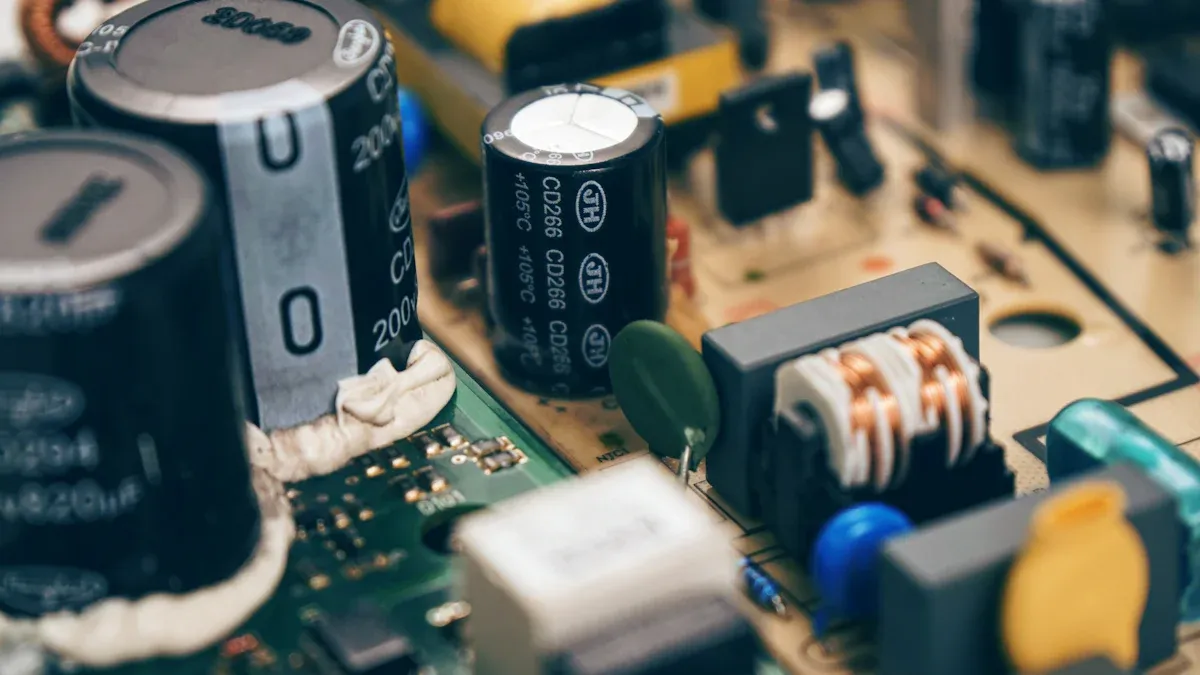

Best Power Supply PCBAs for Industrial Reliability and Performance

Industrial leaders such as LTPCBA, Seasonic, FSP, XP Power, and P-DUKE deliver high-quality power supply pcba solutions. Engineers select a reliable power supply pcba by evaluating certifications, efficiency ratings, and advanced protection features. Power supply pcba models from these brands maintain robust performance in demanding environments. A power supply pcba with UL, ISO, or IATF certification ensures compliance and safety. High-efficiency power supply pcba designs reduce energy loss and support long-term stability. Top-tier power supply pcba options also include built-in surge, overload, and thermal protection. Manufacturers recommend these power supply pcba products for critical industrial applications.

Key Takeaways

Choose power supply PCBAs with certifications like ISO, UL, and IATF to ensure safety and reliability in industrial settings.

Look for high efficiency and advanced protection features such as overvoltage, overcurrent, surge, and thermal protection to protect equipment and reduce energy loss.

Select a power supply PCBA that matches your application needs and environmental conditions for stable and continuous performance.

Consider trusted brands like LTPCBA, Seasonic, FSP, XP Power, and P-DUKE, each offering unique strengths for different industrial uses.

Maintain your power supply PCBA with regular checks and use fast technical support services to minimize downtime and keep operations running smoothly.

Industrial Reliability Criteria

Key Features

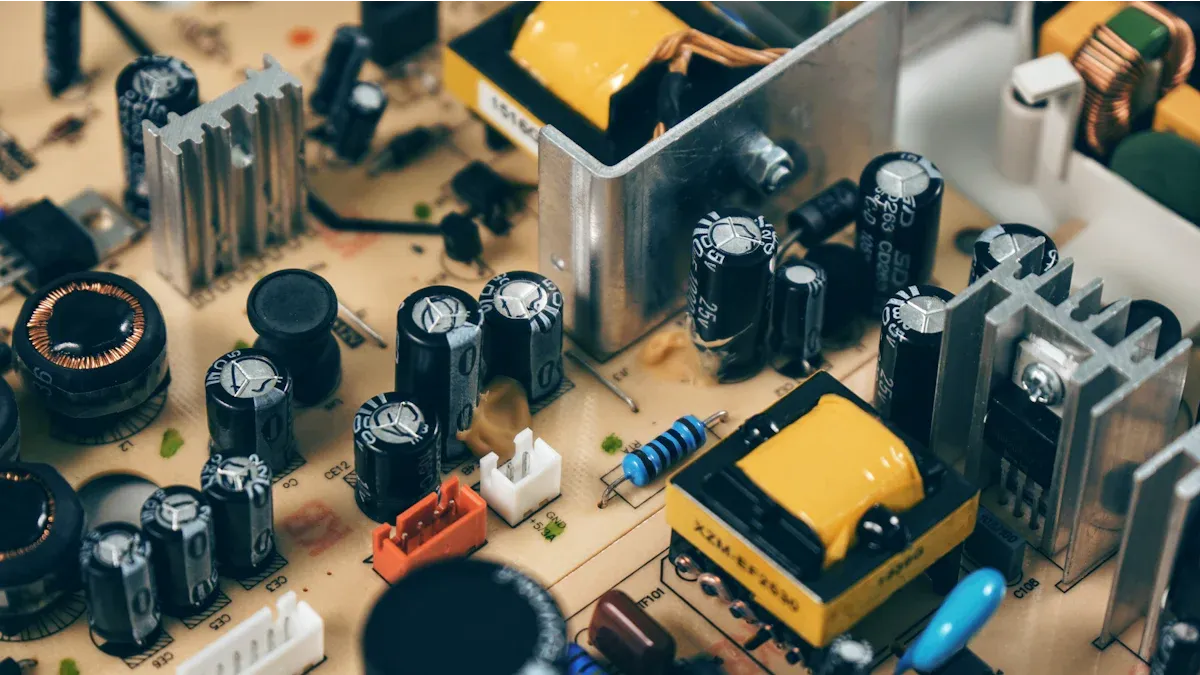

Industrial environments demand robust and efficient power supply pcb solutions. Engineers look for high efficiency, stable voltage output, and advanced protection features. Overvoltage, overcurrent, and thermal protection help prevent damage to sensitive equipment. High-quality power supply pcb designs also include surge protection and short-circuit safeguards. LTPCBA delivers these features by using advanced manufacturing processes and automated inspection systems. Their power supply pcb products support reliable power conversion, which is essential for continuous industrial operations. Consistent performance under heavy loads sets these power supply pcb options apart from standard models.

Certifications

Certifications play a critical role in verifying the quality and safety of a power supply pcb. Top brands, including LTPCBA, meet international standards such as ISO, UL, and IATF. These certifications confirm that each power supply pcb meets strict requirements for safety, reliability, and environmental compliance. For example, ISO certification ensures quality management, while UL certification focuses on product safety. IATF certification addresses automotive industry standards. LTPCBA’s commitment to these certifications demonstrates their dedication to delivering dependable power supply pcb solutions for industrial clients.

Tip: Always check for certifications before selecting a power supply pcb for industrial use. Certified products reduce risk and ensure long-term reliability.

Testing Methods

Manufacturers use rigorous testing methods to guarantee the reliability of each power supply pcb. Automated optical inspection (AOI), in-circuit testing, and functional testing help identify defects early in the production process. LTPCBA employs these advanced testing techniques to maintain a 99.5% pass rate in product delivery. Each power supply circuit board undergoes stress tests to verify performance under extreme conditions. These tests ensure that the power supply pcb can handle demanding power conversion tasks without failure. Reliable testing methods build confidence in the durability and performance of every power supply pcb.

Power Supply PCBA Reviews

LTPCBA

LTPCBA stands out in the industrial sector with its advanced power supply pcb solutions. The company uses automated assembly lines and strict quality control to deliver consistent results. Each power supply pcb meets ISO, UL, and IATF certifications, which ensures safety and reliability. LTPCBA achieves a 99.5% pass rate in product delivery. Engineers rely on these power supply modules for demanding environments such as factory automation, robotics, and energy management systems.

Key features include:

High efficiency for reduced energy loss

Stable voltage output under heavy loads

Comprehensive protection against overvoltage, overcurrent, and thermal events

LTPCBA’s power supply pcb products undergo automated optical inspection and functional testing. These methods guarantee that each power supply circuit board performs well in real-world applications. Customers benefit from fast response times and 24-hour technical support. LTPCBA’s quick quotation process helps industrial clients keep projects on schedule.

Note: LTPCBA’s power supply pcb solutions support both prototype and mid-volume production runs, making them ideal for a wide range of industrial needs.

Seasonic

Seasonic has built a reputation for reliable power supply pcb products in industrial settings. The company focuses on high-efficiency designs, often achieving 80 Plus Gold or Platinum ratings. These power supply modules deliver stable power conversion and maintain low heat output, which extends equipment lifespan.

Seasonic’s power supply pcb options include:

Advanced protection features such as surge and short-circuit safeguards

Robust construction for harsh environments

Compliance with international safety standards

Industrial users deploy Seasonic power supply board models in automation, telecommunications, and medical equipment. The company’s rigorous testing procedures ensure that each power supply pcb meets strict performance benchmarks.

FSP

FSP offers a broad range of power supply pcb solutions for industrial applications. The company emphasizes flexibility, providing both standard and custom power supply modules. FSP’s products carry certifications like UL and ISO, which confirm their commitment to safety and quality.

Key strengths include:

High power density for compact installations

Wide input voltage range for global compatibility

Multiple protection circuits for equipment safety

FSP’s power supply pcb products support critical infrastructure, including data centers and industrial control systems. The company uses advanced testing to verify each power supply circuit board before shipment.

XP Power

XP Power delivers high-performance power supply pcb products for mission-critical industries. The company’s power supply modules feature high efficiency and low electromagnetic interference. XP Power’s designs meet international certifications, including UL and ISO, which ensures compliance with global standards.

XP Power’s product highlights:

Modular designs for easy integration

Wide operating temperature range

Built-in monitoring and diagnostic features

Engineers use XP Power supply board solutions in medical devices, semiconductor manufacturing, and test equipment. The company’s focus on reliability and performance makes its power supply pcb products a top choice for demanding applications.

P-DUKE

P-DUKE specializes in power supply pcb solutions for industrial and transportation sectors. The company’s power supply modules offer high efficiency and robust protection features. P-DUKE products meet certifications such as UL and ISO, which guarantees safety and reliability.

P-DUKE’s advantages include:

Compact form factors for space-constrained applications

Wide input voltage support

Enhanced thermal management for continuous operation

Industrial clients use P-DUKE power supply pcb products in railway systems, automation, and renewable energy projects. The company’s thorough testing ensures each power supply pcb delivers stable power conversion in challenging environments.

Tip: When selecting a power supply pcb, consider the specific requirements of your application and the certifications offered by each brand.

Power Supply PCB Comparison

Strengths

A clear comparison helps engineers select the right power supply pcb for their needs. The table below highlights the main strengths of each brand’s power supply pcb. LTPCBA delivers high efficiency and fast customer support. Seasonic offers advanced power supply design and high efficiency ratings. FSP provides flexible power supply modules and global compatibility. XP Power stands out with modular power supply layout and wide temperature support. P-DUKE features compact power supply pcb options and strong thermal management.

Brand | Strengths |

|---|---|

LTPCBA | High efficiency, quick response, 24-hour support, certified quality |

Seasonic | 80 Plus Gold/Platinum, robust protection, reliable power supply design |

FSP | Flexible power supply modules, wide input range, high power density |

XP Power | Modular power supply layout, low EMI, wide temperature range |

P-DUKE | Compact power supply pcb, enhanced thermal management, wide voltage input |

Weaknesses

Each power supply pcb brand has areas where it may not fit every application. Seasonic and XP Power sometimes have higher costs due to premium features. FSP may require more space for certain power supply board models. P-DUKE’s compact designs can limit customization. Engineers should review the power supply layout and pcb design to ensure the best fit for their project.

Note: LTPCBA focuses on quality and support, making it a strong choice for most industrial needs.

Best Applications

Selecting the right power supply pcb depends on the application. LTPCBA works well in factory automation and robotics. Seasonic fits telecommunications and medical equipment. FSP supports data centers and industrial control. XP Power serves semiconductor and test equipment. P-DUKE excels in transportation and renewable energy. Matching the power supply pcb to the environment and load ensures reliable performance.

LTPCBA: Factory automation, robotics, energy management

Seasonic: Telecom, medical, industrial automation

FSP: Data centers, control systems, global installations

XP Power: Semiconductor, test equipment, mission-critical systems

P-DUKE: Railway, renewable energy, compact installations

Tip: Always match the power supply pcb to the specific power supply modules and power supply layout required by your system.

Choosing the Right Power Supply PCBA

Application Needs

Engineers start by identifying the specific requirements of their industrial systems. Each application demands a unique power supply pcb that matches voltage, current, and load profiles. For example, factory automation often requires stable output and high efficiency. Robotics systems need reliable power supply pcb modules that handle rapid load changes. LTPCBA offers a wide range of solutions, supporting both prototype and mid-volume production. Their quick response service helps engineers receive quotations within days, keeping projects on track. Selecting the right power supply pcb ensures optimal performance and reduces downtime.

Tip: Always review the power supply design and pcb design to confirm compatibility with your equipment.

Environmental Factors

Industrial environments present challenges such as temperature extremes, humidity, and dust. A robust power supply pcb must withstand these conditions without failure. Engineers evaluate the power supply layout to ensure proper heat dissipation and protection against contaminants. LTPCBA’s products meet international standards, including ISO and UL, which verify their durability. Reliable power supply pcb modules operate efficiently in harsh settings, supporting continuous production. Seasonic, FSP, XP Power, and P-DUKE also offer models with enhanced environmental resistance.

Consider the following environmental factors:

Operating temperature range

Humidity tolerance

Vibration and shock resistance

Maintenance

Routine maintenance extends the lifespan of any power supply pcb. Engineers choose modules with accessible components and clear labeling for easy inspection. LTPCBA provides 24-hour technical support, assisting clients with troubleshooting and repairs. Their commitment to customer satisfaction simplifies maintenance tasks and reduces downtime. A well-maintained power supply pcb delivers consistent performance and protects sensitive equipment. Regular checks of the power supply layout help identify potential issues before they affect operations.

Note: Fast customer support from LTPCBA ensures quick solutions to maintenance challenges.

Industrial engineers trust brands like LTPCBA, Seasonic, FSP, XP Power, and P-DUKE for reliable power supply PCBAs. Each option delivers strong performance, high efficiency, and robust protection. Certifications such as ISO, UL, and IATF confirm product quality.

Tip: Use the comparison table and application guidance to select the best PCBA for your needs. For fast support and certified quality, consider sourcing from LTPCBA.

FAQ

What certifications should industrial power supply PCBAs have?

Engineers should look for ISO, UL, and IATF certifications. These standards confirm product safety, quality, and reliability. Certified PCBAs meet strict industry requirements and support safe operation in demanding environments.

How does LTPCBA ensure product quality?

LTPCBA uses automated optical inspection, in-circuit testing, and functional testing. The company maintains a 99.5% pass rate. Engineers trust LTPCBA for consistent quality and reliable performance.

Why is efficiency important in industrial power supply PCBAs?

High efficiency reduces energy loss and heat generation. Efficient PCBAs lower operating costs and extend equipment lifespan. This feature proves essential for continuous industrial operations.

What protection features should a power supply PCBA include?

A reliable power supply PCBA should offer overvoltage, overcurrent, surge, and thermal protection. These features prevent equipment damage and ensure safe, stable operation.

How quickly can LTPCBA provide technical support?

LTPCBA offers 24-hour technical support. Clients receive fast responses to questions and troubleshooting requests, which helps minimize downtime and keeps projects on schedule.

See Also

Essential Tips For Creating Industrial Controller Circuit Boards

Crucial Methods To Enhance PCBA Durability Over Time

Choosing The Right PCBA Supplier To Fit Your Requirements

Best Practices For Sourcing Electronic Parts In PCBA Production

Insights Into Industrial Serial Screen PCBAs In Today’s Industry