs, and get great results.

Reputation and References

Reputation is important when picking a custom pcba partner. Check reviews, references, and case studies to see how the manufacturer does. Look for feedback on quality, reliability, communication, and support.

Criteria | Explanation |

|---|---|

Can the manufacturer handle your pcb’s complexity and requirements? | |

Technology and Equipment | Do they use advanced machines and keep up with new trends? |

Turnaround Time | How fast can they deliver prototypes and production runs? |

Prototyping Service | Do they offer prototyping to test your design? |

Cost-Quality Balance | Is the price fair for the quality you get? |

Communication and Support | Do they provide strong support and clear updates? |

Reputation and Reviews | What do other customers say about their experience? |

Environmental and Ethical | Do they follow eco-friendly and ethical practices? |

Flexibility and Customization | Can they adjust to your project’s needs and order sizes? |

Project-Specific Needs | Do they understand your unique requirements? |

Research and Industry Updates | Do they stay current with industry changes and feedback? |

Customer stories and case studies show real results. They help you check quality, reliability, and how the manufacturer solves problems. Good reviews build trust and lower risks. Always watch for bad feedback, like missed deadlines or poor support.

To pick the best custom PCBA partner, do these things: First, see if they have lots of experience and a good name. Next, look at their machines, certifications, and how they test things. Then, check if they give good help, can change plans, and have fair prices. Always look out for warning signs.

Why Pick LTPCBA? | What You Get |

|---|---|

Happy customers | Boards arrive on time |

New technology | Great quality every time |

Quick help | Projects go easy and smooth |

FAQ

What should you look for in a reliable pcb manufacturer?

Check if they have good skills and knowledge. Make sure they test for quality and have a good name. Look at how well they test, what they can do, and how they help customers. Watch out for warning signs during the pcb assembly process.

Tip: Always ask about how they help customers and if they can make changes for you.

How does pricing affect the cost of pcb assembly?

The price changes based on how many you need. It also depends on how hard the pcb is to make and what tests are needed. Turnkey pcb assembly services can give you better value and good quality for your printed circuit board project.

Why is quality testing important in pcb assembly?

Quality testing makes sure things work well and last long. It helps you find problems early in the pcb assembly process. This step keeps your money safe and helps your project turn out better.

See Also

Tips For Choosing A PCBA Supplier That Fits Requirements

Finding The Ideal Turnkey PCBA Manufacturer For Electronics

Selecting The Top One-Stop PCB Assembly Provider Options

Ways Modern Turnkey PCBA Plants Guarantee High Quality

Improving Business Efficiency Through PCBA Contract Manufacturing