How AOI Inspection Improves PCBA Quality with Defect Detection Rates

AOI inspection helps make PCBA better by finding more defects during PCB production. Automated optical inspection is faster and more correct than manual inspection. Machines can check PCBs over 80 times faster. They also find 25% more defects.

Metric | PCBA-YOLO Improvement / Value | Comparison Baseline(s) |

|---|---|---|

Mean Average Precision (mAP@0.5) | 97.3% (on PCBA-DET dataset) | YOLOv5s, YOLOv7, YOLOv3 |

Precision Improvement | Up to +1.5% (like +1.3% at K=13) | Compared to YOLOv5s |

Recall Improvement | +1.5% at K=17 | Compared to YOLOv5s |

mAP@0.5:0.95 Improvement | +1.4% at K=17, +0.5% at K=13 | Compared to YOLOv5s |

Model Parameters & FLOPs | Lower than YOLOv5m and YOLOv7 | YOLOv5m, YOLOv7 |

Real-time Detection Speed | 322.6 frames per second | Like YOLOv5s |

Single Class APs | 6 out of 8 fault types are as good or better; 5 are better than YOLOv7 | YOLOv5s, YOLOv7 |

Training Loss | Lower total loss and learns faster | Compared to YOLOv5s |

Early and correct inspection helps PCBA production have fewer defects. It also cuts down on waste and keeps quality high.

Key Takeaways

AOI inspection finds problems early and better than people. This helps stop waste and expensive fixes in PCBA production.

Using AI and 3D AOI technology finds more defects. It helps make more good products and checks them faster. Workers do not get tired.

Finding problems early with AOI saves money. It makes products better and helps factories follow tough industry rules every time.

AOI Inspection in PCBA

What Is Automated Optical Inspection

Automated optical inspection, or AOI, uses cameras and smart computer programs to check PCB assemblies for problems. AOI scans each pcb very quickly and takes clear pictures of the board’s surface. The system looks at these pictures and compares them to a perfect example. It checks for missing parts, solder bridges, or parts that are not in the right place. AOI can look at hundreds of printed circuit boards every hour. This is much faster than people checking by hand. Today, AOI often uses machine learning to be more accurate. Deep learning models help lower mistakes from 0.5% to just 0.02%. This technology helps find small or tricky defects that people might not see.

Description / Examples | |

|---|---|

Inspection Algorithms | Learning-based, hybrid methods |

Image Processing Techniques | Pattern recognition, classification |

Machine Vision Components | High-quality sensors, illumination |

Machine Learning Applications | Reducing false negatives, improving accuracy |

System Attributes | Consistency, real-time operation |

AOI’s Role in PCBA Production

AOI is very important in pcba manufacturing. It helps keep quality high and lowers the number of defects. Manufacturers put AOI systems before and after soldering steps on the line. AOI checks each pcb for problems early. This stops expensive fixes later. Studies show fixing defects after assembly can cost ten times more. AOI gives steady results and does not get tired like people do. It also works fast, checking over 1,000 boards every hour. AOI systems collect lots of data. This helps teams see defect patterns and make things better. In industries like cars and medical devices, AOI helps keep strict quality rules. AOI works with other systems to track boards and improve all the time. This makes pcba production more reliable and saves money.

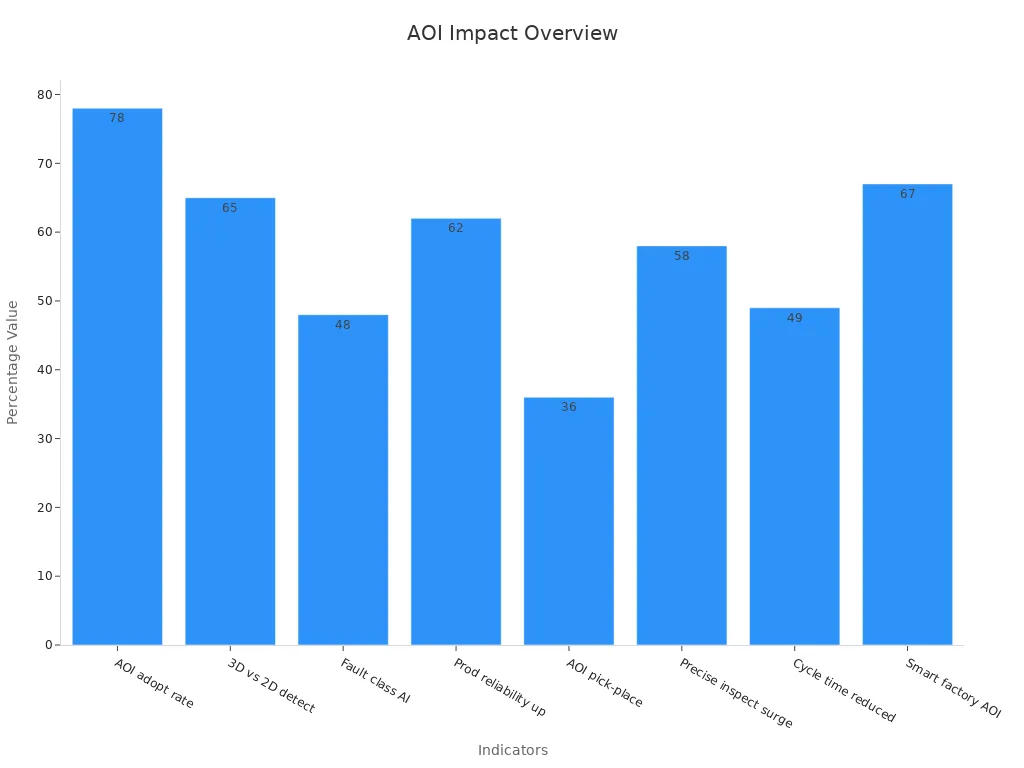

2D vs 3D AOI

Key Differences

AOI technology has two main types: 2D and 3D. Both are important for checking pcbs, but they work differently. 2D AOI uses cameras to take flat pictures of the pcb. It looks for missing parts, wrong pieces, and problems on the surface. 3D AOI uses lasers or special lights to measure height and volume. This helps high-precision aoi systems find things like lifted leads or bad solder joints that 2D might not see.

2D AOI Systems | 3D AOI Systems | |

|---|---|---|

Defect Detection | Surface-level defects only | 3D defects: lifted leads, coplanarity, solder volume, shape irregularities |

Measurement Accuracy | Lower, based on 2D images | Higher, provides true height, volume, and shape measurements |

Lighting Sensitivity | Struggles with lighting changes | More robust against lighting and color variations |

Complexity and Cost | Less complex, cheaper | More complex, costly, needs more computational power |

Inspection Speed | Faster | Slower due to data processing |

Application Suitability | Simple pcb inspection | High-precision aoi for automotive, aerospace, medical, telecoms |

Process Insight | Limited | Advanced pcb inspection with process insights |

Impact on Defect Detection

2D AOI is good for fast and large pcb checks, but it cannot see depth. This means it only finds problems on the surface. 3D AOI uses advanced pcb inspection to look at the shape and height of parts. It can find up to 30% more defects than 2D AOI by measuring these things. This makes it more accurate, especially for hard pcb assemblies. 3D AOI also has fewer mistakes from shadows or reflections. It works well with new pcb designs that have tiny parts and tricky layouts. Studies show 3D AOI can find over 95% of solder joint problems and lower total defects by up to 40%. Even though 3D AOI costs more and is slower, its accuracy and extra information are important for industries that need the best quality.

Tip: Manufacturers pick 3D AOI for advanced pcb inspection when they want high-precision aoi and the best defect detection.

Defect Detection with AOI

Types of Defects Detected

AOI systems are important for checking PCBA quality. They use special cameras and lights to look at each board. These cameras take very clear pictures for the computer to study. AOI can find problems from making mistakes, rough handling, or the environment. Some common problems AOI finds are:

Soldering problems like not enough solder, solder bridges, and empty spots.

Component problems such as parts in the wrong place, tombstoning, or missing and wrong parts.

Substrate problems like scratches, layers coming apart, and dirt.

Surface problems such as open or short circuits, rust, and wrong materials.

Machine learning and deep learning help AOI find more defects. These smart programs let AOI learn new problems and get better over time. But AOI cannot see hidden problems inside thick PCBs or under BGAs. So, factories use AOI with other checks like automated X-ray inspection for full quality control.

Metric / Aspect | Description / Example |

|---|---|

Shows how often good parts are marked bad, measured in ppm. | |

Defect Types Detected by AOI | Finds surface problems: rust, wrong material, solder paste issues, open or short joints, missing parts. |

AOI Limitations | Cannot see hidden solder joints in BGAs; needs X-ray for those. |

Technological Enhancements | 3D AOI and AI help find more surface mount device problems and work faster. |

Application Context | Inline AOI checks boards before and after reflow for quicker, better results. |

Market Growth Metrics | AOI is used more as PCBs get smaller and problems get harder to find. |

AOI uses different ways to look at images and be more exact. These ways include matching, comparing, and looking at shapes and edges. AOI can also learn and update its patterns, so it gets smarter and more trusted.

Note: AOI can find up to 97% of visible problems right away. It can see tiny defects as small as 0.5 microns in semiconductors.

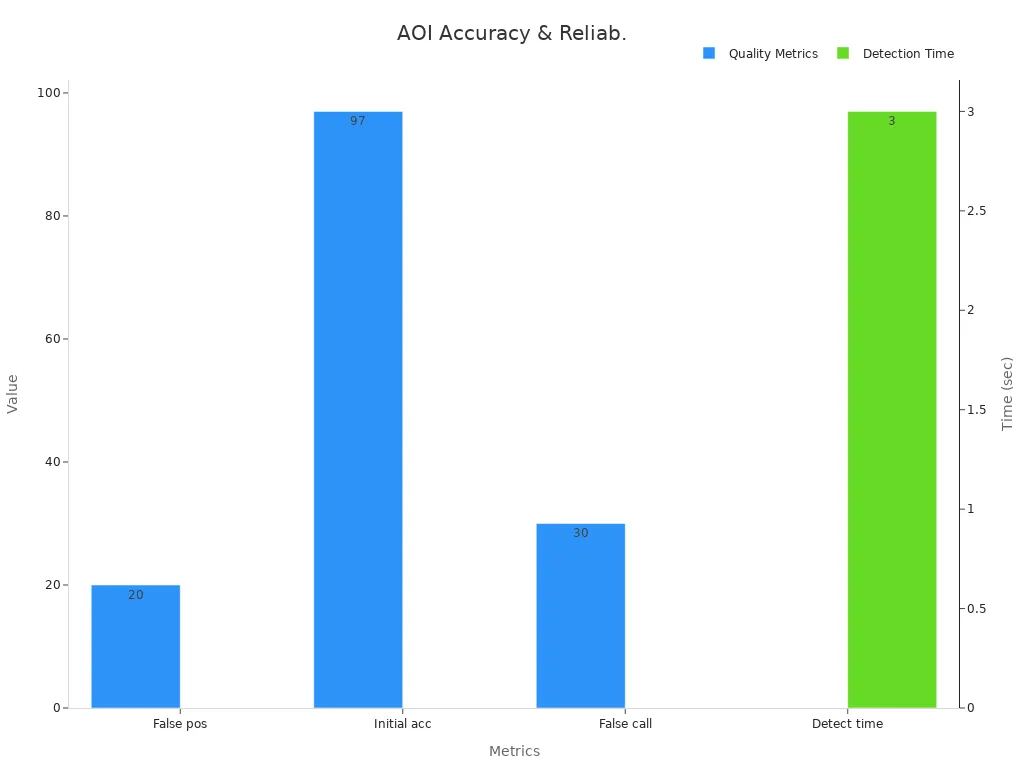

Accuracy and Consistency

High-precision AOI is very good at finding problems again and again. It uses special lights, lasers, and cameras from many angles to make 3D pictures. This lets AOI measure height, volume, and shape. It can find problems that 2D AOI might miss. This means fewer mistakes and better products.

Car, airplane, and medical companies use AOI for strict checks. They need safe and working electronics, so AOI helps them meet high rules. AI and machine learning make AOI even better. They look at data, find small problems, and guess future failures.

Capability | Numerical Data / Performance Indicator |

|---|---|

Accuracy from day one | 97% |

False positive (false call) rate reduction | Up to 30% |

Minimum defect size detected | 0.5 microns (semiconductor inspection) |

Metric Description | Numerical Data / Performance Indicator |

|---|---|

Minimum detectable deviation | 5 microns (3D AOI solder joint measurement) |

False positive reduction | Up to 20% with AI and machine learning |

Processing speed | 100 frames per second (fast GPU) |

Image data throughput | |

Detection and classification time | About 3 seconds for big image sets |

Initial accuracy of AI-driven AOI systems | Up to 97% from the start |

Looking at boards from many angles and using smart image tools helps AOI watch in real time. AOI can also act fast to fix problems. These features help stop waste and keep more good boards. AOI also helps with predictive maintenance, so machines work longer and do not stop often.

High-precision AOI gives steady results for thousands of boards. Workers can change the programs and keep learning, which cuts false calls by up to 30%. This high level of checking helps companies meet tough rules and give customers products they can trust.

Benefits of Early Defect Detection

Reduced Rework and Scrap

Finding defects early in pcba manufacturing helps cut down on rework and scrap. When automated optical inspection systems spot problems at the start, workers can fix them right away. This stops bad boards from moving forward. It saves materials and time.

Lean Six Sigma ideas help by focusing on risky spots first. Teams watch raw materials closely and test at every step. This lowers defects and keeps waste low. Automated lines with robots and sensors catch problems fast. Machine learning helps find mistakes people might miss. Real-time checks stop bad items from going further, which saves materials and keeps the line running.

Note: Machine vision gives quick feedback so teams can fix things fast. Companies using these systems have seen 25% less downtime and 30% less waste as they grow. These results show that early checks make work faster and waste less, even when making more boards.

Manufacturers also use less raw material and energy. This saves money and helps the environment. By finding problems early, factories avoid expensive fixes and throw away fewer boards. This makes the whole process smoother.

Increased Yield and Reliability

Finding defects early helps make more good boards and better products. Automated systems with machine learning check each board very carefully. They find tiny problems that people might miss. This means only good boards move ahead.

Machine learning finds defects automatically, making work faster and cheaper.

Algorithms see small problems people cannot, so teams can fix them early.

Early checks stop quality from dropping, so products work better.

These systems work the same all the time and do not get tired.

They handle lots of data fast, which helps big factories keep quality high.

Looking at data later helps teams spot patterns and keep getting better.

Industry numbers show early AOI checks help yield. AI-powered systems find over 97% of real defects, and false alarms drop to about 4–6%. Checking time is 15–20% shorter, so yield goes up faster. Manual rechecks take hundreds of hours less each month, so workers can do other jobs. Feedback helps keep improving the system and finding more defects, which raises yield.

Metric / Outcome | AI-Powered AOI Performance | Conventional AOI / Legacy Tools |

|---|---|---|

97-99% | Lower, unspecified | |

False Positive Rate | Reduced from ~50% to under 10% (often 4-6%) | ~50% nuisance flags |

True Defect Detection Rate | Over 97% | Lower detection rate |

Die Yield | ~98.5% | ~98.2% |

Overall Fab Yield Gain | 0.3% to 1% increase | Baseline |

Inspection Cycle Time Reduction | 15-20% faster | Baseline |

Defect Escape Rate | As low as 0.2% | Higher escape rates |

Yield Ramp Acceleration | Enabled by faster inspection and feedback | Slower ramp |

These numbers show that early, AI-powered AOI checks help make more good boards. They find more real problems, give fewer false alarms, and let fewer defects slip by. This means pcba factories make better products that work well every time.

Tip: Early defect checks not only help yield but also make machines last up to 20% longer. This helps factories run better for a long time and keeps product quality high.

AOI Data and Real-World Results

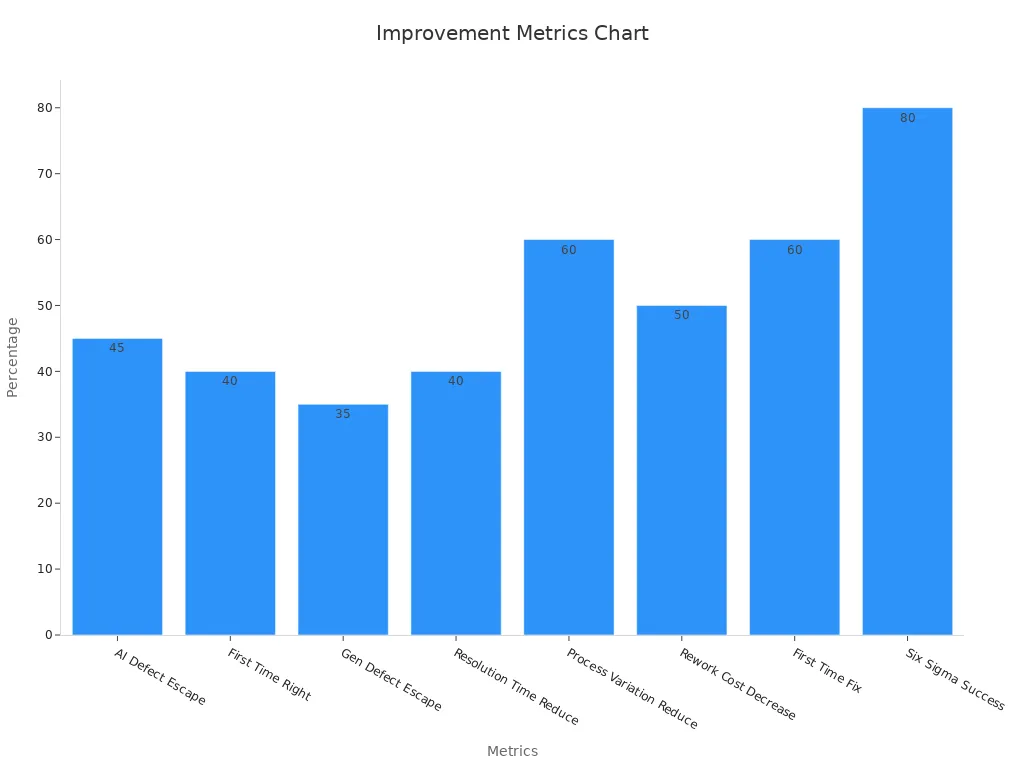

Detection Rate Improvements

AOI helps electronics factories find more defects and make better products. Companies using AOI see fewer problems get missed. AI-driven AOI tools lower missed defects by 45%. More products are made right the first time, with a 40% jump. AOI also makes fixing problems 40% faster. These systems help keep the process steady, cutting changes by 60%. The cost to fix mistakes drops by half. More problems get fixed on the first try, with a 60% boost. AOI helps teams finish more Six Sigma projects, with 80% more success. These gains come from fast feedback and smart inspection programs.

Improvement Metric | Percentage Reduction / Improvement |

|---|---|

Defect escape rate reduction (AI tools) | |

First-time-right deliveries improvement | 40% improvement |

Defect escape rate reduction (general) | 35% decrease |

Defect resolution time reduction | 40% reduction |

Process variation reduction | 60% reduction |

Rework cost decrease | 50% decrease |

Improvement in first-time fix rates | 60% improvement |

Increase in successful Six Sigma projects | 80% more successful projects |

AOI gives quick feedback at every step. This helps teams fix things fast and keep getting better.

Case Examples

Many factories use AOI to make better products and work faster. One electronics company put in AOI and had 30% fewer returns, saving $2 million each year. An auto parts maker used AOI to help train workers, which cut customer complaints by 45% and made car makers happier. An airplane parts company added AI AOI and made 20% more good boards on the first try, saving $5 million in rework costs.

Case Study Type | AOI Implementation Detail | Impact on Defect Reduction and Quality |

|---|---|---|

Consumer Electronics Manufacturer | Implemented AOI system | 30% reduction in field returns; $2M annual savings |

Automotive Electronics Supplier | Enhanced manual visual inspection training | 45% reduction in customer complaints; improved OEM relationships |

Aerospace Electronics Producer | Integrated AI-assisted visual inspection | 20% increase in first-pass yield; $5M savings in rework costs |

AOI gives teams fast feedback, so they can fix problems quickly. These examples show AOI helps factories get better and make higher quality products.

Practical Considerations for AOI

Cost and Integration

Companies that want to use AOI in pcb factories need to think about cost and setup. AOI costs money for hardware, software, and putting it all together. Hardware is about 20–30% of the total price. Software and AI work take up 35–45%. Putting the system together is 15–25%. Most companies get their money back in 8 to 12 months. Some high-tech factories have 99.1% defect detection and cut review time by 40%. They got their money back in just 8 months. Car chip factories lowered returns by 65% and saved $2.3 million each year.

AOI systems can link with MES and quality systems using APIs.

Integration projects often use current IT and cover many machines and lines.

Real-time monitoring and big screens on the floor help everyone see what is happening.

AOI can lower quality costs by 30–40% and drop defect rates from 5% to less than 1%.

AOI also helps teams check boards faster and spend less on fixing mistakes. Easy-to-use screens make it simple for workers to use AOI every day.

Training and Standards

Good training helps AOI work best for pcb checks. Workers must know how to set up, use, and care for AOI tools. Many AOI systems have easy screens, so learning is quick. Training often has hands-on lessons and online guides. Teams learn to read data, change settings, and handle alerts.

Companies use IPC standards to keep pcb checks steady and trusted.

Regular training keeps workers up to date with new AOI tools and rules.

Certification programs help workers keep learning and make sure quality stays high.

When companies spend on training and follow rules, AOI works better. This means better products and fewer mistakes in every pcb batch.

AOI inspection makes PCBA better and more reliable by finding problems early. It helps make sure every board is checked the same way.

Finding problems early means less money spent fixing or throwing away boards.

AOI helps companies follow tough rules and do better against other companies.

When companies use AOI, they make better products and keep customers happy.

FAQ

What types of defects can AOI systems detect?

AOI systems can find missing parts and solder bridges. They also see if parts are not lined up right. AOI can spot scratches on the surface. It finds open circuits and parts in the wrong place too.

How does AOI improve production speed?

AOI checks boards much faster than people can. It looks at hundreds of boards every hour. This helps stop slowdowns and keeps the line moving fast.

Is AOI difficult for operators to learn?

Most AOI systems have easy screens to use. Operators get training and learn fast. They can set up checks, look at results, and handle alerts quickly.

See Also

The Importance Of AOI In Ensuring PCBA Quality Control

X-Ray Inspection Techniques That Improve PCBA Quality Control

SPI Visual Inspection’s Impact After SMT Solder Paste Printing

Essential Methods To Boost PCBA Reliability Over Time

Steps To Ensure Perfect BGA Assembly Through Quality Control