Choosing the Best One-Stop PCB Assembly Service

Choosing the best one-stop PCB assembly service is very important. A good provider gives you expert help, quality checks, and faster work. This saves you time and money.

Ritchey points out fewer U.S. prototype assembly shops exist now. Offshore options are growing, so local services are more valuable.

Companies like Makerfabs make your job easier. You can focus on design while they do the assembly. The right partner helps your PCB projects succeed and work better.

Key Takeaways

Pick a PCB assembly service with good tools and skilled workers. Modern machines and trained engineers help make better products.

Check for quality tests and certifications. ISO or UL certifications show the company makes dependable items.

Look at customer support and communication. A helpful team can make things easier and fix problems fast.

Key Factors to Consider in a One-Stop PCB Assembly Service

Picking the right one-stop PCB assembly service can be tough. But focusing on a few important things makes it easier. Let’s look at what you need to find the best service for your project.

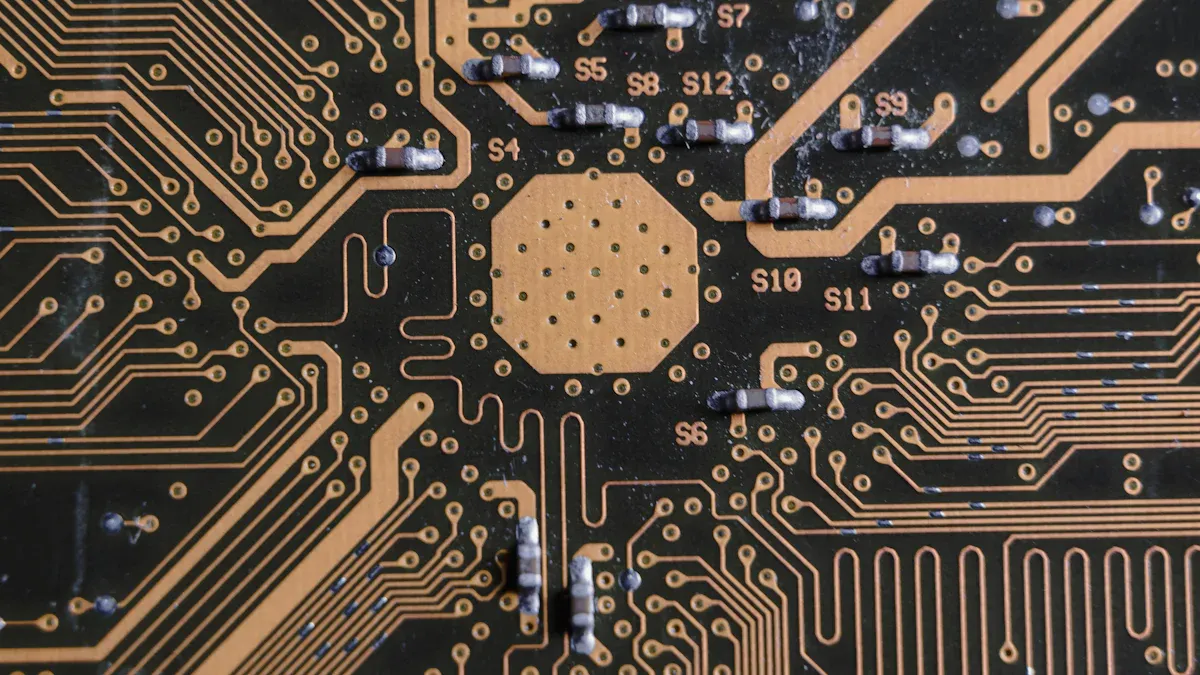

Skills and Technology

PCB assembly needs skilled workers and advanced tools. Choose a company with modern machines and experienced engineers. For example, companies using pick-and-place machines and AOI systems can handle tricky designs well.

Here’s what to check:

Tools used for surface-mount technology (SMT) assembly.

Quality checks like X-ray inspections for small parts.

Experience with hard designs like BGA or QFN parts.

Good PCB services also help improve your design for production. This saves time and money later.

Quality Checks and Certifications

Quality checks are very important for PCB assembly. Look for companies with certifications like ISO or UL. These show they care about making good products.

Top companies use methods like First Article Inspection (FAI) and AOI. These catch problems early so your product works as planned. For example:

Quality Check Method | What It Does |

|---|---|

First Article Inspection | Tests the first piece to match the design. |

Automated Optical Inspection | Finds soldering mistakes by checking parts visually. |

X-ray Inspection | Checks hidden parts like BGAs for quality. |

Picking a company with strong quality checks means your PCB will work well.

Balancing Cost and Quality

It’s important to save money but not lose quality. Good PCB companies use smart ways to cut costs without cutting corners. For example:

Strategy | How It Helps |

|---|---|

Advanced Technology | Speeds up work and lowers costs. |

Strong Quality Checks | Stops mistakes, saving money on fixes. |

Bulk Buying | Buys parts in large amounts to save money. |

These steps help you get great service without overspending. Remember, the cheapest option isn’t always the best. Focus on getting good value.

Customer Service and Communication

Good communication is key when working with a PCB company. You need a team that listens, answers quickly, and keeps you updated.

Surveys show that customer service matters a lot. Scores like CSAT (Customer Satisfaction Score) can tell you how well a company treats its clients. Pick a company that values customer support for a smooth process.

Trust and Reputation

Lastly, check the company’s reputation. A trusted company delivers good products on time. Look for reviews or success stories to see their work. For example:

Project Type | Results Achieved | Benefits Delivered |

|---|---|---|

Smart Electric Meter | 20% cost savings | Solved chip issues, fast delivery |

Three-Phase Electric Meter | 15% cost savings | Met certifications, on-time delivery |

Blood Oxygen Sensor | N/A | Protected design, worked as planned |

These examples show how reliable companies solve problems and deliver great results. A good reputation means they can meet your needs.

By checking these points—skills, quality, cost, service, and trust—you’ll find the best one-stop PCB assembly service for your project.

Benefits of Choosing the Best One-Stop PCB Assembly Service

Easy and Efficient Processes

Picking the best one-stop PCB service makes things easier. You don’t need to manage different suppliers for design, parts, and testing. Everything happens in one place, which saves time and avoids mistakes.

Here’s why simple processes help:

Design, parts buying, and testing happen together, saving time.

Happy customers stay longer, and a 5% rise in loyalty can grow profits by 25%.

Using IPC standards lowers product returns by 30%, showing better workflows.

By keeping things simple, you save time and make sure your PCB projects go smoothly.

Faster Delivery with Shorter Wait Times

Time matters a lot in PCB assembly, especially for quick projects. A one-stop service avoids delays by planning every step carefully. From ordering parts to putting them together, everything is timed to meet deadlines.

Step | What It Means |

|---|---|

Ordering time | How long it takes to order and confirm parts. |

Stock levels | How much inventory is ready for production. |

Assembly timeline | The schedule for building the products. |

Shipping between steps | Time needed to move parts during production. |

Knowing these steps helps find delays and speed up delivery. With faster work, you can launch products quickly and stay ahead.

Saving Money with Smart Solutions

A one-stop PCB service doesn’t just save time—it saves money too. By improving processes and buying in bulk, you get more for your money.

Here’s how costs are cut:

Design for manufacturing (DFM) makes layouts simple and uses fewer parts.

Automated machines work faster and cost less than manual labor.

Buying parts in large amounts lowers the price per piece.

Better workflows and tools stop wasteful spending.

These methods give you great PCB services without spending too much. It’s about getting good quality at a fair price.

Clear Communication and Easy Coordination

Dealing with many suppliers can be confusing and cause mistakes. A one-stop service fixes this problem. You’ll have one contact person who keeps you informed and handles everything.

Good communication means fewer errors and quicker fixes. Companies that focus on customer support often get higher satisfaction scores like CSAT. When your team listens and responds fast, you’ll feel confident in the process.

Simple coordination lets you focus on designing while experts handle the rest. It’s a win-win for your PCB projects.

Why LTPCBA Stands Out as a Leading PCB Assembly Company

Advanced Technology and Automated Systems

LTPCBA uses advanced tools and systems to make great PCBs. Their factory is huge, covering 50,000 square meters, with over 500 workers. Most workers are skilled experts, making sure your projects are done right.

They have top-notch machines like 70 drilling tools, 50 gong machines, and 12 CCD exposure machines. These machines help them create precise and high-quality products. They also use an ERP system to track production live, ensuring steady delivery and good quality.

Feature | Details |

|---|---|

Factory Size | 50,000 square meters with 500+ workers, 68% are experts. |

Advanced Machines | Includes 70 drills, 50 gong machines, and 12 CCD exposure tools. |

Reliable Delivery | ERP system tracks production for stable and timely results. |

Quality Assurance | 36 tests ensure UL, ISO9001, TS16949, and CQC standards are met. |

Production Capability | Handles up to 12 layers, 3.0mm thickness, 8:1 aspect ratio, and 3oz copper thickness. |

Their technology and skilled team ensure your PCB designs are made accurately and efficiently.

Comprehensive Turnkey PCB Assembly Services

LTPCBA offers a full-service PCB assembly process that makes things simple. They handle everything, from getting parts to putting them together, all in one place. This saves you from dealing with many suppliers and keeps your project on schedule.

Their turnkey services work for small prototypes and big production runs. Whether your design is simple or complex, LTPCBA ensures the process is smooth and efficient.

Commitment to Quality and International Standards

Quality is very important to LTPCBA. They follow strict rules like ISO9001, UL, and TS16949 to make sure their products are top-notch. With 36 tests, you can trust their PCBs will work well.

They also use advanced checks like AOI and X-ray to find problems early. This focus on quality means you’ll get products that meet or exceed your expectations.

Quick Response and 24-Hour Technical Support

LTPCBA is quick to help when you need it. They offer 24-hour technical support, so you can always get expert advice. Their quotes are fast too—just 2-3 working days—so your project won’t be delayed.

LTPCBA responds quickly and communicates clearly.

Their 24/7 support ensures you get answers anytime.

Feature | Details |

|---|---|

Quote Response Time | 2-3 working days |

Their fast replies and helpful support make LTPCBA a dependable choice for PCB assembly.

How to Pick the Best One-Stop PCB Assembly Service

Look Up and Compare Companies

Start by searching for PCB assembly companies. Find ones with many services and good experience. Compare their skills, prices, and customer reviews. Make a list of companies that fit your project needs.

Here’s a simple way to compare:

Factor | What It Means | Things to Check |

|---|---|---|

Services Offered | Types of help they provide | Make sure they cover your project. |

Assembly Skills | How good they are at tricky designs | Look for experience with hard layouts. |

Certifications | Proof of quality standards | |

Time Needed | How fast they finish work | Check if their speed fits your plan. |

This table helps you pick the right company for your needs.

Check Reviews and Feedback

Customer reviews tell you a lot about a company. Read what others say about their quality, delivery, and service. Good reviews show the company is reliable and skilled.

If you can, talk to past customers for their opinions. This step helps you choose a company with a strong history of good work.

Ask for Prices and Compare Costs

Getting prices is important. Write down what your project needs, like size, design, and deadlines. Then, ask companies for detailed quotes. Compare their prices, but don’t pick just the cheapest one.

Follow these steps:

Write clear details about your project.

Ask for quotes with all costs included.

Compare offers to find the best value.

Remember, cheap services might cost more later if the quality is bad.

Check Certifications and Skills

Certifications like ISO 9001 and UL show a company cares about quality. Make sure they have these before choosing them. Also, check if they can handle hard designs like BGA or QFN.

Certified companies follow rules that make sure your PCB works well.

Test Communication and Support

Good communication makes working together easier. See how fast a company answers your questions. Do they explain things clearly? Are they helpful with problems?

Companies with great customer service usually do better work. Pick one that listens and solves issues quickly for a smooth process.

Picking the right one-stop PCB assembly service is very important. The right partner helps your project succeed by offering strong skills, good quality checks, and fast work. They also need to be affordable and have expert knowledge.

Factor | Why It Matters |

|---|---|

A company’s ability to handle different techniques affects quality. | |

Quality Checks | Makes sure PCBs are reliable and work as planned. |

Fast Turnaround | Quick delivery helps you stay ahead in a busy market. |

Expert Knowledge | Gives helpful advice and fixes problems during the process. |

Cost-Effectiveness | Good value means balancing price, quality, and long-term benefits. |

Customer Support | Clear and quick communication makes working together easier. |

LTPCBA offers all these advantages and more. Their advanced tools, full-service options, and focus on quality make them a top choice. They also respond quickly and provide 24-hour help to keep your project on schedule.

Start your PCB assembly journey with LTPCBA. Check out their services today and see how they can turn your ideas into reality.

FAQ

What does a one-stop PCB assembly service do?

A one-stop PCB assembly service takes care of everything. They handle design, buying parts, assembly, and testing. This saves you time and effort since you don’t need to deal with many suppliers.

How can I tell if a PCB assembly company is trustworthy?

Look for certifications like ISO or UL. Read customer reviews and check their past work. Trustworthy companies also communicate well and have strong quality checks.

Can I use a one-stop service for small prototype projects?

Yes, you can! Many companies, like LTPCBA, work on small prototypes and big orders. They adjust their services to match what your project needs.

💡 Tip: Always ask for a full quote. This helps you see if the service fits your budget and project needs.

See Also

Choosing the Right PCBA Supplier for Your Requirements

Determining the Best Turnkey PCB Assembly Solution for You

Understanding Full Turn-Key PCB Manufacturing and Its Benefits

The Impact of Quick-Turn PCB Prototypes on Project Efficiency