8 Essential Tips for Choosing a Reliable PCBA EMS Supplier

Finding a trustworthy pcba ems supplier can be challenging. Reliable suppliers help you meet exact order quantities and avoid costly production delays.

Assess supplier capabilities.

Ensure clear communication.

Aspect | Description |

|---|---|

Ensures the supplier meets key international industry standards. | |

Quality assurance | Regular audits and feedback maintain high quality throughout the process. |

Key Takeaways

Evaluate your project needs and assess supplier capabilities to ensure a good fit.

Look for suppliers with key certifications like ISO 9001 and IATF 16949 to guarantee quality and safety.

Choose a supplier with strong communication skills to keep your project on track and avoid misunderstandings.

PCBA EMS Experience

Choosing a supplier with strong experience in electronic manufacturing services gives you a big advantage. You want a partner who understands your needs and can deliver high-quality results every time.

Years in Business

A supplier with many years in business has seen many challenges. They know how to solve problems quickly. More experience in manufacturing electronics often means better quality products. Established companies have deep industry knowledge. You should talk to several suppliers to learn about their background and see if they fit your project.

Tip: Companies like LTPCBA have built a solid reputation over the years. Their advanced technology and skilled team help them handle both simple and complex pcba projects.

Expertise in Your Industry

You need a supplier with expertise in your industry. This ensures they follow the right rules and use the best processes for your products. Industry-specific experience allows suppliers to:

Use tailored manufacturing processes for your sector.

Meet strict regulatory requirements.

Maintain high-quality control, which is vital in fields like automotive, medical devices, and aerospace.

Quality control matters for every project. Good suppliers prevent defects and reduce waste. They also help you stay competitive by meeting all industry standards.

When you choose a pcba ems partner with the right experience, you set your project up for success. LTPCBA offers broad expertise and advanced systems to support your electronic manufacturing services from start to finish.

Certifications

Choosing a PCBA EMS supplier with the right certifications gives you confidence in their quality and reliability. Certifications show that a supplier follows strict industry standards and uses a robust quality management system. This helps ensure your products meet safety and performance requirements every time.

ISO, IATF, UL

You should look for suppliers who hold key international certifications. These include:

ISO 9001: This standard proves the supplier has a strong quality management system and can deliver consistent results.

IATF 16949: This certification is important for automotive projects. It focuses on continuous improvement and defect prevention.

UL Certification: This shows the supplier meets strict safety standards for PCB manufacturing.

Certification | Description |

|---|---|

ISO 9001 | |

IATF 16949 | Focuses on automotive quality and defect prevention. |

UL Certification | Confirms compliance with safety standards for electronics. |

LTPCBA meets these standards, so you can trust their commitment to quality and safety.

Compliance Standards

You also need to check if the supplier follows important compliance standards. These standards help protect the environment and ensure product safety.

Standard | Description |

|---|---|

IPC-A-610 | Sets visual standards for electronic assemblies. |

RoHS | Limits hazardous materials in electronics, making products safer for users and the planet. |

ISO 14001 | Shows the supplier cares about sustainable and green practices. |

WEEE | Requires recycling of electronic waste and safe disposal of materials. |

A supplier who follows these standards will use proper inspection and testing procedures. This reduces risks and helps you deliver safe, high-quality products to your customers.

Manufacturing Process

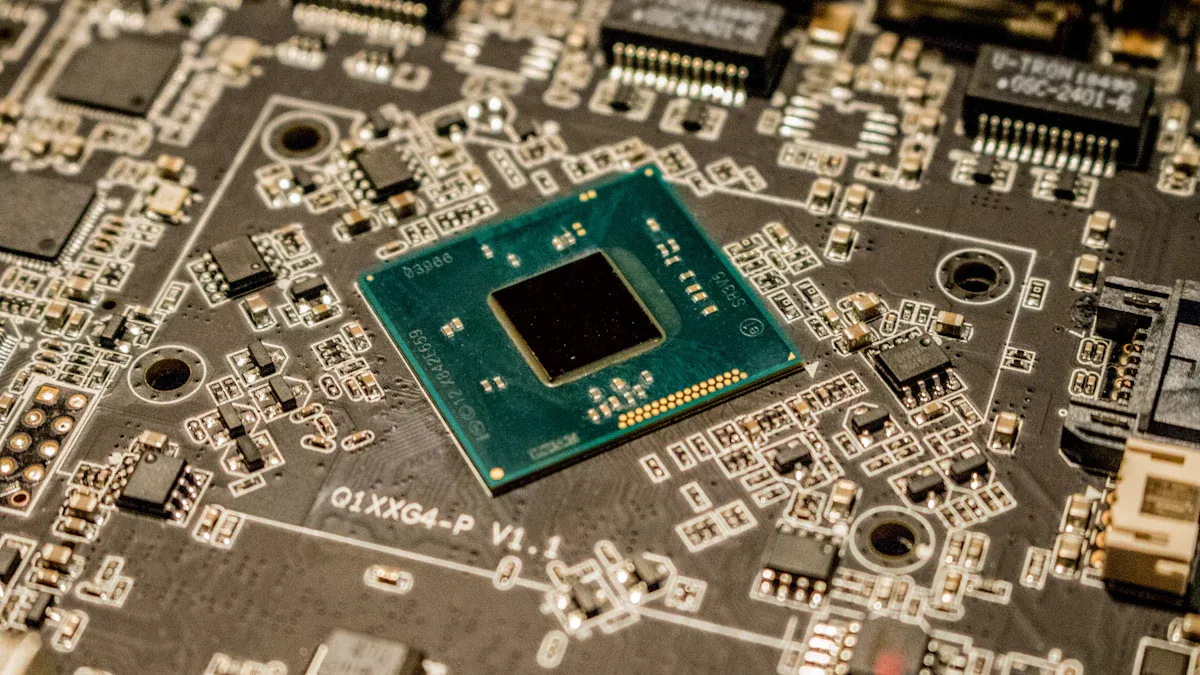

Technology & Automation

You need a supplier who invests in modern and high-tech manufacturing equipment. Advanced technology improves the production process and helps you achieve consistent results. Automated pick-and-place machines place components on pcba boards with speed and accuracy. These machines reduce human error and increase efficiency. You get reliable assemblies that meet strict standards.

A robust quality management system supports every step. Automated inspection tools check for defects and ensure each board matches your design. You can trust that your pcba ems partner will deliver products that perform well in real-world conditions.

Technology Feature | Benefit |

|---|---|

Automated pick-and-place | Fast, precise component placement |

AOI (Automated Optical Inspection) | Detects defects early |

SMT lines | Handles complex assemblies |

Production Scale

You should consider the supplier’s ability to handle different production volumes. LTPCBA offers solutions from prototype to mid-volume runs. This flexibility helps you respond to changing market needs.

Mid-volume PCB assembly provides cost-effective production solutions.

You get enhanced quality because more attention goes to each unit.

Flexibility allows you to adjust orders as demand changes.

Flexibility in production is another significant benefit. A mid-volume PCB assembly allows for changes in market demand or product design iterations with minimal impact on cost and lead time, which is crucial for companies in competitive markets.

Mid-volume production often results in better quality control. Fewer units mean more focus on each board. This is important for industries like medical and aerospace, where reliability matters most.

Quality Control

You need strong quality control to ensure your electronic products work as expected. Careful inspection and testing help you catch problems early and avoid costly mistakes. When you choose a pcba ems supplier, look for one that uses a mix of advanced and traditional inspection methods.

Inspection Methods

Suppliers use several inspection methods to check every board for defects. Each method has a special purpose. Here is a table showing the most common inspection methods and what they do:

Inspection Method | Description |

|---|---|

Visual Inspection | Checks for obvious defects in components and soldering. |

Automated Optical Inspection (AOI) | Uses cameras to spot missing parts and solder joint problems. |

Looks inside the board to find hidden issues, especially for BGA and QFN components. | |

In-Circuit Testing (ICT) | Tests if all parts are connected and working correctly. |

Solder Paste Inspection | Checks the solder paste before placing components to prevent joint problems. |

AOI systems have changed the way suppliers handle quality control. These systems use high-resolution cameras to inspect boards quickly and accurately. AOI can find very small defects that people might miss. You get faster results, fewer mistakes, and better products. Early detection of problems means less rework and lower costs.

Pass Rate

A high pass rate shows that a supplier takes quality seriously. LTPCBA has a 99.5% pass rate, which means almost every board meets strict standards before shipping. This level of performance gives you peace of mind and helps you deliver reliable products to your customers.

Tip: Always ask your supplier about their inspection process and pass rate. High numbers show strong commitment to quality.

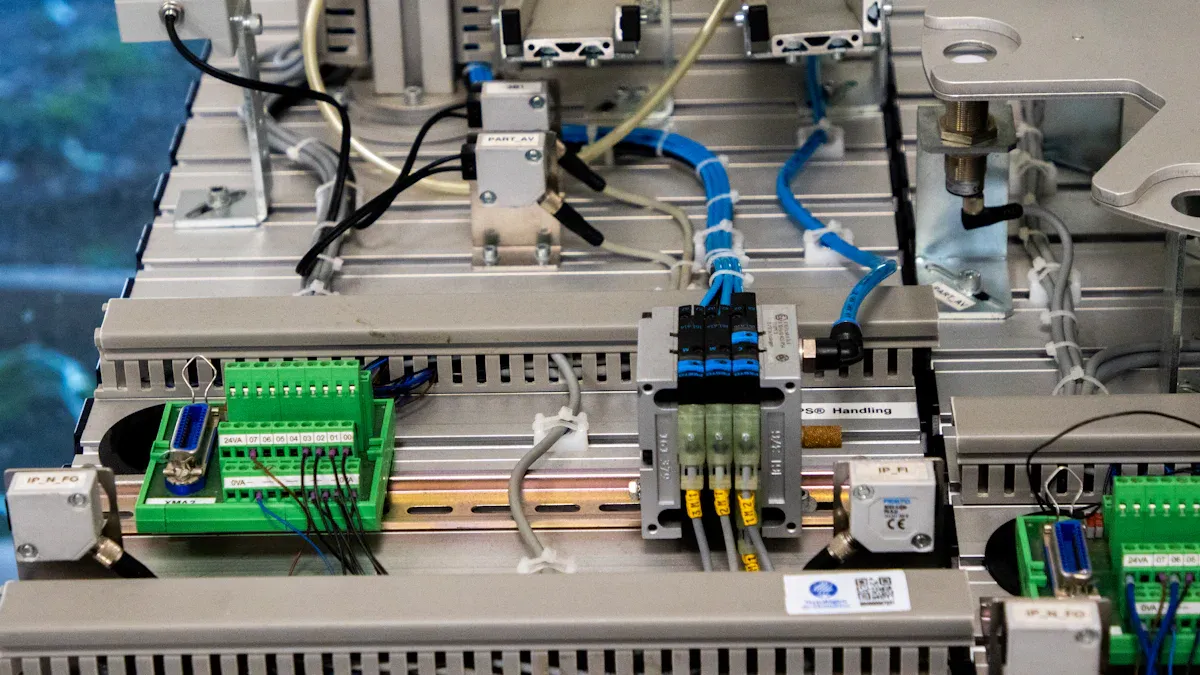

Supply Chain

Component Sourcing

You need strong supply chain management skills to keep your PCBA project on track. Choosing the right suppliers helps you avoid delays and ensures you get quality components every time. Look for vendors with a solid reputation and proven delivery performance. Check their certifications before you place an order.

A tiered sourcing strategy works well. Prioritize high-quality parts for critical functions, and use cost-effective alternatives for less important elements. Regular quality checks help you catch problems early. Keep detailed records of your sourcing decisions so you can review and improve your process.

Here are some best practices for efficient supply chain component sourcing:

Strategy | Description |

|---|---|

Order larger quantities to secure lower prices | |

Vendor Promotions | Stay updated on sales and special offers |

Negotiation | Discuss terms that work for both you and vendors |

Tip: Always test incoming components to make sure they meet your specifications.

Risk Management

Managing risks in the supply chain protects your project from unexpected delays and quality issues. You should use ERP systems for real-time tracking of components. Partner with trusted suppliers who have strong logistics capabilities. Fast and clear communication helps you solve problems quickly.

Consider these steps for better risk management:

Use real-time tracking to spot issues early.

Work with local partners to reduce global shipping risks.

Integrate AI and data analytics for better forecasting.

A supplier with efficient supply chain processes will help you deliver products on time and maintain high standards.

Communication

Clear communication with your PCBA EMS supplier helps your project succeed. You need a partner who answers questions quickly and supports you at every stage. Good communication builds trust and keeps your project on track.

Responsiveness

You should choose a supplier who responds to your inquiries without delay. Fast answers help you solve problems and make decisions quickly. Suppliers who value transparent communication can improve your project’s efficiency. When you work with a team that listens and responds, you avoid misunderstandings and costly mistakes.

Quick replies to emails and calls

Updates on order status

Clear answers to technical questions

LTPCBA stands out by offering 24-hour support and fast quotations. You get the information you need, when you need it. This level of service makes it easier to meet your project requirements and deadlines.

A responsive supplier helps you adapt to changes and keeps your project moving forward.

Project Support

Strong and open communication is key to successful project support. You want a supplier who understands your needs and offers guidance throughout the process. Keeping your supplier informed about any changes helps prevent delays and ensures your boards meet your specifications.

Comprehensive after-sales support also matters. This includes help with troubleshooting, technical advice, and quick solutions if issues arise after delivery. LTPCBA provides ongoing support, so you feel confident from start to finish.

Dedicated project managers

Technical support at every stage

Help with design changes or updates

Good project support gives you peace of mind and helps you deliver quality products to your customers.

Cost & Lead Time

Pricing

You want to keep your project on budget, so understanding what affects pricing is important. Several factors can change the cost of pcba. These include:

Production technology (SMT vs. THT)

Order volume

Additional services required

Material selection matters because different materials offer unique thermal reliability and mechanical properties. Complex designs often need more layers and steps in the production process, which increases costs. The choice between surface mount technology and through-hole technology also impacts labor and efficiency. If you order more units, you may get discounts since larger batches reduce setup time. When you need extra services like testing or design help, prices can rise.

A reliable supplier uses modern and high-tech manufacturing equipment to keep costs fair and quality high. You should always ask for a clear quote that matches your project requirements.

Delivery

On-time delivery is critical for your success. Delays in even one component can stop your whole project for weeks. Most electronic manufacturing services suppliers complete assembly in 7 to 20 working days. The exact time depends on how complex your boards are, how many you need, and the types of components used.

Managing lead times well helps you launch products faster and stay ahead of competitors. Good logistics capabilities ensure your boards arrive when you need them. A supplier who offers comprehensive after-sales support will help you solve any delivery issues quickly.

Tip: Always discuss delivery schedules early to avoid surprises later.

Customer Feedback

Reviews

You should always check reviews before choosing a PCBA EMS supplier. Reviews give you a clear picture of how the supplier works with different customers. They show if the company delivers on time, solves problems quickly, and meets quality standards. Many customers share their experiences online, which helps you avoid suppliers with poor service.

LTPCBA serves a wide range of customers, from professional developers to students. This diversity shows that the company can handle many types of projects. Positive reviews often mention LTPCBA’s fast response times and strong technical support. When you read these reviews, you learn how the company supports its clients at every stage.

References

References help you make a smart choice. You can ask suppliers for references from past clients. These references let you see how the supplier handled similar projects. Most customers look at four main criteria when giving references:

Criteria | Description |

|---|---|

Experience | The EMS partner should have relevant experience in manufacturing the required products, focusing on specific market segments. |

Capabilities | The EMS partner must possess the necessary equipment, facilities, and personnel to meet specific project needs, whether for high volumes or customization. |

Quality | A strong commitment to quality is essential, including a robust quality management system and relevant certifications like ISO 13485, AS9100, and ISO 9001. |

Service | Excellent service is crucial, including responsiveness, regular updates, and efficient problem resolution. |

Testimonials and case studies give you even more confidence. They show real examples of how a supplier solved problems and met customer needs. By reading these stories, you can see if the supplier’s skills match your project. LTPCBA’s satisfied customers often share their success stories, which highlight the company’s focus on quality and service.

When you select a pcba ems supplier, review experience, certifications, process, quality, supply chain, communication, cost, and feedback. This approach helps you avoid costly mistakes and ensures reliable results. Brands like LTPCBA deliver high pass rates and strict quality control, which protect your business and reputation.

FAQ

What certifications should you look for in a PCBA EMS supplier?

You should look for ISO 9001, IATF 16949, and UL certifications. These show the supplier meets international quality and safety standards.

How can you check a supplier’s quality control?

Ask about their inspection methods. Look for AOI, X-ray, and in-circuit testing. A high pass rate, like 99.5%, shows strong quality control.

Why does supplier communication matter?

Good communication helps you solve problems fast. You get updates, answers, and support. This keeps your project on schedule and reduces mistakes.

See Also

Choosing the Right PCBA Supplier for Your Requirements

Finding the Ideal Turnkey PCBA Manufacturer for Electronics

Essential Strategies to Enhance PCBA Reliability Over Time