24-Pin DIP Cable Assemblies: Applications, Specifications and Manufacturing Considerations

24-Pin DIP Cable Assemblies are important for connecting electronics safely. Many industries use them because they work well after strict tests. These tests include checking for open or short circuits every time. They have strong PVC covers, tin copper wires, and UL2651 28AWG specs. These features make 24-Pin DIP Cable Assemblies safe, reliable, and long-lasting.

Key Takeaways

24-pin DIP cables help make strong connections in many fields. These include electronics, cars, and medical tools.

Special cable designs improve how they work. They are made to fit and work well for specific uses.

Making these cables involves testing and checking quality. This ensures they are safe and meet industry rules.

Applications of 24-Pin DIP Cable Assemblies

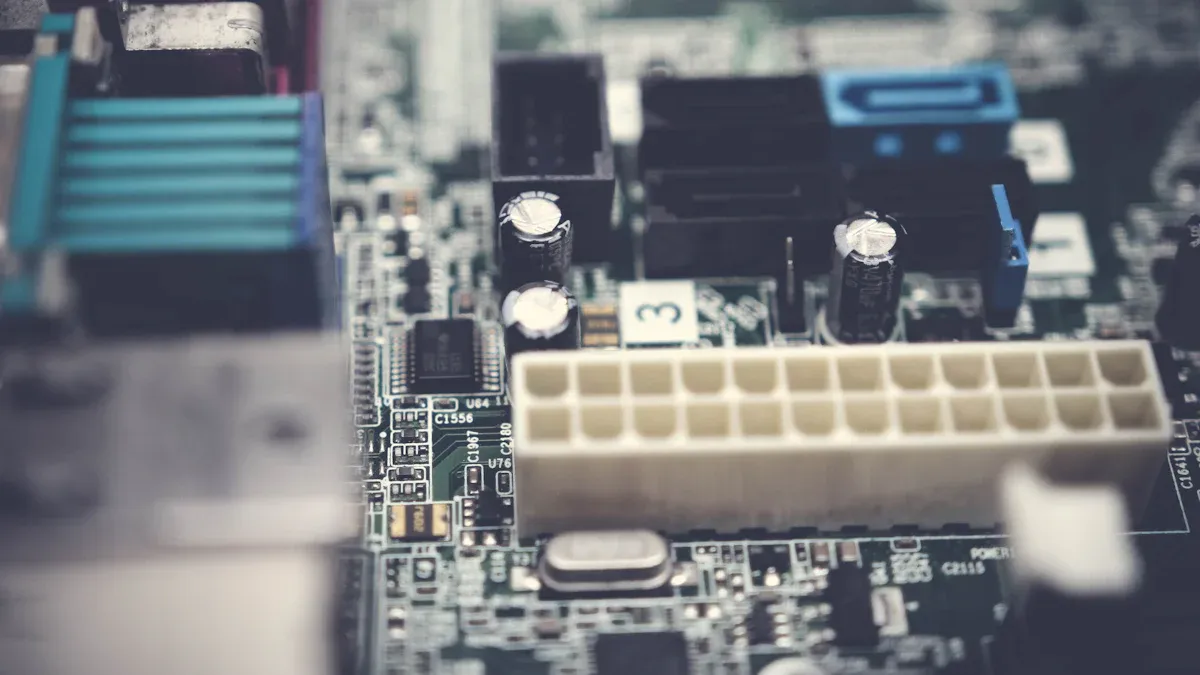

Consumer Electronics and Custom Ribbon Cable Assemblies

24-pin DIP cable assemblies help connect parts in electronics. They are used in TVs, gaming consoles, and audio systems. Their small size and good performance suit modern devices. Custom ribbon cables let makers design them for specific gadgets. This ensures they work well and fit perfectly. As devices get smaller and smarter, these cables are needed more.

Industrial Automation Systems

Factories use 24-pin DIP cable assemblies to link sensors and controls. They send data quickly for monitoring and controlling machines. These cables are tough and handle harsh conditions well. Industry 4.0 technology has increased the need for strong connections. This makes these assemblies important in automated systems.

Medical Devices and Equipment

Medical tools need accurate and steady connections. 24-pin DIP cable assemblies are used in monitors, scanners, and diagnostic machines. They send data reliably, which helps doctors care for patients. The materials meet strict medical rules for safety. As healthcare uses more advanced tech, these cables are used more often.

Automotive and Transportation Systems

Cars use 24-pin DIP cable assemblies for infotainment, engine control, and safety systems. They send power and data inside vehicles. Electric cars and self-driving tech have raised demand for better cables. Reliable connectors are key for vehicle safety and performance.

Aerospace and Defense Applications

Planes and defense systems need cables that handle heat and vibrations. 24-pin DIP cable assemblies work well in avionics, radar, and communication tools. They are built strong and meet strict standards. New aerospace tech needs advanced cables for complex systems.

Market Insight: The market for board-to-board connectors, including 24-pin DIP cable assemblies, is growing fast. It is expected to rise from $4.2 billion in 2023 to $7.5 billion by 2033. This growth shows the need for better connectors as devices become more advanced.

Key Specifications of 24-Pin DIP Cable Assemblies

Connector Pin Setup and Electrical Rules

Connector pin setups show how these cables connect to systems. They help send data and power smoothly without problems. Electrical rules make sure the cables work well in different situations. Below is a table with key details about connector pins:

Feature | Details |

|---|---|

Contact Type | Stamped & Formed |

Total Pin Count | |

Contact Resistance (mΩ) | 10 |

Insulation Resistance (MΩ) | 5000 |

Max Current Rating (A) | 3 |

These features help the cables work precisely and last long. Low contact resistance saves energy, while high insulation stops leaks.

Strong Materials and Eco-Friendly Standards

The materials used must handle stress and tough conditions. PVC and tin copper wires are chosen because they last long. These materials resist damage, rust, and temperature changes. Eco-friendly rules like RoHS and UL are also followed. This ensures the cables are safe and good for the environment. These qualities make them great for cars and planes.

Matching Industry Guidelines

Industry guidelines help these cables fit into systems easily. Groups like ISO and IEC set rules for size and materials. Following these rules prevents system problems and makes repairs easier. It also lets companies use the cables in many ways without big changes.

Electrical Quality and Shielding Needs

Good electrical quality is key for these cables. Strong connectors and wires keep signals steady and power flowing. Shields block electromagnetic interference (EMI) that can cause issues. Braided or foil shields stop outside noise from affecting the cables. This is helpful in places like factories with lots of EMI.

Custom Cable Designs

Custom designs are important for special needs. Makers create ribbon cables to match exact requirements. Custom cables improve performance by adjusting length, connectors, and shields. They also fit better with unique tools and machines. As industries grow, custom designs help systems work more efficiently.

Manufacturing Considerations for 24-Pin DIP Cable Assemblies

Design and Prototyping with LTPCBA

Designing cables is important for making them work well. LTPCBA helps engineers test cable designs before making many units. Each cable is tested for safety and how well it works. Engineers also check how cables handle tough conditions in special labs. These tests make sure cables are strong for cars and planes.

Material Selection for High-Performance Assemblies

Picking good materials is key for strong flat cables. PVC and tin copper wires are used because they last long. Engineers check how materials affect signals and cable length. Bigger wires help signals travel farther without losing strength. Careful choices make cables meet rules and work in hard jobs.

Assembly Techniques and Quality Assurance

Good assembly methods make cables reliable. LTPCBA uses machines to build cables with great accuracy. They check each cable with special tools to find problems. These checks make sure cables are safe and work well.

Testing and Certification Processes

Tests show if cables are safe and work properly. LTPCBA runs tests like checking electricity and tough conditions. Certifications like ISO and UL prove the cables are high quality. These steps make cables ready for medical and defense use.

Scalability and Cost Optimization in Production

Making many cables quickly is important. LTPCBA uses smart systems to go from small tests to big batches. They find ways to save money without lowering quality. This keeps custom cables affordable for different industries.

24-pin DIP cable assemblies are important in many industries. They are used in electronics, cars, and airplanes. These cables work well and last a long time. They provide strong connections even in tough conditions. LTPCBA helps design and make these high-quality cables. Begin your next project with LTPCBA for reliable products.

FAQ

What industries use 24-pin DIP cable assemblies?

Industries like cars, planes, and medical tools need these cables. They provide strong connections in tough conditions and important systems.

Can 24-pin DIP cable assemblies be made for special uses?

Yes, makers create custom cables for specific needs. This helps them fit better, work faster, and connect easily to unique systems.

How does LTPCBA check the quality of 24-pin DIP cables?

LTPCBA tests cables with advanced tools and strict checks. They also follow rules to make sure the cables are safe and work well.

See Also

Understanding DIP Cable Assemblies for PCB Connection Techniques

A Detailed Overview of SMT and DIP Assembly Processes

Essential Aspects of DIP Assembly Technology Explained

Wave Soldering Standards for Effective DIP Assembly Processing

Achieving Precision in DIP Assembly and Through-Hole Tolerances