Assembly SMT Best Practices for High-Quality Electronic Manufacturing

You achieve high-quality electronic manufacturing when you follow assembly smt best practices at every smt stage. These best practices help you reduce defects and improve reliability in surface mount technology. LTPCBA leads the industry with advanced smt solutions. Trust their best practice guide to raise your smt assembly standards.

Key Takeaways

Follow proven SMT assembly principles like precise process control, staff training, and continuous automation to reduce defects and improve product reliability.

Use advanced inspection methods such as automated optical inspection and X-ray to catch defects early and ensure high-quality solder joints.

Partner with experienced providers like LTPCBA who combine cutting-edge technology, strict quality standards, and thorough operator training to deliver consistent, reliable PCB assemblies.

Assembly SMT Best Practices

Key Principles

You achieve reliable results in smt pcb assembly when you follow proven principles at every step. These principles guide you to reduce defects, improve efficiency, and deliver high-quality outcomes in surface mount technology.

Calculate your return on investment before you invest in smt equipment. High initial setup costs require careful planning.

Train your staff to handle fragile smt components. Proper handling prevents damage and ensures consistent results.

Control your process precisely. Pay close attention to solder paste application, component placement, and reflow profiles. This control helps you avoid common defects in smt pcb assembly.

Use automation and optimize your process continuously. Automation reduces human error and increases consistency in surface mount technology.

Follow industry standards and review your process regularly. This practice ensures your pcb assembly remains reliable and scalable.

Invest in quality control and inspection technologies. Early detection of defects supports process improvement and reduces costs.

Tip: Consistency in component orientation and spacing makes inspection and rework easier. Use standard components and pad designs to build a reliable process database.

A case study from a leading electronics manufacturer shows how assembly smt best practices can reduce failure rates. The company used advanced data analysis to trace soldering defects. They found that 53% of defects came from stencil printing, 17% from component placement, and 30% from reflow and raw materials. By focusing on precise component placement and controlled reflow profiles, they improved yield and reduced costs. Integrating process parameters across all smt steps proved more effective than optimizing single steps alone.

You should also design your smt pcb assembly for testability. Add test points early in the design to enable effective in-circuit testing and repair. This approach supports optimal performance and long-term reliability.

LTPCBA Quality Focus

When you choose LTPCBA for your smt pcb assembly, you benefit from a company that leads with quality and innovation. LTPCBA holds internationally recognized certifications, including ISO 9001 and IATF 16929. These certifications confirm their commitment to strict quality systems in pcb assembly.

LTPCBA uses advanced testing methods such as Flying probe testing, AOI, X-ray inspection, In-circuit testing, and Functional testing. These methods ensure your boards meet the highest standards in surface mount technology. Clients report that LTPCBA delivers high-quality boards with negligible reject rates and zero major defects.

You gain access to state-of-the-art manufacturing equipment at LTPCBA. Automated solder paste printers with SPI provide ultra-fine pitch accuracy. Ten-zone reflow ovens offer precise temperature control. Yamaha pick-and-place machines deliver high placement speed and accuracy. AI vision systems and flying probe technology support first article inspection. SMT X-ray inspection systems detect internal solder joint defects that other methods might miss.

LTPCBA’s focus on assembly smt best practices ensures you receive consistent, high-quality results. Their process optimization and quality assurance help you achieve reliable smt pcb assembly every time.

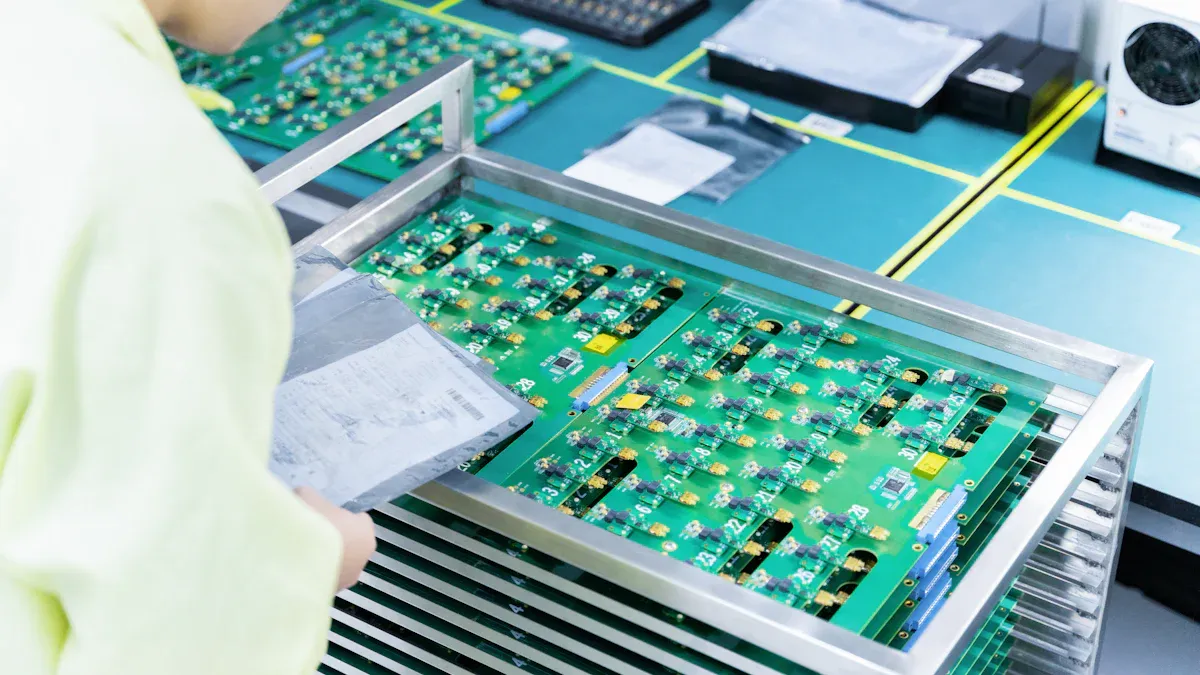

SMT PCB Assembly Process

The smt pcb assembly process forms the backbone of modern electronics manufacturing. You rely on a series of precise, automated steps to achieve high-quality results. LTPCBA uses advanced technology and strict quality assurance at every stage. This approach ensures your pcb assembly meets international standards and delivers consistent performance.

Solder Paste Printing

Solder paste printing is the first critical step in smt pcb assembly. You apply solder paste to the pads on your printed circuit board using a stencil. This process sets the foundation for strong component adhesion and reliable solder joints.

LTPCBA uses automated stencil printers with 3D Solder Paste Inspection (SPI). These systems measure solder paste volume and alignment with high accuracy. SPI detects defects early, allowing you to correct issues before they affect yield. Research shows that controlling solder paste volume, height, and alignment prevents defects like bridging and skipping. You achieve better print quality and higher first-pass yields by optimizing squeegee pressure and table speed.

Note: The addition of silver in solder paste alloys improves wetting and tensile strength, making your solder joints more reliable.

A table below highlights LTPCBA's technology in this step:

SMT Assembly Step | Description | Performance / Accuracy |

|---|---|---|

Solder Paste Application | Uses stencil printing to apply solder paste precisely on PCB pads, critical for welding quality and yield (aiming for 95% first pass yield) | High precision paste thickness control to reduce defects |

You benefit from LTPCBA's focus on quality metrics and real-time monitoring. This ensures your smt pcb assembly starts with a solid foundation.

Component Placement

Component placement is the next vital step in smt pcb assembly. You use automated pick-and-place machines to position components on the solder-pasted board. LTPCBA employs high-speed machines capable of placing up to 35,000 parts per hour with 99.95% accuracy. These machines use advanced vision systems to align each component perfectly.

Modern smt pcb assembly relies on multi-head gantry systems, smart nozzles, and real-time image processing. These features improve placement precision and reduce human error. Software optimizations, such as dynamic path planning and machine learning, further enhance accuracy and production speed.

Automated component placement reduces labor costs and increases consistency.

Smaller smt components allow for higher circuit densities and more compact devices.

AI-driven systems optimize placement sequences and detect potential defects instantly.

SMT Assembly Step | Description | Performance / Accuracy |

|---|---|---|

Component Placement | High-precision pick-and-place machines place components with up to 35,000 parts per hour and 99.95% accuracy | Extremely low error rates (e.g., <1000 ppm for small parts) |

You gain the advantage of LTPCBA's automated systems, which support miniaturization and high-density integration. This step ensures your pcb assembly meets the demands of modern electronics.

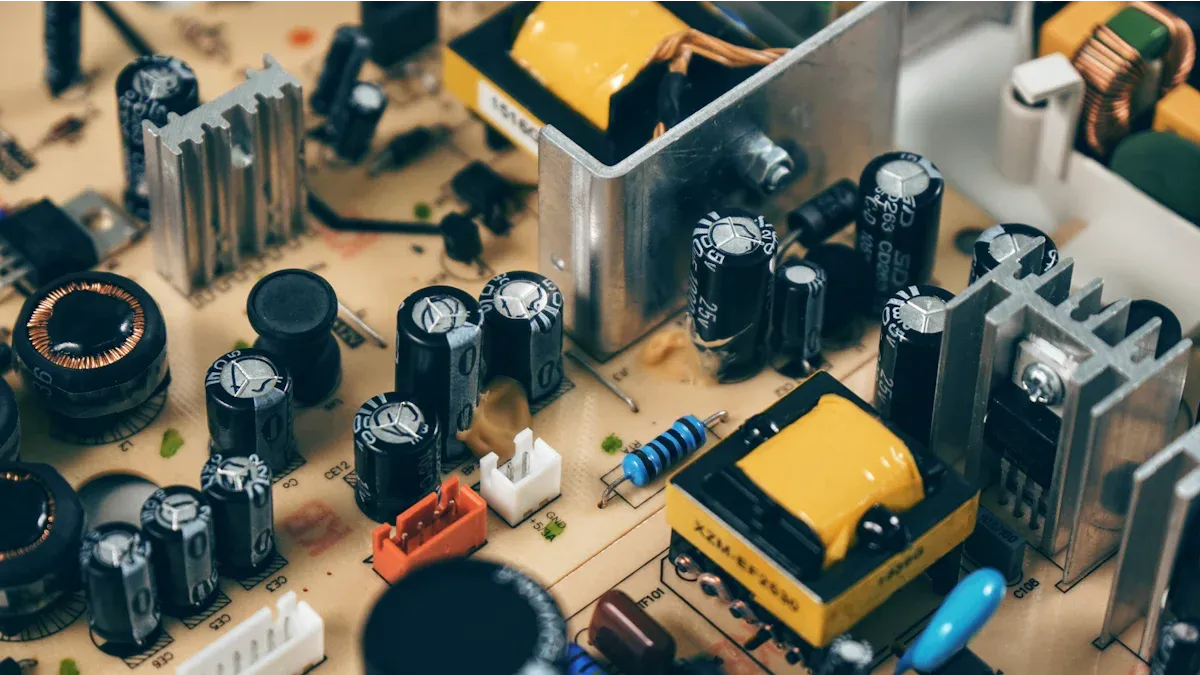

Reflow Soldering

Reflow soldering finalizes the smt pcb assembly process. You heat the entire board in a controlled oven, causing the solder paste to melt and form strong joints. LTPCBA uses automated reflow ovens with precise temperature control. These ovens reduce the risk of cold joints and overheating.

Manufacturers collect real-time data from temperature sensors and use machine learning to optimize oven profiles. This approach increases product yield and reduces energy consumption. After three months of optimization, one manufacturer saw an 8% increase in yield and a 5% drop in energy use.

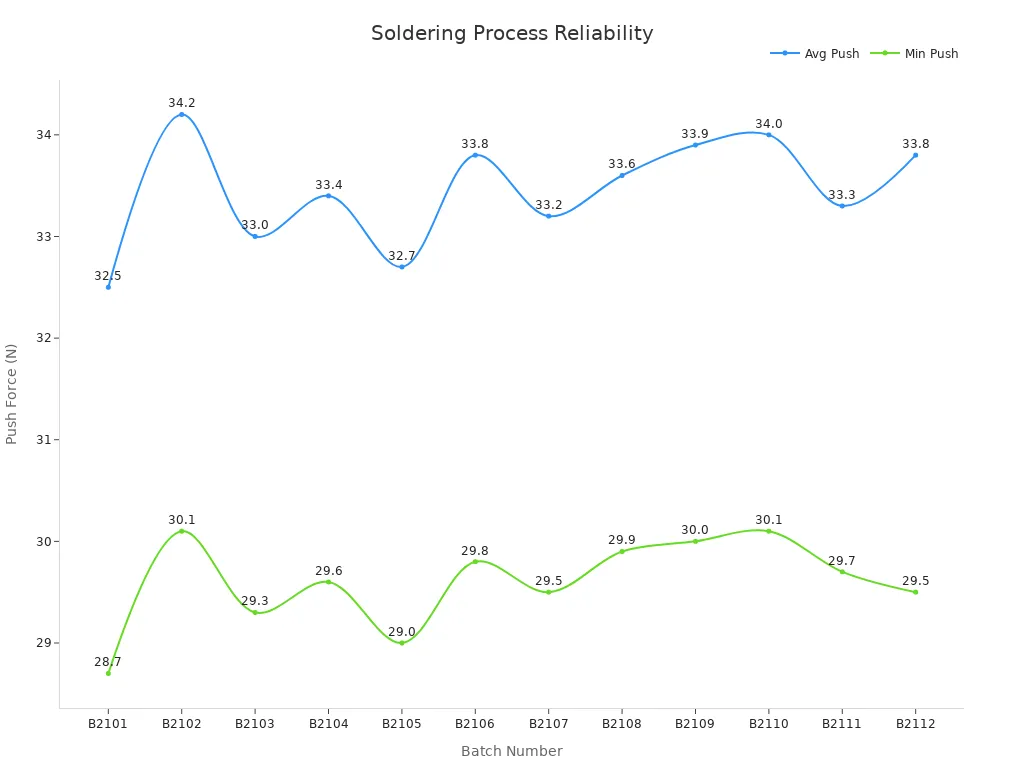

You can see the reliability of reflow soldering in the chart below. All tested solder joints exceeded IPC-A-610G standards for mechanical strength.

Automated inspection methods, such as AOI and X-ray, check for defects after reflow soldering.

Stronger solder joints resist vibration and temperature changes, improving reliability.

LTPCBA's process ensures your pcb assembly meets strict quality standards.

Tip: Automated reflow soldering supports higher operating frequencies and better thermal management, making it ideal for high-performance applications.

You benefit from LTPCBA's commitment to quality and innovation at every stage of smt pcb assembly. Their advanced technology and automated systems deliver reliable, high-quality results for your projects.

Inspection and Quality Control

AOI and X-Ray

You rely on advanced inspection tools to ensure smt quality. Automated optical inspection uses high-resolution cameras and AI algorithms to detect misaligned components, solder bridges, and missing parts. This method can achieve up to 99% inspection accuracy and reduce manual review by 96%. You catch defects early in the smt process, which prevents costly rework.

X-ray inspection allows you to see hidden solder joints under components like BGAs. You identify voids, bridging, or misalignments that are invisible to the naked eye. Both automated optical inspection and x-ray inspection require regular calibration to maintain accuracy. These tools help you meet international standards such as ISO 9001 and AS 9100, which set the benchmark for smt quality.

Tip: Use both AOI and x-ray inspection at different stages to maximize defect detection and improve product reliability.

Manual Checks

You still need manual checks in smt assembly, even with advanced automation. Trained inspectors perform visual inspections after soldering to spot misalignments, poor solder joints, or missing components. Manual checks also verify finished products before shipment, ensuring they meet customer requirements.

Manual inspection accuracy ranges from 70% to 85%. Human error can account for up to 80% of manufacturing defects. Fatigue and limited speed mean manual checks handle fewer items per hour and may miss subtle defects. However, you benefit from manual checks at key points, such as incoming quality control and final product verification. This staged approach helps you minimize defects and maintain high smt standards.

LTPCBA Quality Assurance

You gain confidence in your smt assembly when you work with LTPCBA. The company combines automated optical inspection, x-ray inspection, and manual checks to deliver thorough quality control. LTPCBA follows strict international standards and uses statistical analysis, such as control charts and process capability studies, to monitor process stability.

You benefit from process traceability and detailed documentation at every smt stage. LTPCBA’s technicians receive IPC solder training, which helps prevent common soldering defects. The company’s commitment to continuous improvement and rigorous inspection ensures your smt products meet the highest quality benchmarks.

SMT Design and Panelization

PCB Assembly Layout

You set the foundation for high-quality smt by focusing on your pcb assembly layout. Place critical components, such as microcontrollers and power systems, first. This approach improves signal integrity and thermal management. Group related components together to reduce wiring complexity and tool travel distance. Use short, straight traces with consistent width to minimize electromagnetic interference. Align all components in the same direction to speed up smt assembly and inspection. Standardize footprints and silkscreen markings for easy identification and fewer errors. Maintain adequate clearance around each component for tool access and rework.

Tip: Collaborate with your manufacturing team early. This step helps you avoid design issues and ensures your pcb assembly meets smt production standards.

Panel Design Tips

Effective panelization boosts smt efficiency and reduces waste. Optimize panel size based on your manufacturer’s capabilities and production volume. Include fiducial markers and tooling holes for precise alignment during automated smt assembly. Maintain proper spacing for V-scoring or tab-routing to ensure clean separation. Place test points at least 0.100 inches from the board edge for reliable in-circuit testing. Arrange smt components on one side of the board when possible to simplify pcb assembly and lower costs.

Follow these best practices:

Group similar smt components together.

Maintain spacing for assembly equipment.

Document all panelization decisions.

Add test points and traceability markings.

Regularly review your panel design with your production team. This collaboration ensures your pcb assembly process remains efficient and cost-effective.

Best Practice Guide for SMT

DFM Checks

You set the stage for reliable smt assembly when you follow a best practice guide that emphasizes Design for Manufacturability (DFM) checks. DFM checks help you catch design issues before production starts. This step saves time and reduces costly errors.

Use thermal relief patterns and teardrops to lower stress on vias and pads.

Run electrical rules check (ERC) and design rules check (DRC) to prevent shorts and routing mistakes.

Verify your schematic matches your layout to avoid missing connections.

Submit clear and complete documentation to your manufacturer. Organized files help avoid delays.

Communicate with your manufacturing team early and often.

You also need to focus on smt design principles. Place components to keep signal paths short and reduce interference. Choose the right pad design for strong solder joints. Select materials that support thermal management. Always design with assembly processes in mind, including solder paste application and reflow profiles. When you follow these steps, you ensure optimal performance and high reliability in your smt projects.

Tip: DFM checks at every stage help you maintain quality and speed up your smt assembly process.

Operator Training

You achieve consistent results in smt assembly when your operators receive thorough training. A best practice guide recommends regular training sessions that cover technical skills, equipment use, and quality standards.

Offer hands-on workshops focused on continuous improvement and quality.

Teach operators how to use Statistical Process Control (SPC) and Pareto analysis.

Include practical exercises based on real smt assembly tasks.

Encourage teamwork and empower employees to suggest improvements.

Provide refresher courses and cross-training to keep skills sharp.

You also benefit from training programs that use simulation or augmented reality. These tools help operators learn complex smt processes in a safe environment. When your team understands defect analysis and root cause investigation, you reduce errors and improve product quality. Operator training supports a culture of quality and helps you deliver reliable smt assemblies every time.

Standards and Compliance

IPC and ISO

You build reliable PCB assemblies when you follow strict industry standards. IPC standards set the rules for design, assembly, and inspection in electronics manufacturing. These standards, such as IPC-A-610 and IPC-J-STD-001, guide you through every step, from layout to final inspection. ISO standards, like ISO 9001 and ISO 13485, help you create strong quality management systems. When you use tools that check your designs against ipc standards, you catch errors early and improve your product’s reliability.

You can see how different IPC classes affect your assembly process in the table below:

Attribute | Class 1 | Class 2 | Class 3 |

|---|---|---|---|

Functionality | Basic | Reliable | High-reliability, mission-critical |

Defect Tolerance | High | Moderate | Extremely low to none |

Inspection Level | Visual | AOI | AOI + X-ray + manual magnification |

Operator Skill | Basic | Certified | IPC-A-610 Class 3 certified |

Assembly Cost | Lowest | Moderate | Highest |

You meet global market needs and improve your reputation when you comply with ipc standards and ISO requirements. These standards also help you access new markets and show your commitment to safety and quality.

LTPCBA Certifications

You gain peace of mind when you choose LTPCBA for your PCB assembly needs. LTPCBA holds ISO 9001 and IATF 16949 certifications, proving their dedication to quality and automotive industry standards. The company also follows UL requirements for safety and reliability. LTPCBA uses advanced testing methods, including flying probe, AOI, X-ray, and functional testing, to ensure every board meets strict ipc standards.

LTPCBA serves industries like aerospace, medical, automotive, and military, all of which demand top-level compliance.

Client testimonials praise LTPCBA’s quality, on-time delivery, and strict adherence to ipc standards.

Detailed documentation and traceability support every project, giving you confidence in the final product.

When you work with LTPCBA, you know your assemblies meet the highest international standards for quality and reliability.

You achieve high-quality results when you follow SMT best practices and partner with a trusted provider like LTPCBA.

Process control reduces defects

Quality checks ensure strong solder joints

Workforce training lowers errors

Choose LTPCBA to optimize your SMT assembly and deliver reliable electronics.

FAQ

What is SMT in PCB assembly?

You use SMT, or Surface Mount Technology, to place electronic components directly onto the surface of a printed circuit board. This method allows for smaller, more efficient devices.

Why is automated inspection important in SMT assembly?

You rely on automated inspection to catch defects early. This process improves product quality, reduces manual errors, and helps you meet strict industry standards.

How does LTPCBA ensure high-quality PCB assembly?

You benefit from LTPCBA’s advanced equipment, strict quality checks, and certified processes. The company uses AOI, X-ray, and manual inspections to deliver reliable PCB assemblies.

See Also

Key Criteria To Identify A Top-Quality SMT Assembly Supplier

Effective Strategies To Optimize SMT Lines In PCBA Production

Cutting-Edge BGA Assembly Methods For Reliable Electronics Manufacturing

Common SMT Assembly Techniques And Their Process Workflows Explained

Guidelines To Fulfill SMT Assembly Standards For Automotive Devices