Five Cutting-Edge Trends Transforming Ceramic PCB Assembly

In 2025, five major trends are set to transform ceramic pcb assembly. The ceramic pcb assembly market is experiencing rapid growth, fueled by advancements in 5G infrastructure and innovative ceramic materials. The table below illustrates the market’s expansion:

Year | Market Size (USD Billion) | Projected Growth Rate (CAGR) |

|---|---|---|

2024 | ||

2025 | 1.84 | |

2034 | 5.75 | 13.5% |

The rise of 5G technology is driving increased demand for ceramic pcb assembly, as new ceramic materials and advanced designs deliver superior speed and reliability. Staying informed about these developments is essential for anyone involved in ceramic pcb engineering. LTPCBA is at the forefront of the industry, offering state-of-the-art ceramic pcb assembly solutions that utilize advanced ceramic substrates for high-performance applications. The following table outlines the top trends shaping the future of ceramics and ceramic pcb assembly:

Trend | Description | Expected Impact | Key Technologies Involved |

|---|---|---|---|

Miniaturization | Smaller, lighter pcb components for compact devices. | Enhanced efficiency in electronics. | Microfabrication, Advanced Materials. |

High Thermal Conductivity | Superior heat dissipation for power electronics. | Increased device longevity and reliability. | Ceramic Substrates, Thermal Management. |

Integration with IoT | Ceramic pcb assembly for smart devices. | Improved connectivity and data handling. | Wireless, Sensors, Embedded Systems. |

Eco-Friendly Manufacturing | Sustainable ceramics and processes. | Reduced environmental footprint. | Recyclable Materials, Green Techniques. |

Flexible PCB Technologies | Flexible ceramic pcb assembly for emerging applications. | Expanded possibilities for wearables and automotive electronics. | Flexible Substrates, Advanced Printing. |

This overview provides valuable insights into ceramics and ceramic pcb assembly, helping engineers and technology enthusiasts stay ahead of industry trends.

Key Takeaways

Miniaturization is crucial for modern electronics. Smaller components enhance efficiency and allow for innovative designs in compact devices.

Advanced materials like wide-bandgap semiconductors improve thermal management and performance in high-frequency applications.

Automation through AI and robotics increases precision in ceramic PCB assembly, reducing errors and improving production efficiency.

Sustainability is a growing focus. Using eco-friendly materials and energy-efficient processes helps reduce the environmental impact of ceramic PCBs.

Flexible and rigid-flex ceramic PCBs offer design adaptability, making them ideal for applications in wearables, automotive, and aerospace industries.

Ceramic PCB Assembly Trends 2025

Miniaturization Impact

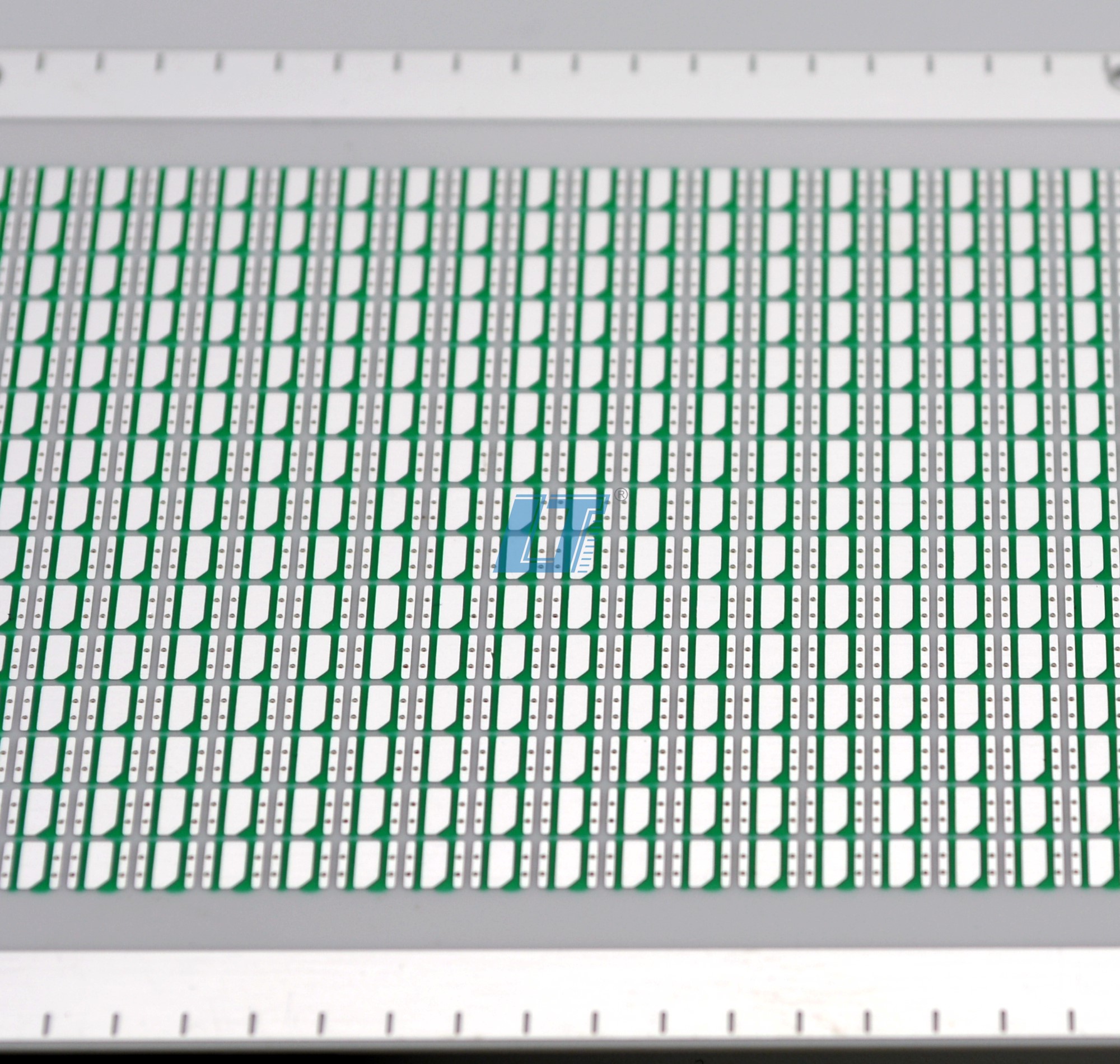

You see miniaturization shaping the ceramic pcb market in powerful ways. As devices get smaller, you need ceramic pcb solutions that fit into tighter spaces without losing performance. Miniaturization trends push manufacturers to stack ceramic components, which has become the most cost-effective approach for the next decade. This shift changes how you design and assemble products.

The ceramic pcb market now demands smaller passive components, which improves product performance and assembly speed.

Technologies like 5G and the Internet of Things drive the need for miniaturization and advanced packaging, so you must rethink your design strategies.

Miniaturization in ceramic pcbs leads to lighter, more efficient electronics, which helps you create innovative products for new markets.

LTPCBA supports your goals by using advanced ceramic pcb assembly techniques. You benefit from their expertise in handling micro-sized components and delivering reliable results.

High-Density Interconnects

High-density interconnects (HDI) bring enhanced integration and functionality to ceramic pcbs. You can now design intricate circuitry and dense interconnections, which are essential for modern electronics. HDI supports miniaturization at both the semiconductor and pcb levels, so your devices become more compact and powerful.

HDI technology lets you create multilayer ceramic pcb assemblies, connecting advanced semiconductor packaging like 2.5-D and 3-D.

You achieve better performance and reliability in applications such as mobile devices, medical equipment, and automotive electronics.

Here’s how LTPCBA’s advanced assembly capabilities help you stay ahead in the ceramic pcb market:

Feature | Description |

|---|---|

Micro Via Technology | Hides wiring between layers, increasing circuit density and allowing small components. |

Improved Electrical Performance | Reduces signal reflection and cross-talk, giving you more accurate signals and less noise. |

Higher Reliability | Micro-holes boost signal transmission reliability compared to traditional through-holes. |

Enhanced Thermal Properties | Higher glass transition temperature (Tg) improves thermal management in ceramic pcbs. |

Applications | Used in mobile, medical, and automotive electronics where miniaturization and HDI are vital. |

You can trust LTPCBA to deliver ceramic pcb solutions that match the latest trends in miniaturization and high-density interconnects. Their focus on innovation ensures your products meet the demands of the evolving ceramic pcb market.

Advanced Materials in Ceramic PCB Market

You see advanced materials changing the way ceramic pcb technology works. These new ceramics help you achieve high-frequency performance and superior reliability in your designs. The demand for ceramic printed circuit boards keeps growing, especially as you look for solutions that handle high-frequency and high-performance needs. You need ceramic pcb assemblies that stay durable and efficient, even in tough environments.

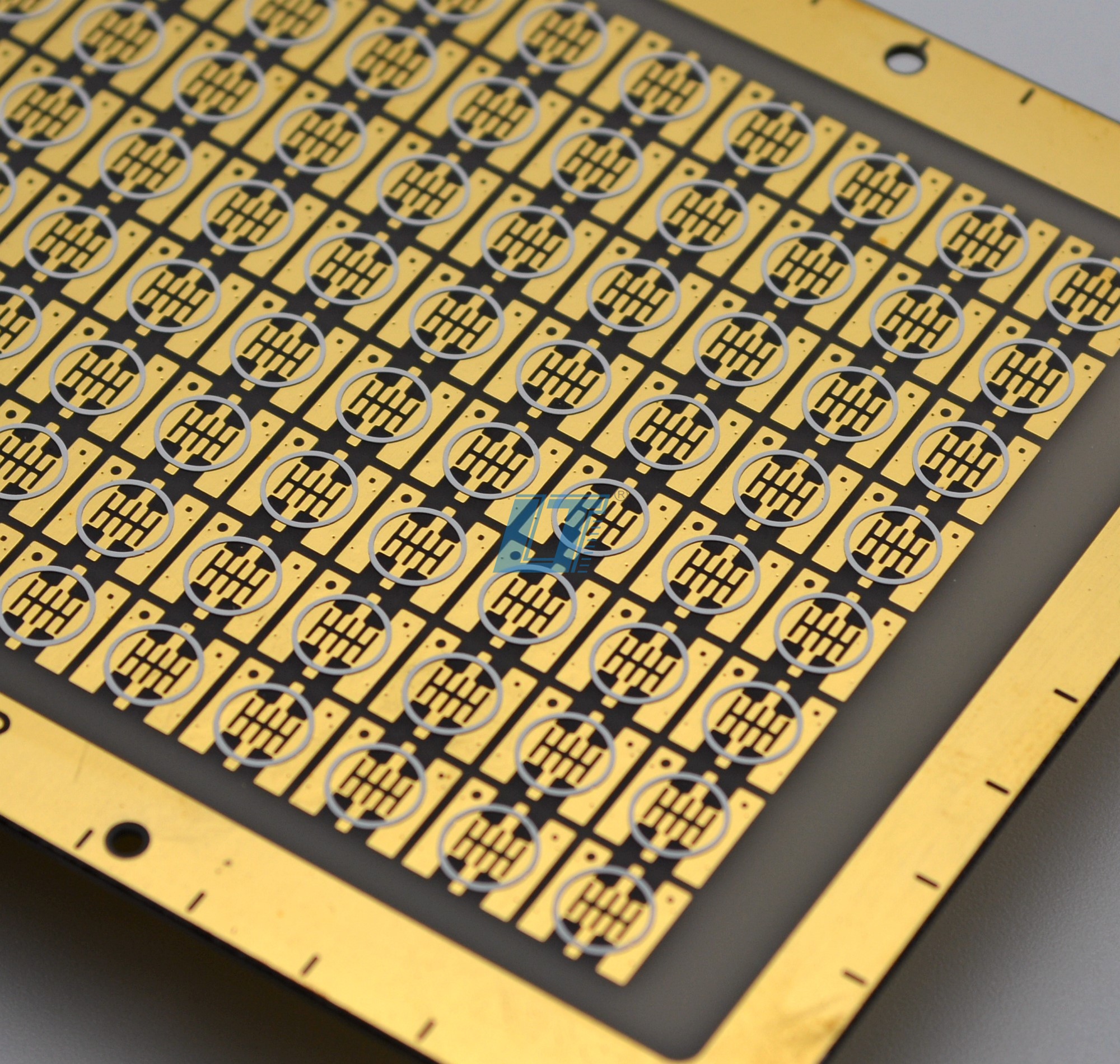

Wide-Bandgap Semiconductors

Wide-bandgap semiconductors play a key role in modern ceramic pcb applications. You use these materials to boost high-frequency performance and thermal management. Zirconia ceramics are now essential for ceramic pcb designs. They help you manage heat in electronics, which is critical for high-frequency and power applications. Advanced ceramics with strong mechanical strength and thermal conductivity let you build ceramic printed circuit boards that last longer and work better. You also see nanotechnology improving the performance of ceramic pcb assemblies, making them more reliable for high-frequency uses.

Tip: When you design for high-frequency performance, choose ceramic pcb materials that offer excellent insulation and heat dissipation. This helps your products run cooler and more efficiently.

Ceramic Matrix Composites

Ceramic matrix composites give you several advantages when you build ceramic pcb assemblies. You get enhanced toughness and thermal stability, which means your ceramic printed circuit boards resist damage and last longer. These ceramics allow for graceful failure, so your pcb does not fail suddenly. You benefit from improved heat management and durability, especially in high-performance applications.

High thermal conductivity

Excellent electrical insulation

Mechanical strength and corrosion resistance

Suitable for power electronics, automotive systems, aerospace, and telecommunications

LTPCBA uses advanced materials and follows strict international standards to ensure quality. You can see their commitment in the table below:

Compliance Standard | Description |

|---|---|

Quality management for medical devices, ensuring safety and effectiveness. | |

ISO 9001 | General quality management for various industries. |

IPC Class 3 | High reliability requirements for electronic assemblies. |

UL Standards | Safety and performance for electrical devices. |

You benefit from LTPCBA’s automated inspection, cleanroom assembly, and regular audits. These steps help you get ceramic pcb assemblies with superior reliability and consistent high-frequency performance.

Automation in Ceramic PCB Assembly

AI and Robotics

You see automation changing the way you assemble ceramic pcb products. AI and robotics bring new levels of precision and speed to the ceramic pcb process. You use AI algorithms to improve design efficiency and performance. Automated routing and component placement help you create complex ceramic pcb layouts with fewer errors.

AI systems position components on ceramic pcb assemblies with high accuracy. This is important for advanced ceramics and intricate designs.

Automated Optical Inspection (AOI) powered by AI finds defects quickly. You spend less time on manual checks and get better results.

AI analyzes sensor data from your equipment. You predict machinery failures before they happen, which keeps your ceramic pcb production running smoothly.

Tip: You can rely on robotics to handle repetitive tasks in ceramic pcb assembly. This reduces human error and boosts consistency in your ceramics projects.

LTPCBA uses advanced robotics and AI to deliver reliable ceramic pcb solutions. Their automated systems support your need for innovation and quality in every ceramic pcb batch.

Smart Manufacturing

Smart manufacturing brings efficiency and quality to your ceramic pcb assembly line. You follow clear Standard Operating Procedures (SOPs) to keep your ceramics production consistent. Cross-training employees gives you flexibility and reduces downtime in ceramic pcb manufacturing.

Strategy | Description | Outcome |

|---|---|---|

Standard Operating Procedures (SOPs) | Set guidelines for ceramic pcb production. | Consistent quality in ceramics batches. |

Cross-Training Employees | Train staff in multiple ceramic pcb tasks. | Flexible workforce and less downtime. |

Regular Quality Audits | Check ceramic pcb quality often. | Find issues early and fix them fast. |

You see mass production capabilities that ensure you meet deadlines for ceramic pcb orders. Durable assembly methods guarantee precision in your ceramics projects. Automated inspections and regular audits keep your ceramic pcb quality high.

LTPCBA leads in smart manufacturing for ceramic pcb assembly. Their MES Intelligent Scheduling System lets you monitor production in real time. You optimize resources and reduce lead times. Predictive maintenance keeps equipment running at over 90% utilization, so your ceramic pcb output stays efficient.

LTPCBA’s quality assurance measures include:

Testing Method | Description |

|---|---|

Automated Optical Inspection (AOI) | Detects defects in ceramic pcb assemblies. |

X-ray Testing | Checks internal ceramic pcb connections. |

Functional Testing (FCT) | Validates ceramic pcb performance. |

Flying Probe Testing | Tests ceramic pcb electrical connections. |

In-circuit Testing (ICT) | Finds shorts and opens in ceramic pcb circuits. |

Burn-in Testing | Stresses ceramic pcb to find early failures. |

Fatigue Testing | Tests ceramic pcb durability under stress. |

Microsection Analysis | Examines ceramic pcb internal structure. |

Solderability Testing | Ensures ceramic pcb solder joints are strong. |

High Pot Testing | Checks ceramic pcb insulation strength. |

You benefit from LTPCBA’s commitment to innovation and quality in every ceramic pcb project. Their automated systems and smart manufacturing practices set a new standard for ceramics in the industry.

Sustainable Ceramic Substrate PCB Production

Sustainability trends now shape the future of ceramic PCB manufacturing. You see more companies focusing on eco-friendly solutions as the demand for ceramic substrate PCB grows. The manufacturing process of ceramic substrate PCBs faces several challenges, but you can address them by choosing the right materials and processes.

Eco-Friendly Materials

You want to use eco-friendly materials in your ceramic PCB projects. These materials help reduce the environmental impact of electronics. Ceramic PCBs use natural, non-toxic materials that make recycling easier and safer for the environment. You also benefit from the excellent thermal management of ceramics, which means your devices need less cooling and use less energy.

Ceramic substrate PCBs use abundant minerals, which have a lower environmental impact than metals in traditional PCBs.

The durability of ceramics gives your products a longer lifespan, so you create less electronic waste.

Non-toxic materials in ceramic PCBs make your manufacturing process safer for workers and the environment.

You see LTPCBA leading the way by using sustainable materials and following strict environmental standards. Their commitment to eco-friendly practices helps you meet global sustainability trends.

Energy-Efficient Processes

You can make a big difference by using energy-efficient processes in ceramic PCB production. High-temperature sintering in ceramics requires a lot of energy, but new methods help reduce this need. For example, optimizing reflow ovens cuts energy use and lowers greenhouse gas emissions. One improvement increased production by 33.3% and reduced heat loss by 53.5%, saving 51% in electrical energy.

You also notice that the manufacturing process of ceramic substrate PCBs produces less chemical waste than traditional PCB methods. LTPCBA invests in advanced equipment and smart scheduling to further reduce energy consumption. Their green initiatives support your goals for sustainability and efficiency.

Note: By choosing LTPCBA, you support a company that values eco-friendly manufacturing and leads in sustainability trends for ceramic PCB demand.

Flexible and Rigid-Flex Ceramic PCB Solutions

Design Adaptability

You now see flexible and rigid-flex ceramic pcb solutions changing how you design advanced electronics. These boards combine the strength of rigid ceramics with the adaptability of flexible circuits. You can bend, twist, or fold them to fit into tight spaces without losing performance. This makes them perfect for devices that need to move or fit into unusual shapes.

Rigid-flex ceramic pcb boards help you reduce mechanical failure at solder joints and connectors.

You can use them in compact electronics, such as smartphones and medical equipment, where space and reliability matter.

Flex ceramic pcb boards let you create products that bend and twist, which is ideal for wearables and robotics.

These boards handle repeated stress, so your devices keep working even when they move.

Complex layouts become possible with rigid-flex ceramics, giving you more design freedom in small spaces.

You benefit from new materials like graphene and conductive polymers. These materials improve electrical and thermal conductivity, making your ceramic pcb designs even more reliable. Advanced composites add thermal stability and mechanical strength, so your products last longer.

Note: LTPCBA produces high-reliability flexible and rigid-flex ceramic pcb solutions. Their advanced manufacturing and strict testing ensure your ceramics meet the highest standards, especially for aerospace and medical uses.

Market Applications

Flexible and rigid-flex ceramic pcb boards now power many industries. You find them in places where lightweight, reliable, and compact circuits are essential. The table below shows how different industries use these ceramics:

Industry | Application |

|---|---|

Aerospace and Defense | Avionics and satellite systems need lightweight, reliable ceramic pcb boards |

Medical Devices | Portable monitors and wearable health trackers use flexible ceramics |

Consumer Electronics | Laptops and gaming consoles get smaller and lighter with ceramic pcb |

Automotive Electronics | Dashboards, sensors, and infotainment systems use ceramics for complex shapes |

IoT Devices | Smart home systems and wearables rely on compact, flexible ceramic pcb |

You also see new trends in the market. The telecommunications industry uses flexible circuits to reduce signal loss. Data centers rely on rigid-flex pcb boards for high-density connections and signal integrity. Future applications include IoT devices and renewable energy systems, driven by better materials and manufacturing.

Laser-based processing and additive manufacturing help you create precise features and specialized conductive patterns in your ceramic pcb designs. Automated optical inspection systems check rigid-flex structures for quality, so you get reliable ceramics every time.

Future of the Ceramic PCB Market

Growth Drivers

You see the ceramic PCB market moving forward because of several strong growth drivers. These trends shape the future of ceramics and PCB assembly. You notice that telecommunications, aerospace, and renewable energy all need advanced ceramic solutions. The rise of 5G networks creates new opportunities for high-frequency circuit applications. You also see the automotive sector shifting to electric vehicles, which increases demand for ceramic PCBs with excellent heat dissipation.

Growth Driver | Description |

|---|---|

Advancements in Power Electronics | You use ceramic PCBs in high-frequency circuits and energy-efficient systems. |

Automotive Sector Transition to EVs | You rely on ceramic PCBs for heat management in automotive electronics. |

Demand for High-Performance Materials | You need lightweight and heat-resistant ceramics for aerospace and telecommunications. |

Innovations in Manufacturing Technologies | You benefit from lower production costs and better quality. |

Adoption of IoT Devices | You design smaller electronics that require reliable ceramic PCB solutions. |

Growth of 5G Networks | You see more ceramic PCBs used for high-frequency signals in telecommunications. |

You notice that the automotive PCB market reached over $11 billion in 2021. Predictions show a 5.6% CAGR by 2027. The number of 5G connections will likely exceed 1 billion by 2025. These market trends point to strong growth for ceramic PCBs.

Opportunities and Challenges

You face both opportunities and challenges in the evolving ceramic PCB market. The five key trends open new doors for ceramics in advanced applications. You can use superior thermal conductivity and miniaturization to create better products. You also see more demand for high-frequency applications and expansion in the automotive industry.

Opportunities | Challenges |

|---|---|

Superior thermal conductivity | High manufacturing costs |

Miniaturization of electronic devices | Complex manufacturing process |

Increasing demand in high-frequency applications | Brittleness of ceramic materials |

Expansion of the automotive industry | Limited material compatibility |

You need to watch for predictions about market growth and technology changes. The ceramic PCB market will grow because of new applications in 5G systems and advanced automotive electronics. You should prioritize supply chain resilience by sourcing ceramics from multiple regions. You can invest in digital process control to improve production efficiency. You may want to work closely with suppliers to develop custom ceramic PCB solutions. You should also embed sustainability in your procurement decisions to support environmental goals.

Tip: Stay updated on market trends and predictions. You can gain a competitive edge by focusing on innovation, quality, and sustainability in ceramic PCB assembly.

You see five trends shaping the future of ceramic pcb assembly: miniaturization, advanced materials, automation, sustainability, and flexible solutions. Staying updated gives you a competitive edge as ceramics drive innovation in electric vehicles and telecom, with ceramic pcb demand rising across industries. LTPCBA leads with strict quality standards, advanced equipment, and a 99.8% first-pass yield in ceramic pcb production. You can explore more about ceramic pcb and ceramics through these resources:

Resource Type | Link |

|---|---|

Ceramic PCB Manufacturing | How to Make Ceramic PCBs: 7 Ceramic PCB Manufacturing Processes |

FAQ

What makes ceramic pcb assembly different from standard pcb assembly?

You work with ceramic pcb assemblies when you need high thermal conductivity and durability. These boards handle heat better than standard pcb options. You choose ceramic substrates for demanding environments like automotive or aerospace electronics.

How do you ensure quality in ceramic pcb production?

You rely on automated optical inspection and strict testing protocols. LTPCBA uses international standards and advanced equipment. You get consistent results and high reliability in every batch.

Can you use ceramic pcb boards for flexible electronics?

You design flexible electronics with ceramic pcb boards by choosing rigid-flex solutions. These boards bend and twist without losing performance. You create compact devices for wearables and medical applications.

What industries benefit most from ceramic pcb technology?

You see industries like automotive, aerospace, medical devices, and telecommunications using ceramic pcb technology. These sectors need reliable, heat-resistant boards for advanced electronics.

How does LTPCBA support fast turnaround for ceramic pcb projects?

You receive quick quotations and 24-hour technical support from LTPCBA. Their automated systems and efficient scheduling help you meet tight deadlines for ceramic pcb production.

See Also

Top 5 Testing Techniques for Expert Through Hole PCB Assembly

Boosting Project Efficiency with Quick-Turn PCB Assembly Prototypes

Combining SMT and DIP Techniques for Enhanced Mixed Technology PCBs

Comprehensive Overview of PCBA Manufacturing for All Skill Levels

Selecting the Ideal All-In-One PCB Assembly Service Provider