Automated Through Hole Assembly What You Need to Know

Automated through hole assembly utilizes advanced machines to efficiently place and solder through-hole components in electronic devices. This method results in faster production and enhanced reliability when compared to manual assembly. Automated systems significantly improve electronics manufacturing by minimizing errors and accelerating the assembly process. Through-hole techniques continue to play a crucial role in creating durable electronics that can withstand demanding environments.

Key Takeaways

Automated through hole assembly speeds up production and reduces errors, leading to higher quality electronics.

This method is ideal for components needing strong connections, making it perfect for demanding environments like aerospace and military applications.

Choosing a reliable provider like LTPCBA ensures strict quality control and technical support, enhancing your assembly process.

Automated Through Hole Assembly Overview

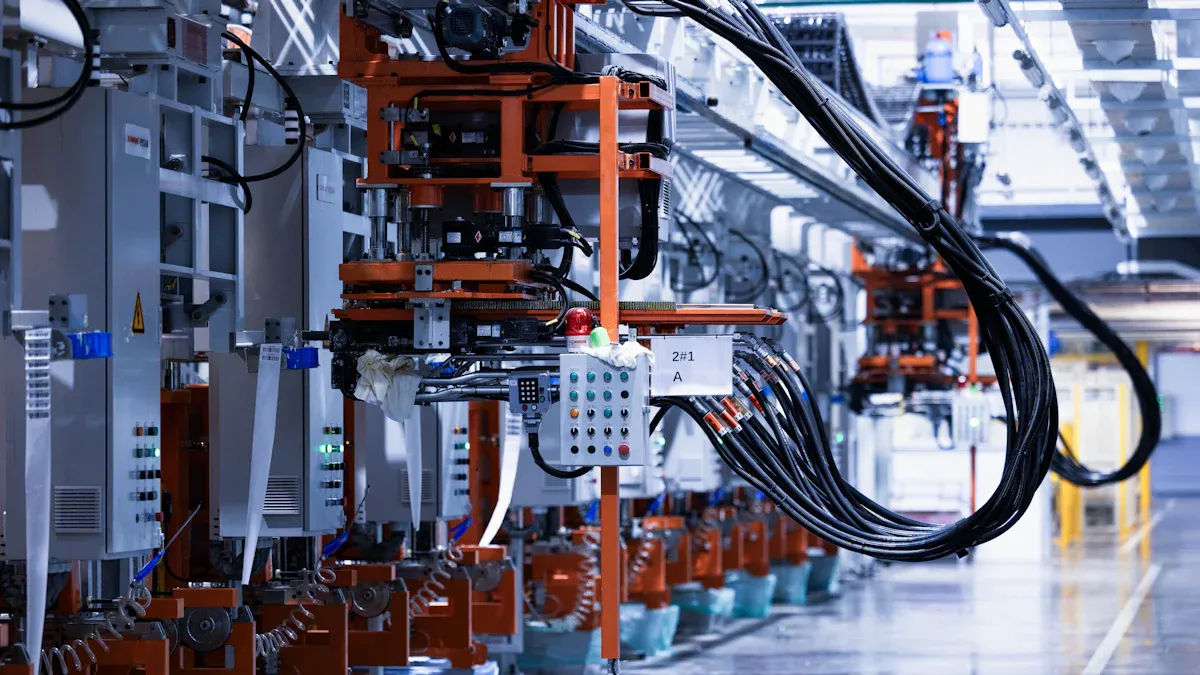

What Is Automated Through Hole Assembly

Automated through hole assembly uses machines to place and solder components with leads into holes on printed circuit boards. You see this method in many electronics that need strong connections and high reliability. Through-hole assembly stands out because it handles components that must pass through the board, unlike surface mount technology. When you choose automated through hole assembly, you get a process that reduces human error and speeds up production.

You find through-hole assembly in products that face tough conditions, such as industrial controls and power supplies. Automation makes the process consistent and repeatable. You rely on automated systems to handle large volumes and complex designs. These systems use precise placement and soldering techniques to ensure quality connections. You benefit from fewer defects and better performance in your electronics.

Manual through-hole assembly requires skilled workers to insert and solder each component by hand. This method takes more time and can lead to mistakes. Automated through hole assembly replaces manual labor with machines that work faster and more accurately. You get higher quality and lower costs when you automate the process.

LTPCBA offers automated through hole assembly with advanced technology and strict quality standards. You can trust LTPCBA to deliver reliable pcb assembly for your electronics projects. The company uses automated inspection and follows international standards to guarantee quality. You receive support from a team that values innovation and customer satisfaction.

Tip: If you want strong and reliable connections in your printed circuit boards, automated through hole assembly gives you the best results.

How It Works

Automated through hole assembly starts with preparing the pcb and gathering all the through-hole components. You load the components into machines designed for precise insertion. These machines place each lead into the correct hole on the board. Automation ensures that every part fits perfectly and follows the design.

After insertion, the assembly moves to the soldering stage. Automated soldering machines heat the leads and apply solder to create secure electrical connections. You see wave soldering and selective soldering used for different types of boards. Automation controls the temperature and timing, which helps maintain quality and prevents damage to the electronics.

Quality checks happen throughout the process. Automated inspection systems scan the assembly for errors, such as misplaced components or poor solder joints. You get reports that show the results of each inspection. LTPCBA uses automated optical inspection and other advanced tools to keep quality high.

You benefit from automating through-hole assembly because it saves time and reduces costs. The process supports both small and large production runs. You can scale your electronics manufacturing without sacrificing quality. LTPCBA provides quick response and technical support, so you always have help when you need it.

Note: Automation in through-hole assembly helps you meet strict industry standards and deliver reliable electronics to your customers.

Key Technologies in Through-Hole Assembly

Through-Hole Component Insertion Machines

You rely on through-hole component insertion machines to achieve precision in robotic through-hole assembly. These machines pick up components and place them into the pcb with accuracy. Robotic arms handle each through-hole part, making sure every lead fits into the correct hole. Automated systems use sensors and cameras to guide placement, which reduces errors. You see these machines work quickly, handling large batches of printed circuit boards. Through-hole assembly benefits from robotic technology because it increases speed and consistency. You notice that robotic through-hole assembly supports both simple and complex pcb designs.

Soldering Methods

You use soldering to create strong electrical connections in through-hole assembly. Automated systems perform wave soldering and selective soldering, depending on the pcb requirements. Robotic through-hole assembly ensures that solder flows evenly around each lead. You get reliable joints that withstand stress and vibration. Through-hole component insertion machines work with soldering equipment to maintain precision. You see automated systems control temperature and timing, which protects sensitive components. Soldering in robotic through-hole assembly gives you durable results for demanding environments.

Inspection and Testing

You trust quality control to verify every step in through-hole assembly. LTPCBA uses automated systems like AOI to inspect solder joints and component placement. You benefit from robotic inspection that catches defects early. The company follows strict standards, including ISO, IATF, and UL, to ensure reliable pcb production. You see multiple testing methods used for quality control:

Testing Method | Quality Metrics / Benchmarks |

|---|---|

In-Circuit Testing (ICT) | Detects up to 90% of defects, covers 90% of faults, identifies ~30% of common PCB issues |

Functional Testing | Verifies repeatability, reliability, traceability, and enables continuous monitoring |

Automated Optical Inspection (AOI) | 100% accuracy, 18% fewer false alarms, early defect detection |

X-ray Inspection | Uncovers hidden solder defects via 2D/3D analysis |

Burn-In Testing | Ensures long-term performance under harsh conditions |

You gain confidence in your through-hole assembly when you choose LTPCBA. Automated systems and robotic technology deliver precision and quality control at every stage.

Benefits and Considerations of Automating Through-Hole Assembly

Advantages for Production

You gain many advantages when you choose automated through hole assembly for your electronics projects. Automation increases efficiency by speeding up the assembly process. Machines insert and solder components faster than manual labor. You see fewer mistakes because automated systems follow precise instructions. This leads to higher reliability in your finished products.

Automating through-hole assembly gives you strong and steady connections. Machines control soldering temperature and timing, which improves soldering quality. You get secure soldering that holds up under stress. Automated through hole assembly also supports high durability, making your electronics last longer in tough environments.

You benefit from consistent quality checks during every stage of assembly. Automated inspection systems catch errors early. This reduces the risk of defects and ensures your pcb production meets strict standards. You can trust the reliability of your electronics when you use automated through hole assembly.

Tip: Automation helps you handle large production runs without sacrificing quality or reliability.

Typical Applications

You find automated through hole assembly in many areas of the electronics industry. This method works best for components that need strong and steady connections. Common applications include:

Connectors that require secure attachment

Semi-conductors that need precise placement

Electrolytic capacitors for power management

Aerospace and military electronics, where reliability and durability are critical

You often see through-hole assembly used in products that must withstand vibration, heat, or other harsh conditions. Automation ensures these electronics meet high standards for reliability and performance.

Choosing a Provider Like LTPCBA

You want a provider that supports your needs at every step of the assembly process. LTPCBA offers automated through hole assembly with advanced technology and strict quality control. The company responds quickly to your requests and provides technical support around the clock. You receive quotations within 2-3 working days, which helps you plan your projects with confidence.

LTPCBA uses automated systems for both component insertion and soldering. The company follows international standards such as ISO, IATF, and UL. You benefit from flexible production options, whether you need a prototype or a mid-volume run. LTPCBA’s focus on quality and customer satisfaction ensures your electronics meet the highest standards for reliability.

Note: When you choose LTPCBA, you get a partner committed to quality, efficiency, and on-time delivery.

Comparison with Surface Mount Technology

You may wonder how automated through hole assembly compares to surface mount technology (SMT). Both methods play important roles in electronics manufacturing. Through-hole assembly uses components with leads that pass through holes in the pcb. SMT places components directly onto the surface of the board.

Through-hole assembly provides strong and steady connections, which are ideal for components that handle high power or mechanical stress. SMT offers higher density and is better for small, lightweight components. You often use through-hole assembly for connectors, transformers, and parts that require high durability. SMT works well for compact devices and high-speed production.

Feature | Through-Hole Assembly | Surface Mount Technology (SMT) |

|---|---|---|

Component Placement | Leads go through pcb holes | Components sit on pcb surface |

Connection Strength | Strong and steady connections | Moderate |

Best For | Large, high-power parts | Small, dense layouts |

Automation | Yes | Yes |

Soldering | Wave/selective soldering | Reflow soldering |

You can combine both methods in one pcb to get the benefits of each. Automated through hole assembly gives you reliability and secure soldering for demanding applications, while SMT offers speed and compact design.

You see automated through hole assembly improve manufacturing speed and quality. Automation reduces errors and boosts reliability in assembly. When you consider automating through-hole assembly, you gain strong connections and consistent results. You should evaluate your assembly needs and focus on quality. LTPCBA supports automation in manufacturing and offers expert assembly solutions. Reach out for guidance on automating through-hole assembly and enhancing your quality.

FAQ

What makes through-hole assembly important for electronics?

You get strong connections with through-hole assembly. This method helps your devices handle stress, vibration, and heat. You see better reliability in demanding environments.

How does automated through-hole assembly improve quality?

You benefit from precise placement and consistent soldering in through-hole assembly. Automated systems reduce errors and ensure every component meets strict quality standards.

Can you use through-hole assembly for prototypes and large batches?

You can use through-hole assembly for both prototypes and mid-volume production. Automated machines support flexible batch sizes and help you scale your manufacturing.

Tip: You should choose through-hole assembly when you need durability and secure connections in your electronics.

See Also

Ultimate Resource for Understanding Through Hole PCB Assembly

Comparing SMT and Through-Hole Assembly for Your Electronics Needs

Expert Tips for DIP Assembly and Through-Hole Precision

In-Depth Guide to DIP Cable and Through-Hole Connections

Selecting the Best Through Hole PCB Assembly for Industrial Use