The basic requirements for PCB boards in SMT production

Meeting the basic requirements for PCB boards keeps quality and efficiency high. Without checks, problems can happen. For example:

Out of six problems studied, four were caused by customer mistakes. This shows why quality checks are important.

Even with good parts, unexpected tech problems occurred. This proves that strict PCB rules are needed to meet basic requirements.

Following rules lowered mistakes and made production faster.

You can achieve better results by improving PCB design, placement, and process steps. These actions cut down errors and help assembly work better.

Key Takeaways

Place components evenly on PCBs to stop bending during soldering. Use IPC rules for balanced designs.

Handle heat well in PCB design. Add thermal vias and heat sinks to cool parts and make them last longer.

Pick the right PCB material and thickness for your project. This changes how it works, lasts, and costs.

Keep enough space to avoid overheating and short circuits. Leave room between high-current paths for safety.

Align and position polarized parts correctly. This lowers assembly mistakes and makes checking easier.

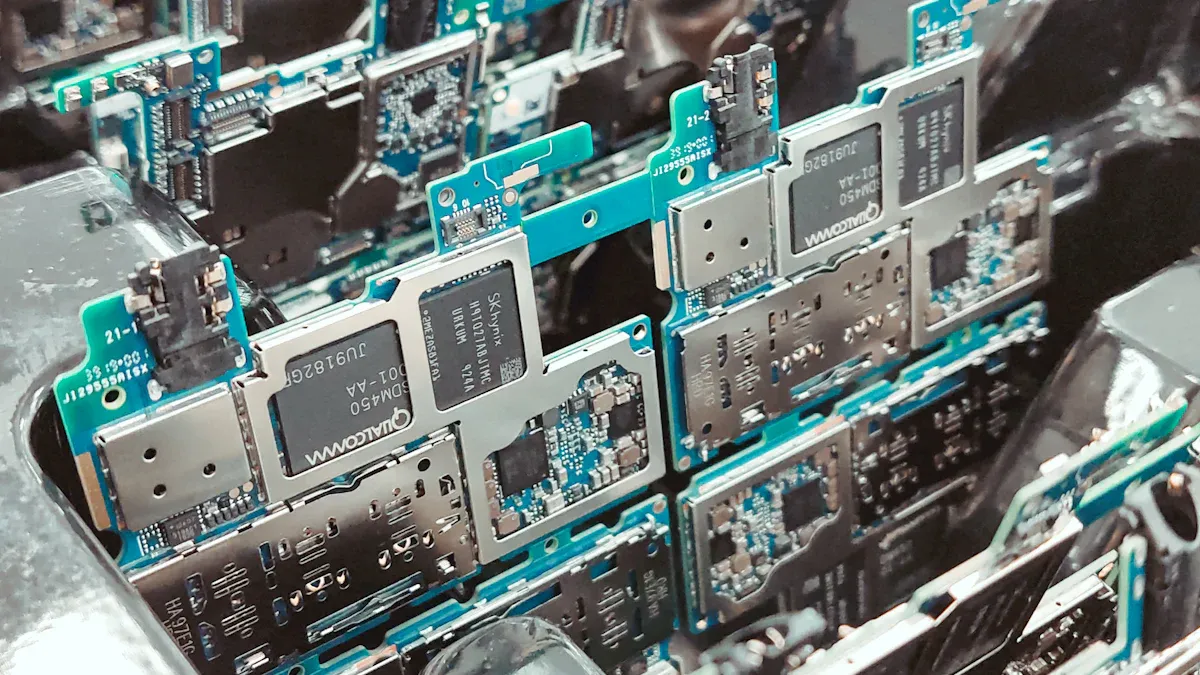

PCB Design Needs for SMT Production

Even Component Placement

Placing parts evenly on the PCB is very important. If parts are grouped in one spot, the board might bend or warp. This is especially true during the reflow soldering process. Avoid putting heavy parts all in one area. Spread out the weight and heat across the board for balance.

To make sure parts are placed evenly, follow rules like IPC-2221. This guide gives general tips for PCB design. Another guide, IPC-7351, helps with spacing and aligning parts correctly. These rules help you create a strong and efficient PCB for SMT production.

Heat Management

Handling heat is a key part of PCB design. Parts can get hot when they work, and too much heat can cause damage. Use copper areas connected to ground planes to spread heat better. This helps keep the board cool.

For boards that use a lot of power, add heat sinks or fans to cool them down. Thermal vias are another good option. They move heat from parts to other layers or heat sinks. Managing heat well keeps your PCB working longer and better.

Soldering-Friendly Layout

The way you arrange parts on the PCB affects soldering. Good spacing and alignment lower the chance of soldering mistakes. For example, placing parts in a grid pattern makes wave soldering easier. This setup avoids shadows and spreads solder evenly.

Workshops like "Mastering Wave Soldering" teach how to improve soldering steps. They also show ways to fix defects and handle lead-free solder. Selective soldering workshops focus on soldering lead-free alloys and process tips. These lessons help you design a PCB layout that works well for soldering.

PCB Material Selection and Thickness

Picking the right PCB material and thickness is very important. It affects how well the board works, lasts, and costs. Knowing the main factors helps your PCB meet modern needs.

Key Factors in Material Selection

When choosing PCB materials, think about their electrical, mechanical, and heat properties. Focus on these key points:

Dielectric Constant (Dk): This shows how well the material holds electrical energy. A steady Dk keeps signals clear, especially in fast circuits.

Dissipation Factor (Df): This measures energy lost as heat. Lower Df means less signal problems, keeping signals strong.

Copper Foil Roughness: Smooth copper helps signals move better and lowers resistance. This is great for high-frequency uses.

FR-4 is a common material because it balances cost and performance. For advanced uses, like communication systems, special materials may be needed. These are tested for signal strength and reliability.

Tip: Match the material to your project’s needs. This avoids problems and keeps production smooth.

Importance of PCB Thickness

PCB thickness affects strength, heat control, and SMT process compatibility. Most boards are 0.8mm to 1.6mm thick. Choose based on these factors:

Component Weight: Thicker boards hold heavy parts better. They don’t bend during soldering.

Thermal Dissipation: Thicker boards spread heat better, protecting delicate parts.

Signal Integrity: Thin boards work better for fast circuits by reducing signal loss.

Think about how the board is made. Thin boards might bend during assembly, causing problems. Thick boards may need changes to soldering settings.

Balancing Cost and Performance

Better materials and thicker boards work well but cost more. Find the right balance. For fast communication, low-Df materials are worth it. For simple designs, FR-4 with medium thickness works fine.

By checking these factors, you can make a PCB that works well for SMT production. This boosts efficiency and keeps the board reliable for a long time.

Component Placement Guidelines in SMT

Arrangement Direction of Components

Placing components correctly helps with smooth assembly and testing. Align parts to match the PCB's design and production needs. For example, keeping parts in the same direction makes automated machines work faster and with fewer mistakes.

Testing methods also affect how parts are arranged. In-circuit testing needs wide test pads, so avoid blocking them with components. Flying probe testing checks the ends of parts and pads to find defects. Coverage analysis shows how much of the circuit can be tested, helping avoid expensive fixes.

Testing Method | What It Does |

|---|---|

In-circuit testing | Needs wide test pads and affects part placement to avoid costly fixes. |

Flying probe testing | Checks ends of parts and pads to find issues. |

Coverage analysis | Measures how much of the circuit can be tested to spot problems. |

Orientation of Similar Components

Grouping similar parts in the same way makes work easier. Polarized parts like diodes and capacitors should face the same direction. This helps reduce mistakes and makes inspections faster. Machines like AOI work better when parts are aligned the same way.

When planning, keep analog circuits away from digital ones to stop interference. Group repeated designs, like resistor networks, to make routing easier. Logical grouping also keeps signals clear and reduces noise.

Tips for Orientation:

Align polarized parts in the same direction.

Keep analog and digital circuits apart.

Group repeated designs for better routing.

Spacing to Prevent Overheating and Short Circuits

Leaving enough space between parts stops overheating and short circuits. Follow spacing rules based on current and power needs. High-current traces need space three to four times their width. Power traces need even more, about four to five times their width.

Trace Type | Recommended Spacing |

|---|---|

High Current | 3x-4x trace width |

Power | 4x-5x trace width |

Good spacing also helps manage heat. High-current traces spread heat better when spaced properly. This keeps nearby traces cool and makes the PCB last longer.

Key Considerations:

Leave enough space for heat to escape.

Give high-current traces room to avoid overheating.

By following these steps, you can place parts better for efficient SMT production and durable PCBs.

Placing Polarized Components and Connectors

Polarized components and connectors need careful placement to work well. Following rules helps avoid mistakes and ensures they function properly.

Why Polarized Components Are Important

Polarized parts like diodes, capacitors, and LEDs must face the right way. If placed wrong, circuits can fail or get damaged. Connectors also need to align correctly to avoid pin mismatches and connection issues.

Tip: Always check polarity marks on the PCB and parts before placing them. This simple check prevents costly assembly mistakes.

Placement Rules

Match Polarity Marks

Line up the positive and negative ends of parts with PCB marks. For example, diodes have a stripe for the cathode, and capacitors show a "+" for the positive side.Add Clear Labels

Use silkscreen labels on the PCB to show part orientation. These labels make assembly faster and easier.Align Connectors Properly

Place connectors to fit their matching parts. Misaligned connectors can cause stress or signal problems.Group Similar Parts

Keep polarized parts together and facing the same way. This makes inspections easier and reduces errors during automated assembly.

Common Problems

Polarized parts might move during soldering. To stop this, use solder paste with the right thickness and design pads that hold parts firmly.

Part Type | Polarity Mark | Placement Help |

|---|---|---|

Diodes | Stripe for cathode | Match stripe to PCB mark |

Capacitors | "+" for positive | Align "+" with PCB label |

LEDs | Flat edge for cathode | Follow silkscreen guide |

By following these steps, you can place polarized parts and connectors correctly. This improves PCB reliability and lowers assembly mistakes.

Process-Specific Basic Requirements in SMT

Reflow Soldering Considerations

Reflow soldering is an important step in SMT production. It helps attach components securely to the PCB. To get good results, control the heat carefully during this process. A proper heat plan reduces soldering mistakes and makes solder joints stronger.

Studies show that temperature control is very important. For example, research suggests keeping peak temperatures between 237.06°C and 237.09°C. This range helps form strong solder connections. Another study shows that managing heat can stop problems like voids or tombstoning. By improving heat settings, you can make your assembly better.

Study Title | Key Findings |

|---|---|

Effective modeling of the reflow soldering process | Best results with peak temperatures of 237.06 to 237.09 °C. |

Thermal parameters optimization of a reflow soldering profile | Shows how heat settings prevent soldering problems. |

Numerical simulation of self-alignment of chip resistor components | Studies how parts align themselves during reflow. |

Optimization of the reflow soldering process | Uses advanced methods to reduce soldering mistakes. |

To improve further, try advanced methods for heat control. Techniques like Response Surface Methodology (RSM) and Hybrid AI Techniques can help. These methods lower errors and give more reliable results.

Optimization Method | Description |

|---|---|

Response Surface Methodology | Traditional way to improve heat settings. |

Nonlinear Programming | Uses math for precise heat control. |

Hybrid AI Technique | Combines AI with other methods for better results. |

By focusing on these steps, you can meet the basic needs for good SMT production.

PCB Entry Direction and Alignment

The way PCBs enter and align affects SMT assembly. Proper alignment lowers stress on parts and helps machines work better. Align parts, especially polarized ones, in the same direction. This makes assembly easier and reduces mistakes.

Spacing is also very important. For surface-mounted devices (SMDs), leave at least 125 mils of space from the board edge. This prevents stress on solder joints when cutting the board. Follow IPC standards like IPC-A-600 and IPC/WHMA-A-620C to meet quality rules.

Key Guidelines for PCB Entry and Alignment:

Align polarized parts in the same direction.

Keep 125-mil space for SMDs near the edge.

Use IPC standards for better quality.

Good alignment and spacing make assembly smoother and PCBs last longer.

Synchronization of Heating Ends

In SMT, even heating is key for good soldering. Uneven heat can cause problems like warping or bad solder joints. To avoid this, make sure all parts of the PCB heat evenly during reflow.

Studies show why even heating matters. For example, simulations of chip resistors show how parts align when heat is spread evenly. This helps parts settle correctly during soldering. Using methods like the grey-based Taguchi approach can also improve heating balance.

Study Title | Simulation Focus |

|---|---|

Numerical simulation of self-alignment of chip resistor components | Shows how melted solder aligns parts during reflow. |

Optimization of the reflow soldering process | Focuses on reducing defects with better heat settings. |

To ensure even heating, check the heat zones in your reflow oven. Make sure preheating, soaking, and reflow stages are set correctly. Advanced ovens with accurate heat controls can help keep the PCB evenly heated.

By balancing heating ends, you can lower defects and improve SMT assembly quality.

Handling Large-Size PCBs in SMT Production

Working with large PCBs in SMT production can be tricky. These boards need extra care for proper alignment, soldering, and assembly. Knowing their specific needs helps you improve production and avoid problems.

Challenges of Large-Size PCBs

Big PCBs have issues that smaller ones don’t. Here are some common problems:

Warping and Bending: Large PCBs can bend during reflow soldering. This may cause parts to shift or solder joints to fail.

Uneven Heating: Standard ovens may not heat large boards evenly. This can lead to defects like tombstoning or poor solder coverage.

Handling and Transportation: Moving large boards carefully is important. Rough handling can damage or misalign them.

Longer Trace Lengths: Longer traces on big PCBs can weaken signals, especially in high-frequency uses.

Tip: Spotting these problems early helps you fix them and improve quality.

Best Practices for Handling Large PCBs

To solve these issues, follow these tips for large PCBs:

Use Support Fixtures

Fixtures keep the PCB flat during reflow. This stops bending and ensures good soldering.Optimize Reflow Profiles

Adjust oven settings for large boards. A longer preheat stage spreads heat evenly.Choose the Right Conveyor System

Use conveyors made for large PCBs. They provide support and prevent damage during movement.Implement Thermal Management Solutions

Add heat sinks and thermal vias to control heat. This protects the board from overheating.Conduct Rigorous Testing

Test for heat and vibration resistance. This ensures the board can handle stress.

Tools and Equipment for Large PCBs

Using proper tools is key for large PCBs. Here’s a helpful table:

Tool/Equipment | Purpose |

|---|---|

Support Fixtures | Stops bending during reflow soldering |

Wide Reflow Ovens | Heats large boards evenly |

Specialized Conveyors | Moves large PCBs safely |

Thermal Cameras | Checks heat spread during soldering |

Automated Optical Inspection (AOI) | Finds defects in large PCBs |

Note: Good tools lower mistakes and make production smoother.

Key Considerations for Large PCBs

When working with large PCBs, remember these points:

Material Selection: Pick materials that don’t expand much with heat to avoid bending.

Component Placement: Spread parts evenly to balance weight and heat.

Design for Manufacturability (DFM): Work with your PCB maker to design for easy production.

By following these steps, you can handle large PCBs well and keep quality high in SMT production.

Common Challenges and Solutions in SMT Production

Stopping Short Circuits

Short circuits can harm your PCB and stop it from working. To avoid them, use tests and checks to find problems early.

Inspection Method | What It Finds |

|---|---|

Finds open or short circuits and performance issues. | |

Optical Inspection | Spots corrosion, bad solder joints, shorts, opens, and surface damage. |

Microsection Analysis | Checks lamination, plating issues, and via strength. |

Contamination Testing | Looks for dirt or contaminants on the board. |

X-ray Inspection | Examines hidden issues and BGA problems. |

Follow these steps to keep your PCB reliable:

Confirm the problem and write it down.

Start with non-destructive tests like X-rays or thermal scans.

Pinpoint where and what the issue is.

If needed, cut into the board for deeper analysis.

Use the data to find the main cause of the problem.

Fix the issue and prevent it from happening again.

Tip: Regular testing during production helps catch short circuits early and saves money.

Fixing Poor Solder Coverage

Weak solder coverage makes connections unreliable. Solve this by improving soldering steps and using better inspection tools.

Inspection Method | What It Does |

|---|---|

Uses magnifiers to spot common solder problems. | |

Automated Optical Inspection | Quickly finds solder issues with programmed systems. |

X-ray Inspection | Checks hidden joints and measures solder quality. |

Electrical Testing | Tests connections to ensure everything works well. |

Change stencil openings based on copper thickness and surface type. Add more solder paste for parts without leads to avoid weak soldering. These changes improve solder coverage and lower defects.

Note: Train workers to use inspection tools properly for better results.

Solving Tombstoning Problems

Tombstoning happens when parts lift during soldering, causing bad connections. Fix this by balancing heat and applying solder paste correctly.

Uneven solder paste and bridging during heating are common causes. Adjust stencils to improve paste flow and stop bridging. Use heat profiles that warm the PCB evenly to reduce tombstoning.

Tip: Use advanced ovens with accurate heat control for better soldering and fewer tombstoning issues.

By solving these problems, you can make your SMT production process better and more reliable.

Handling PCB Warping or Bending

PCB warping or bending can harm how your board works. Fixing this problem means knowing what causes it and using smart solutions during design and production.

Causes of PCB Warping

Certain design and production choices can make PCBs bend. Avoid these to keep your board strong:

Cause of Warping | What Happens |

|---|---|

Uneven Structure | Uneven designs can make boards bend. |

Compression Type | Direct compression structures bend more than copper foil ones. |

Copper Frame Design | Solid copper frames cause more stress than broken-up ones. |

Pressing Settings | |

Uneven Layers | Uneven layers expand differently, causing bends. |

Ways to Stop PCB Warping

You can reduce bending by using these methods during and after production:

How to Stop Warping | What It Does |

|---|---|

Stress Relief After Lamination | Releases stress after layers are pressed together. |

Careful Handling | Gentle handling stops permanent bending. |

Smart Design Choices | Fix bending problems early in the design stage. |

Flattening Plates | Use pressure to fix small bends after production. |

Control Environment | Keep conditions steady to avoid bending during use. |

Checking PCB Warping

Measuring bending helps you find and fix problems. Follow these steps:

Get PCB Ready: Hold it still for accurate checks.

Pick a Method: Choose the right tool for your needs.

Feeler Gauge: Measure gaps to find bending.

Height Gauge: Compare heights to spot uneven areas.

Optical Profilometer: Scan the surface for bending shapes.

Stress Simulation: Use software to find bending zones.

Write Down Results: Compare data with design rules.

Calculate Warping: Turn bending into percentages.

Check Many Spots: Test different areas for better data.

Repeat Tests: Do checks again to confirm results.

By fixing bending early and handling boards carefully, you can make your PCB last longer and work better.

Why Pick LTPCBA for SMT Production Needs

Modern Technology and Quality Focus

LTPCBA uses advanced tools to meet today’s SMT needs. Their systems ensure accurate and reliable assembly. Features like self-aligning parts during reflow soldering reduce mistakes and boost efficiency. They also handle complex designs with high interconnect density, making them great for detailed projects.

Another benefit is saving money. LTPCBA offers lower assembly costs than older SMT methods. This helps you cut expenses without losing quality. These features make LTPCBA a trusted choice for SMT production.

Benefit | Details |

|---|---|

Lower assembly cost | Cheaper than older SMT methods. |

Self-aligning during reflow | Helps parts align correctly during soldering. |

High interconnect density | Handles complex designs for modern SMT needs. |

Skilled in SMT Assembly

LTPCBA’s knowledge of SMT processes ensures smooth production. They are experts in fast prototyping, delivering test PCBs in just 24 hours. This quick service helps you test ideas and start production faster.

They also deliver on time. With a 99% on-time shipping rate, LTPCBA is dependable for meeting deadlines. Their focus on research and development keeps improving their tools and methods, ensuring better results over time.

Feature | Details |

|---|---|

Fast Prototyping | Test PCBs ready in just 24 hours. |

On-time Delivery Rate | 99% of orders shipped on time. |

Research and Development | Constantly improving tools and processes. |

Customer-Focused Services

LTPCBA puts customers first by offering custom services and strong support. They fulfill 90% to 95% of orders, with top performers reaching 98%. Scrap rates stay below 5%, keeping waste and costs low.

Their First Pass Yield (FPY) rates are high, between 95% and 98%, showing their focus on quality. On-time delivery and customer satisfaction scores also prove their dedication to meeting your needs. These numbers highlight LTPCBA’s commitment to great service throughout production.

Metric | Range |

|---|---|

Order Fulfillment Rate | |

Scrap Rate | Below 5% (as low as 2%). |

First Pass Yield (FPY) | 95% to 98%. |

On-Time Delivery Rate | 90% to 95% (Top performers > 98%). |

Customer Satisfaction Score | 70% to 90% (Excellent > 80%). |

Commitment to International Standards

Following international standards helps your PCB assembly meet global quality levels. These rules ensure reliability, safety, and performance, which are very important in SMT production. At LTPCBA, they stick to these standards, making sure your products meet top-quality expectations.

Key International Standards in PCB Assembly

Here are some key standards that guide PCB manufacturing and assembly:

ISO 9001: Focuses on managing quality to keep products consistent.

IATF 16949: Made for the car industry, ensuring reliable electronics.

UL Certification: Confirms the safety of materials used in PCBs.

IPC Standards: Covers PCB design, assembly, and checks, like IPC-A-610 for soldering.

Tip: Learn these standards to make sure your designs meet global rules.

Why International Standards Matter

Following these standards has many benefits:

Global Use: Products made to these standards work worldwide without changes.

Better Reliability: Standards help PCBs work well in different conditions.

Customer Confidence: Certifications show your focus on quality, building trust.

Legal Compliance: Standards help meet laws and industry rules.

Standard | Focus Area | Benefit |

|---|---|---|

ISO 9001 | Quality Management | Consistent product quality |

IATF 16949 | Automotive Electronics | High reliability |

UL Certification | Material Safety | Safe and durable materials |

IPC Standards | PCB Design and Assembly | Improved manufacturing quality |

By working with LTPCBA, you partner with a company that values these standards. This ensures your PCBs meet global needs, improving both quality and market reach.

Following PCB design, placement, and process rules is very important. These steps help lower mistakes, save time, and make boards last longer. For example, Motorola found solder paste problems dropped by 43% after fixing stencil data. Another case showed tombstoning issues fell by 60% with better part placement. These examples show why meeting basic rules at every step matters.

Working with LTPCBA gives you access to modern tools and expert help. They focus on quality and efficiency, making them a reliable choice for your SMT production needs.

FAQ

What is the best thickness for a PCB in SMT?

PCB thickness should be between 0.8mm and 1.6mm. Thicker boards hold heavy parts and spread heat well. Thin boards are good for fast circuits but might bend. Pick the thickness based on your design and use.

How can PCB warping be avoided in SMT?

To stop warping, use supports during soldering. Choose materials that don’t expand much with heat. Spread parts evenly on the board. Adjust oven heat settings for even heating. These steps keep the board strong.

Why does spacing matter in SMT?

Spacing stops overheating and short circuits. High-current traces need space three to four times their width. Power traces need even more space. Good spacing spreads heat and keeps the PCB working well.

What are polarized parts, and why is their placement important?

Polarized parts, like diodes and capacitors, must face the right way. Wrong placement can break circuits or cause damage. Match the PCB’s polarity marks with the parts. This ensures they work correctly and lowers mistakes.

How does LTPCBA make SMT production better?

LTPCBA uses modern tools and strict quality checks. They follow rules like ISO and IPC standards. Their machines and skilled workers ensure accurate assembly. With a 99.5% success rate, LTPCBA makes reliable PCBs.

See Also

Effective Strategies for Enhancing SMT Line Efficiency in PCBA

Understanding SMT and DIP Assembly for PCBA Uses

Essential Tips for Quality Control in Solder Paste Printing

Impact of Solder Paste Quality on SMT PCB Soldering

Importance of SPI Inspection Following Solder Paste Printing in PCBA