BGA Assembly: Advanced Techniques for High-Reliability Electronics Manufacturing

Ball Grid Array (BGA) Assembly is key to making modern electronics. It helps build small, powerful parts for phones, computers, and smart devices. The BGA PCB market grows 8% each year due to smaller and stronger designs. Using copper solder balls improves how well these parts work. LTPCBA provides accurate BGA Assembly using advanced tools to match industry needs.

Key Takeaways

Use machines with cameras to keep BGAs in place. These machines find and fix mistakes during assembly.

Stop soldering gaps by changing heat and using better paste. This makes connections stronger and your assemblies last longer.

Use tools like X-ray and AOI to spot errors early. These tools improve quality and save money on production.

Overcoming Challenges in BGA Assembly

Fixing Misalignment and Placement Problems

Misalignment and placement mistakes are common in BGA Assembly. These happen because parts are getting smaller and designs more complex. Even tiny misalignments can break electrical connections and cause failures. To fix this, use precise tools and advanced machines.

Tip: Automated machines with cameras can help avoid placement mistakes. They check and fix errors during the assembly process.

Misalignment happens due to several reasons:

Different material expansions cause stress on solder bumps, leading to misalignment.

Bigger chips expand more with heat, causing more stress than smaller ones.

High-speed signals often need materials that expand more, affecting designs.

Key Findings | Details |

|---|---|

Reliability Testing | |

Failure Rates | Important uses, like cars, need very low failure rates. |

Testing Changes | New tests use better models instead of old methods. |

By using these methods, you can reduce placement mistakes and make assemblies more reliable.

Avoiding Soldering Problems and Voids

Soldering problems, like voids, can weaken BGA Assembly. Voids make solder joints weaker, shorten their life, and hurt heat performance. Studies show void size and location affect how strong solder joints are. Preventing these problems is key to strong connections.

Note: Voids in solder joints can raise heat levels and lower strength, making products less reliable.

To stop soldering problems:

Adjust heat settings for even heating during soldering.

Use special solder pastes to reduce voids.

Check for hidden problems with X-ray inspections.

Research also shows that tin grain direction in solder affects stress and failure times. Fixing these issues improves assembly quality and reliability.

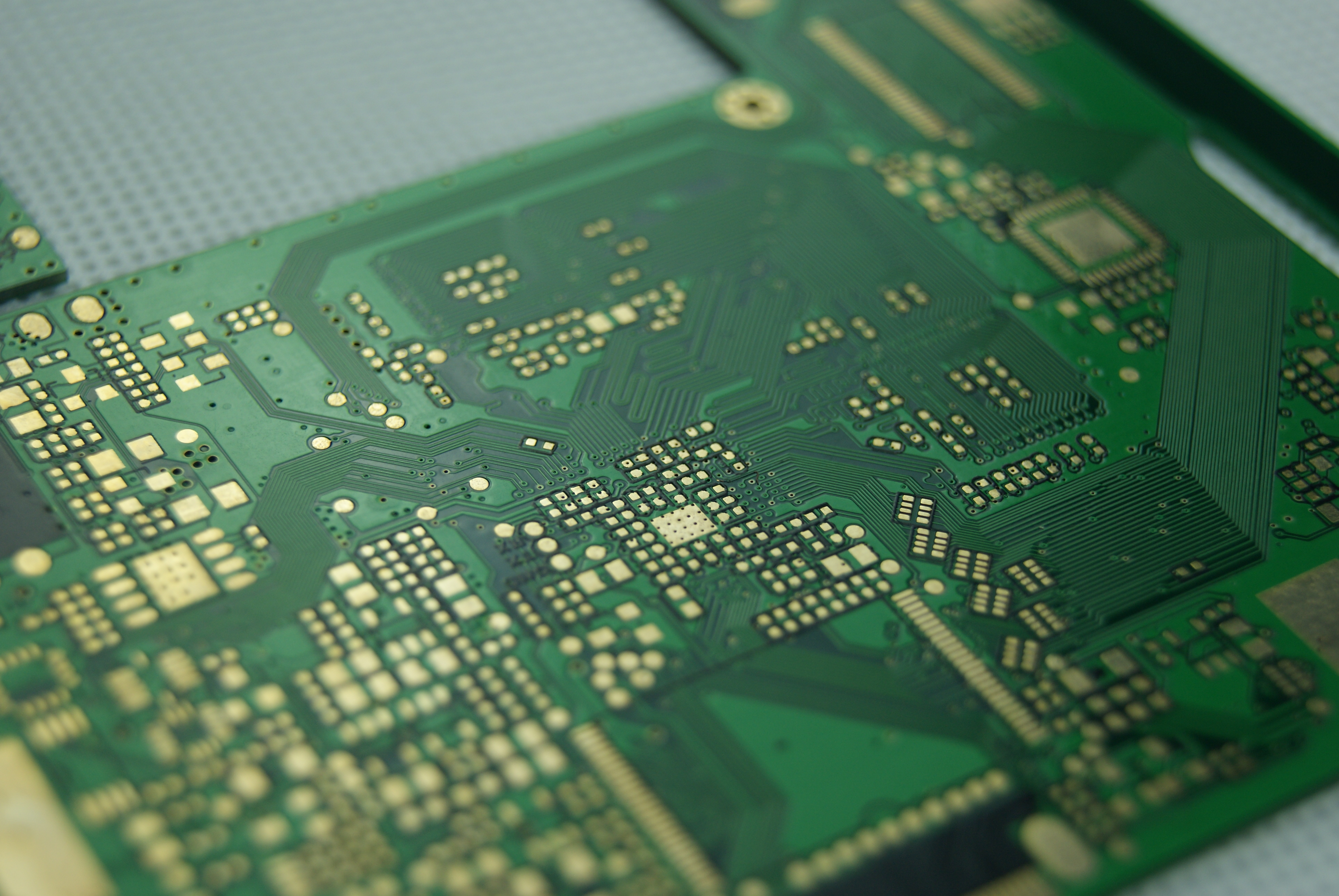

Handling Heat Problems in Dense PCBs

Managing heat is very important in dense PCBs during BGA Assembly. Smaller devices make it harder to get rid of heat. Bad heat management can cause overheating, bending, and weak solder joints, lowering reliability.

Thermal interface materials (TIMs) help manage heat. New materials like nano-enhanced TIMs work better but have limits like separation issues. Better strategies can improve TIM performance.

Did you know? Smaller temperature changes reduce stress and make solder joints last longer. Better cooling and environment control can also help with heat problems.

To handle heat issues:

Use materials that spread heat well.

Keep temperature changes small to reduce stress.

Use advanced cooling to stop bending and weak solder joints.

These steps ensure good heat performance in dense PCBs, even in tough conditions.

Advanced Techniques for BGA Assembly

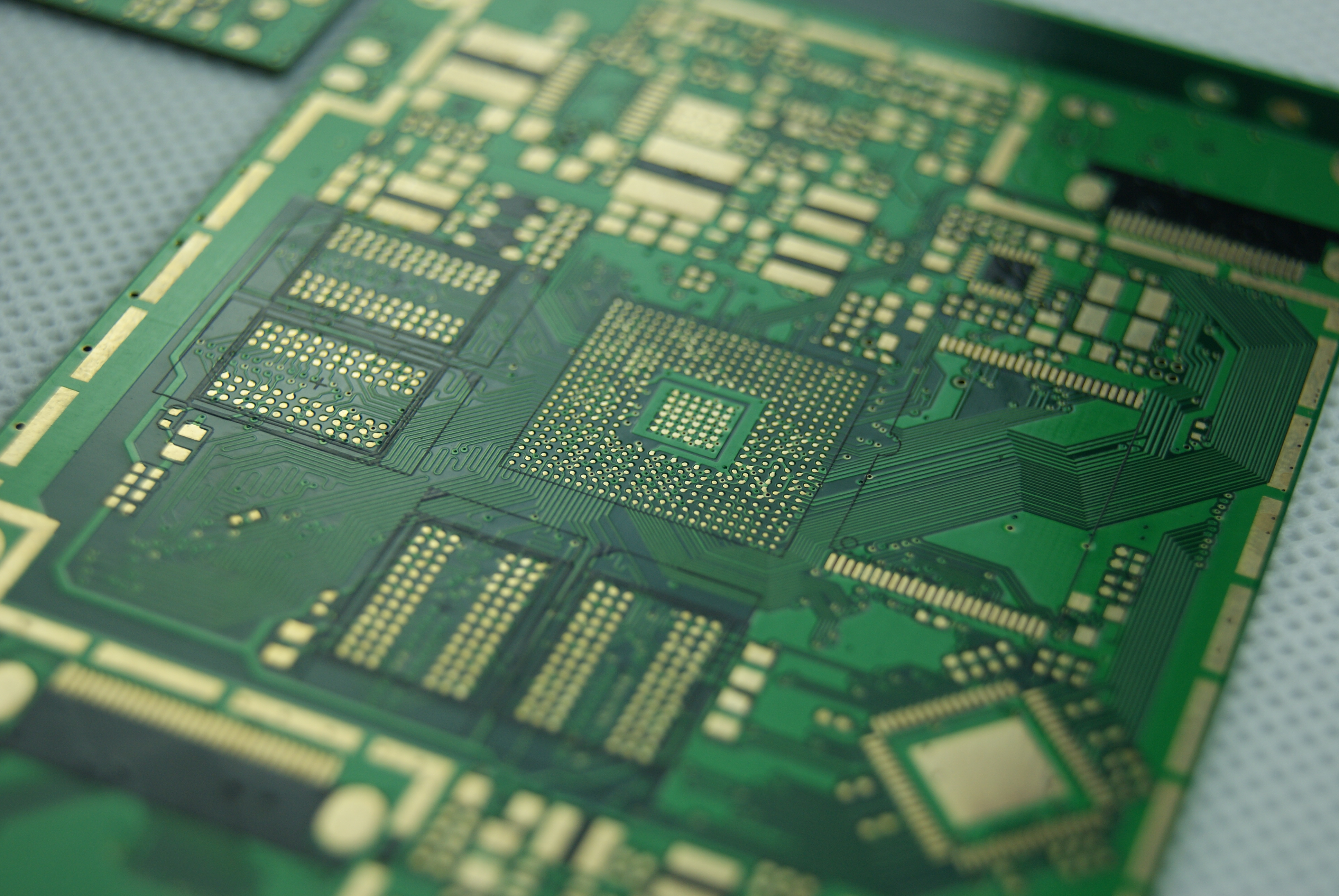

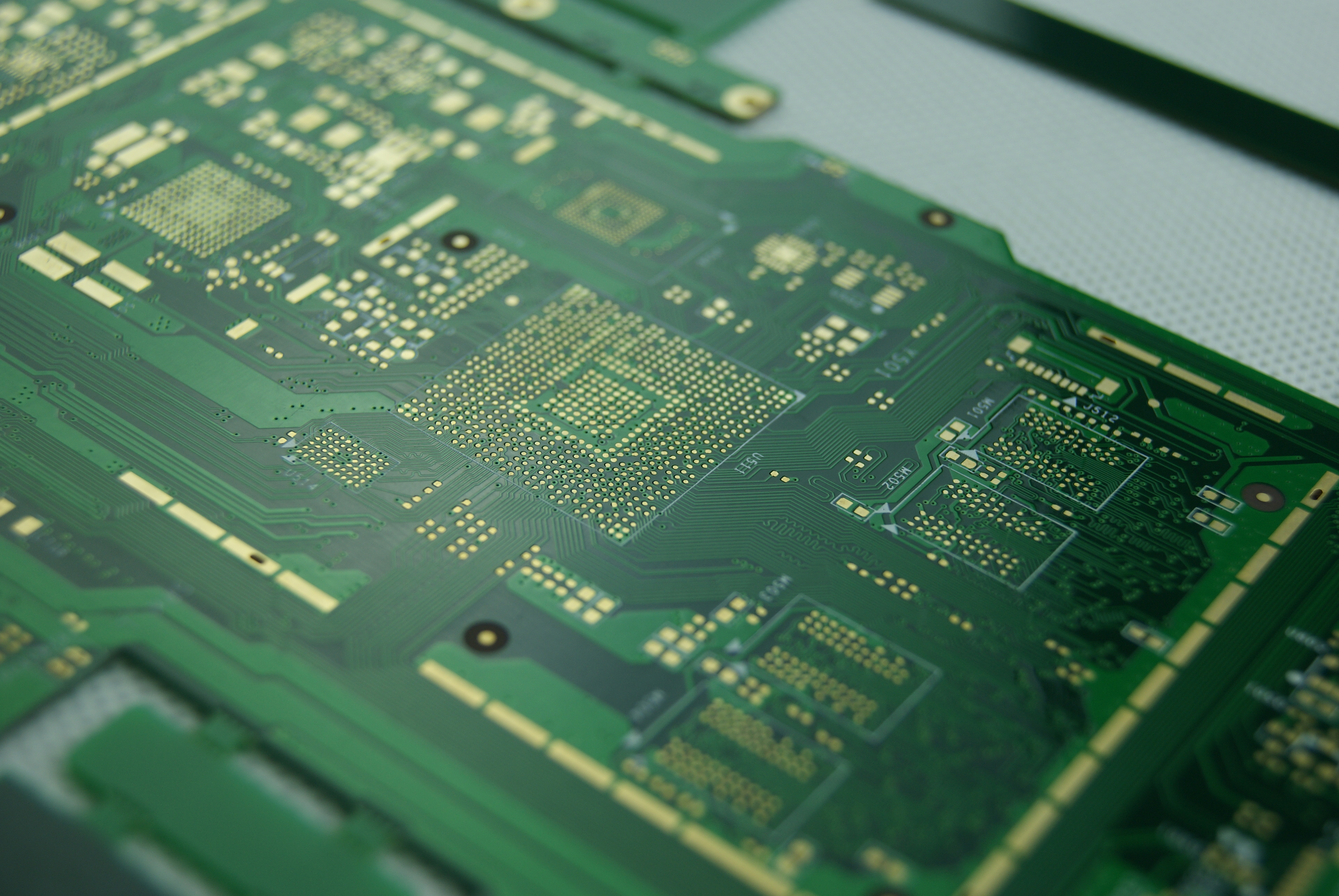

Precision Placement and Automated Systems

Placing parts correctly is very important in BGA Assembly. Machines help make this process faster and more accurate. They reduce mistakes and improve how well the assembly works.

Modern machines are fast and precise. For example:

Machines add solder exactly where it’s needed for strong joints.

Placement tools can handle many parts quickly and keep them aligned.

Special ovens heat parts evenly to keep solder joints strong.

X-ray tools find hidden problems inside BGA parts to ensure quality.

Optical inspection systems check for mistakes during assembly to fix them early.

Equipment Type | Description |

|---|---|

Automatic Solder Dispensing | Adds solder accurately for strong connections. |

Automatic Placement Machines | Places parts quickly and correctly. |

Reflow Ovens | Heats parts evenly for strong solder joints. |

X-ray Inspection Systems | Finds hidden problems inside BGA parts. |

Automated Optical Inspection (AOI) | Spots mistakes during assembly and fixes them early. |

Using these tools makes assembly faster and more reliable. It also helps reduce production time and errors.

Optimized Reflow Soldering for Reliable Joints

Reflow soldering is key to making strong solder joints. Improving this process helps meet industry rules for reliable BGA Assembly. Heating parts carefully stops problems like misplaced parts or weak solder.

You can make reflow soldering better by:

Using ovens that control heat very precisely.

Heating parts in steps to spread solder evenly.

Checking solder paste quality to avoid mistakes.

These steps keep solder joints strong, even under heat stress. Better soldering reduces failures and makes assemblies work well in tough conditions.

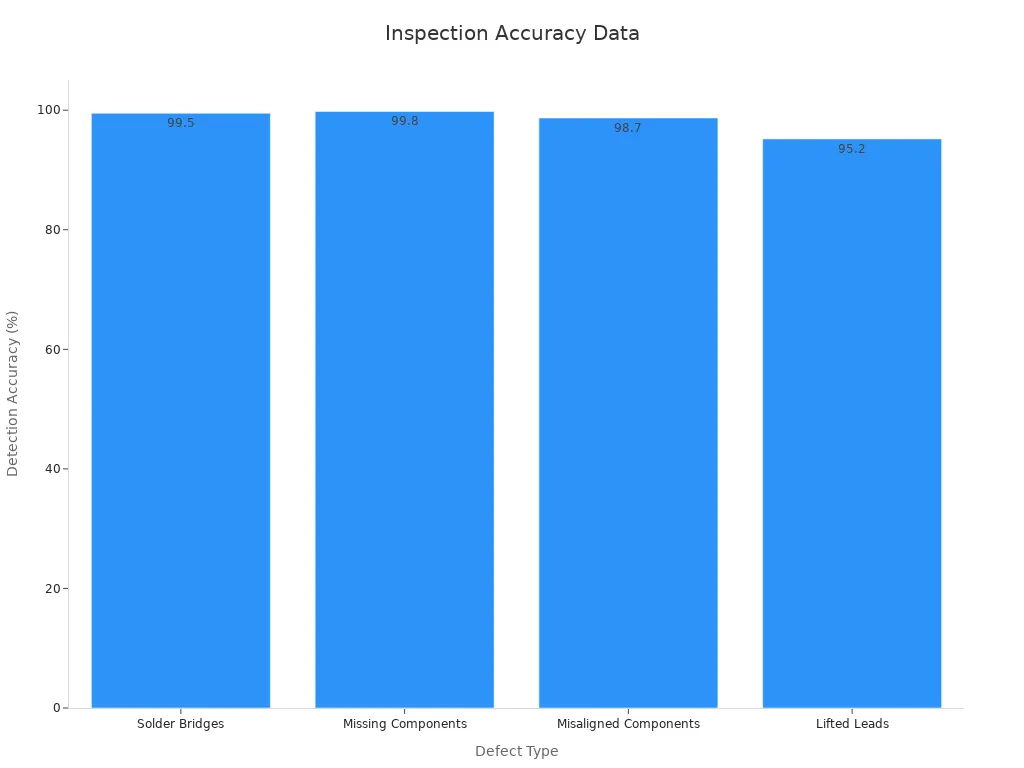

Advanced Inspection Methods: X-Ray and AOI

Checking for mistakes is very important in BGA Assembly. Tools like X-ray and AOI (Automated Optical Inspection) find problems early. This saves time and money.

X-ray tools find hidden problems like weak solder or misplaced parts. AOI checks the surface for missing or wrong parts. Together, these tools make sure assemblies are high quality.

Defect Type | Detection Accuracy |

|---|---|

Solder Bridges | |

Missing Components | 99.8% |

Misaligned Components | 98.7% |

Lifted Leads | 95.2% |

Feature | AOI | AXI |

|---|---|---|

Inspection Depth | Surface Only | Subsurface |

BGA Inspection | No | Yes |

Speed | High (20K/hr) | Medium (5K/hr) |

Cost | $ | $ |

Using X-ray and AOI tools helps find almost all mistakes. This ensures assemblies are reliable and work well.

Innovations in Materials and Processes

High-Thermal-Conductivity Substrates

Getting rid of heat is very important in BGA Assembly, especially for powerful devices. Materials like aluminum nitride (AlN) help move heat away from silicon chips. These materials work better than older ones like FR4, keeping devices cooler and more reliable.

Did you know? Ceramic materials like AlN can handle over 100 watts of heat when used with good heat sink designs, as shown in computer simulations by Han et al.

New cooling methods make heat control even better. For example, microfluidic cooling systems lower heat resistance in CPUs by 44%. Two-phase immersion cooling can handle up to 900 watts for high-power computers. Using these methods stops overheating and helps devices last longer.

Smart Equipment Integration for Efficiency

Using smart machines in factories makes work faster and better. Automated robots, like autonomous mobile robots (AMRs), help move parts and reduce human errors. LG Innotek's Dream Factory shows how this works, making more products with fewer mistakes.

Benefit | Description |

|---|---|

Robots make more products in less time. | |

Higher Throughput Rates | Machines work nonstop without losing quality. |

Flexibility and Versatility | Easy programming changes save time and training. |

Automation improves how factories work and keeps quality steady in BGA Assembly.

LTPCBA's Role in Driving Material Advancements

LTPCBA is a leader in improving materials and processes for BGA Assembly. They use advanced tools like defect analysis, robots, and machine learning to make production better. Regular checks and records keep their work accurate and stable.

Strategy | Description |

|---|---|

Continuous Improvement | Fixes problems to make products better and more reliable. |

Machine Learning and AI | Finds problems early and improves factory processes. |

Traceability | Tracks parts to ensure high quality and trust. |

Working with LTPCBA gives you access to smart solutions that focus on quality, speed, and reliability in every product.

New methods in BGA Assembly improve accuracy, strength, and performance in today’s electronics. New ideas create better materials and processes to meet industry needs.

Work with LTPCBA for top-notch solutions. Their skills, modern tools, and focus on quality make them perfect for your production needs.

Keep leading with LTPCBA!

FAQ

What makes BGA Assembly better than other packaging methods?

BGA Assembly works better for electricity and handles heat well. Its small size fits more circuits, perfect for devices like phones and computers.

How does LTPCBA make sure BGA Assembly is high quality?

LTPCBA uses tools like X-ray and automated machines. These tools find problems early and place parts exactly right for strong assemblies.

Tip: Working with LTPCBA gives you the best tools for your needs.

Can BGA Assembly work in hot environments?

Yes, BGA Assembly can handle heat with special materials. LTPCBA picks the best materials for tough jobs.

Note: Good heat control helps your electronics last longer.

See Also

Essential Tips and Techniques for BGA Assembly Success

Tips to Prevent Frequent Errors in BGA Assembly

Ensuring SMT Assembly Standards for Automotive Manufacturing